Section

7 Portlights, windows and viewing ports, skylights and glass walls

7.1 General

7.1.1 This Section

gives the requirements for portlights, windows, viewing ports, sliding

glass doors, glass walls, skylights, glazing materials, deadlights

and storm covers.

7.1.2 Side scuttles

and portholes are considered to be portlights.

7.1.3 A plan

showing the location of portlights, windows, viewing ports, skylights

and glass walls is to be submitted.

7.1.4 Portlights

and windows, together with their glazing and deadlights if required,

are to be of an approved design or in accordance with a recognised

National or International Standard.

7.1.5 Monolithic glass panels are to be thermally toughened safety glass.

Laminated glass panels can be made of annealed glass, heat strengthened glass,

chemically strengthened glass or thermally toughened safety glass.

7.1.6 Where consideration is given to the use of glazing materials other than

thermally toughened glass, the thickness and arrangements are to take account of any

different material properties in accordance with a recognised National or International

Standard and are to be individually approved and tested as appropriate or be in

accordance with LR’s Type Approval Procedure.

7.1.7 The use

of rubber frames is not generally acceptable.

7.1.8 In position

2, cabin bulkheads and doors are considered effective between portlights

or windows and access below.

7.1.9 Side scuttles

are defined as being round or oval openings with an area not exceeding

0.16 m2. Round or oval openings having areas exceeding,

0,16 m2 shall be treated as windows.

7.1.10 Windows

are defined as being rectangular openings generally, having a radius

at each corner relative to the window size and round or oval openings

with an area exceeding 0,16 m2.

7.2 Applications

7.3 National Authority requirements

7.3.1 In addition

to the requirements of this Section, where relevant, care is to be

given to the statutory requirements of the National Authority.

7.4 Portlights

7.4.1 Portlights

are to be in accordance with a recognised National or International

Standard or of a type accepted for the respective position and having

a valid LR Type Approval certificate. Where the portlight is not type

approved, full details are to be submitted for approval in each case.

7.4.2 Portlights

may be round, elliptical or elongated and are to be of substantial

construction.

7.4.3 Portlights

are not to be fitted in machinery spaces.

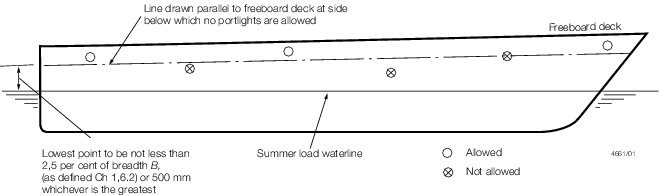

7.4.4 No portlight

is to be fitted in such a position that its sill is below a line drawn

parallel to the freeboard deck at side and having its lowest point

2,5 per cent of the breadth, B, above the load waterline

corresponding to the summer freeboard (as defined in Pt 3, Ch 1, 6.2 Principal particulars 6.2.7), or 500 mm, whichever is

the greater distance, see

Figure 4.7.1 Position of portlights.

Figure 4.7.1 Position of portlights

7.5 Windows

7.5.1 Windows

are to be in accordance with a recognised National or International

Standard or of a type accepted for the respective position and having

a valid LR Type Approval certificate.

7.5.3 A hydrostatic

test is to be carried out in order to examine watertightness of windows

fitted in the side shell. A design pressure p, where p is given in Pt 3, Ch 4, 7.8 Toughened safety glass thickness 7.8.1, is

to be applied to the external face of the window and maintained for

at least 15 minutes.

7.5.4 A structural test is to be carried out in order to examine the capability of

the frame, and glazing retaining arrangements. A design pressure 4p, where

p is given in Pt 3, Ch 4, 7.8 Toughened safety glass thickness 7.8.1 is to be applied to the external face of the window,

utilising an aluminium alloy plate of appropriate temper and thickness to simulate the

flexural response in lieu of the glazing. A full-scale test with actual glazing in place

may be acceptable provided that the stresses induced are within allowable limits.

Details of the calculations made and testing procedures are to be submitted for review

prior to the test. Alternative means of demonstrating adequacy of frame, mullions and

the retaining arrangement for the glazing may be specially considered.

7.5.5 Equivalent

proposals for testing will be considered. Where alternative testing

procedures are proposed, these are to be agreed with LR before commencement.

7.5.6 Window

glazing is, in general, to be toughened safety glass, fitted in substantial

frames supporting both faces of the glass and effectively secured

to the structure. Metal to glass contact is to be avoided.

7.5.7 In general,

no windows are to be fitted in the following locations:

-

below the freeboard

deck;

-

in the first tier

end bulkheads or sides of enclosed superstructures; or

-

in first tier deckhouses

that are considered buoyant in the stability calculations.

7.5.8 Wheelhouse

window glazing is to be toughened safety glass, or where it is of

laminated or sandwich construction, the surface layers are to be of

toughened safety glass.

7.5.9 Large windows

in the aft end of superstructure or deckhouses will be specially considered.

7.5.10 Openings

in the shell for windows are to have well rounded corners.

7.6 Viewing ports

7.6.1 In general,

viewing ports are not to be fitted in the bottom shell of high speed

craft.

7.6.2 Viewing

ports are to be watertight and of substantial construction in accordance

with approved plans.

7.6.3 Glazing

is to be fitted in substantial frames supporting both faces of the

glazing and effectively secured to the hull structure.

7.6.4 Where practicable,

viewing ports are to be fitted with efficient, hinged, deadlights

which are capable of being effectively closed and secured watertight,

with or without the glazing in place.

7.6.5 Hydrostatic

pressure tests are to be carried out to confirm that the proposed

construction, when fitted in the hull, is able to withstand a pressure

of four times the design pressure and remain watertight. Where a deadlight

is fitted, this test is also to be carried out with the glazing removed

and the deadlight closed.

7.7 Sliding glass doors or `glass walls'

7.7.1 Large glass

doors or windows in the aft end of superstructures and deckhouses

and other large glass structures forming the sides, ends or roofs

of deckhouses will be specially considered.

7.7.2 When sliding

glass doors are provided, or a `glass wall' which includes an access,

an alternative access or exit from the space is to be provided and

the arrangements are to be in accordance with approved plans and weathertight

commensurate with their position. Sill heights are, in general, to

be in accordance with Pt 3, Ch 4, 6.2 External doors.

7.8 Toughened safety glass thickness

7.8.1 The thickness, t, of toughened safety glass, which is continuously

supported, i.e. on all four sides for rectangular forms and around the perimeter for

circular forms, is to be not less than 6 mm or that given by the following expression,

whichever is the greater:

for glazing of rectangular form

for glazing of circular form

where

|

r

|

= |

radius

of the glazing, in mm |

|

b

|

= |

length

of shorter side of glazing, in mm |

|

p

|

= |

design

pressure in kN/m2, as defined in Pt 5, Ch 3, 3.1 Hull structures and Pt 5, Ch 4, 3.1 Hull structures

|

|

β |

= |

– 0,17 + 0,54AR –

0,078AR2 for AR ≤ 3 |

|

|

= |

0,75 for AR > 3 |

|

AR

|

= |

aspect ratio of glazing |

|

|

= |

a/b

|

|

a

|

= |

length of longer side of glazing, in mm |

7.8.2 For glass of trapezoidal form, the length of the glazing, a, is to be

taken as the mean of the length of the longer sides. The value of b, the length

of the shorter side, may be similarly determined.

7.8.3 Alternatively, the thickness of the glass can be determined in accordance with EN 16612

or equivalent.

7.9 Laminated glass thickness

7.9.1 Where laminated toughened safety glass is used, the total thickness is to

be greater than that required for the equivalent sized glazing using toughened safety

glass. The equivalent thickness of laminated toughened safety glass,

ts, in mm, is to be determined as follows:

where

|

td

|

= |

the equivalent thickness to resist deflection, in mm, to be taken

as:  |

|

t

i

|

= |

the thickness of the glass ply, in mm |

|

t

max

|

= |

the thickness of the thickest ply in the laminate, in mm |

Note that the influence of the

interlayer is neglected, i.e. the coefficient of shear transfer has been assumed to

zero.

7.9.3 The equivalent strength and bending stiffness to that of a single,

thermally toughened pane of thickness ts, can be demonstrated in a four-point

bending test in accordance with EN 1288-3 or an equivalent recognised National or

International Standard, using no fewer than ten samples. The lower limit of the 90 per

cent confidence level interval for the laminated pane shall not be less than the same

for monolithic toughened safety glass. Comparison shall be made based on a reference

load test area per sample of 0,072 m2. When samples tested under standards

other than EN 1288-3 are smaller, the confidence level used in the statistical reduction

must be increased accordingly:

|

probability |

= |

1,0 - (1,0 - 0,90)0,072/asample |

The minimum number of samples tested must be suitably increased to get a

representative result:

where

|

asample |

= |

area of the sample between the inner rollers. |

Small scale punch test or ring-in-ring test methods shall not be used.

7.9.4 Alternatively, cross-sections of laminated glazing can be accepted on the

basis of direct calculations predicting the result of the required bending test,

see

Pt 3, Ch 4, 7.9 Laminated glass thickness 7.9.3. Direct

calculations are to be in accordance with EN 16612 Annex B or equivalent.

7.10 Other glazing materials

7.10.1 Materials

other than glass may be used for windows, except for those in the

wheelhouse, with the thickness obtained by multiplying the thickness

for toughened safety glass by a factor of 1,3 for polycarbonate and

1,5 for acrylic. Consideration will be given to composite and multi-layer

constructions where documented results of a pressure test confirm

that the proposed construction, when fitted in its appropriate frame,

is able to withstand a test pressure of four times the design pressure

and remain watertight.

7.11 Openings and framing requirements

7.11.1 The strength

and dimensions of the frame section are to be appropriate to the size

of the window, the type of glazing being used and its method of bedding.

The glazing is to be secured to its frame in accordance with the manufacturer's

instructions and recommendations; metal to glass contact is to be

avoided.

7.11.2 Rubber

frames are not acceptable for windows in Positions 1 and 2, and are

not generally acceptable in any other position in external casings.

Any proposals to fit rubber frames are to be submitted for consideration.

The proposed locations, frame dimensions, glass thicknesses and the

results of any tests carried out, are to be forwarded.

7.11.3 Where the supporting structure could be subject to deformations, the framing and

mounting system is to be selected such that the glass is isolated from these

deformations, that the integrity of the glazing is ensured and that the pane will not

detach from the frame due to either deflection or adhesive failure. This is to be

confirmed by means of a prototype test.

7.12 Deadlights and storm covers

7.12.1 Portlights

fitted to spaces below the weather deck, or to spaces within enclosed

superstructures, are to be fitted with efficient, hinged, inside deadlights

which are capable of being effectively closed and secured watertight

below the weather deck and weathertight above the weather deck.

7.12.2 In service

craft less than 24 m Rule length, L

R, and

yachts, portlights in the hull in way of accommodation may have portable

deadlights, provided that they are stored adjacent to the portlight

and can be readily fitted. Also, in the case of these craft, portlights

in superstructures or deckhouses do not require to have deadlights,

unless on the weather deck in exposed positions or protecting direct

access below, in which case, they are to be provided with deadlights

or storm covers.

7.12.3 For craft

in Service Group G1, storm covers or deadlights are generally

not required for windows or portlights in superstructures or deckhouses.

7.12.4 For craft

in Service Group G2, storm covers or deadlights are required

for:

-

50 per cent of the

windows and portlights in the front of the superstructure or deckhouse

on the weather deck.

-

The windows and

portlights in the forward half of the superstructure or deckhouse

side on the weather deck, except where these are interchangeable port

and starboard, in which case a sufficient number to fit the forward

half of one side is to be provided.

-

Each different size

of window and portlight.

7.12.5 For craft

in Service Groups G2A and G3, storm covers or deadlights

are required for:

-

All windows and

portlights in the front of the superstructure or deckhouse on the

weather deck.

-

All windows and

portlights in the sides of the superstructure or deckhouse on the

weather deck, except where they are interchangeable port and starboard,

in which case a sufficient number to fit any one side are to be provided.

-

Each different size

of window and portlight.

7.12.6 For craft

in Service Groups G4 and G5, storm covers

or deadlights are required as follows:

-

If fitted in a deckhouse

in Position 1, windows are to be provided with strong, hinged, weathertight

storm covers. However, if there is an opening leading below deck in

this deckhouse, this opening is to be treated as being on an exposed

deck and is to have weathertight protection.

-

Portlights and windows

at the shell in Position 2, protecting direct access below, are to

be provided with strong permanently attached deadlights.

-

Portlights and windows

at the shell in Position 2, not protecting direct access below, are

to be provided with strong portable steel covers for 50 per cent of

each size, with means for securing at each window.

-

Portlights and windows

set inboard from the shell in Position 2, protecting direct access

below, are either to be provided with strong permanently attached

deadlights or, where they are accessible, strong permanently attached

external storm covers instead or internal deadlights.

-

Portlights and windows

set inboard from the shell in Position 2, not protecting direct access

below, do not require deadlights or storm covers.

-

Windows in the shell,

located at least one standard height of superstructure above the lowest

Position 2 deck, are to be provided with strong portable internal

storm covers for 25 per cent of each size, with means of securing

being provided at each window.

-

Where windows are

permitted in an exposed bulkhead on the weather deck in the forward

0,25L

L, strong external storm covers are to

be provided, which may be portable and stored adjacent.

7.12.7 Deadlights

and storm covers are not required for second tier portlights or windows

in deckhouses without direct access below.

7.12.8 Where

the wheelhouse is in Position 2, in lieu of storm covers being provided

for the wheelhouse windows, a weathertight cover, fitted to a coaming

of not less than 230 mm in height around the internal stairway opening

within the wheelhouse, may be accepted. If this arrangement is accepted,

adequate means of draining the wheelhouse are to be provided.

7.12.9 If necessary,

for practical considerations, the storm covers may be in two parts.

7.12.10 Deckhouses

situated on a raised quarter deck may be treated as being in Position

2 as far as the provision of deadlights is concerned, provided the

height of the raised quarter deck is equal to, or greater than the

standard height.

7.12.11 Sliding

glass doors are to be provided with storm covers of strong construction,

or, in the case of a `glass wall', this may be protected by a strongly

constructed roller shutter or equivalent, which can be readily lowered

and secured to provide adequate protection. When necessary, additional

portable supports are to be provided for the cover. The arrangements

are to be in accordance with approved plans. Alternative arrangements

will be specially considered. In lieu of a weathertight coaming for

the cover, adequate drainage is to be provided between the cover and

the glass which may be in the form of a sump drained overboard, with

a grating over.

7.12.12 Deadlights

and storm covers are to be weathertight and of equivalent strength

to the surrounding structure.

7.12.13 Portable

deadlights and storm covers are to be clearly marked to indicate which

portlights or windows they fit and stowed in such a way as to be readily

fitted.

7.12.14 Consideration can be given to proposals to install permanent deadlights made of

tri-laminated glazing subject to agreement with the Flag Administration. The deadlights

are to have their own independent connection to the shell or bulkhead in which they are

fitted and a mechanical retaining frame is to be provided in accordance with a

recognised International Standard. Glued connections are not permitted, and the frame is

to be tested to four times the design pressure of the window. A drop test is to be

carried out in accordance with EN 356 or equivalent where a 4 kg steel ball is to be

dropped on the glass from a height of 9 metres. The test is to be repeated three times

and after each impact the glazing is to be checked for penetration by the steel ball (a

deadlight is regarded as being penetrated if the steel ball has completely passed

through the glazing). After the impact test is carried out and a positive result

achieved, the damaged deadlight is to be hydrostatically tested to 42 per cent of the

design pressure to confirm that the deadlight will retain watertightness after

damage.

7.13 Emergency exits

7.13.1 Portlights

or windows intended as emergency escapes are to be capable of being

opened from both sides and have a minimum clear opening of 600 mm

x 600 mm.

7.14 Skylights

7.14.1 Skylights,

where fitted, are to be of substantial construction and securely attached

to their coamings. The height of the lower edge of opening is to be

as required by Pt 3, Ch 4, 5.2 Coaming heights 5.2.1. The scantlings

of the coaming are to be as required by Pt 3, Ch 4, 5.3 Scantlings 5.3.2. The thickness of glazing in fixed or opening skylights is

to be appropriate to its size and position as required for portlights

or windows. Glazing in any position is to be protected from mechanical

damage, and where fitted in Positions 1 or 2 (as defined in Pt 3, Ch 1, 6.10 Position 1 and Position 2) is to be provided with robust

deadlights or storm covers permanently attached.

7.15 Testing on completion and installation

7.15.1 In order

to demonstrate that the requirements of this Section are met the closing

arrangements are to be operated under working conditions to the satisfaction

of the Surveyor.

7.16 Bonded windows and side scuttles

7.16.1 A ‘bonded

window or bonded side scuttle’ is one in which the glazing material

is secured in its frame from the outside of the ship by glue or other

adhesive material. No mechanical fixing is provided for the glazing.

Bonded windows and bonded side scuttles are to comply with the requirements

of Pt 3, Ch 4, 7.5 Windows and Pt 3, Ch 4, 7.4 Portlights respectively, in addition to the requirements in this Section.

Proposals to secure glazing from the inside of the ship are to be

specially considered using the requirements in this Section as a basis.

It should be noted that bonding from the inside is not recommended

and where it is proposed, further testing will be required. Nonload-

bearing secondary bonded glazing, e.g. glazing to improve thermal

insulation, is not required to comply with the requirements of this

sub-Section.

7.16.2 The adhesive

is to be flexible enough to support the glazing without holding it

firm. The glue strip is to be elastic, with width and thickness designed

to allow the glazing to move in both directions in the plane of the

glazing without undue forces on the bonding or the substrate. The

glass is to be free to settle under load and not be forced to follow

deflections in the supporting structure. If substantial racking of

the glazing opening under load is expected, the bonding is to be designed

to accommodate such deflections.

7.16.3 Bonded

windows and side scuttles may be considered as acceptable, in general,

on yachts, depending on their position, size of yacht and applicable

statutory requirements, noting the distinction between glazing and

the frame, which may have different requirements.

7.16.4 Bonded

windows and side scuttles are not permitted in galley areas, including

glazing in galley doors (internal or external). They are not permitted

on escape routes and evacuation routes where a fire rating is required.

The fire integrity of bulkheads is not to be impaired.

7.16.5 The failure

of laminated glass is considered to pose a lower risk to safety than

that of single pane glass. In the event of breaking, laminated glass

more readily holds together and tends not to break up into large sharp

pieces. Therefore, in general, laminated glazing is preferred. When

laminated glass is used, the sealant is to be compatible with the

interlayer. Lamination thickness is to be in accordance with Pt 3, Ch 4, 7.9 Laminated glass thickness 7.9.1. Special consideration will be

given to single pane toughened safety glass.

7.16.6 The durability

of the adhesive and the sealant in the long-term marine environment

is to be considered in the approval process. Adhesive is to be approved

in accordance with Ch 14, 2.15 Adhesive and sealant materials.

The adhesive bead is to be resistant to or protected from UV radiation,

either by an optically dense area at the edges of the glazing or by

overlapping trim or UV shielding tape. The adhesive bead is to be

resistant to or protected from fungal attack. Arrangements are to

be in accordance with the adhesive manufacturer’s published

guidelines and relevant LR Rules.

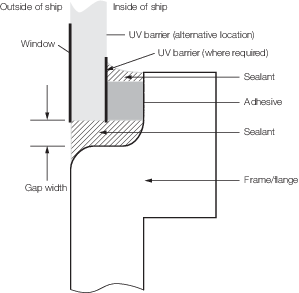

7.16.7 The edges

of the bonding recess are to be rounded to facilitate the application

of the sealant without air entrapment. The width of the gap between

the flange and the glazing is to be large enough to accommodate the

movement of the glazing as a result of hull deflection and thermal

expansion, see

Figure 4.7.2 Gap width between flange and window, bonded from the outside of the ship.

Recommended gap widths for bonded windows are to be taken as:

|

|

Gap width

|

|

Length of longest side of window

|

|

|

10–15 mm

|

|

< 1,5 m

|

|

|

15–20 mm

|

|

1,5–3,0 m

|

Figure 4.7.2 Gap width between flange and window, bonded from the outside of the ship

7.16.8 The minimum

adhesive width and thickness are to be in accordance with the adhesive

manufacturer’s published guidelines.

|