Section

5 Wires and wire-gas combinations for manual, semi-automatic and

automatic welding

5.1 General

5.1.1 Wire-gas

combinations and flux-cored or flux-coated wires (for use with or

without a shielding gas) are divided into the following categories

for the purposes of approval testing:

-

For use in manual

multi-run welding with the inert gas tungsten arc welding process

(GTAW).

-

For use in semi-automatic

multi-run metal arc welding.

-

For use in single

electrode multi-run automatic metal arc and GTAW welding.

-

For use in single

electrode two-run automatic metal arc and GTAW welding.

5.1.2 The term

`manual' is used to describe the technique where the gas-shielded

tungsten arc torch is held in one hand and the filler is added separately

by the other hand.

5.1.3 The term

`semi-automatic' is used to describe processes in which the weld is

made manually by a welder holding a gun through which the wire is

continuously fed.

5.1.4 In the GTAW

process, `automatic' refers to the fully mechanized control and application

of both torch and separate filler wire.

5.1.6 A suffix

S will be added after the grade mark to indicate approval for semi-automatic

multi-run welding.

5.1.7 For wires

intended for automatic welding, the suffixes T or M will be added

after the grade mark to indicate approval for two-run or multi-run

welding techniques, respectively.

5.1.8 For wires

intended for both semi-automatic and automatic welding, the suffixes

will be added in combination.

5.1.9 Solid wire-gas

combinations are considered naturally low hydrogen in character and

qualify for `H15' approval without testing. This is not so for cored

wires and continuous coated wires which must be tested if there is

a need for low hydrogen approval. For the lower strength grades of

steel, low hydrogen testing is not normally a requirement for approval.

With higher strength steels, it is more important and Table 11.5.1 Minimum low hydrogen approval

requirements for wires and wire-gas combinations shows the mandatory minimum

low hydrogen status required for approval of wire-gas combinations.

5.1.10 The testing

methods to be used for low hydrogen approval are to be in accordance

with Ch 11, 3.4 Hydrogen test, modified to use the manufacturer's

recommended welding conditions and adjusting the deposition rate to

give a weld deposit weight per sample similar to that deposited when

using manual electrodes.

5.1.11 Where

applicable, the approved combination will name either the specific

gas composition or its trade name, but in either case the composition

of the shielding gas is to be reported. Unless otherwise agreed, additional

approval tests are required when a shielding gas is used other than

that used for the original approval tests. However a wire and gas

combination approved with an argon/carbon dioxide shielding gas where

the carbon dioxide is between 15-25 per cent is also approved for

other combinations of argon/carbon dioxide, provided the carbon dioxide

content is within the range 15-25 per cent. The range of approval

is limited to ferritic consumables in solid wire, flux cored and coated

wire forms and subject to the agreement of the consumable manufacturer

and LR.

5.1.12 Wires

and wire-gas combinations for multiple electrode automatic welding

will be subject to separate approval tests. Any proposals are to be

submitted for consideration.

5.1.13 Wires

and wire-gas combinations approved with multi-run technique for normal

and higher strength levels up to and including 'Y' are also considered

suitable for welding steels in the three strength levels below that

for which they have been approved.

5.1.14 Wires

and wire-gas combinations approved with multi-run technique for strength

levels Y40 to Y50, but excluding Y47 are also considered suitable

for welding steels in two strength levels below that for which they

have been approved.

5.1.15 Wires

and wire-gas combinations approved with multi-run technique for strength

levels Y47, Y55 and above are also considered suitable for welding

steels in only one strength level below that for which they have been

approved.

5.1.16 Wires and wire-gas combinations approved with multi-run technique for strength level Y89

are considered suitable for welding steels only in this strength level.

5.1.17 Wires and wire-gas combinations approved with multi-run technique for strength level Y96

are also considered suitable for welding steels in one strength level below that for

which they have been approved.

5.1.18 Wires

and wire-gas combinations with two-run technique approval are not

considered suitable for welding steels of any other strength level

with that technique, see

Ch 11, 5.4 Approval tests for two-run automatic welding 5.4.1.

Table 11.5.1 Minimum low hydrogen approval

requirements for wires and wire-gas combinations

| Approval

grades

|

'H' grade for m and S

techniques

|

'H' grade

for M technique

|

'H' grade

for T technique

|

| 1 (1N), 2

(2N), 3 (3N)

|

NR

|

NR

|

NR

|

| 1Y, 2Y, 3Y,

4Y

|

H15

(see Note 2)

|

NR

|

NR

|

| 2Y40 to

5Y40

|

H15

|

H15

|

NR

|

| 3Y47

|

H10

|

H10

|

H10

|

| 3Y42 to 5Y42

|

H10

|

H10

|

H15

|

| 3Y46 to

5Y46

|

H10

|

H10

|

H15

|

| 3Y50 to 5Y50

|

H10

|

H10

|

H10

|

| 3Y55 to

5Y55

|

H5

|

H5

|

H10

|

| 3Y62 to 5Y62

|

H5

|

H5

|

H5

|

| 3Y69 to

5Y69

|

H5

|

H5

|

H5

|

| 3Y89 to

4Y89

|

H5

|

H5

|

H5

|

| 3Y96 to

4Y96

|

H5

|

H5

|

H5

|

1  Ni Ni

|

H15

|

H15

|

NR

|

2 Ni Ni

|

H15

|

H15

|

NR

|

3 Ni Ni

|

H15

|

H15

|

NR

|

| 5 Ni

|

NR

(see Note 3)

|

NR

|

NR

|

| 9 Ni

|

NR (see Note 3)

|

NR

|

NR

|

Note

1. NR – Not required. Approval may be

obtained when requested.

Note

2. Optional in this case. If low hydrogen

approval is not obtained, there is a limitation on the carbon

equivalent of the steel which is permitted to be welded.

Note

3. Assumes use of an austenitic,

non-transformable, filler material.

|

5.2 Approval tests for manual and semi-automatic multi-run welding

5.2.2 Two deposited

metal test assemblies are to be prepared in the downhand position

as shown in Figure 11.3.1 Deposited metal test assembly, one using

the smallest diameter, and the other using the largest diameter of

wire for which approval is required. Where only one diameter is manufactured,

only one deposited metal assembly is to be prepared.

5.2.4 The weld

metal is to be deposited according to the practice recommended by

the manufacturer, and the thickness of each layer of weld metal is

to be between 2 mm and 6 mm, unless it is clearly stated as part of

the consumable manufacturer's published recommendations.

5.2.5 The chemical

analysis of the deposited weld metal in each test assembly is to be

supplied by the manufacturer and is to include the content of all

significant alloying elements. The results of the analysis are not

to exceed the limit values specified in the standards or by the manufacturer,

the narrower tolerances being applicable in each case.

5.2.6 Butt weld

assemblies as shown in Figure 11.3.2 Butt weld test assembly are

to be prepared for each welding position for which the wire is to

be approved. In the case of approvals for normal and higher strength

steels (up to 355 N/mm2 minimum specified yield strength),

tests satisfying the requirements in both the downhand and vertical-upward

positions will be considered as having also satisfied the requirements

for the horizontal-vertical position. In all other cases, approval

in the horizontal-vertical position will require a butt weld to be

made in that position and be fully tested.

5.2.7 The downhand

assembly is to be welded using, for the first run, wire of the smallest

diameter to be approved and, for the remaining runs, wire of the largest

diameter to be approved.

5.2.8 Where approval

is requested only in the downhand position, an additional butt weld

assembly is to be prepared in that position using, if possible, wires

of different diameter from those required by Ch 11, 5.2 Approval tests for manual and semi-automatic multi-run welding 5.2.7. If only one wire diameter is to be approved, this second

downhand butt weld should be made using either larger or smaller beads

than the first assembly.

5.2.9 The butt

weld assemblies, in positions other than downhand, are to be welded

using, for the first run, wire of the smallest diameter to be approved,

and for the remaining runs, the largest diameter of wire recommended

by the manufacturer for the position concerned.

5.3 Approval tests for multi-run automatic welding

5.3.7 At the discretion

of LR, wires approved for semi-automatic welding in the downhand position

may also be approved without additional tests, for use in multi-run

automatic welding.

5.4 Approval tests for two-run automatic welding

5.4.3 If approval

is requested for welding plate thicker than 25 mm, one assembly is

to be prepared using plates approximately 20 mm in thickness and the

other using plates of the maximum thickness for which approval is

requested.

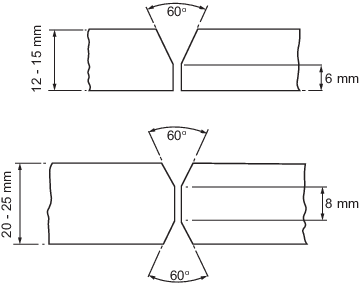

5.4.4 The edge

preparation of the test assemblies is to be as shown in Figure 11.5.1 Normal edge preparation for

two-run butt weld test assemblies. Small deviations in edge

preparation may be allowed, if these form part of the consumable manufacturer's

recommendations. For assemblies using plates over 25 mm in thickness,

the edge preparation is to be reported for information.

5.4.5 The diameters

of wires used are to be in accordance with the recommendations of

the manufacturer and are to be reported.

5.4.7 The weld

metal chemical analysis is to be reported as in Ch 11, 4.6 Butt weld test assemblies (two-run technique) 4.6.9. The results of the analysis are

not to exceed the limit values specified in the standards or by the

manufacturer, the narrower tolerances being applicable in each case.

Figure 11.5.1 Normal edge preparation for

two-run butt weld test assemblies

5.5 Annual tests

|