Section

3 Shell envelope laminate

3.1 General

3.1.1 Except

as otherwise specified within this Section, the scantlings and arrangements

for the shell envelope laminate are to be determined in accordance

with the procedures described in, or as required by Pt 8, Ch 3, 3 Shell envelope laminate for mono-hull craft, using the pressures

from Pt 5 Design and Load Criteria appropriate to multi-hull craft.

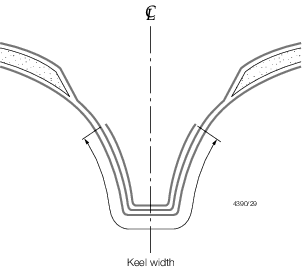

3.2 Keel plates

3.2.1 The breadth, b

K, and thickness, t

K, of

plate keels are not to be taken as less than:

k

t is as defined in Pt 8, Ch 3, 2.1 General.

3.2.2 In no case

is the thickness of the keel to be less than that of the adjacent

bottom shell laminate.

3.2.3 The width

and thickness of plate keels are to be maintained throughout the length

of the craft from the transom to a point not less than 25 per cent

of the freeboard measured at the forward perpendicular (FP) above

the deepest load waterline on the stem. Thereafter the keel thickness

may be reduced to that required by Pt 8, Ch 3, 3.3 Stem plate 3.3.1 for the stem. Laminate tapers are to comply with Pt 8, Ch 3, 3.14 Local reinforcement 3.14.2.

3.2.5 For large,

novel, asymmetric hull form craft, or yachts with externally attached

ballast keels, or where it is proposed to incorporate keels of the

`bar' type the scantlings of the keel will be specially considered.

3.3 Bottom outboard

3.3.1 For all

craft types, the minimum bottom outboard shell laminate thickness

as required by the Rules is to be extended over the region as defined

in Pt 8, Ch 4, 1.5 Symbols and definitions 1.5.2 for displacement and

semi-displacement craft.

Figure 4.3.1 Single skin/Sandwich skin intersection detail

3.3.2 The bending

moment assumed to be carried by the bottom outboard shell laminate

is to be not less than that determined by Pt 8, Ch 3, 1.9 Plate and sandwich laminates 1.9.1, using the design pressure from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate. This bending moment is to

be applied to laminates of both single skin and sandwich construction

in the determination of the panel scantling required by Pt 8, Ch 4, 3.3 Bottom outboard 3.3.3 and Pt 8, Ch 4, 3.3 Bottom outboard 3.3.5 respectively.

3.3.4 In no case

is the minimum thickness of single skin laminate to be taken as less

than 5,5 mm.

3.3.6 The amount

of reinforcement in laminates that form the skins of a sandwich laminate

is to comply with the requirements of Pt 8, Ch 4, 2.1 General 2.1.2.

3.3.7 Special

consideration may be given to laminate thicknesses lesser than those

required by Pt 8, Ch 4, 3.3 Bottom outboard 3.3.4 and Pt 8, Ch 4, 3.3 Bottom outboard 3.3.6, provided that all of the structural

strength requirements of the Rules are complied with, a satisfactory

water barrier is provided, see

Pt 8, Ch 3, 2.3 Sandwich skin laminate 2.3.1, and the equivalent impact resistance is demonstrated

as required by Pt 8, Ch 3, 2.8 Impact considerations 2.8.2.

3.4 Bottom inboard

3.5 Side outboard

3.5.2 For all

craft types, the minimum side outboard shell laminate thickness as

required by the Rules is to be extended over the region as defined

in Pt 8, Ch 4, 3.5 Side outboard 3.5.1 for displacement and

semi-displacement craft.

3.5.3 The bending

moment assumed to be carried by the side outboard shell laminate is

to be not less than that determined by Pt 8, Ch 3, 1.9 Plate and sandwich laminates 1.9.1, using the design pressure from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate. This bending moment is to

be applied to laminates of both single skin and sandwich construction

in the determination of the panel scantling required by Pt 8, Ch 4, 3.5 Side outboard 3.5.4 and Pt 8, Ch 4, 3.5 Side outboard 3.5.6 respectively.

3.5.5 In no case

is the minimum thickness of single skin laminate to be taken as less

than 5 mm.

3.5.7 The amount

of reinforcement in laminates that form the skins of a sandwich laminate

is to comply with the requirements of Pt 8, Ch 4, 2.1 General 2.1.2.

3.5.8 Special

consideration may be given to laminate thicknesses lesser than those

required by Pt 8, Ch 4, 3.5 Side outboard 3.5.5 and Pt 8, Ch 4, 3.5 Side outboard 3.5.7, provided that all of the structural

strength requirements of the Rules are complied with, a satisfactory

water barrier is provided, see

Pt 8, Ch 3, 2.3 Sandwich skin laminate 2.3.1, and the equivalent impact resistance is demonstrated

as required by Pt 8, Ch 3, 2.8 Impact considerations 2.8.2.

3.6 Side inboard

3.7 Wet-deck

3.7.2 The bending

moment assumed to be carried by the wet-deck laminate is to be not

less than that determined by Pt 8, Ch 3, 1.9 Plate and sandwich laminates 1.9.1,

using the design pressure from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for

non-displacement or displacement type craft as appropriate. This bending

moment is to be applied to laminates of both single skin and sandwich

construction in the determination of the panel scantling required

by Pt 8, Ch 4, 3.7 Wet-deck 3.7.3 and Pt 8, Ch 4, 3.7 Wet-deck 3.7.5 respectively.

3.7.4 In no case

is the minimum thickness of single skin laminate to be taken as less

than 5 mm.

3.7.6 The amount

of reinforcement in laminates that form the skins of a sandwich laminate

is to comply with the requirements of Pt 8, Ch 4, 2.1 General 2.1.2.

3.7.7 Special

consideration may be given to laminate thicknesses lesser than those

required by Pt 8, Ch 4, 3.7 Wet-deck 3.7.4 and Pt 8, Ch 4, 3.7 Wet-deck 3.7.6, provided that all of the structural

strength requirements of the Rules are complied with, a satisfactory

water barrier is provided, see

Pt 8, Ch 3, 2.3 Sandwich skin laminate 2.3.1, and the equivalent impact resistance is demonstrated

as required by Pt 8, Ch 3, 2.8 Impact considerations 2.8.2.

3.7.8 The wet-deck

laminate on the underside of the cross-deck structure may require

to be additionally protected, particularly where the air gap is small

and there is a high risk of localised impact due to collision with

floating debris, ice, etc. in the service area. In such cases the

requirements for sheathing, given in Pt 8, Ch 3, 2.9 Sheathing, are to be complied with.

3.8 Transom

3.8.1 The scantlings

and arrangements of transoms are to be not less than as required for

the adjacent bottom inboard or side outboard structure as appropriate.

3.8.2 Where water

jet or sterndrive units are fitted, the scantlings of the plating

in way of the nozzles and connections will be specially considered.

3.9 Haunch reinforcement (SWATH)

3.9.1 For craft

above 30 m in length, L

R, the stresses in

the haunch area are to be derived using a two dimensional fine mesh

finite element analysis. The model is to extend horizontally into

the box structure and vertically into the strut structure. All discontinuities

and cut-outs are to be modelled in order to determine shear stresses

at critical locations and stresses for the determination of fatigue

strength.

3.9.2 Due consideration

is to be given to shear lag when calculating the effective breadth

of the attached laminate.

3.10 Lower hull (SWATH)

3.10.1 Where

the lower hull structure incorporates ring frames and attached shell

laminate fitted between bulkheads or diaphragms, the thickness of

the lower hull shell laminate may be derived from an established method

for shell analysis or recognised standard for pressure vessels. Modes

of failure to be considered are buckling, frame collapse, inter frame

shell collapse and overall frame shell collapse between bulkheads.

Copies of direct calculations are to be submitted for consideration.

3.10.2 In general

the design load to be used is the pressure load given in Pt 5, Ch 4, 3.1 Hull structures. If other loads are considered

to be of significance for the scantling determination these are to

be taken into account.

3.11 Novel features

3.11.1 Where

the Rules do not specifically define the requirements for laminate

elements with novel features then the scantlings and arrangements

are to be determined by direct calculations. Such calculations are

to be carried out on the basis of the Rules, recognised standards

and good practice, and are to be submitted for consideration.

|