Section

3 Electrodes for manual and gravity welding

3.1 Grading

3.1.2 Approval

of an electrode will be given in conjunction with a welding technique

indicated by a suffix `m' for manual welding, `G' for gravity or contact

electrode and `p' for deep penetration electrode.

3.1.3 If the electrodes

are in compliance with the requirements of the hydrogen test given

in Ch 11, 3.4 Hydrogen test, a suffix `H15' or `H10'

or `H5' will be added to the grade mark. Table 11.3.1 Minimum low hydrogen approval

requirements for manual and gravity electrodes shows the mandatory levels of low hydrogen approval

for the various approval grades.

Table 11.3.1 Minimum low hydrogen approval

requirements for manual and gravity electrodes

| Approval grades

|

Low hydrogen grade required

|

| 1 (1N), 2

(2N), 3 (3N)

|

NR

|

| 2Y, 3Y, 4Y

|

H15 (see Note

2)

|

| 2Y40 to

5Y40

|

H15

|

| 3Y47

|

H10

|

| 3Y42 to 5Y42

|

H10

|

| 3Y46 to

5Y46

|

H10

|

| 3Y50 to 5Y50

|

H10

|

| 3Y55 to

5Y55

|

H5

|

| 3Y62 to 5Y62

|

H5

|

| 3Y69 to

5Y69

|

H5

|

| 3Y89 to

4Y89

|

H5

|

| 3Y96 to

4Y96

|

H5

|

1 Ni Ni

|

H15

|

2 Ni Ni

|

H15

|

3 Ni Ni

|

H15

|

| 5 Ni

|

NR

(see Note 3)

|

| 9 Ni

|

NR (see Note 3)

|

Note

1. NR – Not required. Approval may be

obtained when requested.

Note

2. Optional in this case. If low hydrogen

approval is not obtained, there is a limitation on the carbon

equivalent of the steel which is permitted to be welded.

Note

3. Assumes use of an austenitic,

non-transformable, filler material.

|

3.1.4 For each

strength level, electrodes which have satisfied the requirements for

a higher toughness grade are considered as complying with the requirements

for a lower grade.

3.1.5 Electrodes

approved for normal and higher strength levels up to and including

'Y' are also considered suitable for welding steels in the three strength

levels below that for which they have been approved.

3.1.6 Electrodes

approved for strength levels Y40 to Y50, but excluding Y47 are also

considered suitable for welding steels in two strength levels below

that for which they have been approved.

3.1.7 Electrodes

approved for strength levels Y47, Y55 and above are also considered

suitable for welding steels in only one strength level below that

for which they have been approved.

3.1.8 Electrodes approved for strength level Y89 are considered suitable for this strength

level only.

3.1.9 Electrodes approved for strength level Y96 are also considered suitable for welding

steels in one strength level below that for which they have been approved.

3.1.10 The welding

current used is to be within the range recommended by the manufacturer

and, where an electrode is stated to be suitable for both a.c. and

d.c., a.c. is to be used for the preparation of the test assemblies.

3.2 Deposited metal test assemblies

3.2.3 The weld

metal is to be deposited in single- or multi-run layers according

to normal practice, and the direction of deposition of each layer

is to alternate from each end of the plate, each run of weld metal

being not less than 2 mm and not more than 4 mm thick. Between each

run, the assembly is to be left in still air until it has cooled to

less than 250°C, the temperature being taken in the centre of

the weld, on the surface of the seam. After being welded, the test

assemblies are not to be subjected to any heat treatment, except in

those higher strength grades where it is considered necessary to use

the welded joint in the stress-relieved (tempered) condition. In those

cases, the code `sr' will be added to the approval grading.

3.2.4 The chemical

analysis of the deposited weld metal in each deposited metal test

assembly is to be supplied by the manufacturer and is to include the

content of all significant alloying elements. The results of the analysis

are not to exceed the limit values specified in the standards or by

the manufacturer, the narrower tolerances being applicable in each

case.

3.2.5 One tensile

and three impact test specimens are to be taken from each test assembly

as shown in Figure 11.3.1 Deposited metal test assembly. Care

is to be taken that the axis of the tensile test specimen coincides

with the centre of the weld and the mid-thickness of the plates. The

impact test specimens are to be cut perpendicular to the weld, with

their axes 10 mm from the upper surface. The notch is to be positioned

in the centre of the weld and cut in the face of the test specimen

perpendicular to the surface of the plate.

3.2.6 The results

of all tests are to comply with the requirements of Table 11.3.2 Requirements for deposited metal

tests (covered electrodes) as appropriate.

Table 11.3.2 Requirements for deposited metal

tests (covered electrodes)

| Grade (see Note 3)

|

Yield stress

N/mm2 minimum

|

Tensile strength

N/mm2

(see Note 1)

|

Elongation

on 50 mm % minimum

|

Charpy V-notch impact tests

|

| Test temperature °C

|

Average

energy

(see Note 2)

J minimum

|

| 1N, 2N, 3N

|

305

|

400 – 560

|

22

|

+20, 0, –20

|

47

|

|

|

|

|

|

|

|

| 1Y, 2Y, 3Y, 4Y

|

375

|

490 – 660

|

22

|

+20, 0, –20,

–40

|

47

|

|

|

|

|

|

|

|

| 2Y40, 3Y40, 4Y40,

5Y40

|

400

|

510 – 690

|

22

|

0, –20, –40,

–60

|

47

|

| 3Y47

|

460

|

570 – 720

|

19

|

–20

|

64

|

| 3Y40

|

400

|

510 –

690

|

22

|

–20

|

47

|

| 3Y42

|

420

|

520 –

680

|

20

|

–20

|

47

|

| 3Y46

|

460

|

540 –

720

|

20

|

–20

|

47

|

| 3Y50

|

500

|

590 –

770

|

18

|

–20

|

50

|

| 3Y55

|

550

|

640 –

820

|

18

|

–20

|

55

|

| 3Y62

|

620

|

700 –

890

|

18

|

–20

|

62

|

| 3Y69

|

690

|

770 – 940

|

17

|

–20

|

69

|

| 3Y89

|

890

|

940 –1100

|

14

|

–20

|

69

|

| 3Y96

|

960

|

980 –1150

|

13

|

–20

|

69

|

| 4Y40

|

400

|

510 –

690

|

22

|

–40

|

47

|

| 4Y42

|

420

|

520 –

680

|

20

|

–40

|

47

|

| 4Y46

|

460

|

540 –

720

|

20

|

–40

|

47

|

| 4Y50

|

500

|

590 –

770

|

18

|

–40

|

50

|

| 4Y55

|

550

|

640 –

820

|

18

|

–40

|

55

|

| 4Y62

|

620

|

700 –

890

|

18

|

–40

|

62

|

| 4Y69

|

690

|

770 – 940

|

17

|

–40

|

69

|

| 4Y89

|

890

|

940 – 1100

|

14

|

–40

|

69

|

| 4Y96

|

960

|

980 – 1150

|

13

|

–40

|

69

|

| 5Y40

|

400

|

510 –

690

|

22

|

–60

|

47

|

| 5Y42

|

420

|

520 –

680

|

20

|

–60

|

47

|

| 5Y46

|

460

|

540 –

720

|

20

|

–60

|

47

|

| 5Y50

|

500

|

590 –

770

|

18

|

–60

|

50

|

| 5Y55

|

550

|

640 –

820

|

18

|

–60

|

55

|

| 5Y62

|

620

|

700 –

890

|

18

|

–60

|

62

|

| 5Y69

|

690

|

770 – 940

|

17

|

–60

|

69

|

| 11/2Ni

|

375

|

490 –

640

|

22

|

–80

|

34

|

| 21/4Ni

|

375

|

490 –

640

|

22

|

–90

|

34

|

| 31/2Ni

|

375

|

490 –

610

|

25

|

–100

|

34

|

| 5

Ni

|

400

|

540 –

740

|

25

|

–120

|

34

|

| 9 Ni

|

400

|

640 – 790

|

25

|

–196

|

34

|

Note

1. Single values are the minimum

requirements.

|

|

|

|

|

3.3 Butt weld test assemblies

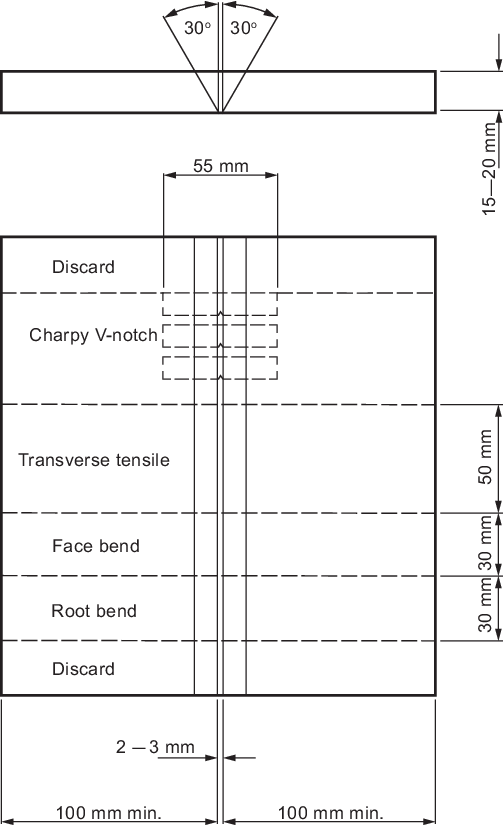

3.3.1 Butt weld

assemblies, as shown in Figure 11.3.2 Butt weld test assembly,

are to be prepared for each welding position (downhand, horizontal-vertical,

vertical-upward, vertical-downward, and overhead) for which the electrode

is recommended by the manufacturer. In the case of electrodes for

normal strength and higher strength steels (up to 355 N/mm2 minimum

specified yield strength), electrodes satisfying the requirements

for downhand and vertical-upward positions will be considered as also

complying with the requirements for the horizontal-vertical position.

In all other cases, approval for the horizontal-vertical position

will require a butt weld to be made in that position and fully tested.

Figure 11.3.2 Butt weld test assembly

3.3.3 Where the

electrode is to be approved only in the downhand position, an additional

test assembly is to be prepared in that position.

3.3.4 The grades

of steel used for the preparation of the test assemblies are to be

as follows:

| Grade 1 (1N) electrodes

|

A

|

| Grade 2 (2N) electrodes

|

A, B or D

|

| Grade 3 3(N) electrodes

|

A, B, D or E

|

| Grade 2Y electrodes

|

AH32, AH36, DH32 or DH36

|

| Grade 3Y electrodes

|

AH32, AH36, DH32, DH36, EH32 or

EH36

|

| Grade 4Y electrodes

|

AH32

AH36, DH32, DH36,

EH32, EH36, FH32 or FH36

|

| Grade 2Y40 electrodes

|

AH40 or DH40

|

| Grade 3Y40 electrodes

|

AH40, DH40 or EH40

|

| Grade 4Y40 electrodes

|

AH40, DH40, EH40 or FH40

|

| Grade 5Y40

electrodes

|

AH40, DH40, EH40 or

FH40

|

| Grade 3Y47 electrodes

|

EH47

|

Where Grade 32 higher tensile steel

is used, the tensile strength is to be not less than 490 N/mm2.

The chemical composition, including the content of grain refining

elements, is to be reported in all cases where higher tensile steel

is used.

3.3.6 The test

assemblies are to be made by welding together two plates of equal

thickness (15 to 20 mm), not less than 100 mm in width and of sufficient

length to allow the cutting out of test specimens of the prescribed

number and size. The plate edges are to be prepared to form a single

V-joint, the included angle between the fusion faces being 60°

and the root gap 2 to 3 mm. The root face is to be 0 to 2 mm.

3.3.7 The following

welding procedure is to be adopted in making the test assemblies:

Downhand (a). The first run with 4 mm

diameter electrode. Remaining runs (except the last two layers) with

5 mm diameter electrodes or above according to the normal welding

practice with the electrodes. The runs of the last two layers with

the largest diameter of electrode manufactured or 8 mm whichever is

the lesser.

Downhand (b) (where

a second downhand test is required). First run with 4 mm diameter

electrode. Next run with an electrode of intermediate diameter of

5 mm or 6 mm, and the remaining runs with the largest diameter

of electrode manufactured or 8 mm whichever is the lesser.

Horizontal-vertical. First run with 4 mm or

5 mm diameter electrode. Subsequent runs with 5 mm diameter electrodes.

Vertical-upward and overhead. First

run with 3,25 mm diameter electrode. Remaining runs with 4 mm diameter

electrodes or possibly with 5 mm if this is recommended by the manufacturer

for the positions concerned.

Vertical-downward. If the electrode being tested is intended for vertical welding

in the downward direction, this technique is to be adopted for the

preparation of the test assembly using electrode diameters as recommended

by the manufacturer.

3.3.8 For all

assemblies, the back sealing runs are to be made with 4 mm diameter

electrodes in the welding position appropriate to each test sample,

after cutting out the root run to clean metal. For electrodes suitable

for downhand welding only, the test assemblies may be turned over

to carry out the back sealing run.

3.3.9 Normal welding

practice is to be used and, between each run, the assembly is to be

left in still air until it has cooled to less than 250°C, the

temperature being taken in the centre of the weld, on the surface

of the seam. After being welded, the test assemblies are not to be

subjected to any heat treatment, except in those higher strength grades

where it is considered necessary to use the welded joint in the stress-relieved

(tempered) condition. In those cases, the code `sr' will be added

to the approval grading.

3.3.10 It is

recommended that the welded assemblies be subjected to a radiographic

examination to ascertain if there are any defects in the weld prior

to the preparation of test specimens.

3.3.12 The results

of all tensile and impact tests are to comply with the requirements

of Table 11.3.3 Requirements for butt weld tests

(covered electrodes) as appropriate.

The position of fracture in the transverse tensile test is to be reported.

Table 11.3.3 Requirements for butt weld tests

(covered electrodes)

| Grade (see Note

3)

|

Tensile

strength

N/mm2

|

Bend test ratio:

|

Charpy V-notch impact tests

|

Test

temperature

°C

|

Average

energy

(see Note 1)

J minimum

|

All

positions

(see Note 2)

|

| 1N, 2N, 3N

|

400

|

3

|

+20, 0,

–20

|

47 (34)

|

|

|

|

|

|

|

| 1Y, 2Y, 3Y, 4Y

|

490

|

3

|

+20, 0,

–20, –40

|

47 (34)

|

|

|

|

|

|

|

| 2Y40, 3Y40, 4Y40,

5Y40

|

510

|

3

|

0, –20,

–40, –60

|

47 (39)

|

| 3Y47

|

570 - 720

|

4

|

–20

|

64

|

| 3Y40

|

510

|

3

|

–20

|

47

(39)

|

| 3Y42

|

520 –

680

|

4

|

–20

|

47

|

| 3Y46

|

540 –

720

|

4

|

–20

|

47

|

| 3Y50

|

590 –

770

|

4

|

–20

|

50

|

| 3Y55

|

640 –

820

|

5

|

–20

|

55

|

| 3Y62

|

700 –

890

|

5

|

–20

|

62

|

| 3Y69

|

770 – 940

|

5

|

–20

|

69

|

| 3Y89

|

940

|

6

|

–20

|

69

|

| 3Y96

|

980

|

7

|

–20

|

69

|

| 4Y40

|

510

|

3

|

–40

|

47

(39)

|

| 4Y42

|

520 –

680

|

4

|

–40

|

47

|

| 4Y46

|

540 –

720

|

4

|

–40

|

47

|

| 4Y50

|

590 –

770

|

4

|

–40

|

50

|

| 4Y55

|

640 –

820

|

5

|

–40

|

55

|

| 4Y62

|

700 –

890

|

5

|

–40

|

62

|

| 4Y69

|

770 – 940

|

5

|

–40

|

69

|

| 4Y89

|

940

|

6

|

–40

|

69

|

| 4Y96

|

980

|

7

|

–40

|

69

|

| 5Y40

|

510

|

3

|

–60

|

47

(39)

|

| 5Y42

|

520 –

680

|

4

|

–60

|

47

|

| 5Y46

|

540 –

720

|

4

|

–60

|

47

|

| 5Y50

|

590 –

770

|

4

|

–60

|

50

|

| 5Y55

|

640 –

820

|

5

|

–60

|

55

|

| 5Y62

|

700 –

890

|

5

|

–60

|

62

|

| 5Y69

|

770 –

940

|

5

|

–60

|

69

|

| 11/2Ni

|

490

|

3

|

–80

|

27

|

| 21/4Ni

|

490

|

3

|

-90

|

27

|

| 31/2Ni

|

490

|

3

|

–100

|

27

|

| 5

Ni

|

540

|

4

|

–120

|

27

|

| 9 Ni

|

640

|

4

|

–196

|

27

|

Note

2. Values in ( ) apply only to welds made

in the vertical position with upward progression.

|

3.3.13 The bend

test specimens can be considered as complying with the requirements

if, after bending, no crack or other open defect exceeding 3 mm in

dimensions can be seen on the outer surface.

3.4 Hydrogen test

3.4.1 The hydrogen gradings are specified in Ch 11, 3.1 Grading 3.1.3. The hydrogen grading required determines the method

of testing permitted as shown in Table 11.3.4 Permitted methods for obtaining

low hydrogen grading. Four test specimens are to be prepared and

tested, and all four hydrogen test results must be below the maximum value for the

hydrogen mark required.

Table 11.3.4 Permitted methods for obtaining

low hydrogen grading

| Hydrogen Grade

|

Permitted

Method

|

| H15

|

ISO 3690

(Mercury or Thermal Conductivity Detector Method) Or Glycerine (See

Note)

|

| H10

|

ISO 3690

(Mercury or Thermal Conductivity Detector Method)

|

| H5

|

ISO 3690 (Mercury or

Thermal Conductivity Detector Method)

|

Note ISO method preferred.

|

3.4.2 The minimum holding time at a given test temperature for Thermal Conductivity Method

should be as shown in Table 11.3.5 Temperature and minimum holding time.

Table 11.3.5 Temperature and minimum holding time

| Measuring Method

|

Test Temperature

(°C)

|

Minimum Holding

Time (h)

|

| Thermal Conductivity Method (see Note 1)

|

Gas

Chromatography

|

45

|

72

|

| 150

|

6

|

|

Note 1. The use of hot carrier gas extraction method will be specially

considered subject to verification of testing procedure to confirm that

collection and measurement of the hydrogen occurs continuously until all

the diffusible hydrogen is quantified.

|

3.5 Fillet weld test assemblies

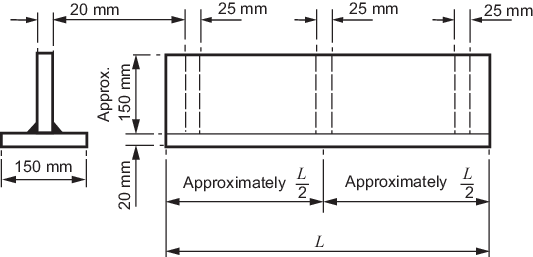

3.5.1 Fillet weld

assemblies as shown in Figure 11.3.4 Fillet weld test assembly are

to be prepared for each welding position (horizontal-vertical, vertical-upward,

vertical-downward or overhead) for which the electrode is recommended

by the manufacturer. The grade of steel used for the test assemblies

is to be as detailed in Ch 11, 3.3 Butt weld test assemblies 3.3.4.

The length of the test assembly, L, is to be sufficient

to allow at least the deposition of the entire length of the largest

diameter electrode being tested. Where an electrode is submitted for

approval of both butt and fillet welding, approval tests are to include

the deposited metal tests as given in Ch 11, 3.2 Deposited metal test assemblies,

the butt weld tests as given in Ch 11, 3.3 Butt weld test assemblies,

and only one fillet weld test as given in subsequent paragraphs of

this sub-Section welded in the horizontal-vertical position.

Figure 11.3.4 Fillet weld test assembly

3.5.3 The electrode

sizes to be used are the maximum and minimum diameters recommended

by the manufacturer for fillet welding. The first side is to be welded

using the maximum diameter. The second side is to be welded only after

the assembly has been allowed to cool below 50°C using the minimum

diameter. The size of these single run fillet welds will, in general,

be determined by the electrode size and the welding current employed

during testing and should represent the range of fillet weld bead

sizes recommended by the manufacturer.

3.5.4 Each test

assembly is to be sectioned to form three macro-sections, each about

25 mm thick. These are to be examined for root penetration, satisfactory

profile, freedom from cracking and reasonable freedom from porosity

and slag inclusions. Any undercut is not to exceed 0,5 mm in depth.

Convexity or concavity of the profile is not to exceed one-tenth of

the fillet bead throat dimension. All such observations are to be

reported.

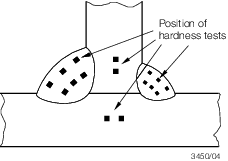

Figure 11.3.5 Hardness tests for fillet weld test assembly

3.5.6 One of the

remaining sections of the assembly is to have the weld on the first

side gouged or machined to facilitate breaking the fillet weld on

the second side by closing the two plates together, subjecting the

root of the weld to tension. On the other remaining section, the weld

on the second side is to be gouged or machined and the section fractured

using the same procedure. The fractured surfaces are to be examined.

They are to show satisfactory penetration, freedom from cracks and

reasonable freedom from porosity and this should be reported.

3.6 Electrodes designed for deep penetration welding

3.6.2 Electrodes

designed solely for the deep penetration welding technique will be

approved as complying with Grade 1 requirements only and will be given

the suffix `p'.

3.6.5 Electrodes

approved for both normal and deep penetration welding will have the

suffix 'p' added after the appropriate grade mark for normal penetration

welding.

3.6.6 Where the

manufacturer prescribes a different welding current and procedure

for the electrode when used as a deep penetration electrode and a

normal penetration electrode, the recommended current and procedure

are to be used when making the test assemblies in each case.

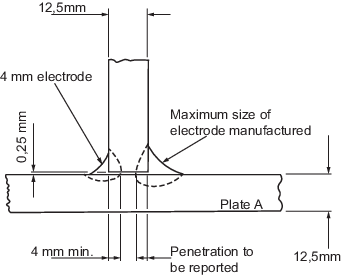

3.7 Deep penetration butt weld test assemblies

3.7.1 Two plates

of thickness equal to twice the diameter of the core of the electrode

plus 2 mm are to be butt welded together with one downhand run of

welding from each side. The plates are to be not less than 100 mm

wide and of sufficient length to allow the cutting out of the test

specimens of the correct number and size as shown in Figure 11.3.6 Deep penetration butt weld test

assembly. Grade A steel is to be

used for these test assemblies. The joint edges are to be prepared

square and smooth and, after tacking, the gap is not to exceed 0,25

mm. The test assembly is to be welded using an 8 mm diameter electrode,

or the largest diameter manufactured if this is less than 8 mm and

the assembly is to be allowed to cool below 50°C between runs.

3.7.4 The discards

at the end of the welded assemblies are to be not more than 35 mm

wide. The joints of these discards are to be polished and etched and

must show complete fusion and inter-penetration of the weld beads.

At each cut in the test assembly, the joints are also to be examined

to ensure that complete fusion has taken place.

3.8 Deep penetration fillet weld test assemblies

3.8.1 A fillet

weld assembly is to be prepared as shown in Figure 11.3.7 Deep penetration fillet weld test

assembly with plates about 12,5 mm in thickness. The welding

is to be carried out with one run for each fillet with plate A in

the horizontal plane during the welding operations. The length of

the fillet is to be 160 mm and the gap between the plates is to be

not more than 0,25 mm. Grade A steel is to be used for these test

assemblies.

Figure 11.3.7 Deep penetration fillet weld test

assembly

3.8.2 The fillet

weld on one side of the assembly is to be carried out with a 4 mm

diameter electrode, and that on the other side with the maximum diameter

of electrode manufactured. The welding current used is to be within

the range recommended by the manufacturer, and the welding is to be

carried out using normal welding practice except that the assembly

is to be allowed to cool below 50°C between runs.

3.8.3 The welded

assembly is to be cut by sawing or machining within 35 mm of the ends

of the fillet welds, and the joints are to be polished and etched.

The welding of the fillet made with a 4 mm diameter electrode is to

show a penetration of 4 mm (see

Figure 11.3.7 Deep penetration fillet weld test

assembly) and the corresponding penetration of the fillet

made with the maximum diameter of electrode manufactured is to be

reported.

3.9 Electrodes designed for gravity or contact welding

3.9.1 Approval

for welding using the gravity, `G', technique is available for welding

only normal strength and higher tensile steels up to and including

Grade 36.

3.9.2 Where an

electrode is submitted solely for approval for use in contact welding

using automatic gravity or similar welding devices, deposited metal

tests, butt weld tests and, where appropriate, fillet weld tests similar

to those for normal manual electrodes are to be carried out using

the process for which the electrode is recommended by the manufacturer.

3.9.3 Where an

electrode is submitted for approval for use in contact welding using

automatic gravity or similar welding devices in addition to normal

manual welding, butt weld and, where appropriate, fillet weld tests,

using the gravity or other contact device as recommended by the manufacturer,

are to be carried out in addition to the normal approval tests.

3.10 Annual tests

3.10.1 For normal penetration electrodes, the annual tests are to consist of two

deposited metal test assemblies. These are to be prepared and tested in accordance with

Ch 11, 3.2 Deposited metal test assemblies. If an electrode is available in one diameter only, one test assembly

is sufficient.

3.10.4 Where an electrode is approved solely for gravity or contact welding, the

annual test is to consist of one deposited metal test assembly using the gravity or

other contact device as recommended by the manufacturer.

3.10.6 A hydrogen test is required for Y89 and Y96 grades.

|