Section

5 Dynamic loading

5.1 General

5.1.1 The

following formulae are to be used to determine the dynamic response

of plate and plate stiffener combinations. The natural frequency of

structural items can be determined from Vol 1, Pt 6, Ch 2, 4 Vibration control and the period T may then be determined as follows:

|

T

|

= |

|

where

5.1.2 For bottom impact pressure loads and bow flare and above waterline impact

pressure loads required by Vol 1, Pt 6, Ch 3, 14 Strengthening for bottom slamming and Vol 1, Pt 6, Ch 3, 15 Strengthening for wave impact loads above waterline respectively, the impact pressure is assumed to be represented by a

triangular pulse load. The rise time, t1, for these impact pressures

is given in Vol 1, Pt 5, Ch 3, 4.2 Bottom impact pressure, IPbi 4.2.2 for bottom impact and Vol 1, Pt 5, Ch 3, 4.3 Bow flare and wave impact pressures, IPbf 4.3.2 for bow flare impact.

5.1.3 For flight deck landing loads, the emergency landing load can be represented by a

triangular pulse load. The rise time, t1, for these impact pressures

can be estimated from the time taken to depress the tyre and oleo strut to their maximum

deflection and the assumed maximum vertical landing velocity. For fixed wing aircraft,

the rise time for a structural element will also depend on forward speed as the aircraft

traverses the structure.

5.2 Gradually applied load

5.3 Instantaneous load

5.4 Triangular pulse load

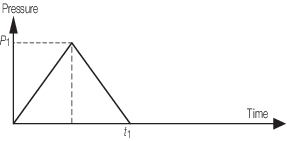

5.4.1 For

a triangular pulse load as shown in Figure 2.5.3 Triangular pulse load, the maximum dynamic load factor DLF be calculated from Table 2.5.1 Tabulated dynamic load

factors. Linear interpolation

may be performed to obtain DLF Rules for intermediate t

1/T values. The t

1 time

value is given in the same section that the impulsive pressure load

is specified.

Figure 2.5.3 Triangular pulse load

5.4.2 The

time to maximum response can be calculated from Table 2.5.1 Tabulated dynamic load

factors with intermediate values

determined by linear interpolation.

Table 2.5.1 Tabulated dynamic load

factors

|

|

Dynamic load factor

|

Time to maximum displacement

|

|

t

1/T

|

Gradual

|

Triangular

|

Instant

|

Gradual

|

Triangular

|

Instant

|

|

|

f

DLF

|

f

DLF

|

f

DLF

|

t

m/t

1

|

t

m/2t

1

|

t

m/T

|

| 0,0

|

2,0

|

0,0

|

0,0

|

|

|

|

| 0,1

|

1,984

|

0,312

|

0,300

|

5,800

|

2,484

|

0,284

|

| 0,2

|

1,935

|

0,608

|

0,600

|

3,000

|

1,700

|

0,316

|

| 0,3

|

1,858

|

0,875

|

0,850

|

2,100

|

1,361

|

0,348

|

| 0,4

|

1,757

|

1,098

|

1,050

|

1,700

|

1,163

|

0,381

|

| 0,5

|

1,637

|

1,273

|

1,200

|

1,450

|

1,029

|

0,400

|

| 0,6

|

1,504

|

1,391

|

1,300

|

1,280

|

0,931

|

0,415

|

| 0,7

|

1,363

|

1,465

|

1,400

|

1,150

|

0,856

|

0,430

|

| 0,8

|

1,232

|

1,501

|

1,480

|

1,080

|

0,795

|

0,440

|

| 0,9

|

1,109

|

1,514

|

1,530

|

1,010

|

0,746

|

0,445

|

| 1,0

|

1,000

|

1,508

|

1,600

|

1,000

|

0,704

|

0,450

|

|

|

|

|

|

1,500(1)

|

|

|

| 1,1

|

1,089

|

1,481

|

1,630

|

1,430

|

0,668

|

0,453

|

| 1,2

|

1,156

|

1,441

|

1,660

|

1,360

|

0,637

|

0,456

|

| 1,3

|

1,198

|

1,397

|

1,690

|

1,290

|

0,609

|

0,459

|

| 1,4

|

1,216

|

1,342

|

1,715

|

1,220

|

0,585

|

0,462

|

| 1,5

|

1,212

|

1,282

|

1,725

|

1,150

|

0,563

|

0,465

|

| 1,6

|

1,189

|

1,228

|

1,730

|

1,119

|

0,544

|

0,466

|

| 1,7

|

1,151

|

1,165

|

1,730

|

1,089

|

0,526

|

0,468

|

| 1,8

|

1,104

|

1,104

|

1,745

|

1,059

|

0,510

|

0,469

|

| 1,9

|

1,052

|

1,052

|

1,748

|

1,029

|

0,495

|

0,471

|

| 2,0

|

1,000

|

1,000

|

1,750

|

1,200

|

0,481

|

0,473

|

| 2,1

|

1,047

|

0,960

|

1,756

|

1,170

|

0,520

|

0,474

|

| 2,2

|

1,085

|

0,953

|

1,763

|

1,140

|

0,540

|

0,475

|

| 2,3

|

1,111

|

0,980

|

1,769

|

1,110

|

0,560

|

0,477

|

| 2,4

|

1,125

|

1,016

|

1,775

|

1,080

|

0,580

|

0,478

|

| 2,5

|

1,127

|

1,055

|

1,781

|

1,050

|

0,600

|

0,480

|

| 2,6

|

1,116

|

1,089

|

1,786

|

1,039

|

0,590

|

0,480

|

| 2,7

|

1,095

|

1,115

|

1,79

|

1,029

|

0,580

|

0,480

|

| 2,8

|

1,067

|

1,126

|

1,797

|

1,019

|

0,570

|

0,481

|

| 2,9

|

1,034

|

1,135

|

1,802

|

1,009

|

0,560

|

0,481

|

| 3,0

|

1,000

|

1,158

|

1,800

|

1,100

|

0,550

|

0,482

|

| 3,1

|

1,032

|

1,168

|

1,800

|

1,089

|

0,545

|

0,482

|

| 3,2

|

1,059

|

1,167

|

1,808

|

|

0,540

|

0,483

|

| 3,3

|

1,078

|

1,155

|

1,812

|

|

0,535

|

0,483

|

| 3,4

|

1,089

|

1,132

|

1,817

|

|

0,530

|

0,484

|

| 3,5

|

1,091

|

1,103

|

1,821

|

|

0,525

|

0,484

|

| 3,6

|

1,084

|

1,084

|

1,825

|

|

0,520

|

0,485

|

| 3,7

|

1,070

|

1,070

|

1,829

|

|

0,515

|

0,485

|

| 3,8

|

1,059

|

1,060

|

1,833

|

|

0,510

|

0,486

|

| 3,9

|

1,025

|

1,025

|

1,837

|

|

0,505

|

0,486

|

| 4,0

|

1,000

|

1,000

|

1,825

|

|

0,500

|

0,487

|

| 4,1

|

1,024

|

0,978

|

1,828

|

|

0,505

|

0,487

|

| 4,2

|

1,045

|

0,976

|

1,831

|

|

0,510

|

0,487

|

| 4,3

|

1,060

|

0,989

|

1,835

|

|

0,515

|

0,487

|

| 4,4

|

1,069

|

1,007

|

1,838

|

|

0,520

|

0,488

|

| 4,5

|

1,071

|

1,029

|

1,842

|

|

0,525

|

0,488

|

| 4,6

|

1,066

|

1,050

|

1,845

|

|

0,530

|

0,488

|

| 4,7

|

1,055

|

1,069

|

1,849

|

|

0,535

|

0,489

|

| 4,8

|

1,039

|

1,083

|

1,852

|

|

0,540

|

0,489

|

| 4,9

|

1,020

|

1,091

|

1,855

|

|

0,545

|

0,489

|

| 5,0

|

1,000

|

1,092

|

1,850

|

|

0,550

|

0,490

|

| 5,1

|

1,019

|

1,083

|

1,853

|

|

0,545

|

0,490

|

| 5,2

|

1,036

|

1,069

|

1,856

|

|

0,540

|

0,490

|

| 5,3

|

1,049

|

1,050

|

1,859

|

|

0,535

|

0,490

|

| 5,4

|

1,056

|

1,056

|

1,862

|

|

0,530

|

0,490

|

| 5,5

|

1,058

|

1,058

|

1,865

|

|

0,525

|

0,490

|

| 5,6

|

1,054

|

1,054

|

1,868

|

|

0,520

|

0,490

|

| 5,7

|

1,045

|

1,045

|

1,870

|

|

0,515

|

0,490

|

| 5,8

|

1,032

|

1,032

|

1,873

|

|

0,510

|

0,490

|

| 5,9

|

1,017

|

1,017

|

1,876

|

|

0,505

|

0,490

|

| ≥6,0

|

1,002

|

1,002

|

1,870

|

|

0,500

|

0,491

|

NOTE

The time to maximum displacement

curve for a gradually applied load has a step at t

1/T = 1,0.

|

|