Section

2 Vehicle decks and fixed ramps

2.1 General

2.1.1 These

requirements are applicable to longitudinally or transversely framed

ships intended for the carriage of tracked vehicles, wheeled vehicles,

or where wheeled vehicles are to be used for cargo handling.

2.1.2 The

deck and supporting structure are to be designed on the basis of the

maximum loading to which they may be subjected in service. Where applicable,

the hatch covers are to be similarly designed. In no case, however,

are the scantlings to be less than would be required for a weather

or cargo deck, or hatch cover, as applicable.

2.1.3 Details

of the deck loading resulting from the proposed stowage or operation

of vehicles are to be supplied by the Builder. These details are to

include axle and wheel spacing, the wheel load, type of tyre and tyre

print dimensions for the vehicles. The vehicle types and wheel loads

for which the vehicle decks, including hatch covers where applicable,

have been approved are to be included in the ship’s documentation

and contained in a notice displayed on each deck. For wheeled vehicles,

the wheel loading is to be taken as not less than 3,0 kN.

2.1.4 The

scantling requirements are based on structural strength and limitations

on stress and deflection, guidance for wear and tear allowances is

given in Vol 1, Pt 4, Ch 3, 2.3 Deck plating. Local reinforcement

is to be fitted as necessary, particularly in way of vehicle lanes

and embarked personnel routes.

2.1.5 The

webs of vehicle deck stiffening members are in no cases to be scalloped.

2.1.6 If wheeled

vehicles are to be used on insulated decks or tanks tops, consideration

will be given to the permissible loading in association with the insulation

arrangements and the plating thickness.

2.1.7 Suitable

fire fighting equipment and services should be provided in the vehicle

space. Arrangements should be made for ventilation and drainage of

spilt fuel.

2.2 Definitions

2.2.1

Load

Area. The load area is defined as the footprint area of an

individual wheel or the area enclosing a group of wheels when the

distance between footprints is less than the smaller dimension of

the individual prints.

2.3 Deck plating

2.3.1 The thickness, t

p, of vehicle deck plating is to be taken as not less than:

where

|

|

= |

|

|

s

|

= |

secondary

stiffener spacing, in mm |

s and k

s are

as defined in Vol 1, Pt 4, Ch 3, 1.2 Symbols and definitions.

Table 3.2.1 Deck plate thickness

calculation

| Symbols

|

Expression

|

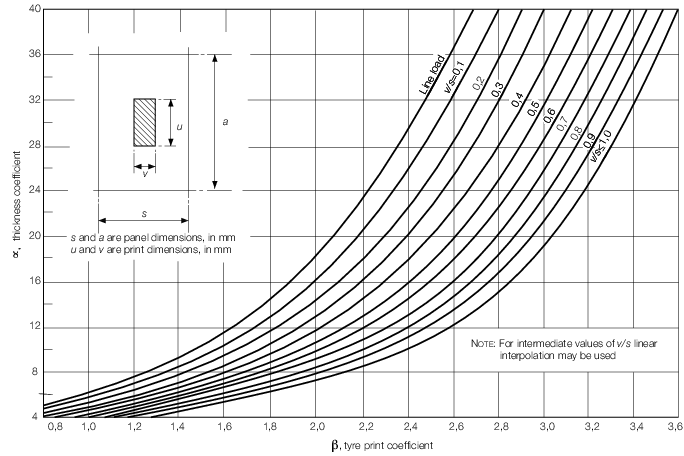

a, s, u and v as defined in Figure 3.2.1 Tyre print chart

|

F

typ

|

= |

corrected patch load for plating, in kN |

|

λ |

= |

dynamic magnification factor |

|

φ1

|

= |

patch aspect ratio correction factor |

|

φ2

|

= |

panel aspect ratio correction factor |

|

φ3

|

= |

wide patch load factor |

|

|

|

φ1

|

= |

|

|

|

|

|

for u ≤

(a – s)

|

|

|

= |

|

|

for a ≥

u > (a – s)

|

|

|

= |

0,77

|

|

for u > a

|

|

|

for v <

s

|

|

|

for 1,5 >

(v/s) > 1,0

|

|

|

for (v/s) ≥ 1,5

|

|

λ |

= |

1,25 for harbour conditions |

| = |

(1 + 0,7n) for sea going conditions |

|

Figure 3.2.1 Tyre print chart

Table 3.2.2 Tyre correction factor, n

| Number of wheels in idealised

patch

|

Pneumatic

tyres

correction factor, n

|

Solid

rubber

tyres

correction factor, n

|

|

|

|

|

2.3.3 Where

transversely framed decks contribute to the hull girder strength or

where secondary stiffening is fitted perpendicular to the direction

of vehicle lanes, the thickness, t

p, derived

from Vol 1, Pt 4, Ch 3, 2.3 Deck plating 2.3.1 is to be increased

by 1,0 mm.

2.3.4 In the

absence of a specific requirement the thickness t

p derived

from Vol 1, Pt 4, Ch 3, 2.3 Deck plating 2.3.1 is to be increased

by a wear and wastage allowance of 1,5 mm for strength decks, weather

decks, tank tops and inner bottom or 0,75 mm elsewhere.

2.4 Secondary stiffening

2.4.1 The

scantlings of vehicle deck stiffeners are to satisfy the most severe

arrangement of print wheel loads.

2.4.2 The

minimum requirements for section modulus, inertia and web area of

vehicle deck secondary stiffeners subject to wheel loading are to

be calculated in accordance with Table 3.2.3 Secondary stiffener

requirements using the loads defined in Table 3.2.4 Design load cases for primary and

secondary stiffening and supporting structure.

Table 3.2.3 Secondary stiffener

requirements

|

Scantling requirement

|

Load

case

|

d ≤

|

d >

|

| Section modulus (Z)(cm3)

|

|

|

Inertia ( )(cm4) )(cm4)

|

|

|

| Web area (A

w)(cm2)

|

where m = d/l

|

|

| Symbol

|

|

= |

overall secondary stiffener length, in metres |

|

|

s

|

= |

stiffener spacing, in metres |

|

|

d

|

= |

dimension of load area parallel to stiffener axis, in

metres |

|

|

E

|

= |

Young's Modulus of elasticity of material, in

N/mm2

|

|

|

w

|

= |

dimension of load area perpendicular to stiffener

axis, in metres |

|

|

k

w

|

= |

lateral loading factor |

| = |

1 for w ≤ s

|

| = |

s/w for w > s

|

|

|

F

tys

|

= |

point load given in Table 3.2.4, in kN |

|

|

F

tym

|

= |

self weight load given in Table 3.2.4, in kN |

|

|

P

tyw

|

= |

weather deck load given in Table 3.2.4, in

kN/m2

|

|

| f

σ,f

δ,f

τ are the structural design factors given in Pt 6, Ch 5

|

|

σo

|

= |

specified minimum yield strength of the material, in

N/mm2

|

|

|

τo

|

= |

shear strength of the material, in N/mm2

|

| = |

|

|

Table 3.2.4 Design load cases for primary and

secondary stiffening and supporting structure

| Condition

|

Loading

|

| Stiffening

|

|

|

UDL

Ptyw

kN/m2

|

Point loads,

Ftys

kN

|

Self weight,

Ftym

kN

|

| Manoeuvring

internal

|

-

|

1,6Wty

|

(1 + a

z)Ws

|

| Manoeuvring external

|

0,5

|

1,75Wty

|

(1 + a

z)Ws

|

| Parking

internal

|

-

|

(1+ n a

z)Wty

|

(1 + a

z)Ws

|

| Parking external

|

2

|

1,1

(1+ n a

z)Wty

|

(1 + a

z)Ws

|

| Symbols

|

|

W

ty

|

= |

maximum effective load per wheel or group of

wheels |

|

|

W

s

|

= |

structural weight of stiffener and supported

structure, in kN |

|

|

UDL |

= |

uniformly distributed load over entire vehicle area,

kN/m2

|

|

|

|

|

a

z is defined in Vol 1, Pt 5, Ch 3, 2 Motion response

|

Note

1. For the design of the supporting

structure for vehicle decks, the applicable self weight and horizontal

loads are to be added to the parking area loads.

|

Note

2. The vehicles are to be positioned so

as to produce the most severe loading condition for each structural

member under consideration.

|

Note

3. Stiffening members may have more than

one point load acting at any time.

|

2.4.3 When

two or more load areas are located simultaneously on the same stiffener

span, the scantling requirements are to be specially considered on

the basis of direct calculation.

2.5 Primary stiffening

2.6 Securing arrangements

2.6.2 Deck

fittings in way of vehicle lanes are to be recessed.

2.6.3 The

vehicle deck structure is to be of adequate strength for the upward

forces imposed at fixed securing points. Local reinforcement is to

be fitted as necessary.

2.7 Access

2.7.3 Doors

providing access between vehicle decks and accommodation spaces are

to be gastight, have scantlings equivalent to the surrounding structure

and where applicable are to comply with the specified fire safety

standard.

2.8 Hatch covers

2.8.1 The

scantlings and arrangements of hatches and hatch covers located within

vehicle decks are to be not less than that required by the Rules for

the supporting structure in which such hatches are fitted. In general

the end fixity of primary stiffening members is to be taken as simply

supported. Local and secondary stiffening members may be either partially

or fully fixed at their end connections dependent upon the proposed

arrangement.

2.8.2 In no

case, however, are the scantlings of plating and stiffeners to be

less than would be required for a weather or cargo deck hatch cover,

as applicable.

2.8.3 Where

unusual arrangements of hatch cover stiffening are proposed, the scantlings

of plating and stiffeners may be determined by direct calculations.

The designers calculations are to be submitted.

2.9 Heavy and special loads

2.9.1 Where

heavy or special loads are proposed to be carried, the scantlings

and arrangements of the deck structure will be individually considered

on the basis of submitted calculations.

2.9.2 Due

account is to be taken of the acceleration levels due to ship motion

as applicable to particular items of heavy mass such as vehicles,

containers, pallets, etc.

2.10 Tracked and steel wheeled vehicles

2.10.1 Where

it is proposed to carry tracked vehicles the patch dimensions may

be taken as the track print dimensions and F

w is

to be taken as half the total weight of the vehicle. Deck fittings

in way of vehicle lanes are to be recessed.

2.10.2 Where

it is proposed to carry tracked vehicles, the total weight of the

vehicle is to be used when determining the section modulus of the

transverse at the top of a ramp or at other changes of gradient.

2.11 Openings in main vehicle deck

2.11.1 Items

such as portable plates in main vehicle deck for the removal of machinery

parts, etc. may be arranged flush with the deck, provided they are

secured by gaskets and closely spaced bolts at a pitch not exceeding

five diameters.

2.11.2 Scuppers

from vehicle or cargo spaces fitted with an approved fixed pressure

water spray fire-extinguishing system are to be led inboard to tanks.

Alternatively they may be led overboard providing they comply with Vol 1, Pt 3, Ch 4, 8.1 General 8.1.3.

2.11.3 Inboard draining scuppers do not require valves but are to be led to

suitable drain tanks (not engine room or hold bilges) and the capacity of the tanks is

to be sufficient to hold at least 20 minutes of drenching water. The arrangements for

emptying these tanks are to be approved and suitable high level alarms provided.

2.11.4 Air

pipes from cofferdams or void spaces may terminate in the enclosed

‘tween deck space on the main vehicle deck provided the space

is adequately ventilated and the air pipes are provided with weathertight

closing appliances.

2.12 Direct calculations

2.12.1 Clasifications

Register (hereinafter referred to as 'LR') will consider direct calculations

for the derivation of scantlings as an alternative to and equivalent

to those derived by Rule requirements. The assumptions made and the

calculation procedures used are to be submitted for appraisal in accordance

with Vol 1, Pt 3, Ch 1, 2 Direct calculations

|