Section

5 Programmable electronic systems (PES)

5.1 General requirements

5.1.1 The requirements of this Section are to be complied with where control,

alarm, monitoring or safety systems incorporate programmable electronic equipment.

Mobility systems, ship type systems and safety critical systems incorporating shared

data communication links and systems which are integrated are to comply with the

additional requirements of Vol 2, Pt 9, Ch 8, 5.2 Data communication links, Vol 2, Pt 9, Ch 8, 5.3 Additional requirements for wireless data communication links,

Vol 2, Pt 9, Ch 8, 5.4 Additional requirements for Mobility category and safety critical systems

and Vol 2, Pt 9, Ch 8, 5.5 Additional requirements for integrated systems as applicable.

5.1.2 Systems

complying with ISO 17894, Ships and marine technology –

Computer applications – General principles for the development

and use of programmable electronic systems in marine applications, may

be accepted as meeting the requirements of this Section in which case

evidence of compliance is to be submitted for consideration.

5.1.3 Where

programmable electronic systems share resources, any components that

can affect the ability to effectively provide required control, alarm

or safety functions are to fulfil the requirements of Vol 2, Pt 9, Ch 8, 5.1 General requirements related to providing those

required functions.

5.1.4 Programmable

electronic equipment is to revert to a defined safe state on initial

start up or re-start in the event of failure.

5.1.5 In the

event of failure of any programmable electronic equipment, the system,

and any other system to which it is connected, is to fail to a defined

safe state or maintain safe operation, as applicable.

5.1.8 Programmable

electronic equipment is to be provided with self-monitoring capabilities

such that hardware and functional failures will initiate an audible

and visual alarm in accordance with the requirements of Vol 2, Pt 9, Ch 7, 4.3 Alarm systems, general requirements and, where applicable, Vol 2, Pt 9, Ch 1, 4.2 Alarm systems for machinery. Hardware failure indications

are to enable faults to be identifiable at least down to the level

of the lowest replaceable unit and the self-monitoring capabilities

are to ensure that diagnostic information is readily available.

5.1.11 Where

it is necessary to store data required for system operation in volatile

memory, a back-up power supply is to be provided that prevents data

loss in the event of loss of the normal power supply. The submission

required by Vol 2, Pt 9, Ch 1, 1.4 Documentation required for design review 1.4.21 is

to include details of any routine maintenance necessary and the measures

necessary to restore system operation in the event of data loss as

a result of power supply failure.

5.1.12 Back-up

power supplies required by Vol 2, Pt 9, Ch 8, 5.1 General requirements 5.1.11 are

to be rated to supply the connected load for a defined period of time

that allows sufficient time for the re-instatement of supply in the

event of loss of the normal power supply as a result of failure of

a main source of electrical power. This period is in any case to be

not less than 30 minutes.

5.1.13 Where regular battery replacement is required to maintain the availability

of volatile memory back-up power supply required by Vol 2, Pt 9, Ch 8, 5.1 General requirements 5.1.11, these are to be included in the schedule of

batteries required by Vol 2, Pt 9, Ch 1, 1.4 Documentation required for design review 1.4.17 and Vol 2, Pt 9, Ch 2, 7.7 Recording of batteries for emergency and essential services,

irrespective of battery type and size. Applicable entries in this schedule are to note

that these batteries are not for safety critical systems, Mobility systems, Ship Type

systems, or emergency services.

5.1.14 Access

to system configuration, programs and data is to be restricted by

physical and/or logical means providing effective security against

unauthorised alteration.

5.1.15 Where

date and time information is required by the equipment, this is to

be provided by means of a battery backed clock with restricted access

for alteration. Date and time information is to be fully represented

and utilised.

5.1.16 Displays

and controls are to be protected against liquid ingress due to spillage

or spraying.

5.1.17 Display

units are to comply with the requirements of an acceptable National

or International Standard, e.g. IEC 60950 in respect of emission of

ionising radiation.

5.1.18 Where

systems detect fault conditions, any affected mimic diagrams are to

ensure that the status of unreliable and incorrect data is clearly

identified.

5.1.19 Multi-function

displays and controls are to be duplicated and interchangeable where

used for the control or monitoring of more than one system, machinery

item or item of equipment. At least one unit at the main control station

is to be supplied from an independent uninterruptible power system

(UPS).

5.1.20 The

number of multi-function display and control units provided at the

main control station and their power supply arrangements are to be

sufficient to ensure continuing safe operation from a multi-function

display and control unit in the event of failure of any unit or any

power supply.

5.1.21 Software lifecycle activities, e.g. design, development, supply and

maintenance, are to be carried out in accordance with an acceptable quality management

system. Project specific software quality plans are to be submitted. These are to

demonstrate that the provisions of ISO/IEC 90003:2014 Software engineering –

Guidelines for the application of ISO 9001:2015 to computer software or an

acceptable International, National or naval standard, are incorporated. The plans are to

define responsibilities for the lifecycle activities, including verification,

validation, module testing and integration with other components or systems.

5.2 Data communication links

5.2.1 Where control, alarm or safety systems use shared data communication links

to transfer data, the requirements of Vol 2, Pt 9, Ch 8, 5.2 Data communication links 5.2.2 are to be complied with. The requirements

apply to local area networks, fieldbuses and other types of data communication link

which make use of a shared medium to transfer control, alarm or safety related data

between distributed programmable electronic equipment or systems.

5.2.2 Data communication is to be automatically restored within 45 seconds in the

event of a single component failure. Upon restoration, priority is to be given to

updating safety critical data and control, alarm and safety related data for Mobility

and/or Ship Type systems. Components comprise all items required to facilitate data

communication, including cables, switches, repeaters, software components and power

supplies.

5.2.4 The properties of the data communication link, (e.g. bandwidth, access

control method, etc.), are to ensure that all connected systems will operate in a safe,

stable and repeatable manner under all operating conditions. The latency of control,

alarm and safety related data is not to exceed two seconds.

5.2.5 Protocols are to ensure the integrity of control, alarm and safety related

data, and provide timely recovery of corrupted or invalid data.

5.2.8 Means are to be provided to prevent unintended connection or disconnection

of any equipment where this may affect the performance of any other systems in

operation.

5.2.10 The installation is to provide adequate protection against mechanical

damage and electromagnetic interference.

5.2.11 Components are to be located with appropriate segregation such that the risk

of mechanical damage or electromagnetic interference resulting in the loss of both

active and standby components is minimised. Duplicated data communication links are to

be routed to give as much physical separation as is practical.

5.2.12 The data communication links are to be resilient as described elsewhere in this section

of the rules to the accumulation of broadcast and multicast network traffic. The audible

and visual alarms required by Vol 2, Pt 9, Ch 8, 5.2 Data communication links 5.2.6 are

to be initiated in the event of such accumulations of traffic occurring and affecting

normal network performance. Demonstration of this resilience is to be shown by a

practical test or other acceptable means appropriate to the communication link, and

documented.

5.3 Additional requirements for wireless data communication links

5.3.3 For

services which need not be in operation continuously, wireless data

communication links may be considered where an alternative means of

operation that can be brought into action within an acceptable period

of time is provided.

5.3.4 Wireless

data communication is to employ recognised international wireless

communication system protocols that incorporate the following:

-

Message integrity:

fault prevention, detection, diagnosis, and correction ensuring the

received message is not corrupted or altered when compared to the

transmitted message.

-

Configuration

and device authentication: is only to permit connection of devices

that are included in the system design.

-

Message encryption:

protection of the confidentiality and/or criticality of the data content.

-

Security management:

protection of network assets, prevention of unauthorised access to

network assets.

5.3.5 The

wireless system is to comply with the radio frequency and power level

requirements of the International Telecommunications Union and any

requirements of the National Administration with which the ship is

registered.

5.3.6 Compliance

with different port state and local regulations pertaining to the

use of radio-frequency transmission that would prohibit the operation

of a wireless data communication link, due to frequency and power

level restrictions, is not addressed by these requirements and is

the responsibility of the Owner.

5.4 Additional requirements for Mobility category and safety critical

systems

5.4.1 The

requirements of Vol 2, Pt 9, Ch 8, 5.4 Additional requirements for Mobility category and safety critical systems 5.4.2 are

to be complied with where control, alarm or safety functions for Mobility

category, or safety critical systems, incorporate programmable electronic

equipment.

-

Safety critical

systems are those which provide functions intended to protect persons

from physical hazards caused by engineering system failures, e.g.

fire, explosion, etc. or to prevent mechanical damage which may result

in the loss of a Mobility category system, e.g. main engine low lubricating

oil pressure shutdown.

-

Functions provided

by Ship Type or Ancillary category systems may also be considered

to be safety critical, e.g. domestic boiler low water level shutdown.

5.4.3 Items

of programmable electronic equipment used to implement control, alarm

or safety functions are to be Type Approved in accordance with LR's

Type Approval System, Test Specification Number 1 (2002).

Type approval to an alternative and relevant National or International

Standard may be submitted for consideration.

5.4.4 The

system is to be configured such that control, alarm and safety function

groups are independent. A failure of the system is not to result in

the loss of more than one of these function groups. Proposals for

alternative arrangements providing an equivalent level of safety will

be subject to special consideration.

5.4.5 For Mobility and/or Ship Type, the system is to be arranged to operate

automatically from an alternative power supply in the event of a failure of the normal

supply.

5.4.6 Volatile

memory is not to be used to store data required to:

- provide a Mobility category system or safety critical function;

or

- ensure safety or prevent damage, including during startup or re-start.

Alternative proposals that demonstrate an equivalent level of

system integrity will be achieved may be submitted for consideration.

5.4.8 Where it is intended that the programmable electronic system implements an

emergency stop functions or safety critical functions, the software is to comply with

the requirements of Vol 2, Pt 1, Ch 3, 21 Software in systems, machinery and equipment and Vol 2, Pt 9, Ch 8, 5.5 Additional requirements for integrated systems of these Rules. Alternative proposals providing an equivalent level of

system integrity will be subject to special consideration, e.g. redundancy with design

diversity, Alternatively, consideration may be given to the use of LR's Software

Conformity Assessment System–Assessment Module GEN1 (1994) or an

equivalent software assessment acceptable to LR.

5.4.9 Control,

alarm and safety related information is to be displayed in a clear,

unambiguous and timely manner, and, where applicable, is to be given

visual prominence over other information on the display.

5.4.10 Means

of access to safety critical functions are to be dedicated to the

intended function and readily distinguishable.

5.5 Additional requirements for integrated systems

5.5.1 The

requirements of Vol 2, Pt 9, Ch 8, 5.5 Additional requirements for integrated systems 5.5.2 apply

to integrated systems such as those providing a grouping of fire safety

or crew and embarked personnel emergency safety functions (see

Vol 2, Pt 9, Ch 7 Control, Alerts and Safety Systems

Vol 2, Pt 9, Ch 8 Programmable Electronic Systems, Vol 2, Pt 9, Ch 9 Fire Safety and Ship Safety Systems and Vol 2, Pt 9, Ch 10 Internal Communication),

power management systems and integrated control, alarm and monitoring

systems for machinery, and include the interconnection of systems

capable of independent operation to provide co-ordinated functions

or common user interfaces.

5.5.2 System

integration is to be managed by a single designated party, and is

to be carried out in accordance with a defined procedure identifying

the roles, responsibilities and requirements for all parties involved.

This procedure is to be submitted for consideration where the integration

involves control functions for Mobility category systems or safety

critical functions.

5.5.4 Reversionary

modes of operation are to be provided to ensure safe and graceful

degradation in the event of one or more failures. In general, the

integrated system is to be arranged such that the failure of one part

will not affect the functionality of other parts, except those that

require data from the failed part.

5.5.5 Where the integration involves control functions for Mobility systems, Ship

Type systems, or safety functions, including fire safety or crew and embarked personnel

or emergency safety functions, the Risk Assessment (RA) required by Vol 2, Pt 1, Ch 3, 3.3 Calculations and specifications 3.3.7 is to additionally to demonstrate that

the integrated system will 'fail-safe', see

Vol 2, Pt 9, Ch 7, 4.4 Safety systems, general requirements 4.4.3 and Vol 2, Pt 9, Ch 7, 4.5 Control systems, general requirements 4.5.4, and that Mobility and/or Ship Type systems in

operation will not be lost or degraded beyond acceptable performance criteria where

specified by these Rules.

5.5.6 The

quantity and quality of information presented to the Operator are

to be managed to assist situational awareness in all operating conditions.

Excessive or ambiguous information that may adversely affect the Operator’s

ability to reason or act correctly is to be avoided, but information

needed for corrective or emergency actions is not to be suppressed

or obscured in satisfying this requirement.

5.5.7 Where

information is required by the Rules or by the System Design Description

requirements to be continuously displayed, the system configuration

is to be such that the information may be viewed without manual intervention,

e.g. the selection of a particular screen page or mode of operation. See also

Vol 2, Pt 9, Ch 8, 5.1 General requirements 5.1.21.

5.5.8 Where

applicable, date and time stamping between separate equipment shall

be synchronised.

5.6 Programmable electronic systems – Additional requirements for the production of software

5.6.1 The requirements of Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.1 to Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.24 apply to

all software created for programmable electronic systems whose safety hazards have

been classified within categories II, III and IV as defined by Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.5. Alternatively, consideration may be given to the use of LR's

Software Conformity Assessment System – Assessment Module GEN1 (1994).

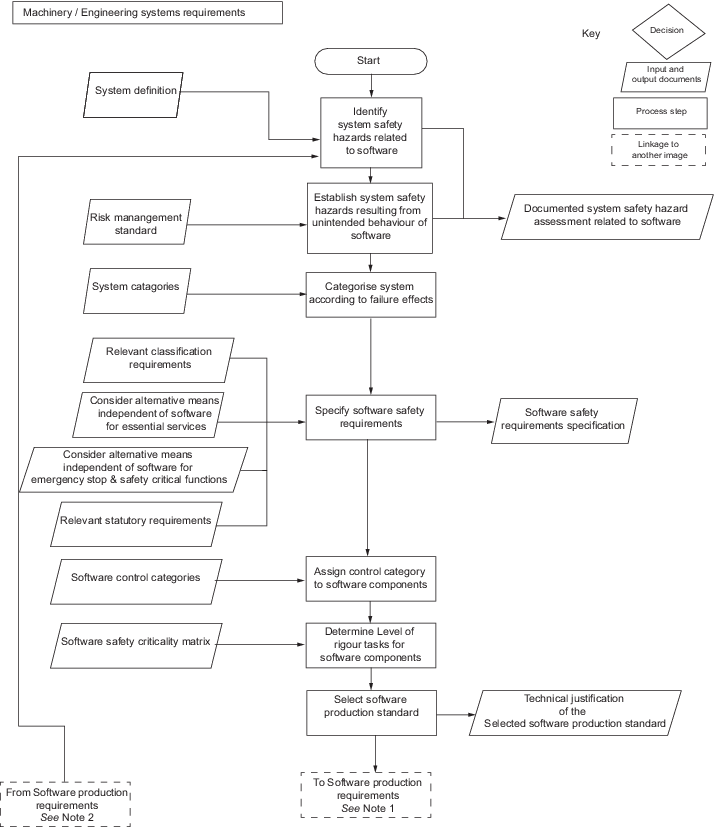

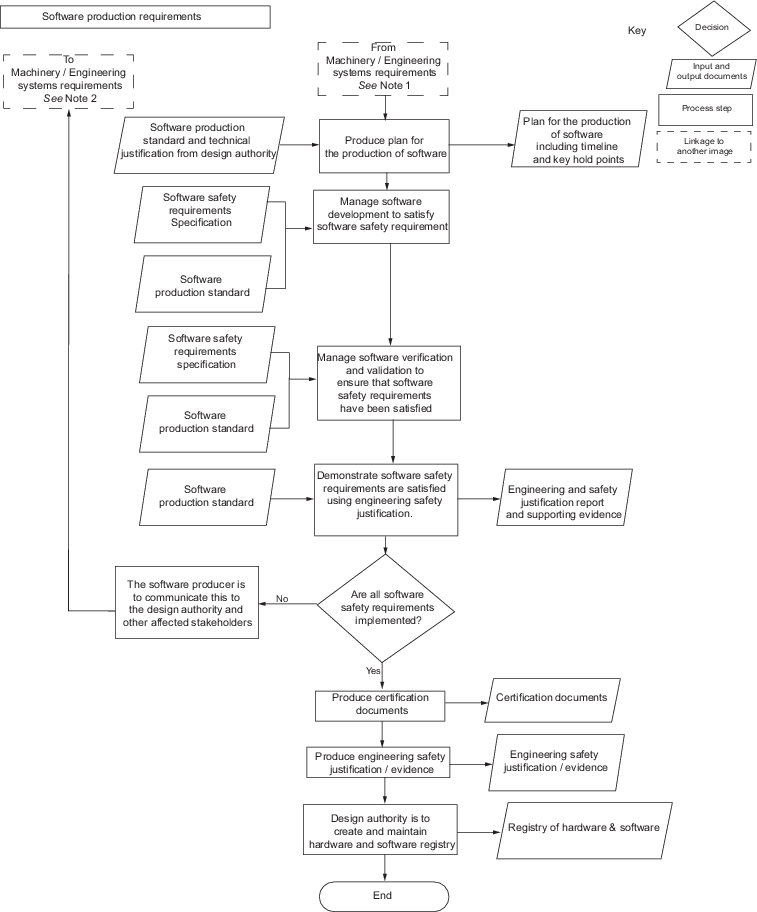

See also

Vol 2, Pt 1, Ch 3, 21 Software in systems, machinery and equipment. A diagrammatic view of the software rules process is shown

in Figure 8.5.1 Software rules process

diagram – Machinery/Engineering system requirements and Figure 8.5.2 Software rules process

diagram – Software production requirements.

Figure 8.5.1 Software rules process

diagram – Machinery/Engineering system requirements

Figure 8.5.2 Software rules process

diagram – Software production requirements

5.6.3 An engineering and safety justification is to be made and documented.

This is to provide compelling, comprehensible and valid arguments that the intent

and requirements of the Rules have been complied with, supported by a body of

evidence that provides a compelling, comprehensible and valid demonstration that the

functional requirements identified in Pt 5, Ch 1, 8.1 Goal, functional requirements

and applicability 8.1.2 have been met. The engineering and safety justification is

to be produced in accordance with ISO/IEC 15026-2 Systems and software

engineering – Systems and software assurance, Part 2: Assurance case or an

alternative standard acceptable to LR.

5.6.5 Configuration management satisfying the requirements of ISO 10007

Quality management systems – Guidelines for configuration management, or

an alternative standard acceptable to LR, is to be used during the production of

software.

5.6.6 Software is to be produced using a quality management system that

satisfies the requirements of ISO 9001 Quality management systems – Requirements

using the guidance of ISO 90003: Software engineering – Guidelines for the

application of ISO 9001: to computer software or an alternative to LR.

Certification documents for the production of software are to be submitted to LR.

5.6.7 A plan for the production of software is to be formulated, documented and used to

direct the production of software. If the plan is incorporated into another

document, the strategy, and the structure of the plan, with appropriate

cross-references to other documentation, are to be documented separately. The level

of detail in the plan is expected to increase as the project progresses through the

lifecycle phases of the production of software. The plan is to be complete with

respect to each lifecycle phase before the phase is initiated.

5.6.8 The plan for the production of software is to include:

- all activities for the production of software, including

production of the justification and supporting evidence required by Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.3;

- the processes, methods, techniques and tools required by the Software

Production Standard and applicable to the degree of reliance placed on the

software by the software safety requirements;

- factors which influence the introduction and mitigation of errors, such as

the size, complexity and novelty of the software;

- any deviations, with justification, from the requirements of the Software

Production Standard; and

- all activities for the creation of the documentation and

testing of the system appropriate to the system category as defined by Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.5 and Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.7.

5.6.9 When there are changes to the software safety requirements which affect the plan for

the production of software, the plan is to be revised.

5.6.10 The production of software is to be performed in accordance with the Software

Production Standard and the plan for the production of software.

5.6.12 Where the software development includes the use of previously developed software, the

plan for the development of the software is to include:

- defined software modification processes which are to be part of the

supplier's quality management system;

- assessment of the impact of the modification on the previously developed

software modules, which is to be used to tailor the producer of software’s

management systems for the specific software development modification; and

- integration of any additional software safety requirements

identified by the risk assessment required by Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.3, implemented through the configuration of the existing

software, by providing new software to work in cooperation with the existing

software, or by other means acceptable to LR.

5.6.13 During the production of software, the producer of software is to

actively maintain the system safety analysis required by Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.2 to

ensure that emerging properties of the software are assessed. Changes in the system

safety analysis are to be documented, endorsed by the System Design Authority and

mitigated through derived software safety requirements.

5.6.15 Where it is not possible to implement the original software safety

requirements, or where updates are necessary as a result of additional system safety

hazards, the producer of software is to communicate this to the System Design

Authority and other affected stakeholders and the software safety requirements are

to be re-evaluated in accordance with Vol 2, Pt 1, Ch 3, 21.3 Performance requirements 21.3.1.

5.6.18 Where software has been previously assessed and certified and the

justification for the suitability of the software relies on the previous

certification, the engineering and safety justification required by Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.3 is to

demonstrate why the existing certification is applicable to the proposed

application. Evidence is to be submitted justifying the applicability of the

software for the specific application, which is to include but is not to be limited

to:

- the configuration(s) of the previously certified software;

- the operating scenario relevant to the previously certified software;

- the standard against which the previous certification was based;

- the applicability of any expected level of risk reduction that was

previously certified;

- the relevance of any conditions of use placed upon the certified software;

- copies of the previous certification for the software;

- a summary of modifications and updates to the software since the issue of

the previous certification; and

- analysis demonstrating that the degree of reliance that can be placed on the

software achieving its safety requirements is less than or equal to that

against which it was previously certified.

5.6.19 Where software has been previously used with development data available,

and the justification for suitability of the software relies on the development

data, the engineering and safety justification required by Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.3 is to

include, but is not to be limited to, the following evidence:

- The evidence supporting the argument is to be for the same

software version as that of the proposed application.

- The producer of software is to provide access to the

development data so that LR can assess the level of compliance of existing

software with the rules.

- Where the production of software has included the use of

sub-contractor(s), the producer of software is to facilitate access to data

held by the sub-contractor(s).

- The argument is to identify any additional assurance activities

that are necessary to verify that the software safety requirements have been

satisfied.

5.6.20 Where software has been previously used with previous-use data

available, and the justification for suitability of the software relies on the

previous-use data, the engineering and safety justification required by Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.3 is to

include, but is not to be limited to, the following evidence:

- The use of the software under the same conditions as the

proposed application including, but not limited to, running on the same

hardware and operating system (if applicable), and having the same

functional requirements.

- The producer of software is to provide access to the

development data so that LR can assess the level of compliance of existing

software with the rules.

- Where the software under assessment provides only part of an

engineering system’s software solution, the production of software is to

include validation of the software module as part of the total software

solution.

5.6.21 The System Design Authority is to create during the ship's design and construction

phase a registry of all programmable electronic systems, logical (virtual) servers,

desktops and network communication devices installed on board the ship, identifying

the hardware and software installed within.

5.6.22 The System Design Authority is to maintain the registry required by

Vol 2, Pt 9, Ch 8, 5.6 Programmable electronic systems – Additional requirements for the production of software 5.6.21 and make it

available to the Surveyors on request. The registry is to record all changes made to

the ship's equipment during the ship's operational life, detailing as appropriate:

- system;

- vendor;

- system version;

- configuration version;

- date tested;

- test record reference;

- plan for production of software document reference;

- static network address; and

- records of reasons for the changes including details of any

alterations to software functionality.

5.6.23 Where remote access features or facilities for enabling temporary connections with

external devices are included for the programmable electronic system, the System

Design Authority is to periodically review the provisions made within the hardware

and software to ensure that new vulnerabilities and dependencies have not occurred

or have been adequately addressed to mitigate the risk related to their possible

exploitation.

5.6.24 The through-life management of the software is to be undertaken by the

System Design Authority in accordance with an acceptable process for the maintenance

of software. The process to be applied is to consider changes to the context of use

and/or amended software in the same manner as the originally developed software by

applying the plans and standards required by these Rules. Alternative processes

acceptable to LR may be applied to the software maintenance activities. The System

Design Authority may delegate the through-life management of software to the

software producer or other organisation when undertaking software modifications.

See also

Vol 2, Pt 9, Ch 1, 1.7 Alterations and additions 1.7.3.

|