Section

1 General

1.1 Application

1.1.1 The requirements

of this Chapter apply to the design and construction of piping systems,

including pipe fittings forming parts of such systems, including pipe

fittings forming parts of such systems, where the temperature does

not exceed 300°C.

1.1.3 The materials

used for pipes, valves and fittings are to be suitable for the medium

and the service for which the piping is intended.

1.2 Design symbols

1.2.1 The symbols

used in this Chapter are defined as follows:

|

a

|

= |

percentage

negative manufacturing tolerance on thickness |

|

c

|

= |

corrosion

allowance, in mm |

|

pt

|

= |

hydraulic test pressure, in MPa |

|

R

|

= |

radius

of curvature of a pipe bend at the centreline of the pipe, in mm |

|

t

|

= |

minimum

thickness of a straight pipe, in mm, including corrosion allowance

and negative tolerance where applicable |

|

t

b

|

= |

the minimum thickness of a straight pipe, in mm, to be used

for a pipe bend including bending allowance corrosion allowance and

negative tolerance, where applicable. |

|

σ |

= |

maximum permissible

design stress, in N/mm2.

|

1.2.2 The outside

diameter, D, is subject to manufacturing tolerances,

but these are not to be used in the evaluation of formulae.

1.2.3 The inside

diameter, d, is not to be confused with nominal pipe

size, which is an accepted designation associated with outside diameters

of standard rolling sizes.

1.2.4 The weld

efficiency factor, e, is to be taken as 1 for seamless

and electric resistance and induction welded steel pipes. Where other

methods of pipe manufacture are proposed, the value of e will

be specially considered.

1.3 Design pressure

1.3.1 The design

pressure, p, is the maximum permissible working pressure

and is to be not less than the highest set pressure of the safety

valve or relief valve.

1.3.2 In boiler

installations, the design pressure for steam piping is to be taken

as the design pressure of the boiler, i.e. not less than the highest

set pressure of any safety valve on the boiler.

1.3.3 The design

pressure of feed piping and other piping on the discharge from pumps

is to be taken as the pump pressure at full rated speed against a

shut valve. Where a safety valve or other protective device is fitted

to restrict the pressure to a lower value than the shut valve load,

the design pressure is to be the highest set pressure of the device.

1.4 Design temperature

1.4.1 The design

temperature is to be taken as the maximum temperature of the internal

fluid, but in no case is it to be less than 50°C.

1.5 Classes of pipes

1.5.1 Pressure

piping systems are divided into three classes for the purpose of assigning

appropriate testing requirements, type of joints to be adopted, heat

treatment and weld procedure.

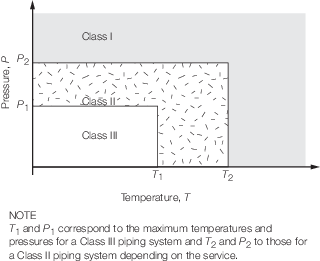

1.5.2 Dependent

on the service for which they are intended, Class II and III pipes

are not to be used for design pressure or temperature conditions in

excess of those shown in Table 10.1.1 Maximum pressure and temperature

conditions for Class II and Class III piping systems.

Where either the maximum design pressure or temperature exceeds that

applicable to Class II pipes, Class I pipes are to be used. To illustrate

this, see

Figure 10.1.1 Classes of piping system. See also

Pt 5, Ch 10, 1.1 Application 1.1.2 for temperatures

exceeding 300°.

Figure 10.1.1 Classes of piping system

Table 10.1.1 Maximum pressure and temperature

conditions for Class II and Class III piping systems

| Piping

|

Class II

|

Class III

|

| system

|

p

|

T

|

p

|

T

|

|

|

MPa

|

°C

|

MPa

|

°C

|

| Steam

|

1,6

|

300

|

0,7

|

170

|

| Thermal oil

|

1,6

|

300

|

0,7

|

150

|

| Flammable

|

1,6

|

150

|

0,7

|

60

|

| liquids (see Note 1)

|

| Other media

|

4

|

300

|

1,6

|

200

|

| Cargo oil

|

4

|

300

|

1,6

|

200

|

Note

1. Flammable liquids include: fuel oil,

lubricating oil and flammable hydraulic oil.

|

1.6 Materials

1.6.1 Materials

for ferrous castings and forgings of Class I and Class II piping systems

are to be produced at works approved by Clasifications Register (hereinafter

referred to as 'LR') unless otherwise specifically mentioned in the

Rules. They are in general, to be tested in accordance with the

Rules for the Manufacture, Testing and Certification of Materials, July 2022

(hereinafter referred to as the Rules for

Materials).

1.6.2 The manufacturer's

test certificate for materials for pipes, valves and fittings of Class

I and Class II piping systems will be accepted in lieu of LR's materials

certificate where the maximum nominal pipe diameter is less than 50

mm or the product of working pressure in bar times nominal diameter

in mm is less than 2500. See

Ch 1, 3.1 General 3.1.3.(c) of the Rules for Materials.

1.6.3 For copper

alloys having a working temperature < 200°C, the manufacturer's

test certificate for materials for pipes, valves and fittings of Class

I and Class II piping systems will be accepted in lieu of LR's materials

certificate where the maximum nominal pipe diameter is less than 50

mm or the product of working pressure in bar times nominal diameter

in mm is less than 1500. See

Ch 1, 3.1 General 3.1.3.(c) of the Rules for Materials.

1.6.4 The manufacturer's

certificate for materials for ship-side valves and fittings and valves

on the collision bulkhead equal to or less than 500 mm nominal diameter

will be accepted in lieu of LR's materials certificate where the valves

and fittings are in accordance with a recognised National Standard

applicable to the intended application and are manufactured and tested

in accordance with the appropriate requirements of Ch 1, 3.1 General 3.1.3.(c) of the Rules for Materials.

|