Section

3 Shell envelope laminate

3.1 General

3.1.1 The requirements

in respect of the general plating elements of the shell envelope,

excluding the deck, are contained within this Section.

3.2 Keel plate

3.2.1 The width, b

K, and thickness, t

K, of

plate keels are not to be taken as less than:

3.2.2 In no case

is the thickness of the keel to be less than that of the adjacent

bottom shell plating.

3.2.3 The width

and thickness of plate keels are to be maintained throughout the length

of the craft from the transom to a point not less than 25 per cent

of the freeboard measured at the forward perpendicular (FP), above

the deepest load waterline on the stem. Thereafter the keel thickness

may be reduced to that required by Pt 8, Ch 3, 3.3 Stem plate for

the stem. Laminate tapers are to be in accordance with Pt 8, Ch 2, 3.9 Laminate detail.

3.2.4 Where the

bottom shell is of sandwich construction the keel is, in general,

to be formed by locally returning to single skin construction for

a width as required by Pt 8, Ch 3, 3.2 Keel plate 3.2.1.

The Rule thickness of keel is to comprise both the inner and outer

skins of the adjacent bottom shell sandwich plus additional reinforcement

as required. The distribution of reinforcement in way of the plate

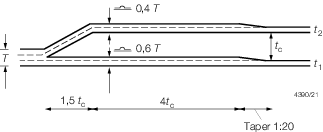

keel and sandwich bottom structure is to be in accordance with Figure 3.3.1 Single skin/sandwich skin intersection detail.

Figure 3.3.1 Single skin/sandwich skin intersection detail

3.2.5 For large

or novel craft, or yachts with externally attached ballast keels,

or where it is proposed to incorporate keels of the `bar' type the

scantlings of the keel will be specially considered.

3.3 Stem plate

3.3.1 The thickness

of the plate stem, t

s, is not to be taken

as less than that given by the following expression:

where

|

k

t

|

= |

as defined in Pt 8, Ch 3, 3.2 Keel plate 3.2.1

|

|

L

R

|

= |

Rule length, in metres, as defined in Pt 8, Ch 3, 1.5 Symbols and definitions 1.5.1

|

|

σf

|

= |

ultimate

flexural strength of the stem plate material, in N/mm2, see

Pt 8, Ch 3, 1.13 Determination of properties and stresses for single skin plate laminates 1.13.6.

|

3.3.2 In no case

is the thickness of the plate stem to be taken as less than the thickness

of the adjacent side shell plating.

3.3.4 Plate stems

are to be supported by horizontal diaphragms and, where the stem radius

is large, a centreline stiffener or web may be required.

3.3.5 Where the

side shell is of sandwich construction the stem is to be formed by

locally returning to single skin construction for a width as required

by Pt 8, Ch 3, 3.2 Keel plate 3.2.1. The Rule thickness

of stem is to comprise both the inner and outer skins of the adjacent

side shell sandwich plus additional reinforcement as required. The

distribution of reinforcement in way of the plate stem and sandwich

bottom structure is to be in accordance with Figure 3.3.1 Single skin/sandwich skin intersection detail.

3.4 Bottom

3.4.1 The bending

moment assumed to be carried by the bottom shell plating is to be

not less than that determined from Pt 8, Ch 3, 1.9 Plate and sandwich laminates 1.9.1,

using the design pressure from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for

high speed or displacement type craft as appropriate. This bending

moment is to be applied to laminates of both single skin and sandwich

construction in the determination of the panel scantling required

by Pt 8, Ch 3, 3.4 Bottom 3.4.2 and Pt 8, Ch 3, 3.4 Bottom 3.4.4 respectively.

3.4.3 In no case

is the minimum thickness of single skin plating to be taken as less

than 5,5 mm.

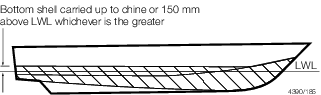

3.4.7 Additionally,

for high speed craft, the minimum thickness requirements for the bottom

shell between the bilge tangential points or chines and the chine

line or 150 mm above the static load waterline, whichever is the greater,

is not to be less than determined for the side shell using the side

shell impact pressure or the bottom shell hydrostatic or pitching

pressures associated with a displacement or semi-displacement type

craft whichever is the greater, see

Figure 3.3.2 Extent of bottom shell.

Figure 3.3.2 Extent of bottom shell

3.4.8 Special

consideration may be given to laminate thicknesses lesser than those

required by Pt 8, Ch 3, 3.4 Bottom 3.4.2 and Pt 8, Ch 3, 3.4 Bottom 3.4.4, provided that all of the structural

strength requirements of the Rules are complied with, a satisfactory

water barrier is provided, see

Pt 8, Ch 3, 2.3 Sandwich skin laminate 2.3.1, and the equivalent impact resistance is demonstrated

as required by Pt 8, Ch 3, 2.8 Impact considerations 2.8.2.

3.5 Side

3.5.1 The bending

moment assumed to be carried by the side shell plating is to be not

less than that determined from Pt 8, Ch 3, 1.9 Plate and sandwich laminates 1.9.1,

using the design pressure from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for

non-displacement or displacement craft as appropriate. This bending

moment is to be applied to laminates of both single skin and sandwich

construction in the determination of the panel scantling required

by Pt 8, Ch 3, 3.5 Side 3.5.2 and Pt 8, Ch 3, 3.5 Side 3.5.4 respectively.

3.5.3 In no case

is the minimum thickness of single skin plating to be taken as less

than 5 mm.

3.5.6 Special

consideration may be given to laminate thicknesses lesser than that

required by Pt 8, Ch 3, 3.5 Side 3.5.3 and Pt 8, Ch 3, 3.5 Side 3.5.5, provided that all of the structural

strength requirements of the Rules are complied with, a satisfactory

water barrier is provided, see

Pt 8, Ch 3, 2.3 Sandwich skin laminate 2.3.1, and the equivalent impact resistance is demonstrated

as required by Pt 8, Ch 3, 2.8 Impact considerations 2.8.2.

3.6 Sheerstrake

3.6.1 The sheerstrake,

is in general, to be taken as the side shell, locally reinforced in

way of deck/hull connection and fender attachment. The amount of local

reinforcement will be dependent upon the arrangement of structure

and the proposed service, but is not to be less than that required

by Pt 8, Ch 3, 3.14 Local reinforcement.

3.6.2 The fendering

arrangements for all craft types are the responsibility of the designers/Builders

and are outside the scope of classification.

3.6.3 Where the

pressure or impact loadings that a particular type of craft will experience

in service are considered by the Builder, or subsequent Owner, to

be not covered by, or be greater than, those indicated in Pt 5 Design and Load Criteria of the Rules, details of the loadings

together with the calculations of how these will be satisfactorily

distributed into the craft's structure, are to be submitted for consideration

with the relevant contruction plans.

3.6.4 The arrangements

indicated in Pt 8, Ch 3, 3.6 Sheerstrake 3.6.5, Pt 8, Ch 3, 3.6 Sheerstrake 3.6.6, Pt 8, Ch 3, 4.19 Fenders and reinforcement in way 4.19.5 and Pt 8, Ch 3, 4.19 Fenders and reinforcement in way 4.19.6 for pilot

and fishing craft are for the guidance of the Builder and subsequent

Owners/operators of the craft. Where the intended service for either

of these types of craft, or other types of craft which may be subject

to loadings resulting from contact with other craft, jetties or similar

loading or boarding facilities, is such that the loadings are greater

than those that can be satisfactorily distributed into the craft's

structure by the arrangements indicated, the strengthening arrangements

are to be increased accordingly.

3.6.5 For pilot

craft and other general workboats which may be subject to repeated

impact loadings from contact with other craft, etc. the sheerstrake

laminate and stiffening arrangements in way are to be increased locally.

An increase in laminate weight of not less than 50 per cent of the

side shell laminate weight is to be fitted, extending in general from

the bow aft over a distance of 0,33L

R or 500

mm aft of the point at which the craft reaches its greatest breadth,

whichever is the greater, and around the quarters. The additional

weight is to extend forward of the quarter and over the transom for

a distance of 0,075L

R or 1,0 m, whichever

is the greater. This reinforcement is in general to extend from the

deck edge to below the first longitudinal stiffener, or a vertical

distance equivalent to 1/3 the freeboard height, whichever is the

greater. The additional laminate weight is then to be tapered out

to the side shell laminate weight in accordance with the Rules, see

Pt 8, Ch 3, 3.14 Local reinforcement 3.14.2. For increase

in stiffening arrangements, see

Pt 8, Ch 3, 4.19 Fenders and reinforcement in way. Where the side shell is of sandwich construction then

in way of the sheerstrake the two skins of the sandwich are to combine

and form a single skin. The weight of this single skin is to be the

Rule single skin reinforced in accordance with the above or 1,5 times

the total sandwich skin laminate weight whichever is the greater.

The arrangement and distribution of this additional laminate between

the skins in way of the taper is to be in accordance with Pt 8, Ch 3, 3.2 Keel plate 3.2.4. Where fendering can be considered

to act as a chine/spray rail the extent of bottom shell laminate is,

in general, to be to above the lower fender.

3.6.6

Fishing

craft are, in general, to have their shell laminate as required

to satisfy the Rule loadings, increased by 20 per cent. Additionally

the side shell is not to be taken as less than the bottom shell weight,

and where there are gallows, gantries, nets, or lines etc. the laminate

in way is to be further increased locally and/or suitably protected

by sheathing in timber, steel or other means. Where the hull is of

sandwich construction in way of the sheerstrake the laminate is to

combine to form a single skin as indicated in Pt 8, Ch 3, 3.6 Sheerstrake 3.6.2.

3.6.7 Individual

consideration will be given to lesser scantlings than those required

by Pt 8, Ch 3, 3.6 Sheerstrake 3.6.3 for fishing craft used

for pleasure, light duties, etc. Details of the service are to be

submitted for appraisal.

3.7 Transom boundary reinforcement

3.7.1 Additional

reinforcement is to be moulded into the transom boundary.

3.7.2 For single

skin construction, the total weight of reinforcement is to be not

less than twice the weight of the adjacent side shell plate laminate,

but need not be greater than Rule keel weight as required by Pt 8, Ch 3, 3.2 Keel plate.

3.8 Chine reinforcement

3.8.1 Additional

reinforcement is to be moulded into the chine line knuckle boundary,

chines and other areas where there is a change of section.

3.8.3 Chine details

are to be such that the continuity of structural strength across the

panel is maintained. Details of all chines are to submitted for consideration, see also LR's Guidance Notes for Structural Details.

3.9 Skeg

3.9.1 The thickness

of the skeg plating is, in general, to be not less than the thickness

of the keel at bottom or 1,5 times the thickness of the bottom shell

on the sides, whichever is the greater, see also

Pt 8, Ch 3, 5.10 Skeg construction.

3.10 Shell openings

3.10.1 Openings

are to have smooth edges and well rounded corners. Exposed edges in

way of cut-outs in single skin/plate laminate are, in general, to

be suitably sealed over laminating with not less than 2 x 450 g/m2 CSM

(or equivalent) reinforcements. Alternative arrangements demonstrating

the equivalent protection to the ingress of moisture into the laminate

will be individually considered in association provided on the relevant

plans.

3.10.2 The exposed

edges of all openings cut in sandwich panels are to be suitably sealed.

In general a high density foam core (or equivalent material) is to

be used around the perimeter of such openings. Exposed edges in way

of cut-outs in sandwich panels are to be overlaminated with a weight

of laminate not less than that required for the outer skin of the

sandwich panel.

3.10.4 Sea inlet

boxes are to have well rounded corners and, so far as possible are

to be kept clear of the bilge radius. Arrangements are to be made

to maintain the continuity of structural strength in way of the openings.

3.11 Appendages

3.11.1 The scantlings

of appendages will be subject to special consideration on the basis

of the Rules and the design loadings anticipated, but are in no case

to be taken as less than that of the surrounding structure.

3.12 Fin and tuck

3.12.1 Additional

reinforcement is to be moulded into the fin and tuck areas of yachts

which have either internal fixed ballast or external attached ballast

keels, see also

Pt 16 Control and Electrical Engineering.

3.12.2 For single

skin construction the total weight of reinforcement is not to be less

than 1,50 times the weight of the adjacent bottom shell plate laminate,

but need not be greater than the Rule keel weight as required by Pt 8, Ch 3, 3.2 Keel plate.

3.13 Transom

3.13.1 The thickness

of the stern or transom is to be not less than that required by Pt 8, Ch 3, 3.4 Bottom and Pt 8, Ch 3, 3.5 Side as

appropriate. Where water jet or sterndrive units are fitted, the scantlings

of the plating in way of the nozzles and connections will be specially

considered.

3.14 Local reinforcement

3.14.1 The hull

and deck are to be locally increased in thickness in way of fittings

for rudder tubes, propeller brackets, passenger routes, vehicle lanes,

etc. The amount of increase is to be not less than 50 per cent of

the adjacent plate laminate. Details of such reinforcement are to

be submitted.

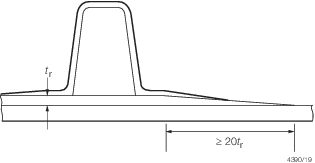

3.14.2 Local

reinforcement is in general to extend under the adjacent supporting

structure and then be tapered gradually to the base laminate thickness

over a distance of not less than 20 times the difference in thickness, see

Figure 3.3.3 Arrangement of local reinforcement.

Figure 3.3.3 Arrangement of local reinforcement

3.14.3 The amount

of material laid ‘wet on wet’ is to be limited to avoid

excessive heat generation.

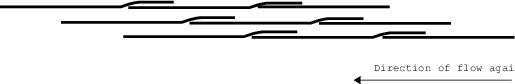

3.15 Hull laminate arrangement

3.15.1 The hulls

of all craft with a service speed of 25 knots or greater are to be

moulded, such that following local impact, damage progressive stripping

of surface reinforcements will not occur. This may be achieved by

arranging all hull reinforcements as shown in Figure 3.3.4 Arrangement of hull reinforcement.

Figure 3.3.4 Arrangement of hull reinforcement

3.15.2 Details

of the laminate sequence and direction of orientation are to be indicated

in the laminate schedule as required by Pt 8, Ch 2, 3.3 Laminating 3.3.7.

3.15.3 It is

recommended that woven reinforcements be laid transversely to minimise

the susceptibility to progressive stripping of hull laminates following

local impact.

3.15.4 Special

consideration is to be given to hull laminates where high glass content

is proposed and where orthophthalic resins are used.

3.16 Novel features

3.16.1 Where

the Rules do not specifically define the requirements for novel features

then the scantlings and arrangements are to be determined by direct

calculations. Such calculations are to be carried out on the basis

of the Rules, recognised standards and good practice, and are to be

submitted for appraisal.

|