Section

5 Single bottom structure and appendages

5.1 General

5.1.1 The requirements

of this Section provide for single bottom construction of mono-hull

craft in association with either transverse or longitudinal framing.

5.1.2 All girders

are to extend as far forward and aft as practicable and care is to

be taken to avoid any abrupt discontinuity particularly in way of

skegs. Where girders are cut at bulkheads, their longitudinal strength

is to be maintained.

5.1.3 Particular

attention is to be taken to ensure that the continuity of structural

strength in way of the intersection of transverse floors and longitudinal

girders is maintained. The face reinforcement of such stiffening members

is to be effectively continuous.

5.1.4 The single

bottom structure in way of the keel, skeg and girders is to be sufficient

to withstand the forces imposed by dry-docking the craft.

5.2 Centreline girder

5.2.1 In craft

with single bottoms, a centreline girder is, in general, to be fitted

in association with transverse frames, transverses supporting longitudinals

or where the breadth of floors at the upper edge is greater than 1,5

m.

5.2.2 Centreline

girders may be in the form of intercostal or continuous top hat or

plate webs. Where the girder is intercostal, additional bracketing

and local reinforcement as given in Pt 8, Ch 3, 3.14 Local reinforcement are

to be provided to maintain the continuity of structural strength.

The face reinforcement in all cases is to be continuous.

5.2.3 The web

depth of the centre girder in general is to be equal to the depth

of the floors at the centreline as specified in Pt 8, Ch 3, 5.4 Floors, general.

5.2.8 The face

thickness, t

f, is to be not less than the

web thickness of the centre girder.

5.3 Side girders

5.3.1 Where the

floor breadth at the upper edge exceeds 6,0 m, side girders are to

be fitted at each side of the centre girder such that the spacing

between the side and centre girders or between the side girders themselves

is not greater than 3 m. Side girders, where fitted, are to extend

as far forward and aft as practicable and are, in general, to terminate

in way of bulkheads, deep floors or other primary transverse structure.

5.3.2 In the

engine room, additional side girders are generally to be fitted in

way of the main machinery.

5.3.4 The face

thickness, t

f, is not, in general, to be less

than the web thickness of the side girder.

5.4 Floors, general

5.4.1 In transversely

framed craft, floors are generally to be fitted at every frame and

underneath each bulkhead.

5.4.2 In longitudinally

framed craft, floors are to be fitted at every transverse web frame

and bulkhead and generally at a spacing not exceeding 2 m. Additional

transverse floors or webs are, in general, to be fitted at half web-frame

spacing in way of engine seatings and thrust bearings, pillars, skegs,

ballast/bilge keels and the bottom of the craft in the forefoot region.

5.4.3 The overall

depth of transverse floors at the centreline, d

f,

is not to be taken as less than:

| when B < 10 m

|

d

f =40 (B + 0,85D) mm

|

| when B ≥ 10 m

|

d

f = 40 (1,5B + 0,85D) - 200 mm

|

where B is as defined

in Pt 8, Ch 3, 1.5 Symbols and definitions 1.5.1.

5.4.6 If side

frames are attached to the floors by brackets, the depth of floor

may be reduced by 15 per cent and the floor thickness determined using

the reduced depth. The brackets are to have the same thickness as

the floors, and their arm lengths clear of the frame are to be the

same as the reduced floor depth given above.

5.4.8 The thickness

of the face reinforcement, t

f, is to be not

less than the web thickness.

5.4.10 Floors

are generally to be continuous from side to side.

5.4.11 The tops

of floors, in general, may be level from side to side. However, in

craft having considerable rise of floor the depth of the floor plate

may require to be increased to maintain the required mechanical properties

of the section.

5.4.12 The floors in the aft peak are to extend over and provide efficient support

to the sterntube where applicable.

5.5 Floors in machinery spaces

5.5.2 The depth

and mechanical properties of floors between engine or gearbox girders

is to be not less than that required to maintain continuity of structural

integrity or 50 per cent of the depth given in Pt 8, Ch 3, 5.4 Floors, general 5.4.3. The web thickness and face reinforcement

weight of such reduced height floors are to be increased appropriately

in order to maintain the continuity of structural strength.

5.6 Machinery seating

5.6.2 Main and

auxiliary engines are to be effectively secured to the hull structure

by seatings of adequate scantlings to resist the gravitational thrust,

torque and vibration forces which may be imposed upon them.

5.6.3 The longitudinal

girders forming the engine seating are to extend as far forward and

aft as is practicable and are to be adequately supported by transverse

floors or brackets.

5.6.4 Where stiffening

is of plate construction, engine holding-down bolts are to be arranged

as near as practicable to floors and longitudinal girders. When this

cannot be achieved, bracket floors are to be fitted.

5.7 Drainage arrangements

5.7.2 Sufficient

limber holes are to be positioned in the internal bottom structure

to allow for the drainage of water from all parts of the bilge to

the pump suctions.

5.7.3 Particular

attention is to be given to the positioning of limbers to ensure adequate

drainage and to avoid stress concentrations. See LR's Guidance Notes for Calculation Procedures for Composite Construction.

5.7.4 Openings

in the webs of stiffening sections, baffle plates, etc. are, in general,

to be formed by moulded-in preforms under top hat type stiffening.

Edges of openings in plate laminates are to be suitably sealed in

accordance with Pt 8, Ch 3, 1.30 Openings in the webs of stiffening members.

5.8 Rudder horns

5.8.1 The scantlings

of the rudder horn will be specially considered and in the case of

high aspect ratio or novel designs direct calculations will be required

to be submitted in accordance with Pt 3, Ch 1, 2 Direct calculations.

5.9 Sternframes

5.9.1 Where it

is proposed to mould a composite sternframe, the scantlings and arrangements

will be specially considered on the basis of direct calculations and

loadings submitted by the Builders and designers.

5.10 Skeg construction

5.10.1 Skegs

are to be effectively integrated into the adjacent structure and their

design is to be such as to facilitate this, see also

Pt 8, Ch 3, 3.9 Skeg.

5.10.2 The scantlings

of skegs and the internal diaphragms at bulkheads and web frames are

to be sufficient to withstand any docking forces to which they may

be subjected.

5.11 Forefoot and stem

5.11.1 For craft

of composite sandwich construction the forefoot region is to be so

designed that in the event of local impact (see also

Pt 8, Ch 3, 2.8 Impact considerations) with floating debris, the resultant

damage will be limited. This may be achieved by:

-

Arranging the individual

plies of the laminate such that any delamination will be directed

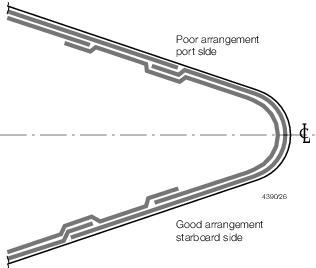

to the outer surface of the laminate, see

Figure 3.5.1 Arrangement of laminate in way of forefoot and stem.

-

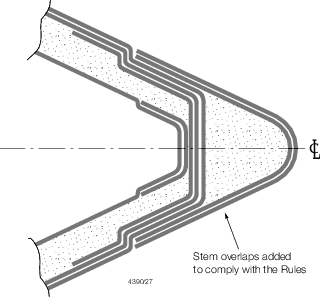

The addition of

a sacrificial `nose', see

Figure 3.5.2 `Sacrificial nose'.

-

By the addition

of suitable sheathing, in accordance with Pt 8, Ch 3, 2.9 Sheathing.

-

For vessels where

the operating high speed waterline results in the exposure of the

forefoot region, the laminate sequence in the keel area will be specially

considered.

Figure 3.5.1 Arrangement of laminate in way of forefoot and stem

5.12 Transom knee

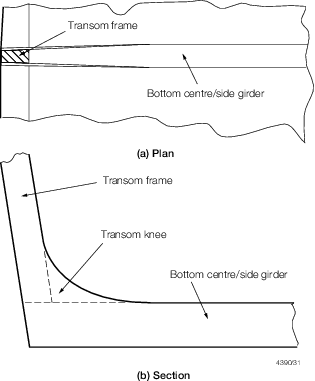

5.12.1 Centre

and side girders are to be bracketed to the transom framing members

by means of substantial knees. The face flat area of the girders may

be gradually reduced to that of the transom stiffening member in accordance

with Figure 3.5.3 Transom knee.

Figure 3.5.2 `Sacrificial nose'

Figure 3.5.3 Transom knee

5.12.2 Hard

spots are to be avoided in way of the end connection, and care taken

to ensure that the stiffening member to which the transom knee is

bracketed can satisfactorily carry the transmitted bending moment.

|