Section

14 Strengthening for bottom slamming

14.1 General

14.1.1 This

section may be used to determine the additional scantlings for strengthening

in respect of the bottom structure forward for NS1 and NS2 type ships.

14.1.2 The

additional scantlings for strengthening in respect of the bottom structure

forward for NS3 type ships will be specially considered on the basis

of this Section.

14.2 Strengthening of bottom forward

14.2.1 The bottom forward is to be additionally strengthened where the ship has a

draught forward of less than 0,045LR in any operational loading

condition. The minimum draught, TFB, see

Vol 1, Pt 6, Ch 3, 14.2 Strengthening of bottom forward 14.2.7 (NS1) or Vol 1, Pt 5, Ch 3, 1.3 Symbols and definitions 1.3.1 (NS2 or NS3), is to be indicated

on the shell expansion plan, the plan showing the internal strengthening, the Loading

Manual and loading instrument, where fitted.

14.2.2 The requirements for the additional strengthening apply to ships where

LR is greater than 65 m.

14.2.3 The

scantling requirements outside the areas which have been strengthened

for bottom slamming are to be suitably tapered to maintain adequate

continuity of strength in both longitudinal and transverse directions.

Table 3.14.1 Additional strengthening of bottom

forward

| Item

|

Requirements

|

(1)

Longitudinally framed bottom shell plating (including keel)

(see Notes 1 and 2)

|

t = 0,003s f

|

| (2) Bottom

longitudinals – other than flat bars

|

|

| (3) Bottom

longitudinals – flat bars

|

Will be specially considered

|

|

|

Transverse framing

|

Longitudinal framing

|

| (4) Primary structure in

way of single bottoms

|

(a)

|

Centreline

girder:

Scantlings as required by Table 3.3.12 Single bottom construction

forward, minimum requirements as appropriate, except that in

determining Z in way of a deep tank forward of

0,8LR the value of h5 is to be

increased by the following percentages:

where

TFB ≤ 0,03L

2, 30 per cent

where TFB ≥

0,04L2, 0 per cent

The increase in

h5 for intermediate values of TFB

to be obtained by interpolation

|

(a)

|

Ships having one or more longitudinal

bulkheads:

(i) Centreline girder

Scantlings

as required by Table 3.3.12 Single bottom construction

forward, minimum requirements as appropriate

(ii)

Bottom transverses

Maximum spacing as for midships region,

scantlings as required by Section 2, as appropriate

(iii) For

horizontally stiffened longitudinal bulkheads and girders the depth to

thickness ratio of the panel attached to the bottom shell plate is not to

exceed 55

(iv) Where TFB

<0,025L2 the scantlings and arrangements will

receive individual consideration

|

| (b)

|

Floors:

Scantlings as required by Table 3.3.12 as appropriate, except that in

way of dry spaces the minimum face area is to be increased by the

following percentages:

where T

FB ≤ 0,03L2, 50 per

cent

where TFB ≥

0,04L2, 0 per cent

The increase of

minimum face area for intermediate values of TFB to be

obtained by interpolation

|

(b)

|

Other ship arrangements will

receive individual consideration

|

| (c)

|

Side

girders:

Arrangement and scantlings as required by Table 3.3.12 Single bottom construction

forward, minimum requirements as appropriate, with the

addition of intermediate half-height girders or equivalent fore and aft

stiffening

|

|

|

| (5) Primary structure in

way of double bottoms (see Note 3)

|

(a)

|

Plate

floors:

Maximum spacing, every

frame

Scantlings as required by Vol 1, Pt 6, Ch 3, 2 Minimum structural requirements

|

(a)

|

Plate floors:

Maximum spacing:

0,002sF m for

T

FB < 0,04L

2

0,003sF m for T

FB ≥ 0,04L

2

but not to exceed that required by Table 3.3.12 Single bottom construction

forward, minimum requirements as appropriate

|

| (b)

|

Centreline and side

girders:

Maximum spacing,

0,003sF m

Scantlings as required by Vol 1, Pt 6, Ch 3, 2 Minimum structural requirements

|

(b)

|

Centreline and side

girders:

Maximum

spacing:

0,003s

L m for T

FB < 0,04L

2

0,004s

L m for T

FB ≥ 0,04L

2

but not to exceed that required by Table 3.3.12 Single bottom construction

forward, minimum requirements, as appropriate

|

| (c)

|

Intermediate

half-height girders to be arranged midway between side girders:

|

Scantlings as required by Table 3.3.12 Single bottom construction

forward, minimum requirements, as appropriate

|

| Scantlings as required for non-watertight side

girders by Section 2

|

| (6) Primary

structure in way of double bottoms supported by longitudinal

bulkheads

|

—

|

The scantlings and arrangements will receive

individual consideration on the basis of direct calculations using, if

necessary, a suitably defined two-dimensional grillage model

|

| Symbols

|

| L

R, T as defined in Vol 1, Pt 3, Ch 1, 5.2 Principal particulars

|

| L

2, S, s, k

s as defined in Vol 1, Pt 6, Ch 3, 3.2 Symbols 3.2.1

|

|

|

|

|

= |

(0,87 + 0,16S) c

1 for S > 2,5 m |

|

|

|

|

|

= |

(1,14 – 0,14S) for 1,0 m < S ≤ 4,0 m |

|

|

|

= |

for S > 4,0 m for S > 4,0 m |

|

|

|

|

f

|

= |

but not greater than 1,0 but not greater than 1,0 |

|

|

|

|

|

|

|

= |

S, in metres, where in way of a single bottom |

|

|

p

|

= |

9,81h

s

sc

1

x 10-3 kN x 10-3 kN |

|

|

s

F

|

= |

spacing of transverse frames, in mm, for

longitudinally framed side and bottom construction s

F may be taken as s

L

|

|

|

s

L

|

= |

spacing of bottom longitudinals, in mm |

|

|

t

w

|

= |

web thickness, in mm |

|

|

A

f

|

= |

cross-sectional area of primary member web stiffener,

in cm2

|

|

|

A

fc

|

= |

effective area of primary member web stiffener in way

of butted end connection to the longitudinal, in cm2

|

|

|

A

L

|

= |

area of weld of lapped connection, in cm2,

calculated as total length of weld, in cm x throat thickness, in cm |

|

|

A

w

|

= |

area of weld of lug and web connection to the

longitudinal, in cm2, calculated as total length of weld

in cm x throat thickness, in cm |

|

|

A

1

|

= |

effective total cross-sectional area of the lug and

web connection to the longitudinal, in cm2

|

|

|

|

|

α |

= |

A

f

for the web stiffeners for the web stiffeners |

|

|

|

= |

A

fc

for a butted connection to the longitudinals for a butted connection to the longitudinals |

|

|

|

= |

A

L

for a lapped connection for a lapped connection |

|

|

|

|

|

Note

1. If intermediate stiffening is fitted

the thickness of the bottom shell plating may be 80 per cent of that

required by (1) but is to be not less than the normal taper

thickness.

|

Note

2. For transverse framing the bottom

shell plating is to be specially considered.

|

Note

3. Particular care is to be taken to

limit the size and number of openings in way of the ends of floors or

girders or to fit suitable reinforcement where such openings are

essential.

|

|

|

Table 3.14.2 Permissible stresses

14.2.5 Bottom

longitudinals are to pass through and be supported by the webs of

primary members. The vertical web stiffeners are to be connected to

the bottom longitudinals. The cross-sectional area of the connections

is to comply with the requirements given in Table 3.14.1 Additional strengthening of bottom

forward

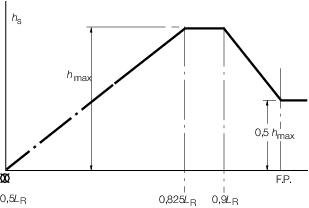

14.2.7 For NS1 ships with a block coefficient, Cb, greater than

0,6, the equivalent slamming pressure expressed as a head of water,

hs, is to be obtained from Figure 3.14.1 Pressure heads where hmax is calculated

from the following expressions:

where

is the minimum draught, in metres, at the location under

consideration for all operational loading conditions, and is to be measured from the

underside of the keel to the operational waterline is the minimum draught, in metres, at the location under

consideration for all operational loading conditions, and is to be measured from the

underside of the keel to the operational waterline

LR is as defined in Vol 1, Pt 3, Ch 1, 5.2 Principal particulars

Figure 3.14.1 Pressure heads

14.2.8 For NS1 ships where Cb < 0,6 and for NS2 and NS3

ships, the equivalent bottom impact pressure head, hs, is to be

derived in accordance with the following:

where

|