Section

2 Carbon and low alloy steels

2.1 Carbon and low alloy steel pipes, valves and fittings

2.1.1 Materials

for Class I and Class II piping systems, also for shipside valves

and fittings and valves on the collision bulkhead, are to be manufactured

and tested in accordance with the appropriate requirements of the

Rules for Materials, see also

Pt 5, Ch 10, 1.6 Materials.

2.1.2 Materials

for Class III piping systems are to be manufactured and tested in

accordance with the requirements of acceptable national specifications.

Pipes having forge butt welded longitudinal seams are not to be used

for fuel oil systems, for heating coils in oil tanks, or for pressures

exceeding 4,0 bar. The manufacturer’s certificate will be acceptable

and is to be provided for each consignment of material. See

Ch 1, 3.1 General 3.1.3.(c) of the Rules for Materials.

2.2 Wrought steel pipes and bends

2.2.1 The maximum

permissible design stress, σ, is to be taken as the lowest of

the following values:

|

σ |

= |

|

|

|

σ |

= |

|

|

|

E

t

|

= |

specified minimum lower yield or 0,2 per cent proof stress at

the design temperature. In the case of austenitic stainless steels,

the 1,0 per cent proof stress at design temperature is to be used. |

|

R

20

|

= |

specified minimum tensile strength at ambient temperature. |

Values of the maximum permissible design stress,

σ, may be obtained from the properties of the steels specified

in Chapter 6 of the Rules for Materials are shown in Table 10.2.1 Mechanical properties of finished

chain cable and fittings for carbon and carbon-manganese

steels. For intermediate values of specified minimum tensile strengths

and temperatures, values of the permissible design stress may be obtained

by interpolation.

2.2.2 Where

it is proposed to use alloy steels other than those detailed in Ch 6 Steel Pipes and Tubes of the Rules for Materials, particulars

of the tube sizes, design conditions and appropriate national or proprietary

material specifications are to be submitted for consideration.

2.2.4 For pipes passing through tanks, an additional corrosion allowance is to be

added to take account of external corrosion; the addition will depend on the external

medium and the value is to be in accordance with Table 10.2.2 Values of

c

for steel pipes .

Table 10.2.1 Carbon and carbon-manganese steel

pipes

| Specified minimum

|

Maximum permissible stress, in N/mm2

|

| tensile

strength, in

|

Maximum design temperature, in °C

|

| N/mm2

|

50

|

100

|

150

|

200

|

250

|

300

|

| 320

|

107

|

105

|

99

|

92

|

78

|

62

|

| 360

|

120

|

117

|

110

|

103

|

91

|

76

|

| 410

|

136

|

131

|

124

|

117

|

106

|

93

|

| 460

|

151

|

146

|

139

|

132

|

122

|

111

|

| 490

|

160

|

156

|

148

|

141

|

131

|

121

|

Table 10.2.2 Values of

c

for steel pipes

| Piping service

|

c

|

|

|

mm

|

| Saturated steam systems

|

0,8

|

| Steam coil systems in cargo tanks

|

2,0

|

| Feed water for boilers in open circuit

systems

|

1,5

|

| Feed water for boilers in closed circuit

systems

|

0,5

|

| Blow down (for boilers) systems

|

1,5

|

| Compressed air systems

|

1,0

|

| Hydraulic oil systems

|

0,3

|

| Lubricating oil systems

|

0,3

|

| Fuel oil systems

|

1,0

|

| Cargo oil systems

|

2,0

|

| Refrigerating plants

|

0,3

|

| Fresh water systems

|

0,8

|

| Water systems in general

|

3,0

|

| (ballast & cooling water)

|

|

| Cargo pipes of ships carrying liquefied natural

or petroleum gases

|

0,3

|

2.2.5 Where

the pipes are efficiently protected against corrosion, the corrosion

allowance may be reduced by not more than 50 per cent.

2.2.7 The minimum

thickness, t

b, of a straight steel pipe to

be used for a pipe bend is to be determined by the following formula,

except where it can be demonstrated that the use of a thickness less

than t

b would not reduce the thickness below t at any point after bending:

|

t

b

|

= |

|

p, D, R, e, b and a are as defined in Pt 5, Ch 10, 1.2 Design symbols 1.2.1

σ is defined in Pt 5, Ch 10, 2.2 Wrought steel pipes and bends 2.2.1,

and c is to be obtained from Table 10.2.2 Values of

c

for steel pipes

In general, R is to be

not less than 3D.

2.2.8 Where

the minimum thickness calculated by Pt 5, Ch 10, 2.2 Wrought steel pipes and bends 2.2.4 or Pt 5, Ch 10, 2.2 Wrought steel pipes and bends 2.2.5 is less than that shown in Table 10.2.3 Minimum thickness for steel

pipes, the minimum nominal

thickness for the appropriate standard pipe size shown in the Table

is to be used. No allowance is required for negative tolerance, corrosion

or reduction in thickness due to bending on this nominal thickness.

For larger diameters, the minimum thickness will be specially considered.

For threaded pipes, where permitted, the minimum thickness is to be

measured at the bottom of the thread.

Table 10.2.3 Minimum thickness for steel

pipes

| External

diameter,

|

Minimum pipe

|

Air and sounding pipes

for

|

|

D, mm

|

thickness, mm

|

structural tanks,

mm

|

| 10,2 - 12

|

1,6

|

--

|

| 13,5 - 19

|

1,8

|

--

|

| 20 - 44,5

|

2,0

|

4,5

|

| 48,3 - 63,5

|

2,3

|

4,5

|

| 70 - 82,5

|

2,6

|

4,5

|

| 88,9 - 108

|

2,9

|

4,5

|

| 114,3 - 127

|

3,2

|

4,5

|

| 133 - 139,7

|

3,6

|

4,5

|

| 152,4 - 168,3

|

4,0

|

4,5

|

| 177,8

|

4,5

|

5,0

|

| 193,7

|

4,5

|

5,4

|

| 219,1

|

4,5

|

5,9

|

| 244,5 - 273

|

5,0

|

6,3

|

| 298,5 - 368

|

5,0

|

6,3

|

| 406,4 - 457,2

|

6,3

|

6,3

|

Note

1. The thickness of bilge, ballast and

general outboard water systems is to be not less than 4,0 mm.

Note

2. The thickness of bilge, air, overflow

and sounding pipes through ballast and fuel oil tanks, ballast lines

through fuel oil tanks and fuel oil lines through ballast tanks is to

be not less than 6,3 mm.

Note

3. For air bilge, ballast, fuel oil,

overflow, sounding, and venting pipes as mentioned in Notes 1 to 2,

where the pipes are efficiently protected against corrosion, the

thickness may be reduced by not more than 1 mm.

Note

4. For air and sounding pipes, the

minimum thickness applies to the part of the pipe outside the tank but

not exposed to the weather. The section of pipe exposed to the weather

is required to be suitably increased in thickness or in compliance

with the requirements of the relevant Authorities.

|

2.3 Pipe joints - General

2.3.1 Joints

in pressure pipelines may be made by:

- Welded-on bolted flanges, see

Pt 5, Ch 10, 2.5 Welded-on flanges, butt welded joints and fabricated branch pieces.

- Butt welds between pipes or between pipes and valve chests or

other fittings, see

Pt 5, Ch 10, 2.5 Welded-on flanges, butt welded joints and fabricated branch pieces.

- Loose Flanges, see

Pt 5, Ch 10, 2.6 Loose flanges.

- Socket weld joints, see

Pt 5, Ch 10, 2.7 Socket weld joints.

- Welded sleeve joints, see

Pt 5, Ch 10, 2.8 Welded sleeve joints.

- Threaded sleeve joints, see

Pt 5, Ch 10, 2.9 Threaded sleeve joints.

- Screwed fittings, see

Pt 5, Ch 10, 2.10 Screwed fittings.

- Other mechanical couplings, see

Pt 5, Ch 10, 2.11 Other mechanical couplings.

- Special types of approved joints that have been shown to be suitable

for the design conditions. Details are to be submitted for consideration.

2.3.2 The dimensions

and materials of flanges, gaskets and bolting, and the press-temperature

rating of bolted flanges in pressure pipelines are to be in accordance

with recognised national or other established standards.

2.3.3 With the

welded pressure piping system referred to in Pt 5, Ch 10, 2.3 Pipe joints - General 2.3.1 it is desirable that a few flanged

joints be provided at suitable positions to facilitate installation,

cold ‘pull up’ and inspection at Periodical Surveys.

2.3.4 Piping

with joints is to be adequately adjusted, aligned and supported. Supports

or hangers are not to be used to force alignment of piping at the

point of connection.

2.3.5 Consideration

will be given to accepting joints in accordance with a recognized

National or International Standard which is applicable to the intended

service and media conveyed.

2.3.6 Where

welded pipes are protected against corrosion then the corrosion protection

is to be applied after welding or the corrosion protection is to be

made good in way of the weld damaged area.

2.3.7 Where

it is not possible to make good the corrosion protection of the weld

damaged area, the pipe is to be considered to have no corrosion protection.

2.4 Steel pipe flanges

2.4.1 Flanges

may be cut from plates or may be forged or cast. The material is to

be suitable for the design temperature.

2.4.2 Flange

attachments to pipes and pressure-temperature ratings in accordance

with National or other approved Standards will be accepted.

2.5 Welded-on flanges, butt welded joints and fabricated branch pieces

2.5.1 The types

of welded-on flanges are to be suitable for the pressure, temperature

and service for which the pipes are intended.

2.5.2 Typical

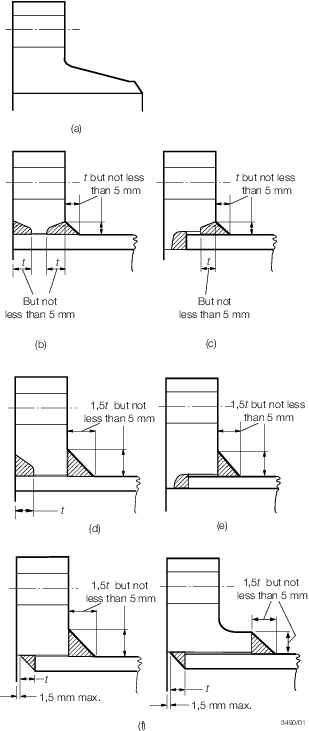

examples of welded-on flange attachments are shown in Figure 10.2.1 Typical welded-on flanges(a) to (f). Types (c) and

(e), however, are not to be used for pipes having a bore of less than

75 mm.

Figure 10.2.1 Typical welded-on flanges

2.5.4 Welded-on

flanges are not to be a tight fit on the pipes. The maximum clearance

between the bore of the flange and the outside diameter of the pipe

is to be 3 mm at any point, and the sum of the clearances diametrically

opposite is not to exceed 5 mm.

2.5.5 Where

butt welds are employed in the attachment of flange type (a), in pipe-to-pipe

joints or in the construction of branch pieces, the adjacent pieces

are to be matched at the bores. This may be effected by drifting,

roller expanding or machining, provided that the pipe wall is not

reduced below the designed thickness. If the parts to be joined differ

in wall thickness, the thicker wall is to be gradually tapered to

the thickness of the thinner at the butt joint. The welding necks

of valve chests are to be sufficiently long to ensure that the valves

are not distorted as the result of welding and subsequent heat treatment

of the joints.

2.5.6 Where

backing rings are used with flange type (a), they are to fit closely

to the bore of the pipe and should be removed after welding. The rings

are to be made of the same materials as the pipes or of mild steel

having a sulphur content not greater than 0,05 per cent.

2.5.7 Branches

may be attached to pressure pipes by means of welding provided that

the pipe is reinforced at the branch by a compensating plate or collar

or other approved means, or, alternatively, that the thicknesses of

pipe and branch are increased to maintain the strength of the pipe.

These requirements also apply to fabricated branch pieces.

2.5.8 Welding

may be carried out by means of the shielded metal arc, inert gas metal

arc, oxy-acetylene or other approved process, but in general, oxy-acetylene

welding is suitable only for flange type (a) and is not to be applied

to pipes exceeding 100 mm diameter or 9,5 mm thick. The welding is

to be carried out in accordance with the appropriate paragraphs of Pt 5, Ch 14 Requirements for Fusion Welding of Pressure Vessels and Piping.

2.6 Loose flanges

2.6.1 Loose

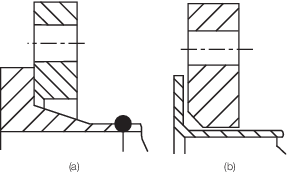

flange designs as shown in Figure 10.2.2 Loose flange arrangements may

be used, provided they are in accordance with a recognized National

or International Standard.

Figure 10.2.2 Loose flange arrangements

2.7 Socket weld joints

2.7.1 Socket

weld joints may be used in Class III systems with carbon steel pipes

of any outside diameter. Socket weld fittings are to be of forged

steel and the material is to be compatible with the associated piping.

In particular cases, socket welded joints may be permitted for piping

systems of Class I and II, having outside diameter not exceeding 88,9

mm. Such joints are not to be used where fatigue, severe erosion or

crevice corrosion is expected to occur or where toxic media are conveyed.

2.7.2 The thickness

of the socket weld fittings is to meet the requirements of Pt 5, Ch 10, 2.2 Wrought steel pipes and bends 2.2.4 but is to be not less than 1,25

times the nominal thickness of the pipe or tube. The diametral clearance

between the outside diameter of the pipe and the bore of the fitting

is not to exceed 0,8 mm, and a gap of approximately 1,5 mm is to be

provided between the end of the pipe and the bottom of the socket. See also

Ch 13, 5.2 Manufacture and workmanship 5.2.9 of

the Rules for Materials.

2.7.3 The leg

lengths of the fillet weld connecting the pipe to the socket weld

fitting are to be such that the throat dimension of the weld is not

less than the nominal thickness of the pipe or tube.

2.8 Welded sleeve joints

2.8.1 Welded

sleeve joints may be used in Class III systems with carbon steel pipes

of any outside diameter. In particular cases, welded sleeve joints

may be permitted for piping systems of Class I and II, having outside

diameter not exceeding 88,9 mm. Such joints are not to be used where

fatigue, severe erosion or crevice corrosion is expected to occur

or where toxic media are conveyed.

2.8.2 Sleeve

joints are not to be used in the following locations:

- Bilge pipes in way of deep tanks.

- Air and sounding pipes passing through cargo tanks.

2.8.3 Welded

sleeve joints may be used in piping systems for the storage, distribution

and utilisation of fuel oil, lubricating or flammable oil systems

in machinery spaces provided they are located in readily visible and

accessible positions. See also

Pt 5, Ch 12, 2.6 Precautions against fire 2.6.2.

2.8.4 The thickness

of the sleeve is to satisfy the requirements of Pt 5, Ch 10, 2.2 Wrought steel pipes and bends 2.2.4and Table 10.2.3 Minimum thickness for steel

pipes but is to be not less than 1,42 times the nominal

thickness of the pipe in order to satisfy the throat thickness required

in Pt 5, Ch 10, 2.8 Welded sleeve joints 2.8.5. The radial clearance

between the outside diameter of the pipe and the internal diameter

of the sleeve is not to exceed 1 mm for pipes up to a nominal diameter

of 50 mm, 2 mm on diameters up to 200 mm nominal size and 3 mm for

larger size pipes. The pipe ends are to be separated by a clearance

of approximately 2 mm at the centre of the sleeve. Alternatively,

consideration will be given to sleeve thickness in accordance with

a relevant National Standard.

2.8.5 The sleeve

material is to be compatible with the associated piping and the leg

lengths of the fillet weld connecting the pipe to the sleeve are to

be such that the throat dimension of the weld is not less than the

nominal thickness of the pipe or tube.

2.9 Threaded sleeve joints

2.9.1 Threaded

sleeve joints, in accordance with national or other established standards,

may be used with carbon steel pipes within the limits given in Table 10.2.4 Limiting design conditions for

threaded sleeve joints. Such joints are not

to be used where fatigue, severe erosion or crevice corrosion is expected

to occur or where flammable or toxic media is conveyed.

Table 10.2.4 Limiting design conditions for

threaded sleeve joints

| Thread type

|

Outside pipe diameter, in mm

|

| Class I

|

Class II

|

Class III

|

| Tapered thread

|

<33,7

|

<60,3

|

<60,3

|

| Parallel thread

|

–

|

–

|

<60,3

|

2.10 Screwed fittings

2.10.1 Screwed

fittings, including compression fittings, of an approved type may

be used in piping systems for pipes not exceeding 51 mm outside diameter.

Where the fittings are not in accordance with an acceptable standard

then LR may require the fittings to be subjected to special tests

to demonstrate their suitability for the intended service and working

conditions.

2.11 Other mechanical couplings

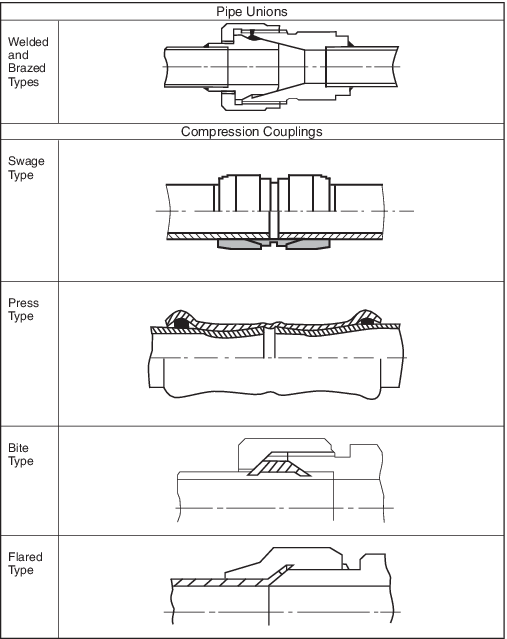

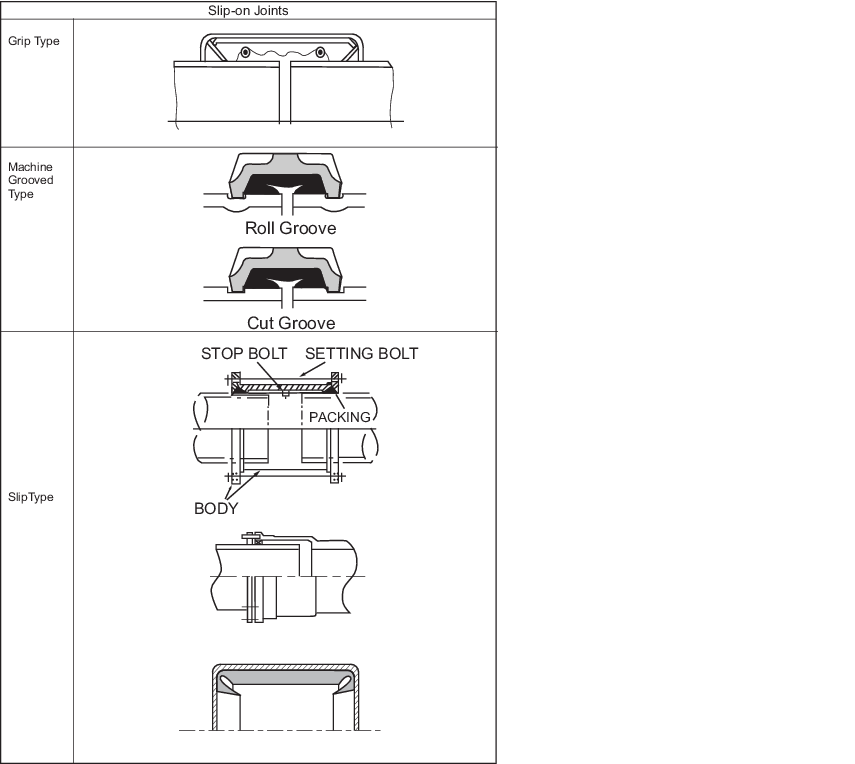

2.11.1 Pipe unions, compression couplings, or slip-on joints, as shown in Figure 10.2.3 Examples of mechanical joints

(Part 1) and Figure 10.2.4 Examples of mechanical joints

(Part 2) may be used if

Type Approved for the service conditions and the intended application. The Type Approval

is to be based on the results of testing of the actual joints. The acceptable use for

each service is indicated in Table 10.2.5 Application of mechanical

joints and dependence upon the Class of piping, with

limiting pipe dimensions, is indicated in Table 10.2.6 Application of mechanical joints

depending on class of piping.

Figure 10.2.3 Examples of mechanical joints

(Part 1)

Figure 10.2.4 Examples of mechanical joints

(Part 2)

Table 10.2.5 Application of mechanical

joints

| Systems

|

Kind of connections

|

|

|

| Pipe unions

|

Compression

couplings

|

Slip-on

joints

|

Classification of

pipe system

|

Fire endurance test

condition, see Note 7

|

| Flammable fluids (flash point < 55°C)

|

| Cargo oil lines,

see Note 4

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Crude oil washing

lines, see Note 4

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Vent lines,

see Note 3

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Inert gas

|

| Water seal effluent

lines

|

+

|

+

|

+

|

wet

|

30 min wet

(*)

|

| Scrubber effluent

lines

|

+

|

+

|

+

|

wet

|

30 min wet

(*)

|

| Main lines,

see Notes 2 & 4

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Distribution lines,

see Note 4

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Flammable fluids (flash point > 55°C)

|

| Cargo oil lines,

see Note 4

|

+

|

+

|

+

|

dry

|

30 min dry

(*)

|

| Fuel oil lines,

see Notes 2 & 3

|

+

|

+

|

+

|

wet

|

30 min

wet (*)

|

| Lubricating oil

lines, see Notes 2 & 3

|

+

|

+

|

+

|

wet

|

| Hydraulic oil,

see Notes 2 & 3

|

+

|

+

|

+

|

wet

|

| Thermal oil,

see Notes 2 & 3

|

+

|

+

|

+

|

wet

|

| Sea water

|

| Bilge lines,

see Note 4

|

+

|

+

|

+

|

dry/wet

|

8 min dry + 22 min

wet (*)

|

| Permanent water

filled fire‑extinguishing systems, e.g. fire main, sprinkler systems,

see Note 3

|

+

|

+

|

+

|

wet

|

30 min wet

(*)

|

| Non-permanent water

filled fire‑extinguishing systems, e.g. foam, drencher systems and fire

main, see Note 3

|

+

|

+

|

+

|

dry/wet

|

8 min dry + 22 min

wet (*)

|

| Ballast system,

see Note 1

|

+

|

+

|

+

|

wet

|

30 min wet

(*)

|

| Cooling water

system, see Note 1

|

+

|

+

|

+

|

wet

|

30 min wet

(*)

|

| Tank cleaning

services

|

+

|

+

|

+

|

dry

|

Fire endurance test

not required

|

| Non-essential

systems

|

+

|

+

|

+

|

dry, dry/wet,

wet

|

Fire endurance test

not required

|

| Fresh water

|

| Cooling water

system, see Note 1

|

+

|

+

|

+

|

dry

|

Fire

endurance test not required

|

| Condensate return,

see Note 1

|

+

|

+

|

+

|

dry

|

| Non-essential

system

|

+

|

+

|

+

|

dry

|

| Sanitary/drains/scuppers

|

| Deck drains

(internal), see Note 6

|

+

|

+

|

+

|

dry

|

Fire

endurance test not required

|

| Sanitary

drains

|

+

|

+

|

+

|

dry

|

| Scuppers and

discharge (overboard)

|

+

|

+

|

-

|

dry

|

| Sounding/vent

|

| Water tanks/dry

spaces

|

+

|

+

|

+

|

dry, wet

|

Fire

endurance test not required

|

| Oil tanks (f.p. >

55°C), see Notes 2 & 3

|

+

|

+

|

+

|

dry

|

| Miscellaneous

|

| Starting/control

air, see Note 1

|

+

|

+

|

-

|

dry

|

30 min dry

(*)

|

| Service air

(non-essential)

|

+

|

+

|

+

|

dry

|

Fire

endurance test not required

|

| Brine

|

+

|

+

|

+

|

wet

|

| CO2

system (outside protected space), see Note 1

|

+

|

+

|

-

|

dry

|

30 min dry

(*)

|

| CO2

system (inside protected space)

|

+

|

+

|

-

|

dry

|

Mechanical joints shall be constructed of materials with a

melting point above 925°C.

|

| Steam

|

+

|

+

|

+ see Note

5

|

wet

|

Fire endurance test

not required

|

| Abbreviations:

+ Application is allowed.

- Application is

not allowed.

* Fire endurance test as specified in LR’s Test

Specification No. 2, Ch 5, Appendix 4 – Mechanical pipe joints – Fixed

connections, 4.2.7.

|

|

Note

1. Mechanical joints that include any components which readily

deteriorate in case of fire, are to be of an approved fire-resistant type

when fitted in machinery spaces of category A. Mechanical couplings

fitted on the ‘bilge main’ in machinery spaces of category A are to be of

steel or equivalent material.

Note

2. Mechanical joints that include any components which readily

deteriorate in case of fire are not permitted in machinery spaces of

category A or accommodation spaces. Mechanical joints that include any

components which readily deteriorate in case of fire that are of an

approved fire-resistant type may be fitted in other machinery spaces

provided the joints are located in easily visible and accessible

positions.

Note

3. Mechanical joints that include any components which readily

deteriorate in case of fire fitted on fuel oil lines are to be of an

approved fire-resistant type. Mechanical joints that include any

components which readily deteriorate in case of fire fitted on other

systems are to be of an approved fire-resistant type except when fitted

on open decks having little or no fire risk.

Note

4. Mechanical joints that include any components which readily

deteriorate in case of fire are to be of an approved fire-resistant type

when fitted in pump-rooms and on open decks.

Note

6. Mechanical joints are only permitted above bulkhead deck of

passenger ships and freeboard deck of cargo ships.

Note

7. A category A machinery space is a machinery space containing

internal combustion machinery for main propulsion or internal combustion

machinery used for purposes other than main propulsion where such

machinery has a total power of not less than 375 kW, or containing any

oil-fired boiler or fuel oil unit, or any other oil-fired equipment other

than boilers.

|

Table 10.2.6 Application of mechanical joints

depending on class of piping

| Types of

joints

|

Classes of piping systems

|

| Class I

|

Class II

|

Class III

|

|

Pipe unions

|

|

|

|

| Welded and brazed

type

|

+(OD ≤ 60,3 mm)

|

+(OD ≤ 60,3 mm)

|

+

|

|

|

|

|

|

|

Compression couplings

|

|

|

|

| Swage type

|

–

|

–

|

+

|

| Bite type

|

+(OD ≤ 60,3 mm)

|

+(OD ≤ 60,3 mm)

|

+

|

| Flared type

|

+(OD ≤ 60,3 mm)

|

+(OD ≤ 60,3 mm)

|

+

|

| Press type

|

–

|

–

|

+

|

|

|

|

|

|

|

Slip-on joints

|

|

|

|

| Machine grooved

type

|

+

|

+

|

+

|

| Grip type

|

–

|

+

|

+

|

| Slip

type

|

–

|

+

|

+

|

| KEY

|

|

|

|

| +

|

Application is allowed

|

|

|

|

| –

|

Application is not allowed

|

|

|

|

2.11.2 Where

the application of mechanical joints results in a reduction in pipe

wall thickness due to the use of bite type rings or other structural

elements, this is to be taken into account in determining the minimum

wall thickness of the pipe to withstand the design pressure.

2.11.3 Materials

of mechanical joints are to be compatible with the piping material

and internal and external media.

2.11.4 Mechanical

joints for pressure pipes are to be tested to a burst pressure of

4 times the design pressure. For design pressures above 200 bar, the

required burst pressure will be specially considered.

2.11.5 Mechanical joints, which in the event of damage could cause fire or

flooding, are not to be used in piping sections directly connected to the ship’s side

below the bulkhead deck of passenger ships and freeboard deck of cargo ships or tanks

containing flammable fluids.

2.11.6 The

mechanical joints are to be designed to withstand internal and external

pressure as applicable and, where used in suction lines, are to be

capable of operating under vacuum.

2.11.7 The number of mechanical joints in flammable fluid systems is to be kept to a minimum.

In general, flanged joints are to conform to a recognised standard.

2.11.8 Generally,

slip-on joints are not to be used in pipelines in cargo holds, tanks,

and other spaces which are not easily accessible. Application of these

joints inside tanks may only be accepted where the medium conveyed

is the same as that in the tanks.

2.11.9 Usage of slip type slip-on joints as the main means of pipe connection is

not permitted except for cases where compensation of axial pipe deformation is

necessary.

2.11.10 Restrained

slip-on joints are permitted in steam pipes with a design pressure

of 10 bar or less on the weather decks of oil and chemical tankers

to accommodate axial pipe movement, see

Pt 5, Ch 11, 2.7 Provision for expansion.

2.11.11 Mechanical joints are to be tested in accordance with the test requirements

in LR’s Type Approval Test Specification Number 2, as relevant to the service conditions

and the intended application. The programme of testing is to be agreed with LR.

2.12 Non-destructive testing

|