4.1.1 The

Owner is responsible for determining the level of signature control

required and agreeing any resultant design to achieve the required

levels. There are however, instances where signature levels are not

specified but good design practice may be applied. The following is

offered as guidance.

4.1.2 All

constructional details on the exposed surfaces of the hull, superstructures,

masts and equipment above the design waterline should be considered

for their radar reflection properties.

4.1.3 The

Radar Cross Section (RCS) of the ship will primarily be controlled

by shaping. This concentrates the returned energy into a small number

of narrow beams, orientated in sacrificial directions or by directing

the returned energy at an angle away from the incident energy. The

extent of the orientation of the sacrificial directions should be

agreed between the Owner and designer.

4.1.4 Appropriate

modelling tools and expert judgement should be used for RCS calculation

and assessment at various stages of the design iteration. Consideration

should also be given to the RCS measurement of equipment.

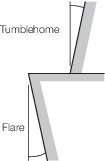

4.1.5 Flare

and tumblehome as defined in Figure 1.4.1 Radar reflection are to be used where possible on all otherwise vertical

surfaces. The angle used should be greater than 6°. Consideration

should be given to using a single or multiple elevation angles, see

Vol 1, Pt 4, Ch 1, 4.1 Radar signature 4.1.3. This practice

also eliminates the dihedral reflector potentially formed between

a horizontal and a vertical surface.

4.1.6 Orthogonal

corners give rise to high radar returns in the direction of the originating

antenna. Creating dihedral or trihedral right angled reflectors should

be avoided. This applies equally to disconnected orthogonal corners,

where two (or three) surfaces do not meet but are orthogonal and a

clear line of sight exists between them. This can include items such

as: boat bays, reception areas, superstructure overhangs, sponsons

and equipment mounts.

4.1.7 Corners

which would otherwise be orthogonal should be made non-orthogonal

by a minimum of 4°, i.e. avoiding an internal angle of between

86° and 94°. Any shaping which uses angles less than 4°

could inadvertently be made ineffective by local plate deformation

or build tolerances.

4.1.8 Where

doors providing access to the deck penetrate sloped structure, it

will be desirable for the door itself to be hung vertically on its

hinges. To achieve this it is necessary to recess the door into the

sloped plate. Where this approach is adopted, the structure of the

door recess should be made non-orthogonal by rotating the vertical

sides of the recess by a minimum of 4°.

4.1.9 Avoid

single curved surfaces (such as cylinders or cones) with diameters

greater than 30 mm. Consideration should be given to replace these

items by combinations of flat plates (with appropriate orientations),

shielding or choice of appropriate material property.

4.1.10 The

use of lattice type masts and equipment supports should be avoided.

4.1.11 Consideration

should be given to reducing the amount of clutter (microgeometry)

by design, hiding it behind bulkheads or shielding (i.e. shutters

for when equipment is not in use).

4.1.12 Where

the use of homogenous reflective material is impractical for shielding,

a mesh of electrical conductive fibres with an appropriate mesh spacing

to simulate a reflective surface over the radar frequency range of

interest can be used. This can also be applied to windows and non-structural

bulkheads. Where a mesh is applied to windows which may be used for

navigation purposes consideration should be given to the effects on

visibility.

4.1.13 The

number of external ladders should be kept to a minimum. Where they

are unavoidable, ladder uprights should be rotated to avoid forming

dihedral corners with the bulkheads on which they are mounted. As

an alternative, external ladders could be constructed from a material

translucent to radar.

4.1.14 Consideration

should be given to the use of radar absorbent materials either as

appliqués or more preferably as an inherent part of the structure

i.e. Structural Radar Absorbent Material (SRAM).

4.1.15 Composites

are generally semi-transparent to radar and therefore attention should

be paid to equipment/ structures placed behind composite structures.

Alternatively, consideration can be given to altering the composite

properties, applying a metallic backing to the composite or by using

SRAM.

Figure 1.4.1 Radar reflection