Section

2 Tensile tests

2.1 Dimensions of test specimens

2.1.1 Proportional

test specimens with a gauge length L

0 of  or 5d where S

o is

the cross-sectional area, d the diameter and L

C the parallel test length, have been adopted as the standard

form of test specimen, and in subsequent Chapters in these Rules the

minimum percentage elongation values are given for test specimens

of these proportions. or 5d where S

o is

the cross-sectional area, d the diameter and L

C the parallel test length, have been adopted as the standard

form of test specimen, and in subsequent Chapters in these Rules the

minimum percentage elongation values are given for test specimens

of these proportions.

2.1.2 The gauge

length is to be greater than 20 mm and may be rounded off to the nearest

5 mm provided that the difference between the adjusted gauge length

and the calculated one is less than 10 per cent of the calculated

gauge length.

2.1.7 As an alternative

to Ch 2, 2.1 Dimensions of test specimens 2.1.6, test specimens with a

width of other than 25 mm may be used subject to any requirements

for minimum cross-sectional area given in subsequent Chapters of these

Rules. A ratio of width/thickness of 8:1 should not be exceeded.

2.1.8 For pipes

and tubes, the test specimens may consist of a suitable length tested

in full cross-section with the ends plugged. The gauge length is to

be  or 50 mm, and the length of the test specimen between

the grips or plugs, whichever is the smaller, is to be not less than

the gauge length plus D, where D is the

external diameter. Alternatively, test specimens may be prepared from

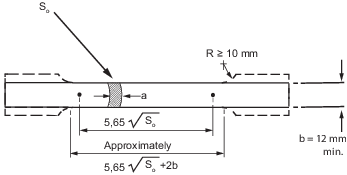

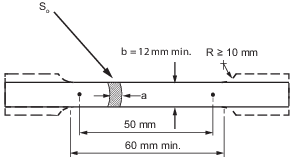

strips cut longitudinally and machined to the dimensions shown in Figure 2.2.5 Test specimen dimensions for pipes

and tubes - I or Figure 2.2.6 Test specimen dimensions for pipes

and tubes - II. The parallel test length is not to be flattened, but

the enlarged ends may be flattened for gripping in the testing machine.

The cross-sectional area of this type of test specimen is to be calculated

from: or 50 mm, and the length of the test specimen between

the grips or plugs, whichever is the smaller, is to be not less than

the gauge length plus D, where D is the

external diameter. Alternatively, test specimens may be prepared from

strips cut longitudinally and machined to the dimensions shown in Figure 2.2.5 Test specimen dimensions for pipes

and tubes - I or Figure 2.2.6 Test specimen dimensions for pipes

and tubes - II. The parallel test length is not to be flattened, but

the enlarged ends may be flattened for gripping in the testing machine.

The cross-sectional area of this type of test specimen is to be calculated

from:

where

|

S

o

|

= |

cross-sectional area |

|

a

|

= |

average

radial thickness |

|

b

|

= |

average

width |

Test specimens of circular cross-section may also be used provided

that the wall thickness is sufficient to allow the machining of such

specimens to the dimensions shown in Figure 2.2.1 Test specimen dimensions for forgings and castings - I, with their axes located at the mid-wall thickness.

Figure 2.2.5 Test specimen dimensions for pipes

and tubes - I

Figure 2.2.6 Test specimen dimensions for pipes

and tubes - II

2.1.9 For wire,

the test specimen may consist of a suitable length tested in full

cross-section. The gauge length is to be 200 mm and the parallel

test length 250 mm.

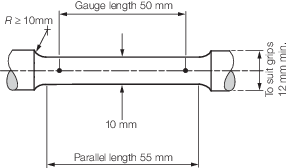

2.1.12 Deposited

weld metal tensile test specimens are to be machined to the dimensions

shown in Figure 2.2.9 Test specimen for deposited weld metal tensile, and may be

heated to a temperature not exceeding 250°C for a period not exceeding

16 hours for hydrogen removal, prior to testing.

Figure 2.2.9 Test specimen for deposited weld metal tensile

2.1.13 Butt weld

tensile test specimens are to be machined to the dimensions shown

in Figure 2.2.10 Test specimen for butt weld. For thicknesses

of more than 2 mm, the test width is to be 25 mm. For thicknesses

less than 2 mm, the test width is to be reduced to 12 mm. The upper

and lower surfaces of the weld are to be filed, ground or machined

flush with the surface of the plate.

Figure 2.2.10 Test specimen for butt weld

2.1.14 Through thickness tensile test specimens may be, at the option of the

steelmaker, either plain test specimens, or test specimens with welded extensions, in

accordance with a Recognised Standard such as EN 10164 or ASTM A770/A770M.

The extension pieces are to be of steel with a tensile strength

exceeding that of the plate to be tested and may be attached to the

plate surfaces by manual, resistance or friction welding carried out

in such a way as to ensure a minimal heat affected zone.

2.1.15 Tolerances

on tensile specimen dimensions are to be in accordance with ISO 6892-1

or another Recognised Standard as appropriate.

2.2 Definition of yield stress for steel

2.2.1 The yield

phenomenon is not exhibited by all the steels detailed in these Rules

but, except for austenitic and duplex stainless steels, the term `yield

stress' is used throughout when requirements are specified for acceptance

testing at ambient temperature. For the purposes of the Rules, the

terms `yield stress' and `yield strength' are to be regarded as synonymous.

2.2.2 Where reference

is made to `yield stress' in the requirements for carbon, carbon-manganese

and alloy steel products and in the requirements for the approval

of welding consumables, either the upper yield stress or, where this

is not clearly exhibited, the 0,2 per cent proof stress or the 0,5

per cent proof stress under load is to be determined. In cases of

dispute, the 0,2 per cent proof stress is to be determined.

2.2.3 For austenitic

and duplex stainless steel products and welding consumables, both

the 0,2 and the 1,0 per cent proof stresses are to be determined.

2.3 Procedure for testing at ambient temperature

2.3.1 Except as provided in Ch 2, 2.3 Procedure for testing at ambient temperature 2.3.5, the elastic stress rate for the determination of

the upper yield for steels is to be between 6 and 60 N/mm2 per second and

between 2 and 20 N/mm2 per second for aluminium and copper alloys. After

reaching the yield or proof load, the straining rate may be increased to a maximum of

0,008s

–1 for the determination of the tensile strength.

2.3.2 For steel,

the upper yield stress is to be calculated from:

-

the value of stress

measured at the commencement of plastic deformation, or

-

on a load/extension

diagram using the value of stress measured at the first peak obtained

during yielding even when the peak is equal to or less than any subsequent

peaks observed during plastic deformation at yield.

2.3.3 When a well

defined yield point cannot be obtained, the 0,2 or 1,0 per cent proof

stress (non-proportional elongation) is to be determined from an accurate

load/extension diagram by drawing a line parallel to the straight

elastic portion and a distance from it where the amount represents

0,2 or 1,0 per cent of the extensometer gauge length. The point of

intersection of this line with the plastic portion of the diagram

represents the proof load, from which the 0,2 or 1,0 per cent proof

stress can be calculated.

2.3.4 For stainless

steels the 1,0 per cent proof stress and/or 0,2 per cent proof stress

is specified as required by the relevant Chapters in these Rules.

2.3.5 For the determination of the tensile strength of flake graphite cast iron,

the strain rate is not to exceed 0,0067 per second.

2.4 Equivalent elongations

2.4.1 When a gauge

length other than  is used, the equivalent percentage elongation value is

to be calculated using the following formula: is used, the equivalent percentage elongation value is

to be calculated using the following formula:

where

|

A

R

|

= |

actual measured percentage elongation of test specimen |

|

S

o

|

= |

actual cross-sectional area of test specimen |

|

L

o

|

= |

actual gauge length of test piece |

|

A

|

= |

equivalent

percentage elongation for a test specimen with a gauge length of

|

2.4.2 Alternatively,

where a number of test specimens of similar material and dimensions

are involved, the actual percentage elongation values may be recorded,

provided that the equivalent specified minimum elongation value appropriate

for the test specimen dimensions is calculated from the formula in Ch 2, 2.4 Equivalent elongations 2.4.1 and is recorded on the test certificate.

2.4.4 For non-proportional test specimens with gauge lengths of 50 mm and 200 mm,

the equivalent elongation values tabulated in ISO 2566-1 are to apply. For Austenitic

steels, conversion of room temperature percentage elongations after fracture obtained on

various proportional and non-proportional gauge lengths to other gauge lengths shall be

in accordance with ISO 2566-2.

2.4.5 The above

conversions are reliable only for carbon, carbon-manganese and low

alloy steels with a tensile strength not exceeding 700 N/mm2 in

the hot rolled, annealed, normalised, or normalised and tempered condition.

2.4.7 Any proposals

to use conversion factors for equivalent elongation values for the

following materials are to be agreed with the Surveyors:

-

Carbon, carbon-manganese

and alloy steels in the normalised or normalised and tempered condition

with a tensile strength exceeding 700 N/mm2.

-

Cold-worked steels.

-

Austenitic stainless

steels.

-

Non-ferrous alloys.

2.5 Procedure for testing at elevated temperatures

2.5.1 Tensile testing

at elevated temperatures is to be carried out according to ISO 6892-2

Method B or an equivalent National Standard.

|