Section

9 Bulwarks, guard rails, raised walkways and other means for the

protection of crew and embarked personnel

9.1 General requirements

9.1.1 Bulwarks or guard rails are to be provided at the boundaries of exposed

decks. Bulwarks or guard rails are to be not less than 1,0 m in height measured above

sheathing, and are to be constructed as required by this Section. Consideration will be

given to cases where this height would interfere with the normal operation of the ship.

Guard rails provided around aircraft operating areas may be of the type which drop

outwards with nets which are to comply with Vol 1, Pt 3, Ch 4, 9.6 Safety nets. Droppable guard rails must be capable of being secured

in both the upright and lowered position. Where bulwarks or guard rails are undesirable,

e.g. for radar signature purposes, alternative equivalent arrangements will be required.

Guidance on radar signatures is provided in Vol 1, Pt 4, Ch 1, 4.1 Radar signature.

9.1.3 Guard

rails fitted on superstructure and exposed decks are to have at least

three courses. The opening below the lowest course of guard-rails

is not to exceed 230 mm. The other courses are to be spaced not more

than 380 mm apart. In the case of ships with rounded gunwales, the

guard-rail supports are to be placed on the flat of the deck. In other

locations, guard rails with at least two courses are to be fitted.

9.1.4 Guard rails are to be fitted with fixed, removable or hinged stanchions

fitted no more than 1,5 m apart. Removable or hinged stanchions shall be capable of

being locked in the upright position. When retracted, collapsed or removed, the guard

rails are not to impede access/egress. Stowage is to be provided for portable stanchions

and stays, sited adjacent to where they are to be used.

9.1.5 At least

every third stanchion is to be supported by a stay.

9.1.6 Where

necessary for the normal operation of the ship, steel wire ropes may

be accepted in lieu of guard rails. Wires are to be made taut by means

of turnbuckles. Chains are only permitted in short lengths in way

of access openings.

9.1.7 Satisfactory means for safe passage of personnel, in the form of guard

rails, life-lines, handrails, gangways, underdeck passageways or other equivalent

arrangements, are to be provided for the protection of the crew and embarked personnel

in getting to and from their quarters, the machinery space and all other spaces used in

the operation of the ship.

9.1.8 A well

illuminated and ventilated underdeck passage (with a clear opening

at least 0,8 m in width and 2 m in height) is to be provided as close

as practicable to the weatherdeck, connecting and providing access

to the following locations:

- between superstructures;

- from the forwardmost superstructure to the forward end of the

vessel;

- from the aftmost superstructure to the aft end of the vessel.

9.1.9 A means of passage over obstructions such as pipes or other fittings of a permanent

nature is to be provided where practicable.

9.1.10 To

assist movement in adverse weather conditions, handrails are to be

fitted to bulkheads in passageways and superstructure on weatherdecks.

9.1.11 Handrails

are to be fitted at a height of not less than 1 m, measured from the

top of the rail to the deck. Handrails should be made of steel tubes

of 42,4 mm outside diameter, with a wall thickness of at least 2,6

mm.

9.1.12 Handrails

are to be secured by way of supports that are not to be spaced more

than 1,5 m apart. The supports are to hold the rails not less than

50 mm from the bulkhead, measured from the inside of the rail to the

bulkhead.

9.1.13 Raised

walkways which form escape routes or assembly areas, or provide for

the transfer of heavy equipment, stores or munitions, are to comply

with the requirements of Vol 1, Pt 3, Ch 4, 9.5 Walkways.

9.2 Bulwark construction

9.2.1 Plate

bulwarks are to be stiffened by a strong rail section and supported

by stays from the deck. The spacing of these stays forward of 0.93L

R is to be not more than 1,2 m. Elsewhere, bulwark

stays are to be not more then 1,83 m apart. Where bulwarks are cut

to form a gangway or other opening, stays of increased strength are

to be fitted at the ends of the openings. Bulwarks are to be adequately

strengthened in way of eyeplates for RAS points, and in way of mooring

pipes the plating is to be doubled or increased in thickness and adequately

stiffened.

9.2.2 Bulwarks

should not be cut for gangway or other openings near the breaks of

superstructures, and are also to be arranged to ensure their freedom

from main structural stresses. See shell plating in appropriate

Chapters.

9.2.3 The

section modulus, Z, at the bottom of the bulwark stay

is to be not less than:

|

Z

|

= |

(33,0

+ 0,44L) h

2

s cm3

|

where

|

h

|

= |

height

of bulwark from the top of the deck plating to the top of the rail,

in metres |

9.2.4 In the

calculation of the section modulus, only the material connected to

the deck is to be included. The bulb or flange of the stay may be

taken into account where connected to the deck, and where, at the

ends of the ship, the bulwark plating is connected to the sheerstrake,

a width of plating not exceeding 600 mm may also be included. The

free edge of the stay is to be stiffened.

9.2.5 Bulwark

stays are to be supported by, or to be in line with, suitable underdeck

stiffening, which is to be connected by double continuous fillet welds

in way of the bulwark stay connection.

9.3 Freeing arrangements

9.3.1 The

following requirements are applicable to all ship types.

9.3.2 Where

bulwarks on the weather decks or superstructure decks form wells,

ample provision is to be made for rapidly freeing the decks of large

quantities of water by means of freeing ports, and also for draining

them.

9.3.3 The

minimum freeing area on each side of the ship, for each well on the

weather deck is to be derived from the following formulae:

-

where the length,

l, of the bulwark in the well is 20 m or less: area required

= 0,7 + 0,035l m2

-

where the length,

l, exceeds 20 m, area required = 0,07l m2

l need not be taken greater than 0,7L

R,

where L

R is the length of the ship as defined

in Vol 1, Pt 3, Ch 1, 5.2 Principal particulars.

9.3.4 If the

average height of the bulwark exceeds 1,2 m or is less than 0,9 m,

the freeing area is to be increased or decreased, respectively, by

0,004 m2 per metre of length of well for each 0,1 m increase

or decrease in height respectively.

9.3.6 Two-thirds

of the freeing port area required is to be provided in the half of

the well nearest to the lowest point of the sheer curve.

9.3.7 When

the deck has little or no sheer, the freeing area is to be spread

along the length of the well.

9.3.8 In ships

with no sheer the freeing area as calculated from Vol 1, Pt 3, Ch 4, 9.3 Freeing arrangements 9.3.3 is to be increased by 50 per

cent. Where the sheer is less than the standard, as given in Table 4.9.1 Standard sheer profile, the percentage is to

be obtained by linear interpolation.

Table 4.9.1 Standard sheer profile

| Position from A.P.

|

Ordinate (in mm)

|

| A.P.

|

|

| 0,16L

R

|

|

| 0,33L

R

|

|

| 0,5L

R

|

0

|

| 0,67L

R

|

|

| 0,83L

R

|

|

| F.P.

|

|

Note

1. Sheer is measured from the deck at

side to a line drawn parallel to the keel through the sheer line

amidships.

Note

2. In ships with a rake of keel, the

sheer is measured in relation to a reference line drawn parallel to

the design waterline.

|

9.3.9 Where

the length of the well is less than 10 m, or where a deckhouse occupies

most of the length, the freeing port area will be specially considered

but in general need not exceed 10 per cent of the bulwark area.

9.3.10 Where

it is not practical to provide sufficient freeing port area in the

bulwark, particularly in small ships, credit can be given for bollard

and fairlead openings where these extend to the deck.

9.3.11 Where

a deckhouse has a breadth less than 80 per cent of the beam of the

ship, or the width of the side passageways exceeds 1,5 m, the arrangement

is considered as one well. Where a deckhouse has a breadth equal to

or more than 80 per cent of the beam, B, of the ship,

or the width of the side passageways does not exceed 1,5 m, or when

a screen bulkhead is fitted across the full breadth of the ship, this

arrangement is considered as two wells, before and abaft the deckhouse.

9.3.12 Suitable

provision is also to be made for the rapid freeing of water from recesses

formed by superstructures and deckhouses, etc. in which water may

be shipped and trapped. Deck gear is not to be stowed in such a manner

as to obstruct unduly the flow of water to freeing port.

9.3.13 The

lower edges of freeing ports are to be as near to the deck as practicable,

and should not be more than 100 mm above the deck.

9.3.14 Where

freeing ports are more than 230 mm high, vertical bars spaced 230

mm apart may be accepted as an alternative to a horizontal rail to

limit the height of the freeing port.

9.3.15 Where

shutters are fitted, the pins or bearings are to be of a non-corrodible

material, with ample clearance to prevent jamming. The hinges are

to be within the upper third of the port. Shutters are not to be fitted

with securing appliances.

9.3.16 All

ships are to have open rails for at least half the length of the exposed

part of the weather deck. Alternatively, if a continuous bulwark is

fitted, the minimum freeing area is to be at least 33 per cent of

the total area of the bulwark. The freeing area is to be placed in

the lower part of the bulwark.

9.3.17 In

ships having superstructures which are open at either or both ends

to wells formed by bulwarks on the open deck, adequate provision for

freeing the open spaces are to be provided as follows:

The freeing port area, A

w for the open

well:

The freeing port area, A

s for

the open superstructure:

where

|

lw

|

= |

the

length of the open deck enclosed by bulwarks, in metres. |

|

ls

|

= |

the

length of the common space within the open superstructure, in metres |

|

b

o

|

= |

breadth of openings in the end bulkhead of the enclosed superstructure,

in metres |

|

h

w

|

= |

distance of the well deck above the freeboard deck, in metres |

|

h

s

|

= |

one standard superstructure height |

|

h

b

|

= |

actual height of the bulwark, in metres |

|

A

c

|

= |

bulwark height correction factor taken as; |

| = |

0 for bulwarks between 0,9 and 1,2 m in height |

| = |

for bulwarks of height greater than 1,2 m and for bulwarks of height greater than 1,2 m and

|

| = |

for bulwarks of height greater than 0,9 m for bulwarks of height greater than 0,9 m

|

To adjust the freeing port area for the distance

of the well deck above the weatherdeck, for decks located more than

0,5h

s above the weatherdeck, multiply by the

factor 0,5 (h

s/h

w).

9.3.18 Where

a ship operates for extended periods in a cold weather environment, see

Vol 1, Pt 5, Ch 2, 4.2 Definitions 4.2.3,

closing devices fitted to freeing port arrangements are to remain

effective. The arrangement will be specially considered.

9.4 Free flow area

9.4.1 The

effectiveness of the freeing port area in bulwarks of vessels not

fitted with a continuous deck obstruction, depends on the free flow

across the deck.

9.4.2 The

free flow area is the net total longitudinal area of the transverse

passageways or gaps between hatchways and superstructures or deckhouses,

due account being made for any obstructions such as equipment or other

fittings. The height of passageways or gaps used in the calculation

of the area is the height of the bulwark.

9.5 Walkways

9.5.1 Walkways

are to be designed to an agreed specified standard.

9.5.2 Plans

are to be submitted showing the proposed scantlings and arrangements

of the structure.

9.5.4 For

the design of the supporting structure of walkways, the applicable

self weight of the walkway structure is to be added to the total load

derived in Vol 1, Pt 3, Ch 4, 9.5 Walkways 9.5.3.

9.6 Safety nets

9.6.1 Safety netting used around flight decks is to be arranged so as to safely arrest the

fall of personnel. For this purpose the netting is to be raised at the outboard edge

by an approximate angle of 10 degrees to the horizontal. The netting is to extend a

minimum of 1,25 metres in the horizontal plane. It is recommended that the outboard

edge is not above the level of the landing area but in no case is it to protrude

greater than 250mm. Materials for the netting are to be specially considered, due

consideration is to be given to the fire resistance and weathering properties.

9.6.2 The design load applied to safety nets and their supporting structure is

to be taken as 2,7kN per metre of netting acting at the centre of the net in

addition to the self-weight of the structure. The sag of the net is to be considered

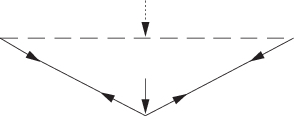

when resolving this force at the inner and outer fixings of the net, see

Figure 4.9.1 Safety netting sag. Where the netting terminates at a support, the full

load is to be applied to the support. The stress criteria to be applied for supports

and supporting structure are given in Table 4.9.2 Permissible stress.

Figure 4.9.1 Safety netting sag

Table 4.9.2 Permissible stress

|

|

Permissible stress

|

| Bending and direct stress

|

0,8σo

|

| Shear stress

|

0,5σo

|

| Combined stress

|

0,9σo

|

| Symbols

|

| σo = specified

yield stress of the material, in N/mm2

|

9.7 Ladders

9.7.1 Fixed ladders of any type are to be designed in accordance with an appropriate

recognised Standard, e.g. BSMA 39-1 Vertical steel ladders, BSMA 39-2

Sloping steel ladders.

9.7.2 Ladders may be constructed from alternative materials than those specified in the

standards for the purposes of satisfying radar signature requirements. Equivalent

levels of usability and robustness are to be demonstrated.

9.7.3 When the climbing height of a single ladder is 3m or more, fall arrest features are

to be provided. Where practicable, staging platforms are to be provided for climbing

heights in excess of 6m so as to divide the climbing height into multiple

stages.

9.8 Means of embarkation and disembarkation

9.8.2 Accommodation ladders, embarkation ladders and gangways are to be in

accordance with an appropriate recognised Standard, e.g. ISO 5488 Accommodation

ladders, ISO 5489 Embarkation ladders or ISO 7061 Shipbuilding –

aluminium shore gangways for seagoing vessels.

|