Section

3 Internal blast

3.1 General

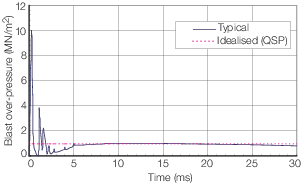

3.1.1 Internal

blast is defined as that which occurs from detonation of a high explosive

from a hostile weapon or detonation of a shipís own ammunition

inside the hull envelope. In an internal explosive loading situation

the loading on a boundary can be characterised by a series of decaying

reflected pressure waves (blast impulses) followed by the rapid formation

of a slowly decaying static pressure (Quasi static pressure QSP) as

shown in Figure 2.3.1 Typical blast pressure time history.

Figure 2.3.1 Typical blast pressure time history

3.1.2 The

magnitude of the initial blast impulse is related to the distance

from structure under consideration to the explosion. The reflections

are a function of the compartment geometry. The QSP is dependent on

the compartment volume with the rate of decay related to the vent

area.

3.2 Threat level determination

3.2.1 The

threat protection levels for a given vessel should be determined through

a vulnerability analysis against customer specified threat weapons.

In the absence of such a study the following levels may be used as

a guide:

- Level I Watertight bulkheads at R4N ≥

1 and zone bulkheads at R4N > 1

- Level II Watertight bulkheads at R4N ≥

1,5 and zone bulkheads at R4N > 2

- Level III Watertight bulkheads at R4N >

3 and zone bulkheads at R4N > 3

R4N is the normalised blast resistance 2,5 m high,

4 mm thick, mild steel, fillet welded bulkhead.

3.3 Notation assessment levels and methodology

3.3.1 The

Rules are aimed at limiting the spread of blast damage to compartments

adjacent to that directly affected by the explosion. For an explosion

where the ratio of charge size to compartment volume is small, it

may be possible to limit the damage to the affected compartment.

3.3.2 Ships

complying with the requirements of this section will be eligible for

the IB1 notation. Where further analysis or testing is

used to determine the blast resistance of the structure an IB2 notation

may be assigned.

3.3.3 For

the IB2 notation, the assumptions made for initial deformations

are to be submitted. Where these differ from normal ship building

practice, the details are to be recorded on the approved plan.

3.3.4 There

are specific scenarios such as fuel air explosions within aircraft

hangars where the internal blast wave characteristics will need to

be specially considered on request.

3.4 Materials

3.4.1 For

level III protection all plate bulkhead materials are

to have a sulphur content less than 0,01 per cent. This may be achieved

by the specification of through thickness properties in accordance

with the requirements of Ch 3, 8 Plates with specified through thickness properties of

Rules for Materials.

3.4.2 Consideration

should be given to the use of austenitic electrodes for fillet welding

of ferritic materials subject to high strain loading. In selecting

the filler material, consideration is to be given to the materialís

proof strength and elongation; the 0,2 per cent proof stress of the

filler material as welded is to match the strength of the ferritic

parent steel plate, and the elongation to failure is to be as great

as possible. Care should be taken to ensure that coatings are maintained

as far as practicable. Where such materials are in wet or immersed

areas, special attention is to be given to corrosion protection and

the selection of a material that is not prone to chemical or electro-chemical

attack. Details of the weld procedure are to be submitted for approval.

3.5 Quasi static pressure

3.5.1 Structural

failure can be caused by either the impulsive loading or the dynamic

loading imparted by the combined blast waves and QSP. Normally if

the weapon is sufficiently large to cause failure by impulse it will

also fail under a dynamic loading assessment based on a step function

to the QSP level. For the purposes of general design the step function

to the QSP level assessment can be used as the loading criteria to

determine failure. Safety or mission critical areas should be specially

considered.

3.5.2 The

actual threat level used in the calculation and areas of the ship

to be protected are to be specified by the Owner and will remain confidential

to LR.

3.5.3 The

QSP can be determined from the following:

|

Pqs

|

= |

2,25 (We

/V)0,72 x103 kN/m2

|

where

|

Pqs

|

= |

quasi static pressure, in kN/m2

|

|

We

|

= |

weapon equivalent weight of TNT, in kg |

|

V |

= |

free compartment

volume, in m3.

|

3.6 Structural resistance

3.6.1 The

blast resistance for a given bulkhead material, thickness and joint

style can be determined as a proportion of 2,5 m high, 4 mm thick,

mild steel, fillet welded bulkhead using the following formula based

on a combination of explosive tests and analytical techniques:

|

R

4N

|

= |

(K

j + K

m) t/

|

where

|

|

= |

R

4N is the normalised blast resistance

2,5 m high, 4 mm thick, mild steel, fillet welded bulkhead

|

|

|

= |

K

m is the material type factor, see

Table 2.3.1 Material type factor, K

m

|

|

|

= |

K

j is the joint type factor, see

Table 2.3.2 Joint type factor, K

j

|

|

|

= |

t is the thickness of steel, in metres

|

|

|

= |

is the short span length, in metres. is the short span length, in metres.

|

Table 2.3.1 Material type factor, K

m

| Steel grade

|

K

m

|

| A, D, E, AH32, AH36

|

0

|

| DH32, EH32

|

86

|

| DH36, EH36

|

196

|

Table 2.3.2 Joint type factor, K

j

| Joint style

|

K

j

|

Note

|

| Normal fillet weld

|

625

|

Valid up for t

bh ≤ 8 mm

|

| Full penetration weld

|

665

|

Valid for t

bh ≤ 12 mm

|

| Austenitic fillet weld

|

701

|

Valid for t

bh ≤ 6 mm

|

|

Note

Values of Kj up to 1200 can be achieved using

blast resistant bulkhead designs.

|

3.6.2 The

primary mode of failure for bulkhead structures is through the edge

connection. Alternatives to the basic fillet weld have been assessed

and incorporated in the joint type factor presented in Table 2.3.2 Joint type factor, K

j

.

3.6.3 Alternative

joint types may be used but are to be categorised using a dynamic

joint test and blast assessment. For novel designs a further large

scale controlled blast test of the proposed arrangement is to be tested.

LR can provide details of the test and analysis requirements on request.

3.7 Bulkhead arrangements

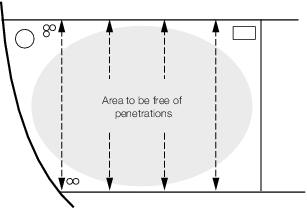

3.7.1 Piping

that passes through the bulkhead is to be fitted with expansion pieces

either side of the bulkhead. In addition, piping and other penetrations

are to be arranged at the edges of the bulkhead where the relative

movement is less as shown in Figure 2.3.2 Blast bulkhead penetrations.

Figure 2.3.2 Blast bulkhead penetrations

3.7.2 Bulkhead

attachments are to be kept to a minimum and designed for good dynamic

performance.

3.7.3 The

strength of doors if fitted will be specially considered. Steps are

to be taken to prevent their detachment from or pushing through the

surrounding structure.

3.7.4 Consideration

should be given to the use of flexible collars around deep girder

penetrations through the blast bulkhead to allow relative movement

but retain watertight or gas-tight integrity.

3.7.5 Under

blast loading, large displacements of the bulkhead may occur. Any

nearby structure or equipment is to be located so as to provide a

minimum clearance of 350 mm from the bulkhead. This distance is generally

appropriate for deck heights of between 2 m and 3 m. The minimum clearance

for other deck heights will be specifically considered.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|