Section

8 Anchor windlass design and testing

8.1 General

8.1.1 A windlass, capstan or winch used for handling anchors, suitable for the

size of chain cable required by Vol 1, Pt 3, Ch 5, 5 Anchor cable and complying with the following criteria is to

be fitted. Where Owners require equipment significantly in excess of Rule requirements,

it is their responsibility to specify increased windlass power.

8.1.2 The design, construction and testing of windlasses are to conform with a relevant

National or International Standard or code of practice acceptable to LR. To be

considered acceptable, the standard, or code of practice, is to specify criteria for

evaluation of stresses, performance and testing.

8.1.3 Operation and maintenance procedures for the anchor windlass are to be incorporated in

the vessel operations manual.

8.2 Plans and particulars to be submitted

8.2.1 The following plans showing the design specifications, the standard of compliance,

engineering analyses and details of construction, as applicable, are to be submitted

for evaluation:

- Windlass design specifications, anchor and chain cable

particulars, performance criteria, and standard of compliance.

- Windlass foundation drawings including the supporting

structure below deck. The details shall include bolts, chocks, shear

stoppers etc. along with the foot print loads for the specified windlass

ratings.

- Chain stopper foundation drawings including the

supporting structure below deck. The details shall include bolts, chocks,

shear stoppers etc. along with the foot print loads for the specified

rating.

- Windlass arrangement plans showing all the components of

the anchoring/mooring system such as the prime mover, shafting, cable

lifter, anchors and chain cables; mooring winches, wires and fairleads, if

they form part of the windlass machinery; brakes; controls, etc.

- Dimensions, materials, welding details, as applicable,

of all torque-transmitting components (shafts, gears, clutches, couplings,

coupling bolts, etc.) and all load-bearing components (shaft bearings,

cable lifter, sheaves, drums, bed-frames, etc.) of the windlass and of the

winch, where applicable, including brakes, chain stopper (if fitted), and

foundation.

- Hydraulic system, to include:

- piping diagram along with system design

pressure;

- safety valves arrangement and settings;

- material specifications for pipes and

equipment;

- typical pipe joints, as applicable;

- technical data and details for hydraulic

motors;

- cooling systems arrangements for hydraulic

system oil.

- Electrical one-line diagram along with cable

specification and size, motor controller, protective device rating or

setting, as applicable.

- Control, monitoring and instrumentation

arrangements.

- Engineering analyses for torque-transmitting and

load-bearing components demonstrating their compliance with recognised

standards or codes of practice. Analyses for gears are to be in accordance

with a recognised standard.

- Calculations proving satisfactory inertia loads for the

intended windlass, see

Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1.(b).

- Plans and data for windlass electric motors including

associated gears rated 100 kW and over.

- Calculations demonstrating that the windlass prime mover

is capable of attaining the hoisting speed, the required continuous duty

pull, and the overload capacity are to be submitted if the ‘load testing’

including ‘overload’ capacity of the entire windlass unit is not carried out

at the shop (see

Vol 1, Pt 3, Ch 5, 8.10 Shop inspection and testing 8.10.1.(b)).

8.3 Materials and fabrication

8.3.1 Materials used in the construction of torque-transmitting and

load-bearing parts of windlasses are to comply with LR's Rules for the Manufacture, Testing and Certification of Materials, July 2022 or an

appropriate National or International Standard acceptable to LR, provided that the

Standard gives reasonable equivalence to the requirements of LR. The proposed

materials are to be indicated in the construction plans and are to be approved in

connection with the design. All such materials are to be certified by the material

manufacturers and are to be traceable to the manufacturers’ certificates.

8.3.2 Weld joint designs are to be shown in the submitted construction plans and are to be

appraised in association with the approval of the windlass design in accordance with

an appropriate National or International Standard acceptable to LR. .

8.3.4 The degree of non-destructive examination of welds and post-weld heat treatment, if

any, are to be specified and submitted for consideration.

8.4 Windlass design

8.4.1 In addition to the requirements of the National or International Standard

or code of practice acceptable to LR (see

Vol 1, Pt 3, Ch 5, 8.1 General 8.1.2) the following performance requirements are to

be complied with:

- Holding Loads: Calculations are to be made to show that, in the

holding condition (single anchor, brake fully applied and chain cable lifter

declutched) and under a load equal to 80 per cent of the specified minimum breaking

strength of the chain cable, the maximum stress in each load bearing component will

not exceed the maximum permissible yield. For installations fitted with a chain cable

stopper, 45 per cent of the specified minimum breaking strength of the chain cable

may instead be used for the calculation.

- Inertia Loads: The design of the drive train, including prime

mover, reduction gears, bearings, clutches, shafts, cable lifter and bolting is to

consider the dynamic effects of sudden stopping and starting of the prime mover or

chain cable, so as to limit inertial load.

- Continuous Duty Pull: The windlass is to

have sufficient power to exert a continuous duty pull , Zcont1,

over a period of 30 minutes corresponding to the grade and diameter,

dc, of the chain cables as follows:

- for specified design anchorage depths up to 82,5 m when using

ordinary stockless anchors: :

| Chain cable

grade

|

Zcont1 (N)

|

| U1

|

37,5d

c

2

|

| U2

|

42,5d

c

2

|

| U3

|

47,5d

c

2

|

- for specified design anchorage depths greater

than 82,5 m a continuous duty pull Zcont2 is:

- where

|

dc |

= |

is the chain diameter, in mm |

|

Da |

= |

is the specified design anchorage depth, in metres |

The anchor masses are assumed to be the masses as given in Table 5.6.1 Equipment - Kedge anchors and

wires, towlines and mooring lines. The value of Zcont is

based on the hoisting of one anchor at a time, and assumes that the effects of

buoyancy and hawse pipe efficiency (assumed to be 70 per cent) have been accounted

for. In general, stresses in each torque-transmitting component are not to exceed

40 per cent of yield strength (or 0,2 per cent proof stress) of the material under

these loading conditions.

-

Overload Capability: The windlass prime mover is to be able to

provide, for a period of at least two minutes, the necessary temporary overload

capacity for breaking out the anchor. This temporary overload capacity is to be a

pull equal to the greater of:

-

short term pull:

1,5 times the continuous duty pull as defined in

Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1.(c), or

-

anchor breakout pull:

Note The speed in this period may be lower than normal.

- Hoisting Speed: The mean speed of the chain cable

during hoisting of the anchor and cable is to be 0,15 m/s.

- Brake Capacity: The capacity of the windlass brake is

to be sufficient to stop the anchor and chain cable when paying out the chain cable

in a controlled manner. Where a chain cable stopper is not fitted, the brake is to

produce a torque capable of withstanding a pull equal to 80 per cent of the specified

minimum breaking strength of the chain cable without any permanent deformation of

strength members and without brake slip. Where a chain cable stopper is fitted, 45

per cent of the breaking strength may instead be applied. The following simplified

formula is to be used to calculate the required brake capacity:

K

b

d

c

2 (44 − 0,08d

c) N

where K

b is given in Table 5.8.1 Values of Kb

.

Table 5.8.1 Values of Kb

|

|

Kb

|

| Cable grade

|

Windlass used in conjunction with chain

stopper

|

Chain stopper not fitted

|

| U1

|

4,41

|

7,85

|

|

| U2

|

6,18

|

11,0

|

|

| U3

|

8,83

|

15,7

|

|

8.4.2 As an alternative to conducting the engineering analyses required by Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1, approval of the windlass

mechanical design can be based on a type test, in which case the testing procedure is to

be submitted for consideration.

8.4.3 Calculations for torque transmitting components are to be based on 1500

hours of operation with a nominal load spectrum factor of Km = 1,0.

Alternatively unlimited hours with a nominal load spectrum factor of

Km = 0,8 can be applied.

8.4.4 The following criteria are to be used for gearing design:

-

Torque is to be based on the performance criteria specified in Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1.

-

The use of an equivalent torque, Teq, for dynamic

strength calculations is acceptable but the derivation is to be submitted to LR

for consideration.

-

The application factor for dynamic strength calculation,

KA, is to be 1,15.

-

Calculations are to be based on 1500 hours of operation.

-

The static torque is to be 1,5 x Tn where

Tn is the nominal torque.

-

The minimum factors of safety for load capacity of spur and helical

gears, as derived using ISO 6336 or a relevant National or International standard

acceptable to LR, are to be 1,5 for bending stress and 0,6 for contact stress.

Gears intended to transmit power greater than 100 kW are to be certified by

LR, and the gears are to meet the requirements of Vol 2, Pt 3, Ch 1 Gearing.

8.5 Additional requirements for windlass design for naval ships

8.5.1 Hand-operated windlasses are only acceptable if the effort required at the handle

does not exceed 150N for raising one anchor at a speed of not less than 2 m/min and

making about thirty turns of the handle per minute.

8.5.2 Windlasses suitable for operation by hand as well as by external power are to be so

constructed that the power drive cannot activate the hand drive.

8.5.3 Where a chain stopper is fitted, the windlass braking system is only to ensure safe

stopping when paying out the anchor and chain. It is the Master's responsibility to

ensure that the chain stopper is in use when riding at anchor. At clearly visible

locations on the bridge and adjacent to the windlass control position, the following

notice is to be displayed:

“The brake is rated to permit controlled descent of the anchor and chain only. The

chain stopper is to be used at all times whilst riding at anchor“

8.6 Hydraulic systems

8.7 Electrical systems

8.8 Control arrangements

8.8.1 All

control devices are to be capable of being controlled from readily

accessible positions and protected against unintentional operation.

8.8.2 The

maximum travel of the levers is not to exceed 600 mm if movable in

one direction only, or 300 mm to either side from a central position

if movable in both directions.

8.8.3 Wherever

practical, the lever is to move in the direction of the intended movement.

If this cannot be achieved, it is to move towards the right when hauling

and towards the left when paying out.

8.8.4 For

lever-operated brakes, the brake is to engage when the lever is pulled

and disengage when the lever is pushed. The physical effort on the

brake for the operator is not to exceed 160 N.

8.8.5 For

pedal-operated brakes, the maximum travel is not to exceed 250 mm

and the physical effort for the operator is not to exceed 320 N.

8.8.6 The

handwheel or crankhandle is to actuate the brake when turned clockwise

and release it when turned counterclockwise. The physical effort for

the operator is not to exceed 250 N for speed regulation and 500 N

at any moment.

8.8.7 When

not provided with automatic sequential control, separate push-buttons

are to be provided for each direction of operation.

8.8.8 The

push-buttons are to actuate the machinery when depressed and stop

and effectively brake the machinery when released.

8.8.9 The

above mentioned individual push-buttons may be replaced by two ‘start’

and ‘stop’ push-buttons.

8.8.11 Windlass

motors are to be protected against overload, overspeed and overpressure,

using appropriate safety techniques suitable for the intended installation.

8.9 Protection arrangements

8.9.1 Where applicable, moving parts of windlass machinery are to be provided with

suitable railings and/or guards to prevent injury to personnel.

8.9.2 Protection is to be provided for preventing persons from coming into contact

with surfaces having temperatures over 50°C.

8.9.3 Steel surfaces not protected by lubricant are to be protected by a coating,

in accordance with the requirements of a relevant National or International Standard

acceptable to LR.

8.9.5 Electrical cables installed in exposed locations on open deck are to be provided with

effective mechanical protection.

8.9.6 Means are to be provided to contain potential debris resulting from severe damage of the

prime mover due to over-speed in the event of uncontrolled rendering of the cable,

particularly when an axial piston type hydraulic motor forms the prime mover.

8.9.7 An arrangement to release the anchor and chain in the event of windlass power failure is

to be provided. Windlasses are to be fitted with couplings which are capable of

disengaging between the cable lifter and the drive shaft. Hydraulically or electrically

operated couplings are to be capable of being disengaged manually.

8.9.8 The design of the windlass is to be such that the following requirements or equivalent

arrangements will minimise the probability of the chain locker or forecastle being

flooded in bad weather:

- a weathertight connection can be made between the windlass

bedplate, or its equivalent, and the upper end of the chain pipe by means of a cover

or seal, and

- access to the chain pipe is adequate to permit the fitting of a

cover or seal, of sufficient strength and proper design, over the chain pipe while

the ship is at sea.

8.10 Shop inspection and testing

8.10.1 Windlasses are to be inspected during fabrication at the manufacturers’

facilities by a Surveyor for conformance with the approved plans. Acceptance tests,

as specified in the specified Standard (see

Vol 1, Pt 3, Ch 5, 8.1 General 8.1.2), are to be witnessed by the Surveyor and

include the following tests, as a minimum:

- No-load test. The windlass is to be run without load at

nominal speed in each direction for a total of 30 minutes. If the windlass is

provided with a gear change, an additional run in each direction for 5 minutes

at each gear change is required.

- Load test. The windlass is to be tested to verify that the

continuous duty pull, overload capacity and hoisting speed as specified in Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1 can

be achieved.

Where the manufacturer’s works does not have

adequate facilities, these tests, including the adjustment of the overload

protection, can be carried out on board ship. In these cases, functional

testing in the manufacturer’s works is to be performed under no-load

conditions.

- Brake capacity test. The holding power of the brake is to be

verified through testing if not verified by calculation.

8.10.2 Windlass performance characteristics specified in Vol 1, Pt 3, Ch 5, 8.10 Shop inspection and testing 8.10.1 are

based on the following assumptions:

-

one cable lifter only is connected to the drive shaft;

-

continuous duty and short term pulls are measured at the cable

lifter;

-

hawse pipe efficiency assumed to be 70 per cent.

8.11 On-board testing

8.11.1 Each windlass is to be tested under working conditions after installation on board to

demonstrate satisfactory operation. Each unit is to be independently tested for braking,

clutch functioning, lowering and hoisting of the chain cable and anchor, proper riding

of the chain over the cable lifter, proper transit of the chain through the hawse pipe

and the chain pipe, and effecting proper stowage of the chain and the anchor. It is to

be confirmed that anchors properly seat in the stored position and that chain stoppers

function as designed, if fitted. The braking capacity is to be tested by intermittently

paying out and holding the chain cable by means of the application of the brake.

8.11.2 The mean hoisting speed, as specified in Vol 1, Pt 3, Ch 5, 8.4 Windlass design 8.4.1.(e) is to be

measured and verified. For testing purposes, the speed is to be measured over two shots

of chain cable and initially with at least three shots of chain (82.5 m or 45 fathoms in

length) and the anchor submerged and hanging free.

8.11.4 Where the depth of water in the trial area is inadequate, suitable equivalent simulating

conditions will be considered as an alternative.

8.12 Marking and identification

8.12.1 The windlass is to be permanently marked with the following information:

- The size designation of the windlass (e.g. 100/3/45, where 100

is the nominal diameter of the chain cable in mm, 3 is the numeral in the chain cable

steel grade U3, and 45 refers to the holding load expressed as a percentage of the

chain cable breaking load).

- Maximum anchorage depth, in metres.

8.13 Seatings

8.13.1 The windlass is to be efficiently bedded and secured to the deck. The

thickness of the deck in way of the windlass is to be increased, and the supporting

structure for the anchor windlass should be examined for the brake holding loads

specified by Vol 1, Pt 3, Ch 5, 8.4 Windlass design. The allowable stresses specified in

Table 5.5.1 Allowable stresses in windlass and

chain stopper supporting structure

are to be used to derive the net scantlings of the supporting structure. The capability

of the supporting structure to withstand buckling is also to be assessed. The structural

design integrity of the bedplate is the responsibility of the Builder and windlass

manufacturer.

8.14 Structural requirements for windlasses on exposed fore decks

8.14.1 Windlasses located on the exposed deck over the forward

0,25LR of the Rule length, of naval ships of sea-going service

of length 80 m or more, where the height of the exposed deck in way of the item is

less than 0,1LR or 22 m above the design draught, whichever is the

lesser, are to comply with the following requirements. Where mooring winches are

integral with the anchor windlass, they are to be considered as part of the

windlass.

8.14.3 Forces in the bolts, chocks and stoppers securing the windlass to the

deck are to be calculated. The windlass is supported by N bolt groups, each

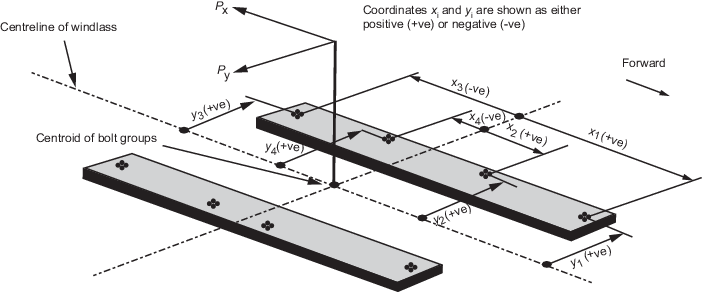

containing one or more bolts, see

Figure 5.8.2 Direction of forces and

weight.

Figure 5.8.2 Direction of forces and

weight

8.14.4 The axial force Ri in bolt group (or bolt) i, positive

in tension, may be calculated from:

|

Rxi |

= |

Px h xi Ai/Ix in

kN |

|

Ryi |

= |

Py h yi Ai/Iy in

kN, and |

|

Ri |

= |

Rxi + Ryi - Rsi in kN |

where

|

Px |

= |

force acting normal to the shaft axis, in kN |

|

Py |

= |

force acting parallel to the shaft axis, either inboard or

outboard whichever gives the greater force in bolt group i, in kN |

|

h |

= |

shaft height above the windlass mounting, in cm |

|

xi, yi |

= |

x and y coordinates of bolt group i from the centroid of

all N bolt groups, positive in the direction opposite to that of the

applied force, in cm |

|

Ai |

= |

cross-sectional area of all bolts in group i, in

cm2 |

|

Ix |

= |

for N bolt groups, in

cm4 for N bolt groups, in

cm4 |

|

Iy |

= |

for N bolt groups, in

cm4 for N bolt groups, in

cm4 |

|

Rsi |

= |

static reaction at bolt group i, due to weight of windlass,

in kN. |

8.14.5 Shear forces Fxi, Fyi applied to the bolt group

i, and the resultant combined force Fi may be calculated from:

|

Fxi |

= |

(Px- μ g M) /N in kN |

|

Fyi |

= |

(Py- μ g M) /N in kN |

and

where

|

μ |

= |

coefficient of friction (0,5) |

|

M |

= |

mass of windlass, in tonnes |

|

g |

= |

gravity acceleration (9,81 m/sec2) |

|

N |

= |

number of bolt groups. |

8.14.6 Tensile axial stresses in the individual bolts in each bolt group i are to be

calculated. The horizontal forces Fxi and Fyi are normally to be

reacted by shear chocks. Where ‘fitted’ bolts are designed to support these shear

forces in one or both directions, the von Mises equivalent stresses in the

individual bolts are to be calculated, and compared to the stress under proof load.

Where pourable resins are incorporated in the holding down arrangements, due account

is to be taken in the calculations.

8.14.7 The safety factor against bolt proof strength is to be not less than 2,0.

8.14.8 Bolts are to be of lSO 898/1 material Grade 8.8, 10.9 or 12.9 or equivalent and are

to be pretensioned by controlled means to 70 to 90 per cent of their yield stress.

Pretensioning is to be in accordance with the manufacturer’s instructions and, in

general, pretensioning by bolt torqueing up to bolt size M30 may be used. Beyond

this, pretensioning is to be carried out by an hydraulic tensioning device and the

elongation of the bolts measured to determine pre-load. Where resin chocks are

proposed, plans and calculations are to be submitted for consideration.

8.14.9 The windlass is to be efficiently bedded and secured to the deck. The

thickness of the deck in way of the windlass is to be increased. Adequate stiffening

of the deck in way of the windlass is to be provided. The scantlings of the

supporting structure and deck are to be determined by additional calculations

applying the weight of the windlass combined with the resultant force on the seat

due to the application of the following design loads:

The allowable stresses specified in Pt 3, Ch 13, 8.12 Structural requirements associated with anchoring 8.12.2 are to be used to derive the net scantlings of the supporting

structure. The capability of the supporting structure to withstand buckling is also

to be assessed.

|