Section

2 Castings for valves, liners and bushes

2.1 Scope

2.1.1 This Section

makes provision for copper alloy castings for valves, liners, bushes

and other fittings intended for use in the construction of ships,

other marine structures, machinery and pressure piping systems.

2.1.3 As an alternative

to Ch 9, 2.1 Scope 2.1.2, castings which comply

with National or proprietary specifications may be accepted provided

that these specifications give reasonable equivalence to the requirements

of this Section or alternatively are approved for a specific application.

Generally, survey and certification are to be carried out in accordance

with the requirements of Ch 1 General Requirements.

2.2 Manufacture

2.2.1 Castings

are to be manufactured at foundries approved by LR.

2.3 Quality of castings

2.3.1 All castings

are to be free from surface or internal defects which would be prejudicial

to their proper application in service.

2.4 Chemical composition

2.4.1 The chemical

composition is to comply with the requirements of a National or International

Standard and, where appropriate, with the limits for the principal

elements of the preferred alloys listed in Table 9.2.1 Chemical compositions of long

freezing range alloys: principal elements only and Table 9.2.2 Chemical compositions of short

freezing range alloys: principal elements only.

Table 9.2.1 Chemical compositions of long

freezing range alloys: principal elements only

| Alloy

type

|

Designation

|

Chemical composition

|

Typical

applications

|

| Cu

|

Sn

|

Zn

|

Pb

|

Ni

|

P

|

| Phosphor bronze

|

Cu Sn11 P

|

87,0 –

89,5

|

10,0 –

11,5

|

0,05

max.

|

0,25

max.

|

0,10

max

|

0,5 –

1,0

|

Liners, bushes, valves and fittings

|

| Cu

Sn12

|

85,0 –

88,5

|

11,0 –

13,0

|

0,50

max.

|

0,7

max.

|

2,0

max

|

0,60

max

|

|

|

|

|

|

|

|

|

|

|

| Gunmetal

|

Cu Sn10

Zn2

|

Remainder

|

9,5 –

10,5

|

1,75 –

2,75

|

1,5

max.

|

1,0

max

|

–

|

Liners,

valves and fittings

|

|

|

|

|

|

|

|

|

|

|

| Leaded

gunmetal

|

Cu Sn5 Zn5

Pb5

|

83,0 – 87,0

|

4,0 –

6,0

|

4,0 –

6,0

|

4,0 –

6,0

|

2,0

max

|

0,10

max

|

Bushes,

valves and fittings

|

| Cu Sn7 Zn2 Pb3

|

85,0 – 89,0

|

6,0 – 8,0

|

1,5 –

3,0

|

2,5 –

3,5

|

2,0

max

|

0,10

max

|

| Cu Sn7 Zn4

Pb7

|

81,0 –

85,0

|

6,0 –

8,0

|

2,0 –

5,0

|

5,0 –

8,0

|

2,0

max

|

0,10

max

|

| Cu Sn6 Zn4

Pb2

|

86,0 –

90,0

|

5,5 –

6,5

|

3,0 –

5,0

|

1,0 –

2,0

|

1,0

max

|

0,05

max

|

|

|

|

|

|

|

|

|

|

|

| Leaded

bronze

|

Cu Sn10

Pb10

|

78,0 –

82,0

|

9,0 –

11,0

|

2,0

max.

|

8,0 –

11,0

|

2,0

max

|

0,10

max

|

Bushes

|

| Cu Sn5

Pb9

|

80,0 –

87,0

|

4,0 –

6,0

|

2,0

max.

|

8,0 –

10,0

|

2,0

max

|

0,10

max

|

| Cu Sn7

Pb15

|

74,0 –

80,0

|

6,0 –

8,0

|

2,0

max.

|

13,0 –

17,0

|

0,5 –

2,0

|

0,10

max

|

| Cu Sn5 Pb20

|

70,0 – 78,0

|

4,0– 6,0

|

2,0

max.

|

18,0 –

23,0

|

0,5 –

2,5

|

0,10

max

|

Table 9.2.2 Chemical compositions of short

freezing range alloys: principal elements only

| Alloy type

|

Designation

|

Chemical composition

|

Typical

applications

|

| Cu

|

Ni

|

Fe

|

Mn

|

Cr

|

Nb

|

Si

|

Al

|

| Copper 30%

nickel

|

Cu Ni30

Fe1 Mn1

|

64,5

min.

|

29,0–31,0

|

0,5–1,5

|

0,6–1,2

|

–

|

–

|

0,1

max.

|

–

|

Flanges, valves and fittings

|

| Cu Ni30

Fe1 Mn1 Nb Si

|

Remainder

|

29,0–31,0

|

0,5–1,5

|

0,6–1,2

|

–

|

0,5–1,0

|

0,3–0,7

|

–

|

| Cu Ni30

Cr2 Fe Mn Si (see Note)

|

Remainder

|

29,0–32,0

|

0,5–1,0

|

0,5–1,0

|

1,5–2,0

|

–

|

0,15–0,50

|

–

|

|

|

|

|

|

|

|

|

|

|

|

|

| Copper

10% nickel

|

Cu Ni10

Fe1 Mn1

|

84,5

min.

|

9,0–11,0

|

1,0–1,8

|

1,0–1,5

|

–

|

1,0

max.

|

0, 10

max.

|

–

|

Flanges,

valves and fittings

|

| Aluminium

|

Cu Al10

Fe5 Ni5

|

76,0–83,0

|

4,0–6,0

(See Note 2)

|

4,0–5,5

(See Note 2)

|

3,0

max.

|

–

|

–

|

0,1

max.

|

8,5–10,5

|

Bushes, valves and

fittings

|

| bronze

|

Cu Al11

Fe6 Ni6

|

72,0–78,0

|

4,0–7,5

(See Note 2)

|

4,0–7,0

(See Note 2)

|

2,5

max.

|

–

|

–

|

0,1

max.

|

10,0–12,0

|

Note

1. Normally alloy Cu Ni30 Cr2 Fe Mn Si

contains 0,1 to 0,25% titanium and 0,05 to 0,15% zirconium.

Note

2. For Naval ships, the nickel content is

to be higher than the iron content.

|

2.4.3 Where a cast

is wholly prepared from ingots for which an analysis is already available,

and provided that no significant alloy additions are made during melting,

the ingot maker's certified analysis can be accepted subject to occasional

check tests as requested by the Surveyor. The frequency of these check

tests should, as a minimum, be one in every ten casts. If one of these

check analyses fails to comply with the specification, checks are

to be made on the previous and subsequent melts. If one or both of

these further analyses is unsatisfactory, chemical analysis is to

be carried out on all further melts until the Surveyor is satisfied

that a return can be made to the use of occasional check tests.

2.5 Heat treatment

2.5.1 Where required

by the specification, castings may be supplied in either the `as-cast'

or heat treated condition.

2.5.2 Where castings

are supplied in a heat treated condition, the test samples are to

be heat treated with the castings they represent prior to the preparation

of the tensile test specimens.

2.6 Test material

2.6.1 Test material

sufficient for the tests specified in Ch 9, 2.6 Test material 2.6.4 and

for possible re-test purposes is to be provided for each cast of material.

2.6.2 The test

material is to be separately cast into moulds made of the same material

as that used for the castings they represent.

2.6.5 If it is

proposed to use any other form of test bar, this is to be agreed in

advance with the Surveyor.

2.6.6 As an alternative,

for liners and bushes, the test material may be taken from the ends

of the castings.

2.7 Mechanical tests

2.7.2 The results of all tests are to comply with the appropriate requirements

given in Table 9.2.3 Mechanical properties of long

freezing range alloys for acceptance purposes and Table 9.2.4 Mechanical properties of short

freezing range alloys for acceptance purposes.

Table 9.2.3 Mechanical properties of long

freezing range alloys for acceptance purposes

| Alloy type

|

Designation

|

0,2% proof stress

N/mm2

minimum

(See Note 1)

|

Tensile strength

N/mm2

minimum

|

Elongation on 5,65 % minimum % minimum

|

| Sand

|

Centrifugal

|

Sand

|

Centrifugal

|

Sand

|

Centrifugal

|

| Phosphor bronze

|

Cu Sn11

P

|

130

|

170

|

250

|

330

|

5

|

4

|

| Cu

Sn12

|

140

|

150

|

260

|

280

|

7

|

5

|

| Gunmetal

|

Cu Sn10

Zn2

|

130

|

130

|

270

|

250

|

13

|

5

|

| Leaded gunmetal

|

Cu Sn5 Zn5

Pb5

|

90

|

110

|

200

|

250

|

13

|

13

|

| Cu Sn7 Zn2

Pb3

|

130

|

130

|

230

|

260

|

14

|

12

|

| Cu Sn7 Zn4

Pb7

|

120

|

120

|

230

|

260

|

15

|

12

|

| Cu Sn6 Zn4

Pb2

|

110

|

110

|

220

|

240

|

15

|

12

|

| Leaded bronze

|

Cu Sn10

Pb10

|

80

|

110

|

180

|

220

|

8

|

6

|

| Cu Sn5

Pb9

|

60

|

90

|

160

|

200

|

7

|

6

|

| Cu Sn7

Pb15

|

80

|

90

|

170

|

200

|

8

|

7

|

| Cu Sn5

Pb20

|

70

|

80

|

150

|

170

|

5

|

6

|

Note

1. The 0,2% proof stress values are given

for information purposes only and, unless otherwise agreed, are not

required to be verified by test.

Note

2. Castings may be supplied in the chill

cast condition in which case the mechanical properties requirements

are to be in accordance with a specification agreed by LR.

|

Table 9.2.4 Mechanical properties of short

freezing range alloys for acceptance purposes

| Alloy type

|

Designation

|

0,2% proof stress

N/mm2

minimum

|

Tensile strength

N/mm2

minimum

|

Elongation on 5,65 % minimum % minimum

|

| Sand

|

Centrifugal

|

Sand

|

Centrifugal

|

Sand

|

Centrifugal

|

| Copper 30% Nickel

|

Cu Ni30 Fe1

Mn1

|

120

|

120

|

340

|

340

|

18

|

18

|

| Cu Ni30 Fe1

Mn1 Nb Si

|

230

|

–

|

440

|

–

|

18

|

–

|

| Cu Ni30 Cr2

Fe Mn Si

|

250

|

–

|

440

|

–

|

18

|

–

|

| Copper 10%

Nickel

|

Cu Ni10

Fe1 Mn1

|

120

|

100

|

280

|

280

|

20

|

25

|

| Aluminium

Bronze

|

Cu Al10

Fe5 Ni5

|

250

|

280

|

600

|

650

|

13

|

13

|

| Cu Al11 Fe6

Ni6

|

320

|

380

|

680

|

750

|

5

|

5

|

2.8 Inspection

2.8.1 All castings

are to be cleaned and adequately prepared for inspection. Before acceptance,

all castings are to be presented to the Surveyor for visual examination.

This is to include the examination of internal surfaces, where applicable.

2.8.2 For valves

and other pressure components, dye penetrant inspection is required

and the Surveyor is to witness the tests. Unless otherwise agreed,

the acceptance criteria to be applied are to meet the requirements

of Table 9.2.5 Visual and surface NDE acceptance

criteria for valves and pressure components, or equivalent.

Table 9.2.5 Visual and surface NDE acceptance

criteria for valves and pressure components

| Defect type

|

Acceptance criteria for visual

and surface NDE, see Note

|

| Linear indications

|

Not permitted

|

| Porosity

|

Individual pores are not to exceed 3 mm diameter

bleed out, and the sum of the diameters of all indications in an area of 70

x 70 mm is not to exceed 24 mm2

|

Note Inspection is to be in accordance with a procedure

acceptable to LR.

|

2.8.3 The accuracy

and verification of dimensions are the responsibility of the manufacturer.

However, the report on dimensional inspection is to be presented to

the Surveyor who may request to witness confirmatory measurements.

2.9 Rectification of defective castings

2.9.1 Subject to

the prior approval of the Surveyor, castings containing local porosity

may be rectified by impregnation with a suitable plastic filler provided

that the extent of the porosity is such that it does not adversely

affect the strength of the casting.

2.9.2 Proposals

to repair a defective casting by welding are to be submitted to the

Surveyor before this work is commenced. The Surveyor is to be satisfied

that the number, position and size of the defects are such that the

castings can be efficiently repaired.

2.9.3 Where approval

is given for the repair by welding, complete elimination of the defects

is to be proven by adequate non-destructive testing.

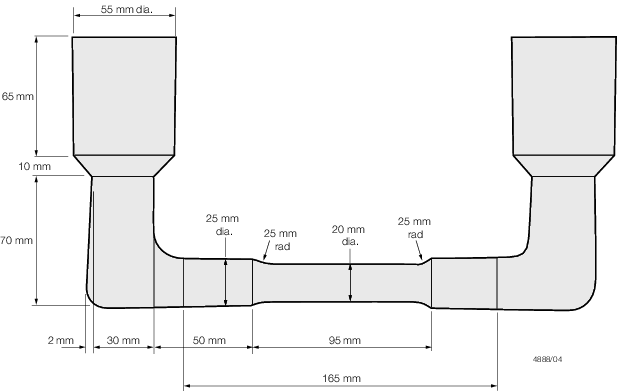

Figure 9.2.1 Sand cast test bars for long freezing range alloys

2.9.4 All welding

is to be in accordance with an approved and qualified weld procedure

and carried out by a qualified welder.

2.9.5 A statement

and/or sketch detailing the extent and position of all weld repairs

is to be prepared by the manufacturer as a permanent record. These

records are to be available for review by the Surveyor, and copies

of individual records are to be supplied to the Surveyor on request.

2.9.7 The welding

during manufacture of liners is not permitted in any alloy containing

more than 0,5 per cent lead.

2.10 Pressure testing

2.10.1 Where required

by the relevant Rules, castings are to be pressure tested before final

acceptance. Unless otherwise agreed, these tests are to be carried

out in the presence of the Surveyors and are to be to their satisfaction.

2.11 Identification

2.11.1 The manufacturer is to adopt a system of identification as per the requirements of Ch 1, 4.8 Identification of materials, which will

enable all finished castings to be traced to the original cast and the Surveyor is to be

given full facilities for tracing the castings when required.

2.11.2 Before

acceptance, all castings which have been tested and inspected with

satisfactory results are to be clearly marked by the manufacturer

with the following details:

-

Identification number,

cast number or other markings which will enable the full history of

the casting to be traced.

-

LR or Clasifications Register

and the abbreviated name of LR's local office.

-

Personal stamp of

the Surveyor responsible for inspection.

-

Test pressure, where

applicable.

-

Date of final inspection.

2.11.3 Where small

castings are manufactured in large numbers, modified arrangements

for identification may be specially agreed with the Surveyor.

2.12 Certification of materials

2.12.2 The manufacturer

is to provide the Surveyor with the following particulars for each

casting or batch of castings which has been accepted:

-

Purchaser's name and

order number.

-

Description of castings

and alloy grade.

-

Identification number.

-

Ingot or cast analysis.

-

Full details of heat

treatment, where applicable.

-

Mechanical test results.

-

Test pressure, where

applicable.

|