Section

6 Construction details

6.1 Continuity and alignment

6.1.1 Continuity

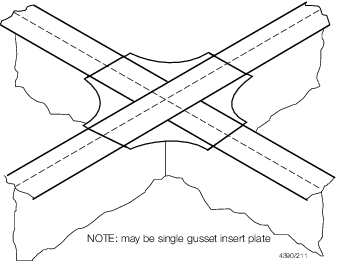

is to be maintained where primary members intersect and where the

members are of the same depth, a suitable gusset plate or brackets

are to be fitted, see

Figure 6.6.1 Primary member intersection

6.1.2 The

toes of brackets, etc. are not to land on unstiffened panels of plating.

Special care is to be taken to avoid notch effects at the toes of

brackets, by making the toe concave or otherwise tapering it off.

Figure 6.6.1 Primary member intersection

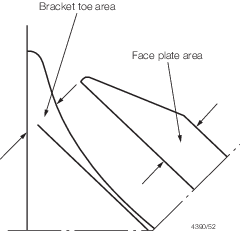

6.1.3 Particular

care is to be paid to the design of the end bracket toes in order

to minimise stress concentrations. Sniped face plates which are welded

onto the edge of primary member brackets are to be carried well around

the radiuses bracket toe and are to incorporate a taper not exceeding

one in three. Where sniped face plates are welded adjacent to the

edge of primary member brackets, adequate cross-sectional area is

to be provided through the bracket toe at the end of the snipe. In

general, this area measured perpendicular to the face plate, is to

be not less than 60 per cent of the full cross-sectional area of the

face plate, see

Figure 6.6.2 Bracket toe construction

Figure 6.6.2 Bracket toe construction

6.2 Primary end connections

6.2.1 The

requirements for section modulus and inertia (if applicable) of primary

members are given in the appropriate Chapter. The scantling requirements

for primary member end connections in dry spaces and in tanks of all

ship types are generally to comply with the requirements of Vol 1, Pt 6, Ch 2 Design Tools,Vol 1, Pt 6, Ch 3 Scantling Determination,

taking Z as the section modulus of the primary member.

6.2.3 Connections

between primary members forming ring system are to minimise stress

concentrations at the junctions. Integral brackets are generally to

be radiused or well rounded at their toes. The arm length of the bracket,

measured from the face of the member, is to be not less than the depth

of the smaller member forming the connection.

6.2.4 The

requirements of this Section may be modified where direct calculation

procedures are adopted to analyse the stress distribution in the primary

structure.

6.2.6 The

minimum thickness or area of material in each component part of the

primary member is given in Table 6.6.1 Minimum thickness of primary

members.

Table 6.6.1 Minimum thickness of primary

members

| Item

|

Requirement

|

| (1)

|

Member web plate

(see Note)

|

tw = 0,01Sw

but not less than 6 mm in

dry

spaces

and not less than 7 mm in

tanks

|

| (2)

|

Member face plate

|

Af not to exceed  cm2 cm2

|

| (3)

|

Deck plating forming the upper flange of

underdeck girders

|

Plate thickness not less than

mm mm

|

| Symbols

|

|

dw

|

= |

depth of member web, in mm |

|

tw

|

= |

thickness of member web, in mm |

|

Af

|

= |

area of member face plate or flange, in cm2

|

|

Sw

|

= |

spacing of stiffeners on member web, or depth of

unstiffened web, in mm |

|

Note For primary members having a web depth exceeding 1500 mm,

the arrangement of stiffeners will be individually considered, and

stiffening parallel to the member face plate may be required.

|

6.3 Secondary member end connections

6.3.1 Secondary

members, that is longitudinals, beams, frames and bulkhead stiffeners

forming part of the hull structure, are to be effectively continuous

and are to be suitably bracketed at their end connections. Where it

is desired to adopt bracketless connections, the proposed arrangements

will be individually considered, see also

Table 6.5.3 Connections of primary

structure.

6.3.2 Where

bracketed end connections are fitted in accordance with these requirements,

they may be taken into account in determining the effective span of

the member.

6.4 Scantlings of end brackets

6.4.1 For

a naval ship, longitudinal strength members are to be continuous through

primary supports. In exceptional cases for ships having a military

distinction notation MD and in areas not subject to significant

fatigue loading, longitudinal strength members may be cut at a primary

support and the continuity of strength is to be provided by brackets.

In such cases the scantlings of the brackets are to be such that their

section modulus and effective cross-sectional area are not less than

those of the member. Care is to be taken to ensure correct alignment

of the brackets on each side of the primary member.

6.4.2 In other

cases the scantlings of the bracket are to be based on the modulus

as follows:

-

Bracket connecting

stiffener to primary member – modulus of the stiffener.

-

Bracket at the

head of a main transverse frame where frame terminates – modulus

of the frame.

-

Brackets connecting

lower deck beams or longitudinals to the main frame in the forward

0,5L

R – modulus of the frame.

-

Elsewhere –

the lesser modulus of the members being connected by the bracket.

6.4.5 The

lengths, d

a and b

a,

of the arms are to be measured from the plating to the toe of the

bracket and are to be such that:

-

d

a + b

a ≥ 2,0lb

-

d

a ≥

0,8lb

-

b

a ≥

0,8lb

where

a and b are the

actual lengths of the two arms of the bracket, in mm, measured from

the plating to the toe of the bracket

|

lb

|

= |

|

|

Z

|

= |

the

section modulus of the secondary member, in cm3. In no

case is lb to be taken as less than twice the web

depth of the stiffener on which the bracket scantlings are to be based.

|

6.4.6 The

scantlings of deep web frames are based on the inclusion of the standard

brackets specified in Vol 1, Pt 6, Ch 6, 6.4 Scantlings of end brackets 6.4.5 at

top and bottom, while the scantlings of side frames are normally to

be based on a standard bracket at the top only. Where the actual arm

lengths fitted, d

a1, and b

a1 (in

mm) are smaller than Rule size above or the bracket is omitted then,

for comparison purposes, an equivalent arm length, la,

is to be derived from:

-

-

d

a1 ≥ 0,8la

-

b

a1 ≥ 0,8la

-

la =

0

where

-

bracket is omitted

from the upper or lower ends of the frame, or

-

lower frame

bracket at bilge is at same level as the inner bottom, or

-

lower frame

is welded directly to the inner bottom.

6.4.7 The

free edge of the bracket is to be stiffened where any of the following

apply:

-

The section modulus, Z, exceeds 2000 cm3.

-

The length of

free edge exceeds 50 times the bracket thickness.

-

The bracket is

fitted at the lower end of main transverse side framing.

6.4.8 Where

a face flat is fitted, its breadth, b

f, is

to be not less than:

6.4.9 Where

the edge is stiffened by a welded face flat, the cross-sectional area

of the face flat is to be not less than:

-

0,009k

s

b

f

t

b cm2 for

offset edge stiffening.

-

0,014k

s

b

f

t

b cm2 for

symmetrically placed stiffening.

|

b

f

|

= |

breadth of face flat, in mm |

6.4.10 Where

the stiffening member is lapped on to the bracket, the length of overlap

is to be adequate to provide for the required area of welding. In

general, the length of overlap is not to be less than  , or the depth of stiffener, whichever is the greater. , or the depth of stiffener, whichever is the greater.

6.4.11 Where

the free edge of the bracket is hollowed out, it is to be stiffened

or increased in size to ensure that the modulus of the bracket through

the throat is not less than that of the required straight edged bracket.

6.4.12 The

arrangement of the connection between the stiffener and the bracket

is to be such that at no point in the connection is the actual modulus

reduced to less than that of the stiffener with associated plating.

6.4.13 The

design of end connections and their supporting structure is to be

such as to provide adequate resistance to rotation and displacement

of the joint.

6.4.14 The

thickness of the bracket is to be not less than as required by Table 6.6.2 Thickness of end brackets.

Table 6.6.2 Thickness of end brackets

| Bracket

|

Thickness, in mm

|

LImits

|

| Minimum, in mm

|

Maximum, in mm

|

| With edge stiffened:

|

|

|

|

| (a)

|

in dry spaces

|

3,5 + 0,25

|

6,5

|

12,5

|

| (b)

|

in deep tanks

|

4,5 + 0,25

|

7,5

|

13,5

|

| Unstiffened brackets:

|

|

|

|

| (a)

|

in dry spaces

|

|

7,5

|

|

| (b)

|

in deep tanks

|

|

8,5

|

|

6.5 Arrangement at intersection of continuous

secondary and primary members

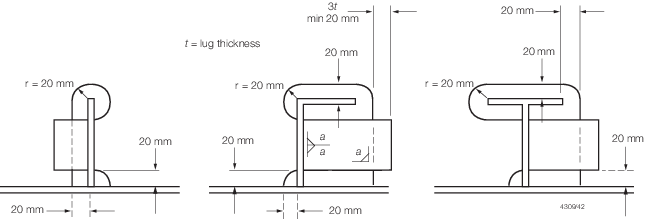

6.5.1 Lugs or tripping brackets are to be fitted where shell longitudinals are

continuous through web frames in way of highly stressed areas of the side shell (e.g. in

way of equipment supports, bollards, fenders, etc.).

6.5.2 Lugs or tripping brackets are also to be fitted where continuous secondary

stiffeners are greater than half the depth of the primary stiffeners.

6.5.5 The breadth of cut-outs is to be as small as practicable, with the top edge

suitably radiused. Cut-outs are to have smooth edges, and the corner radii are to be as

large as practicable. Where the web depth is greater than 100 mm the corner radii are to

be a minimum of 20 per cent of the breadth of the cut-out or 20 mm, whichever is the

greater, and for large cut-outs greater than 250 mm deep, the web plate connection to

the hull envelope, or bulkhead, should end in a smooth tapered ‘soft toe’. Recommended

shapes of cut-out are shown in Figure 6.6.4 Typical lug connections, but consideration will be given to other

shapes on the basis of maintaining equivalent strength and minimising stress

concentration.

6.5.6 Consideration is to be given to the provision of adequate drainage and

unimpeded flow of air and water when designing the cut-outs and connection details.

6.5.7 Asymmetrical secondary members are to be connected on the heel side to the

primary member web plate. Additional connection by lugs on the opposite side may be

required.

6.5.8 Symmetrical secondary members are to be connected by lugs on one or both

sides, as necessary.

6.5.9 Where a bracket is fitted to the primary member web plate in addition to a

connected stiffener it is to be arranged on the opposite side to, and in alignment with

the stiffener. The arm length of the bracket is to be not less than the depth of the

stiffener, and its cross-sectional area through the throat of the bracket is to be

included in the calculation of A

f, see

Vol 1, Pt 6, Ch 6, 5.13 Intersection of primary and secondary members 5.13.1.

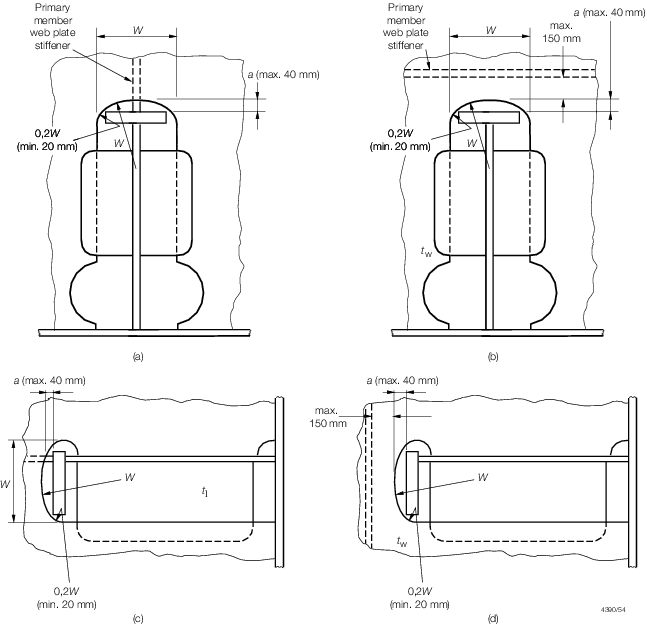

6.5.10 In general where the primary member stiffener is connected to the secondary

member it is to be aligned with the web of the secondary member, except where the face

plate of the latter is offset and abutted to the web, in which case the stiffener

connection is to be lapped. Lapped connections of primary member stiffeners to mild

steel bulb plate or rolled angle secondary members may also be permitted. Where such

lapped connections are fitted, particular care is to be taken to ensure that the primary

member stiffener wrap around weld connection is free from undercut and notches.

Figure 6.6.4 Typical lug connections

Figure 6.6.5 Cut-out and connections

6.5.11 Fabricated longitudinals having the face plate welded to the underside of

the web, leaving the edge of the web exposed, are not recommended for side shell and

longitudinal bulkhead longitudinals. Where it is proposed to fit such sections, a

symmetrical arrangement of connection to transverse members is to be incorporated. This

can be achieved by fitting backing brackets on the opposite side of the transverse web

or bulkhead. The primary member stiffener and backing brackets are to be lapped to the

longitudinal web, see

Vol 1, Pt 6, Ch 6, 6.5 Arrangement at intersection of continuous secondary and primary members 6.5.10.

6.5.12 The cross-sectional areas of the connections are to be determined from the

proportion of load transmitted through each component in association with the

appropriate allowable stress coefficient given in Table 6.6.3 Allowable stress

coefficients.

Table 6.6.3 Allowable stress

coefficients

| Item

|

Allowable direct stress

coefficient, f

σ (see Note 1)

|

Allowable shear

stress coefficient, f

τ(see Note 1)

|

| Primary web plate stiffener adjacent

to connection with secondary member

|

0,67

|

—

|

| Welded connection of primary member

web plate stiffener to secondary member:

|

|

|

| Double continuous fillet

|

0,50

|

—

|

| Automatic deep penetration

|

0,67

|

—

|

| Lug or collar plate and weld connection

|

—

|

0,72

(see Note

2)

|

|

Note 2. For emergency landing areas, the allowable shear stress

coefficient fτ is to be taken as 0,90.

|

6.5.13 The load transmitted through the intersection arrangement is to be

determined using the design pressure for the structural element being assessed in

accordance with Vol 1, Pt 5, Ch 3 Local Design Loads.

6.5.14 Total load, P, transmitted to the primary member from the secondary member is to

be derived by:

where

|

s |

= |

secondary stiffener spacing, mm |

|

S |

= |

primary stiffener spacing, m |

|

p |

= |

design plating pressure, kN/m2 |

|

P |

= |

total load, kN |

6.5.15 The arrangement of lug/collar/direct connection to the primary web

stiffener determines the load apportioned to each component. The effect on each

component of the intersection is to be assessed for shear and direct stress. Where the

web stiffener is not connected to the secondary member, the load, P, is

transmitted through the lug/collar/direct connection.

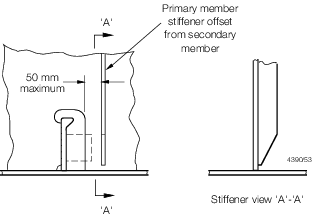

6.6 Arrangement with offset stiffener

6.6.1 Where

the stiffeners of the double bottom floors and transverse bulkheads

are unconnected to the secondary members and offset from them (see

Figure 6.6.6 Arrangement with offset stiffener) the collar arrangement

for the secondary members are to satisfy the requirements of Vol 1, Pt 6, Ch 6, 6.5 Arrangement at intersection of continuous secondary and primary members 6.5.4. In addition, the fillet welds

attaching the lugs to the secondary members are to be based on a weld

factor of 0,44 for the throat thickness. To facilitate access for

welding the offset stiffeners are to be located 50 mm from the slot

edge furthest from the web of the secondary member. The ends of the

offset stiffeners are to be suitably tapered and softened.

Figure 6.6.6 Arrangement with offset stiffener

6.6.2 Alternative

arrangements will be considered on the basis of their ability to transmit

load with equivalent effectiveness. Details of the calculations made

and testing procedures are to be submitted.

6.7 Watertight collars

6.7.1 Watertight

steel collars are to be fitted, where stiffeners are continuous through

watertight or oiltight boundaries.

6.7.2 Watertight

steel collars or equivalent are to be fitted at gastight boundary.

6.8 Insert plates

6.8.1 Where

thick insert plates are butt welded to thin plates, the edge of the

thick plate may require to be tapered. The slope of the taper is generally

not to exceed one in three.

6.8.2 The

corners of insert plates are generally to be suitably radiused.

6.9 Doubler plates

6.9.1 Doubler

plates are to be avoided and are not to be fitted in areas where corrosion

may be a problem and access for inspection and maintenance is limited.

6.9.2 Where

doubler plates are fitted, they are to have well radiused corners

and the perimeter is to be continuously welded. Large doubler plates

are also to be suitably slot welded, the details of which are to be

submitted for consideration.

6.10 Other fittings and attachments

6.10.1 Gutterway

bars and spurnwaters are not to be welded to boundary angles, or within

100 mm of the deck edge.

6.10.2 Minor

attachments, such as pipe clips, staging lugs and supports, are generally

to be kept clear of toes of end brackets, corners of openings and

similar areas of high stress. Where connected to asymmetrical stiffeners,

the attachments may be in line with the web providing the fillet weld

leg length is clear of the offset face plate or flange edge. Where

this cannot be achieved the attachments are to be connected to the

web, and in the case of flanged stiffeners they are to be kept at

least 25 mm clear of the flange edge. On symmetrical stiffeners, they

may be connected to the web or to the centreline of the face plate

in line with the web.

6.10.3 Where

necessary in the construction of the ship, lifting lugs may be welded

to the hull plating but they are not to be slotted through.

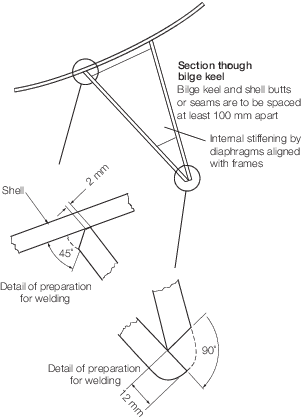

6.11 Bilge keels and ground bars

6.11.1 Bilge

keel plating is to be attached to the shell plating as shown in Figure 6.6.7 Double plate bilge keel construction. Butt and seam welds

in shell plating and bilge keels are to be staggered by at least 100

mm.

Figure 6.6.7 Double plate bilge keel construction

6.11.2 The

shell plating in way of the bilge keel is to be at least grade D.

Insert plates of 50 per cent greater thickness than the as fitted

surrounding shell plate are to be fitted. They are to be greater than

300 x 300mm2 with well rounded corners.

6.11.3 The

thickness of the bilge keel is to be assessed using the appropriate

scantling equation for shell envelope plating. To prevent possible

damage to the shell, the bilge keel plate is not to be thicker than

the adjacent shell plate. The material class, grade and quality of

the bilge keel plating is to be the same as the adjacent shell plating, see

Table 6.2.1 Material classes and

grades.

6.11.4 Full

continuous welding is to be used to connect the bilge keel to the

shell.

6.11.5 The

ends of the bilge keels are to have a 1 in 3 taper and terminate within

300 mm to 100 mm past an internal frame. Suitable internal framing

is to be arranged in way of the ends of the bilge keels where, for

hydrodynamic reasons, a steeper taper is necessary, the termination

of the bilge keels will be especially considered.

6.11.6 For

ships over 65 m in length, all welds are to be subject to non-destructive

examination.

6.11.8 Internal

stiffening is to be arranged in line with hull framing but is not

to be attached to the shell plating.

6.11.10 The

internal surfaces of the bilge keel and stiffening are to be suitably

protected against corrosion.

6.12 Rivetting of light structure

6.12.1 Where

it is proposed to adopt rivetted construction, full details of the

rivets or similar fastenings, including mechanical test results, are

to be indicated on the construction plans submitted for approval or

a separate rivetting schedule is to be submitted.

6.12.2 Samples

may be required of typical rivetted joints made by the Builder under

representative construction conditions and tested to destruction in

the presence of the Surveyor in shear, tension, compression or peel

at LR’s discretion.

6.12.3 Where

rivetting strength data sheets have been issued by a recognised Authority,

the values quoted in these sheets will normally be accepted for design

purposes.

6.12.4 Where

two dissimilar metals are to be joined by rivetting, precautions are

to be taken to eliminate electrolytic corrosion to LR’s satisfaction,

and where practicable, the arrangements are to be such as to enable

the joint to be kept under observation at each survey without undue

removal of lining and other items.

6.12.5 Where

a sealing compound is used to obtain an airtight or watertight joint,

details are to be submitted of its proposed use and of any tests made

or experience gained in its use for similar applications.

6.12.6 Sealing

paints or compounds are not to be used with hot driven rivets.

6.13 Adhesive bonding of structure

6.13.1 Where

adhesive bonding of any load-bearing structure is proposed, details

of the materials and the processes to be used are to be submitted

for approval. These details are to include test results of samples

manufactured under LR survey under workshop conditions to verify the

strength, ageing effects and moisture resistance of a typical joint.

6.13.2 The

adhesive manufacturer’s recommendations in respect of the specified

jointing system, comprising preparation of the surfaces to be adhered,

the adhesive, bonding and curing processes, are to be strictly followed

as variation of any step can severely affect the performance of the

joint.

6.13.3 Meticulous

preparation is essential where the joint is to be made by chemical

bonding. The method of producing bonded joints is to be documented

so that the process is repeatable after the procedure has been properly

established.

6.13.4 Bonded

joints are suitable for carrying shear loads, but are not, in general,

to be used in tension or where the load causes peeling or other forces

tending to open the joint. Loads are to be carried over as large an

area as possible.

6.13.5 Bonded

joints are to be suitably supported after assembly for the period

necessary to allow the optimum bond strength of the adhesive to be

developed. Air pockets are to be avoided.

6.13.6 The

use of adhesive for main structural joints is not to be contemplated

unless considerable testing has established its validity, including

environmental testing and fatigue testing where considered necessary

by LR.

6.14 Triaxial stress considerations

6.14.1 Particular

care is to be taken to avoid triaxial stresses which may result from

poor joint design.

6.15 Aluminium/steel transition joints

6.15.1 Provision

is made in this Section for bi-metallic composite aluminium/steel

transition joints used for connecting aluminium structures to steel

plating. Such joints are to be used in accordance with the manufacturer’s

requirements, see also

Ch 8, 4 Aluminium/steel transition joints of

the Rules for Materials.

6.15.2 Where

a manufacturer is not approved, details of the materials to be used

and the manufacturing procedures are to be submitted for approval

before use.

6.15.3 Bimetallic

joints where exposed to seawater or used internally within wet spaces

are to be suitably protected to prevent galvanic corrosion.

6.15.4 Control

of heat input is required when welding the transition joints to the

steel structure in order to prevent disbondment.

6.16 Steel/wood connection

6.16.1 To

minimise corrosion of steel when in contact with wood in a damp or

marine environment the timber is to be primed and painted in accordance

with good practice. Alternatively the surface of the steel in contact

with the timber is to be coated with a substantial thickness of a

suitable sealant.

|