Section

2 External blast

2.1 General

2.1.1 Structures

and their response to air blast loadings, can be considered to fall

into two categories:

- Diffraction-type structures.

- Drag-type structures.

2.1.2 In a

nuclear type explosion, the diffraction-type structures would be affected

mainly by diffraction loading and the drag-type structures by drag

loading.

2.1.3 Large

flat sided structures, with few openings, will respond mainly to diffraction

loading because it will take an appreciable time for the blast wave

to engulf the structure and the pressure differential between front

and rear exists during the whole of this period. A diffraction-type

structure is primarily sensitive to the peak over-pressure in the

shock wave to which it is exposed.

2.1.4 If structures

are small, or have numerous openings, the pressures on different areas

of the structure are quickly equalised; the diffraction forces operate

only for a very short time. The response of this type of structure

is then mainly due to the dynamic pressure (or drag forces) of the

blast wind. This is typical of masts and funnels. The drag loading

on the structure is determined not only by the dynamic pressure but

also by the shape of the structure. The drag coefficient is less for

rounded or streamlined structures than for irregular or sharp edged

structures.

2.1.5 The

relative importance of each type of loading in causing damage will

depend upon the type of structure as well as the characteristics of

the blast wave.

2.2 Threat level determination

2.2.2 External

blast loading can come from a variety of threats the two main ones

are far field from nuclear or fuel air type threats and near field

from detonation by close in weapon systems. This part of the Rules

is concerned only with the far field explosions.

2.2.3 The

actual threat level used in the calculation of performance and the

areas of the ship to be protected by this design method are to be

specified by the Owner and will remain confidential to LR.

2.3 Notation assessment levels and methodology

2.3.1 Design

to withstand increasing levels of blast pressure needs to employ increasing

sophistication and complexity of analysis method if the structure

is to be kept lightweight.

2.3.2 An EB1 assessment method may utilise the simple design methodology

suggested in Vol 1, Pt 4, Ch 2, 2.8 Conventional explosive pressure loads for structural

assessment. The design criteria should ensure that the structure behaves

in an elastic perfectly plastic manner with small displacements when

subjected to the proposed blast level.

2.3.3 An EB2 assessment method may utilise an extension of simple design

methodology suggested in Vol 1, Pt 4, Ch 2, 2.8 Conventional explosive pressure loads to

look at the elasto-plastic behaviour for the structural assessment.

The structure is to be designed such that maximum displacements experienced

by all structure does not compromise the structural integrity, water

or gas-tight integrity or functioning of critical items of equipment

required for operation of the ship and systems that is attached or

adjacent to the structure.

2.3.4 An EB3 assessment method should employ a failure criterion based

on an elasto-plastic methodology which considers the following structural

responses:

- Local response of the plating, here the plating can be represented

as a 2D plate strip and a large displacement, elasto-plastic dynamic

response analysis carried out using a beam-column approach.

- Local bending response of stiffened panels, the preferred model

will be to evaluate the non-linear dynamic response of a single stiffener

with an attached strip of plating modelled as a beam-column with the

appropriate boundary conditions under blast pressure.

- A lumped parameter model can be employed to look at ‘overall

sidesway’ response of a ships superstructure.

The structure is to be designed such that maximum displacements

experienced by all structure does not compromise the structural integrity,

water or gas-tight integrity or functioning of critical items of equipment

required for operation of the ship and systems that are attached or

adjacent to the structure.

2.3.5 An EB4 assessment method should employ a full non-linear analysis

using finite element methods to predict the structural response. Using

this methodology it is assumed that the ship must survive, this implies

the need to retain primary hull structural integrity, water and gas-tight

integrity or functioning of critical items of equipment required for

operation of the ship and systems that is attached or adjacent to

the structure.

2.3.6 For EB3 and EB4 notations, the assumptions made for initial

deformations are to be submitted. Where these differ for normal ship

building practice, the details are to be recorded on the approved

plan.

2.4 Definitions

2.4.1 Atmospheric

pressure P

o is to be taken as 101,3 kN/m2.

2.5 Blast pressure loads

2.5.1 For

explosions of different magnitude, the range at which the peak blast

incident and dynamic pressures occur can be scaled using the following

equation.

where where

|

D

i

|

= |

incident distance |

|

D

n

|

= |

the distance at which the pressure occurs, in metres |

|

W |

= |

the equivalent

weight of TNT for the explosive, in kg. |

2.5.2 Similarly

for weapons of a different magnitude, the duration tp+ of

a blast can be scaled using the scaling equation

where where

|

t

i

|

= |

incident duration |

|

t

n

|

= |

duration the pressure occurs, in seconds |

|

W

|

= |

the

equivalent weight of TNT for the explosive, in kg. |

2.5.3 When

a pressure shock front strikes a solid surface placed normal to the

direction of shock travel there is an instantaneous rise in pressure

above that of the shock front itself. The total pressure referred

to as the reflected pressure is given by:

when P

i << P

o (small charge at large stand off) P

r may

be taken as 2Pi similarly when P

i >>P

o (large charge at short range) P

r may

be taken as 8P

i

where P

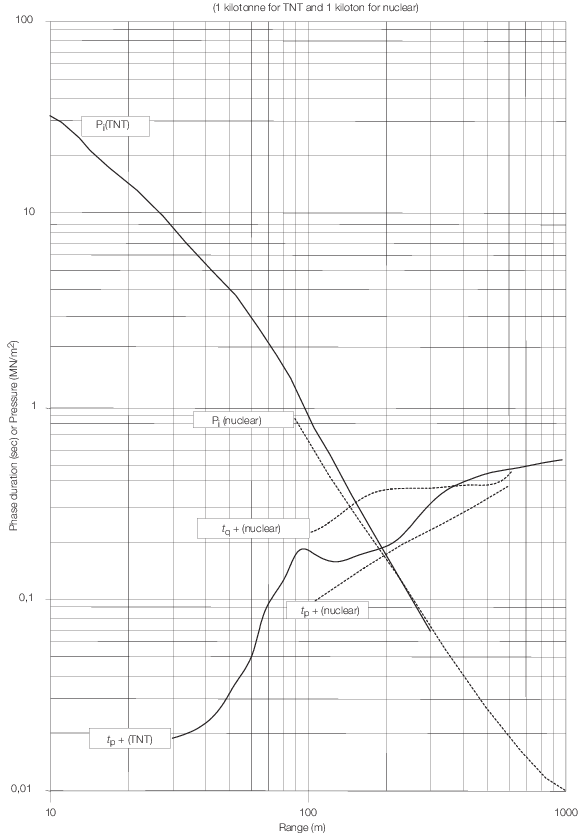

i = peak blast incident over-pressure in kN/m2 from Figure 2.2.2 Blast parameters for TNT and nuclear explosions

Figure 2.2.2 Blast parameters for TNT and nuclear explosions

2.5.4 The

reflected pressure, P

r can be assumed to diminish

linearly until it reaches the stagnation pressure P

s at

time t

s where

where

|

d

|

= |

is

the lesser of h or ⋉/2 in metres, see

Figure 2.2.1 Superstructure definitions

|

|

U

|

= |

shock

front velocity in m/s |

| = |

|

|

U

o

|

= |

speed of sound in air in m/s |

| = |

332+0,6T

o

|

|

T

o

|

= |

ambient air temperature in °C. |

2.5.6 The

stagnation pressure, P

s, is determined for

the front of the superstructure block by

and for the top, sides and rear by

Table 2.2.1 Drag coefficients

| Structure

|

Drag coefficient,

C

D

|

| Ship

sides

|

+1,0

|

| Front

face

|

+1,0

|

|

|

|

| Top and

sides

|

|

| 0–170

kN/m2

|

+0,4

|

| 170–340

kN/m2

|

+0,3

|

| 340–930

kN/m2

|

+0,2

|

|

|

|

| Masts and

funnels

|

+0,75

|

2.5.7 For

the top and sides of the superstructure the peak pressure will occur

at time t

t which is given by:

2.5.8 For

the rear of the superstructure the peak pressure will occur at time t

r which is given by:

2.5.9 Pressure

distributions for the faces of the superstructure block are given

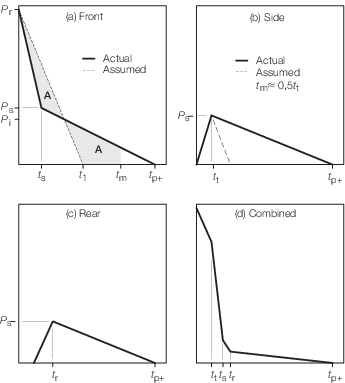

in Figure 2.2.3 Pressure distribution, together with

the overall pressure acting on the block which is obtained by subtracting

the forces on the rear face from those on the front.

Figure 2.2.3 Pressure distribution

2.6 Nuclear threats

2.6.1 An atmospheric

nuclear explosion is most likely to occur at some height above ground

level at a location known as ground zero, which may be optimised to

produce maximum damage effects. The blast wave is reflected from the

surface and at a certain distance from ground zero, primary reflected

waves combine to form a vertical ‘mach’ front or stem

that propagates outwards from ground zero with diminishing intensity.

The peak blast incident over pressure P

i can

be determined from Vol 1, Pt 4, Ch 2, 2.3 Notation assessment levels and methodology.

2.7 Fuel air pressure loads

2.7.1 In general

a structure designed to resist a moderate degree of nuclear blast

will also have a reasonable resistance to fuel air threats and calculations

is not normally required.

2.7.2 Where

there is a risk of fuel air explosions, and for ships for which there

is no nuclear threat position required, consideration needs to be

given to the blast wave characteristics of such explosions, see

also

Vol 1, Pt 4, Ch 2, 3.1 General.

2.7.3 The

effects of temperature on the material of the structure due to fuel

air threats are to be considered using the structure surface temperature.

2.8 Conventional explosive pressure loads

2.8.1 Blast

waves caused by free field explosions in air are dependent upon the

mass shape and type of explosive, the distance from the target and

the height of the burst. As blast waves travel through air, rapid

variations occur in pressure, density, temperature and particle velocity.

2.9 Structural assessment

2.9.1 The

rules for the EB1 and EB2 structural assessment

are based on the assumption that the structure can be idealised as

a single degree of freedom system. They assume that there is no significant

loading on the superstructure or ship’s sides at the time of

the blast. In cases where there are significant lateral loadings or

concentrated point loads or fluids, the natural frequency and strength

of the structure will be specially considered.

2.9.2 The

acceptance criteria based contained in this section assume that the

structure is loaded beyond its elastic limit but not such that significant

deformations result.

2.9.3 For

plating the thickness is not to be less than:

where

|

l |

= |

the length

of the plate panel, in metres |

|

s

|

= |

width

of the panel, in mm (short span length) |

|

σo

|

= |

yield

stress of the material, N/mm2

|

|

f

p

|

= |

plate aspect ratio factor, see

Table 2.2.2 Plate factors

|

|

fσ

|

= |

stress

factor |

| = |

1,3 for σo ≤ 300 N/mm2

|

| = |

1,2 for σo > 300 N/mm2

|

|

P

p

|

= |

the peak pressure, P

r, for the front

of the superstructure, or P

s for the top sides

and rear, as defined in Vol 1, Pt 4, Ch 2, 2.5 Blast pressure loads,

in KN/m

|

|

f

DLF

|

= |

dynamic load factor to be determined from Vol 1, Pt 6, Ch 2, 5 Dynamic loading:

|

| = |

for superstructure front and ship sides using a linearly decreasing

load with initially: |

| = |

t

1 = P

r

t

s/P

s seconds

|

| = |

if t

m determined from Vol 1, Pt 6, Ch 2, 5 Dynamic loading is greater than 1,1 P

r

t

s/P

s then f

DLF, is to be recalculated such that:

|

| = |

|

| = |

For superstructure top, sides and rear using a triangular load

with: |

| = |

t

1 = 2t

t seconds

|

| = |

t

1 = 2t

r seconds

as appropriate.

|

|

|

= |

where |

|

Pr

|

= |

peak

reflected pressure as defined in Vol 1, Pt 4, Ch 2, 2.5 Blast pressure loads 2.5.3

|

|

Ps

|

= |

stagnation

pressure, as defined in Vol 1, Pt 4, Ch 2, 2.5 Blast pressure loads 2.5.6

|

|

tm

|

= |

time

at which maximum deflection occurs |

|

tp+

|

= |

positive

blast pulse duration |

|

ts

|

= |

corresponding

time at stagnation pressure, P

s.

|

Table 2.2.2 Plate factors

| Aspect ratio (A

R)

|

f

p

|

| 1,0

|

1000

|

| 0,9

|

916

|

| 0,8

|

858

|

| 0,7

|

817

|

| 0,6

|

775

|

| <0,5

|

750

|

2.9.4 The

minimum edge through thickness area of the plate is not to be less

than:

where

|

|

= |

t, σo, l, s are

given in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.3

|

|

τo

|

= |

shear

yield stress in N/mm2

|

|

P

tm

|

= |

Pressure at the time of maximum displacement, t

m,

in kN/m2 based on assumed pressure distribution.

|

|

f

p1,f

p2

|

= |

shear load factors, given in Table 2.2.3 Plate shear factors.

|

Table 2.2.3 Plate shear factors

Aspect ratios/

|

short span sides

|

long span side

|

|

|

f

p1

|

f

p2

|

f

p1

|

f

p2

|

| 1,0

|

0,18

|

0,07

|

0,18

|

0,07

|

| 0,9

|

0,16

|

0,06

|

0,20

|

0,08

|

| 0,8

|

0,14

|

0,06

|

0,22

|

0,08

|

| 0,7

|

0,13

|

0,05

|

0,24

|

0,08

|

| 0,6

|

0,11

|

0,04

|

0,26

|

0,09

|

| 0,5

|

0,09

|

0,04

|

0,28

|

0,09

|

2.9.5 The

stiffener and plate combination is considered to be satisfactory if

the plastic modulus of the beam plate combination is greater than:

where

P

p, f

DLF, f

σ and σ

o are

given in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.3

|

Z

p

|

= |

plastic section modulus of the stiffener and attached plate,

in cm3

|

e

e

|

= |

effective

length of the beam, in metres |

|

= |

the length of the beam,

in metres |

|

fbz

|

= |

beam

support factor |

| = |

12 for fully fixed |

| = |

8 for simply supported |

|

s

|

= |

spacing

of the beams, in mm. |

2.9.6 The

maximum elastic deflection given by:

is not to be greater than

where

P

p, fDLF, s, l and l

e are given

in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.3

|

I |

= |

second

moment of inertia cm4

|

|

fbd

|

= |

beam

support factor |

| = |

384 for fully fixed |

| = |

76,8 for simply supported. |

2.9.7 The

shear area of the stiffener web is not to be less than:

where

|

|

= |

Z

p, σo, le,

l, s are given in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.3

|

|

|

= |

τo, P

tm are given in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.4

|

|

|

= |

f

s

1, f

s

2 = shear load factors, given in Table 2.2.4 Beam shear factors.

|

|

|

= |

f

b

z is given in Vol 1, Pt 4, Ch 2, 2.9 Structural assessment 2.9.5.

|

Table 2.2.4 Beam shear factors

| Beam type

|

Location

|

f

s1

|

f

s2

|

| Simply

supported

|

Both ends

|

0,39

|

0,11

|

| Fixed

ends

|

Both

ends

|

0,36

|

0,14

|

| Simple and

fixed

|

Fixed

end

|

0,43

|

0,12

|

|

|

Simple

support

|

0,26

|

0,19

|

2.9.8 Direct

calculations or analyses based on the elastoplastic or plastic response

of structure using a dynamic load factor or finite element approach

will be specially considered. The designers’ calculations are

to be submitted for approval.

2.9.9 In addition

to the assessment of plating and stiffeners, the global capability

of superstructure and above water structure are to be assessed. The

designers' calculations are to be submitted.

2.10 Design considerations

2.10.1 To

minimise the effects of external blast, protrusions from the superstructure

are to be kept to a minimum.

2.10.2 Re-entrant

corners are to be avoided, where this is impractical they are to be

covered by a blast deflecting plate, or be constructed such that the

included angle between orthogonal faces is to be as large as possible.

2.10.3 Where

the clear air gap between superstructure blocks is less than 0,1L

R, the interaction under external blast loading will be specially

considered.

|