Section

1 Introduction

1.1 Background

1.1.1 This guidance note has been produced to provide guidance on the Classification of

tugs with Lloyd’s Register, including information on tug types, operational

restrictions, notations and design calculations. In addition, for tugs with a

(freeboard) length LLL ( as defined in the International Convention on

Load Lines (ICLL)) of not more than 100 m, this note goes beyond the limited scope

of Class Rules to provide guidance on best practice and general statutory

requirements.

1.2 Scope

1.2.1 The content of this guidance note relating to Classification aspects is

relevant to all tugs eligible for Classification to which one or more of the Type

Notations specified in Ch 2, 1.1 Type and Service Restriction Notations intended

to be are assigned.

1.2.2 The content of this guidance note relating to statutory aspects is relevant to tugs

having a (freeboard) length LLL, as defined in the International

Convention on Load Lines (ICLL), of not more than 100 m.

1.2.3 Classification of tugs requires that the vessel complies with the Rules

and Regulations of Lloyds Register. The relevant requirements are made up of the

general requirements for all vessels in the Rules and Regulations for the

Classification of Ships (The Rules and Regulations for the Classification of Ships, July 2022) and any relevant specific

requirements.

For all tugs the Classification requirements may include;

- Pt 1, Ch 2, 2.1 Definitions 2.1.6

- Pt 1, Ch 2, 3.2 New construction surveys 3.2.6

- Pt 3, Ch 1, 7.1 Calculation of Equipment Number 7.1.6

- Pt 3, Ch 8, 5.5 Special requirements for tugs and offshore supply ships

- Pt 3, Ch 13, 7 Equipment

- Pt 4, Ch 3 Tugs

The above list of applicable requirements is not exhaustive and may vary from vessel

to vessel based on the operational profile, the tug type, equipment, fit out

etc.

1.2.4 All vessels are subject to the requirements set out by their relevant Flag

Administration(s). Typically, such statutory requirements go beyond the scope of

class. This Guidance note sets out some general guidelines in these areas however in

all cases the requirements of the relevant flag Administration(s) are to be

applied.

1.2.5 There should be no instances where this guidance conflicts with the requirements of

the Flag Administration, however if an instance is identified for a vessel that is

to be Classed the conflict should be highlighted to Lloyd’s Register at the earliest

opportunity to ensure that the conflict is rectified as soon as possible to allow

Classing and Flagging of the vessel.

1.2.6 The Rules and these guidance notes assume that no escort operations will be conducted

at speeds greater than 10 kn, however for vessels designed to conduct escort at

speeds greater than this application of the Rules and these guidance will be

specially considered.

1.2.7 The sizing of the prime mover and the propulsion chain to develop sufficient thrust

for the vessel to perform her predicted duties is beyond the scope of

Classification.

1.3 Definitions

1.3.1 Design bollard pull

The design bollard pull TBP, in kN, is the maximum sustained

towline force a tug is capable of generating at zero forward speed, to be initially

specified by the designer and to be verified by a full scale test, generally

referred to as bollard pull test.

Where TBP is not available, the following default values may be

used as an estimate for a preliminary design review:

-

|

TBP |

= |

0,204NPS for conventional tugs with propellers

fitted with nozzles; |

-

|

TBP |

= |

0,176NPS for tractor tugs and ASD tugs with

steerable propellers fitted with nozzles |

where:

N : number of propellers;

PS : maximum continuous power per propeller shaft, in kW.

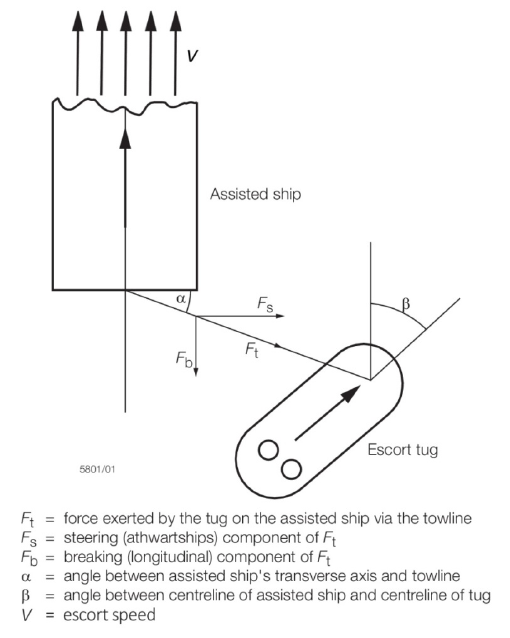

1.3.2 Escort forces and speed

The steady towline force during escorting, Ft in kN, is the towline

force associated with the (quasi-static) equilibrium in indirect towing mode,

excluding short time-duration dynamic effects, for a given loading condition and

escort speed V, see

Figure 1.1.1 Typical escort configuration. The

steady towline force is applied by the tug on the stern of the escorted ship.

Figure 1.1.1 Typical escort configuration

Additionally, the steady towline force Ft can be decomposed into a

steering force Fs and a braking force Fb :

- The steering force Fs, in kN, is the transverse component

of the steady towline force Ft with respect to the

escorted ship;

- The braking force Fb, in kN, is the longitudinal component

of the steady towline force Ft with respect to the

escorted ship.

For the purpose of this guidance note the following rated values of the above defined

escort forces are defined as:

- The rated steady towline force Ft,R, in kN, is the highest

anticipated steady towline force Ft, as obtained from the

evaluation of the escort forces for a particular loading condition and

escort speed, taking into account the applicable stability and strength

criteria in this guidance note;

- The rated steering force Fs,R, in kN, is the highest

anticipated steering force Fs, as obtained from the

evaluation of the escort forces for a particular loading condition and

escort speed, taking into account the applicable stability and strength

criteria in this guidance note;

- The rated maximum braking force Fb,R, in kN, is the

highest anticipated braking force Fb, as obtained from the

evaluation of the escort forces for a particular loading condition and

escort speed, taking into account the applicable stability and strength

criteria in this guidance note.

And the associated maximums are,

- The design maximum steady towline force Ft,MAX, in kN, is

the highest rated steady towline force Ft,R over the

applicable range of loading conditions and escort speeds;

- The design maximum steering force Fs,MAX, in kN, is the

highest rated steering force Fs,R over the applicable

range of loading conditions and escort speeds;

- The design maximum braking force Fb,MAX, in kN, is the

highest rated braking force Fb,R over the applicable range

of loading conditions and escort speeds.

- The maximum escort speed VMAX, in kn, is the highest

escort speed V for which the escort tug is considered to perform

escort operations.

For the purpose of this guidance note the following relevant angles are defined

as:

- The towline angle α, in deg, is the angle between the towline and the

centreline of the escorted ship and;

- The drift angle β, in deg, is the angle between the centreline of the tug

and the centreline of the escorted ship (also referred to as yaw

angle).

1.3.3 Reference towline force

The reference (quasi-static) towline force T, in kN, is considered

to represent:

1.3.4 Design load

The design load (DL), in kN, is the force taken into consideration for the strength

assessment and testing of the towing equipment and the associated supporting

structures, and for the purposes of design appraisal it is taken as not less than:

where

DAF: dynamic amplification factor

The dynamic amplification factor takes into consideration dynamic effects. Reference

values for the dynamic amplification factor are given in:

1.3.5 Winch brake holding load

The winch brake holding load (BHL), in kN, is the maximum towline force the towing

winch can withstand without slipping of the (activated) brake, considering the

towline at the first inner layer.

The BHL is a reference value for strength assessment and testing of towing winches

and associated towing fittings (e.g. fairlead, staple, gob-eye) as well as their

supporting structures.

1.3.6 Towline breaking strength

The towline breaking strength, in kN, is the tension required to cause failure of the

towline (parting of the towline).

1.4 General Guidance

1.4.1 All bollard pull tests should be performed in accordance with a recognised Standard,

such as the ‘Lloyd’s Register Bollard Pull certification procedures guidance

information’, and witnessed by a Lloyd’s Register Surveyor.

1.4.2 For tugs capable of towing over the stern (ahead towing) as well as over the bow

(astern towing), the bollard pull test should be performed for both scenarios.

1.4.3 If the measured bollard pull for any vessel is higher than the design bollard pull

(TBP) by 1 per cent or more then aspects of the design

appraisal of the vessel may need to be redone reflecting this new bollard pull. The

extent of reappraisal is at the discretion of Lloyds Register.

1.4.5 The matrix of rated steady towline forces Ft,R, steering forces

Fs,R and braking forces Fb,R should be

specified by the designer for design appraisal and are latterly verified by Lloyd’s

Register on the basis of the results of:

- full scale trials, or

- model testing, or

- a computer simulation program accepted by Lloyd’s Register.

1.4.6 All full scale trials conducted to verify the above matrix of forces,

should be performed in accordance with a procedure agreed with Lloyd’s Register

prior to commencement of the trials. Further guidance on such trials is contained in

Ch 3, 2.3 Intact stability 2.3.6.

1.4.7 All Model testing, where applicable, should be performed in accordance

with a procedure agreed with Lloyd’s Register before commencement of the tests. The

testing should comply with the relevant aspects of Ch 3, 2.3 Intact stability 2.3.6.

1.4.8 Special attention should be paid to scale effects when processing any model scale

measurement results to create predictions at full scale.

1.4.11 In order to maintain the Classification of any tug, the vessel will be

subject to an ongoing periodical survey regime to ensure that the vessel and the

equipment relevant for Classification remain in a worthy condition. Details of the

through life survey requirements can be found in Part 1 of the Rules and Regulations for the Classification of Ships, July 2022.

1.4.12 For high powered escort tugs (with a free running speed of more than 15 kn) Lloyd’s

Register will specially consider the application of the Rules and these Guidance

notes to the vessel assuming an escort speed of 12 kn.

1.4.13 Propulsion engines and propulsion train should develop sufficient thrust for

manoeuvring the tug quickly for any drift angle, and in the case of loss of

propulsion, the heeling moment due to the remaining forces should lead to a safe

equilibrium position of the tug with reduced heeling angle.

1.5 Escorting dynamics

1.5.1 For the purpose of this guidance note, escorting is considered to include active

(emergency) steering, braking and otherwise controlling of the escorted ship by the

tug operating in indirect towing mode, whereby the ahead speed of the escorted ship

is within a typical speed range of 6 to 10 kn.

1.5.2 In indirect towing mode the towline force is the resultant of the (quasi-static)

equilibrium condition reached between the forces and moments arising from the

hydrodynamic lift and drag forces acting on the hull and appendices of the tug

advancing through the water at a drift angle relative to the water flow, the thrust

vector and the towline force (In direct towing mode the thrust is directly applied

to generate the towline force, hydrodynamic lift and drag forces play no significant

role).

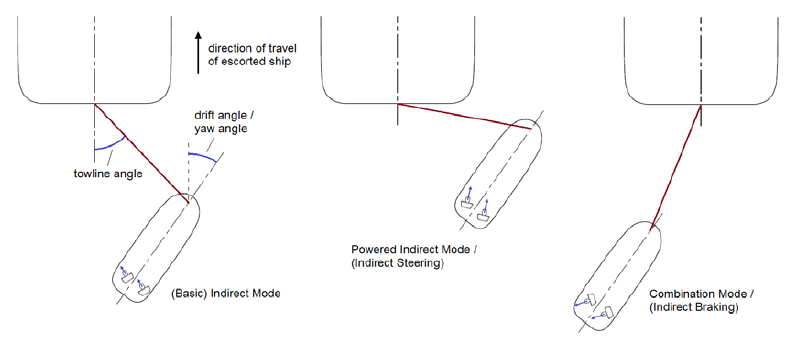

Escort tugs may work in different indirect towing modes, depending on the required

action towards the escorted ship (e.g. steering, braking). The main indirect towing

modes relevant for escort tugs are schematically shown in Figure 1.1.2 Schematic overview of indirect towing modes (escort tug). Where reference is made to ‘indirect steering’ the

objective is to maximise the steering force in indirect towing mode. Where reference

is made to ‘indirect braking’ the objective is to maximise the braking force in

indirect towing mode.

In (basic) indirect mode the towline force is generated primarily by the hydrodynamic

forces acting on the hull and skeg, with the thrust used solely to maintain the

desired drift angle (also referred to as yaw angle).

In powered indirect mode (indirect steering) the transverse component of thrust is

used to maintain the desired drift angle, while a significant longitudinal component

of thrust is applied in forward direction of the tug.

Compared to the (basic) indirect mode, the tug is operating more sideways of the

escorted ship with a relatively large towline angle, generating a higher steering

force.

In combination mode (indirect braking) the same principle as for the indirect

steering mode is applied, except that the longitudinal component of thrust is

applied in aftward rather than forward direction.

Compared to the (basic) indirect mode, the tug is operating more behind the escorted

ship with a relatively small towline angle, generating a higher braking force.

For indirect towing modes it is generally recognised that it is beneficial to design

the tug to generate high (indirect) towline forces with minimal propulsion thrust,

while respecting the limits imposed by stability and strength considerations (towing

equipment, general hull structure).

Figure 1.1.2 Schematic overview of indirect towing modes (escort tug)

|