Section

15 Strengthening for wave impact loads above waterline

15.1 General

15.1.1 This

Section may be used to determine the required scantlings for strengthening

against bow flare slamming for NS1 and NS2 type ships and for wave

impacts on the shell envelope. Direct calculations may also be used

to determine the required scantling.

15.1.2 The

required scantlings for strengthening against wave impact loads for

NS3 type ships will be specially considered on the basis of this Section.

15.1.3 The

scantling requirements contained in this Section are based on no permanent

set of plating. If acceptable, special consideration will be given

to an alternative plating performance standard where specified. Areas

designed in accordance with an alternative performance specification

are to be clearly marked on the plans. Direct calculations may be

used to determine the required scantlings.

15.2 Strengthening against bow flare wave impacts

15.2.1 The

shell envelope above the design waterline is to be strengthened against

bow flare wave impact pressures. The strengthening is to extend vertically

to the uppermost deck level, including the forecastle deck, if fitted.

15.2.3 The

thickness of the side shell is to be not less than:

where

|

CR

|

= |

panel ratio factor |

| = |

but is not to be taken less than 0,06 or greater than 0,1 but is not to be taken less than 0,06 or greater than 0,1

|

|

= |

overall panel length,

in metres, measured along a chord between the primary members |

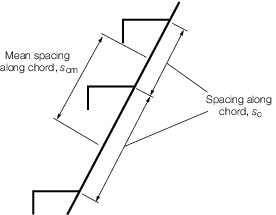

Figure 3.15.1 Chord spacing and mean chord spacing for secondary members

15.2.4 The

scantlings of primary members are not to be less than:

-

Section modulus

of primary members

-

Web area of

primary members

-

The web of the

primary member is to be adequately stiffened.

for q < 1 γA = q

3

– 2q

2 + 2 and γZ =

3q3 – 8q

2 + 6q

for q = 1 γA = 1 and γZ =

1

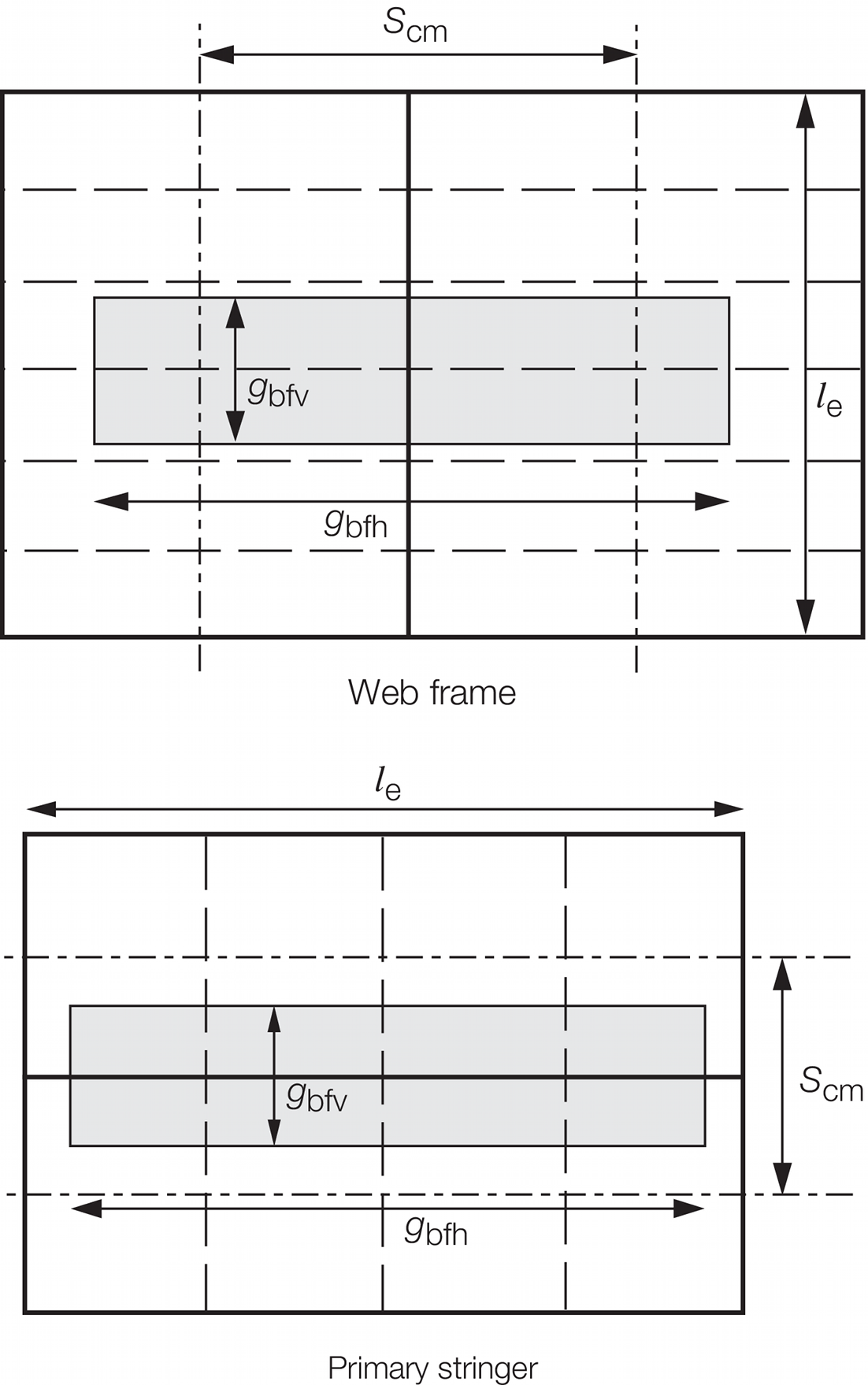

for web frames:

|

u

|

= |

is the minimum of g

bfv or  e

e

|

|

ν

|

= |

is the minimum

of g

bfh or S

cm

|

for primary stringers:

where

|

u

|

= |

is the minimum of g

bfh or  e

e

|

|

ν

|

= |

is the minimum

of g

bfv or S

cm

|

g

bfv and g

bfh are

defined in Vol 1, Pt 5, Ch 3, 4.3 Bow flare and wave impact pressures, IPbf 4.3.3

Other symbols are as defined in Vol 1, Pt 6, Ch 2, 1 General.

Figure 3.15.2 Mean spacing between primary

members, S

cm and the extents of the bow flare wave impact pressure, g

bfh and g

bfv

15.2.6 The

effective section properties of secondary stiffeners are to be taken

as:

-

Plastic section

modulus of secondary stiffeners, Z

p is to

be taken as:

|

Z

p

|

= |

(2,8 x 10-4 scm

t

p

2) - (10-3

b

f

b

fc

t

f sinθe) + (5 x

10-4 (h

w

2

t

w + 2b

f

t

f

h

w) cosθe) cm3

|

- where

|

θe

|

= |

Co (90 -ϕ )

|

|

Co

|

= |

1,1 |

|

ϕ |

= |

the angle

between the stiffener and the side shell, in degrees |

|

bfc

|

= |

0,5(b

f - t

w)

for L profiles

|

|

|

= |

0 for flat bar

and T profiles |

|

|

= |

see

Figure 2.2.1 Dimensions of longitudinals in Chapter 2, for bulb profiles for

c

see

Figure 2.2.1 Dimensions of longitudinals in Chapter 2, for bulb profiles for

c

|

|

hw

|

= |

height of web, in mm |

|

tw

|

= |

web thickness, in mm |

|

bf

|

= |

breadth of flange, in mm |

|

tf

|

= |

flange thickness, in mm |

|

tp

|

= |

thickness of attached plating, in mm |

|

scm

|

= |

defined

in Vol 1, Pt 6, Ch 3, 15.2 Strengthening against bow flare wave impacts 15.2.5.

|

-

Web area of secondary

stiffeners, A

s is to be taken as:

|

A

s

|

= |

0,01 (h

w + t

p) t

w sinϕ cm2

|

15.2.7 For

primary members with cut-outs for the passage of secondary stiffeners,

and which may have web stiffeners connected to the secondary stiffener,

buckling checks are to be carried out to ensure that the primary member

web plating and web stiffener will not buckle under the design load.

The buckling procedure to be followed is given in Table 3.15.1 Buckling procedure for primary

member web plating and web stiffener Where the web stiffener

is fitted with a bracket, the buckling capability of the web stiffener

in way of the cut-out is to take into account the bracket. Where no

web stiffener is fitted, the buckling capability of the primary member

web plating is to be checked for the total load transmitted to the

connection.

15.2.8 The

structural scantlings required in areas strengthened against bow flare

wave impact are to be tapered to meet the normal shell envelope requirements.

15.2.9 Where

the stiffener web is not perpendicular to the plating, tripping brackets

may need to be fitted in order to obtain adequate lateral stability.

15.2.10 Where

the angle between the primary structure web and the plating is less

than 70°, the effective section modulus and shear area are to

take account of the non-perpendicularity.

15.3 Strengthening against wave impact loads

15.3.1 The

requirements of Vol 1, Pt 6, Ch 3, 15.2 Strengthening against bow flare wave impacts are to

be applied to areas of plating which are liable to be subjected to

wave impact loads; for example, bottom plating of wide transom sterns,

undersides of sponsons for aircraft lifts.

Table 3.15.1 Buckling procedure for primary

member web plating and web stiffener

| Steps

|

Members

|

| Primary member

web plating

|

Primary member

web stiffener

|

| Determination of the

design compressive stress, σa, N/mm2

(kgf/mm2)

|

|

|

Determination of

the elastic critical buckling stress, σe, in

compression,

N/mm2 (kgf/mm2)

|

|

|

| Determination of the

corrected critical buckling stress, σcr, in compression,

N/mm2 (kgf/mm2)

|

σcr = σ0

σcr = σe

|

where

σe>

where σe ≤

|

| Requirement

|

σcr ≥ σa

|

| Symbols

|

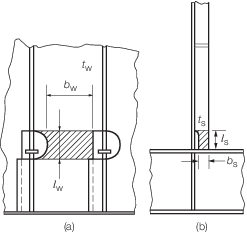

bw, bs,  w and w and  s are dimensions, in mm, as shown in Figure 3.15.3 Dimensions of critical areas of (a) primary member web plating and (b) primary member web stiffener s are dimensions, in mm, as shown in Figure 3.15.3 Dimensions of critical areas of (a) primary member web plating and (b) primary member web stiffener

|

|

|

|

|

|

ts

|

= |

thickness of primary member web stiffener, in mm |

|

|

tw

|

= |

thickness of primary member web plating, in mm |

|

|

|

|

|

|

E

|

= |

modulus of elasticity, in N/mm2

|

| = |

206000 N/mm2 for steel |

|

|

Is

|

= |

|

|

|

Iw

|

= |

|

|

|

P

|

= |

total load transmitted to the connection |

| = |

10,06 S

cm

s

cm

h

s x 10–3 kN |

|

|

Ps

|

= |

load transmitted through the primary member web

stiffener, in kN, to be determined from P

2 = P – P

1, in kN, or by direct calculations. Where P

1 = pressure transmitted through collar arrangement and

P = total load transmitted to the primary member |

|

|

Pw

|

= |

load transmitted through the primary member web

plating, in kN |

| = |

P – P

s, or by direct calculations |

|

|

|

|

σo

|

= |

specified minimum yield stress, in N/mm2

|

|

Figure 3.15.3 Dimensions of critical areas of (a) primary member web plating and (b) primary member web stiffener

|