Section

2 Classification Guidance

2.1 Hull

2.1.1 The Hull design and construction requirements for tugs are all contained

within the Rules and Regulations for the Classification of Ships, July 2022 and both vessels with the

Type notation Tug or Escort Tug are to comply with the Rules and

regulations of this Ruleset to be eligible for classification with Lloyds

Register.

In addition to the Ship structures (general) requirements for all vessels

of the Rules and Regulations for the Classification of Ships, July 2022 (all contained within Pt 3), there are is

also a specific ship structures section of the Rules dedicated to tug structures.

This section is Pt 4, Ch 3 Tugs and it contains the following

sections:

- Pt 4, Ch 3, 1 General

- Pt 4, Ch 3, 2 Longitudinal strength

- Pt 4, Ch 3, 3 Floors in single bottoms

- Pt 4, Ch 3, 4 Panting and strengthening of bottom forward

- Pt 4, Ch 3, 5 Machinery casings

- Pt 4, Ch 3, 6 Freeing arrangements

- Pt 4, Ch 3, 7 Towing arrangements

- Pt 4, Ch 3, 8 Fenders

- Pt 4, Ch 3, 9 Escort operation, performance numeral and trials

The content of each of these sections is generally self-explanatory with

content referring out to other sections of the Rules and Regulations for the Classification of Ships, July 2022 to be complied with and/or listing

additional requirements or exceptions.

Of particular interest in the above is Pt 4, Ch 3, 7 Towing arrangements and Pt 4, Ch 3, 8 Fenders (additionally Pt 4, Ch 3, 9 Escort operation, performance numeral and trials for Escort Tugs), these are discussed in the following

sub-Sections.

2.2 Towing arrangements for Tugs

2.2.1 The Rule requirements relating to the towing equipment and their

foundations are contained within Pt 4, Ch 3, 7 Towing arrangements of The Rules and Regulations for the Classification of Ships, July 2022.

In addition, materials used in towing equipment should comply with the applicable

class requirements for materials. Class certificates are generally required for the

materials used for winch drums, drum shafts, winch brake components, winch

supporting frames, towing hooks and towline guiding fittings installed upon classed

vessels.

2.2.2 Documents to be submitted

In order for the plan appraisal of the towing equipment and the associated

foundations to be undertaken, the following documents should be submitted for

appraisal (assuming no Type Approval is in place):

- Drawings of towing winches, including winch drums, main shaft, load carrying

non-rotating structures (support frame), winch brakes. Gear and clutch

information is also to be submitted for information;

- Hydraulic, electrical and control system diagrams of the towing winch, as

applicable (note that this may be used for information as required);

- Drawings of towing hook and towline guiding fittings;

- Drawings of foundations and under deck supporting structures (clearly

showing reinforcements) of towing equipment including scantlings and

attachment methods as appropriate.

In addition to the above and to further facilitate the plan appraisal the follow may

be supplied to Lloyd’s Register for information:

- Towing arrangement plan, showing the location and general layout of the

towing equipment, the range of anticipated lines of action of the towlines

with the associated maximum steady towline forces (also known as the

quasi-static towline force) and the corresponding points of application of

the towline forces on the towing equipment;

- Arrangement drawings of towing winches, towing hooks and towline guiding

fittings (fairleads, staples, gob-eyes, towing pins, stern roller,

etc.);

- Design information of towing winches, including maximum rated line pull,

winch brake holding force, rendering load and specification of emergency

quick-release arrangements;

- Design calculations of towing winches, including winch drums, main shaft,

load carrying non-rotating structures (support frame) and braking

capacity;

- Design load of towing hook and towline guiding fittings;

- Design calculations of the towline guiding fittings and the supporting

structures of towing equipment, including detailed analysis reports in case

three-dimensional finite element models have been used.

Additionally, where deemed necessary by Lloyd’s Register, buckling and/or fatigue

analysis, performed in accordance with a standard or code of practice recognised by

Lloyd’s Register, may be required to be submitted for information.

2.2.3 Consideration of the design load

One of the critical factors in the design appraisal of the towing

equipment and its foundation is the design load (DL) that should be considered for

the strength assessment of the towing equipment and the associated supporting

structures. This is outlined in the Rules and also given in Table 2.2.1 Design loads: tug of this guidance

for easy reference.

Table 2.2.1 Design loads: tug

| tug with service restriction notation protected

waters e.g. a harbour tug

|

General case

|

| Bollard

pull, TRP

[kN]

|

Design load,

DL

[kN]

|

Bollard

pull, TRP

[kN]

|

Design

load, DL

[kN]

|

| T ≤

200

|

[2]T

|

T ≤

400

|

[2,5]T

|

| 200 <

T < 800

|

[(2600 −

T)/1200]T

|

400 <

T < 1000

|

[(3400 −

T)/1200)]T

|

| T ≥

800

|

[1,5]T

|

T ≥

1000

|

[2]T

|

The DL (in the Rules and in the table) take into consideration the

assumed dynamic effects through the application of the dynamic amplification factor

(DAF) which is clearly designated in square brackets in Table 2.2.1 Design loads: tug (see also

Ch 1, 1.3 Definitions 1.3.4).

2.2.4 Design requirements for towing winches

The Rules require that the scantlings for towing winches (including winch drums, drum

shafts, brakes, support frames and connections to the hull structure) are to be

determined by direct calculations using the Design Loads (outlined in Table 2.2.1 Design loads: tug)

The calculations should demonstrate that the towing winches (in particular the

components which are exposed to the tension in the towline, such as the winch drums,

drum shafts, brakes, support frame and connection to the hull structure) are able

to:

- sustain the DL, without permanent deformation, and;

- sustain the BHL, (as defined in Ch 1, 1.3 Definitions 1.3.5), without exceeding an

equivalent stress level (based on von Mises criterion) of

0,80σy;

- sustain the loads for the RP condition, as foreseen by the designer, without

exceeding an equivalent stress level (based on the von Mises criterion) of

0,40σy.

where

- σy: Minimum specified yield stress of material, in

N/mm2;

- RP: Is the Rated Pull i.e. the winch maximum hauling in load at the first

inner layer.

In each calculation case the most unfavourable anticipated position of the

towline should be considered.

2.2.5 Additional design guidance for towing winches

In addition to the Rule requirements outlined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.4, the following

design guidelines should be followed.

Towing winches should generally be arranged in such a position (noting the position

of guiding fittings and towline path) as to minimise heeling moment due to the

towline force.

The winch brake should normally act directly on the drum and should be operable

(either manually or otherwise) in case of failure of the primary power supply

system.

The towline attachment to the winch drum should be provided by means of a weak link

or equivalent.

Towing winches should be provided with an emergency release system as

described in Ch 2, 2.2 Towing arrangements for Tugs 2.2.10.

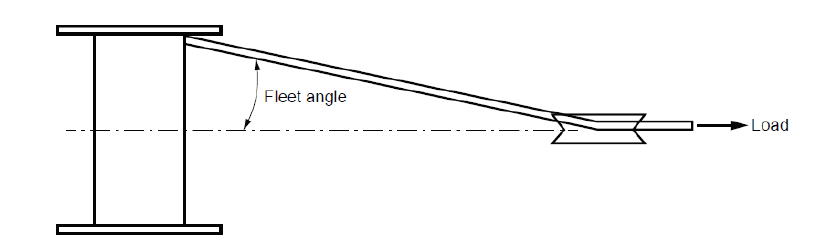

Means should be provided to prevent the fleet angle (as shown on Figure 2.2.1 Fleet angle) from becoming great

enough to inhibit operation of the emergency release system.

Figure 2.2.1 Fleet angle

The dimensioning of the winch drum should take into account the rope bending

specifications provided by the towline manufacturer.

Due consideration should be given to the proper spooling of the towline on the winch

drum, as well as preventing the towline slipping over the flanges of the drum.

Towing winches may be equipped with an active pay-out and haul-in system

automatic adjustment of towline. In such a case, the relevant requirements of Ch 2, 2.3 Towing arrangements for Escort Tugs 2.3.6 and Ch 2, 2.3 Towing arrangements for Escort Tugs 2.3.8 should be complied with.

It is recommended that the towing winch should be fitted with equipment to

continuously measure the tension (mean tension, tension peaks and slack line events)

in the towline.

In case a towline measurement system is installed on board, the measured data should

be displayed on the bridge.

2.2.6 Guidelines on testing of towing winches

The following guidelines outline the appropriate testing regimes for towing winches

installed on board tugs.

Towing winches, including the associated emergency quick-release devices

should be load tested at the DL, as defined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.3, or the BHL, as defined in Ch 1, 1.3 Definitions 1.3.5, whichever is the

greatest. Generally, load testing should be conducted at a specialised facility

equipped to generate the required line tension (e.g. maker’s premises) and witnessed

by Lloyd’s Register.

In case a towing winch is of conventional, proven design, for which load testing has

been previously performed in a manner deemed acceptable by Lloyd’s Register

(evidence and results of load testing should be supplied), it may be sufficient to

perform on board function testing in accordance with the guidelines specified

below.

The proper functioning of the towing equipment should be verified by on

board testing witnessed by Lloyd’s Register. Function testing should be performed

both for normal operating conditions in accordance with the towing arrangement plan

(see

Ch 2, 2.2 Towing arrangements for Tugs 2.2.2) and for emergency conditions (emergency quick-release, failure of

main power supply). The safe operation of the towing winch from all control stations

should be demonstrated.

Towing winches should be function tested on board. The correct

functioning of the winch brake, the load carrying winch components and the

associated supporting structure should be demonstrated at a towline force equal to

the bollard pull, as defined in Ch 1, 1.3 Definitions 1.3.1. The emergency quick-release

should be function tested under normal power supply conditions with a towline force

corresponding to the minimum thrust (engine(s) clutched in and running at idle

speed), as well as in a dead-ship condition (without strain in the towline).

Winch operating modes which should be function tested include hauling in and paying

out of the towline, as well as braking.

Hydraulic and electrical systems should be function tested on board in accordance

with Lloyd’s Register’s requirements for machinery and electrical systems.

Operational tests should be performed by the crew in order to ensure the satisfactory

operation of the towing equipment, in particular the emergency quick-release

systems, as requested by the operating manual.

Records of operational tests are should be kept on board and made available to

Lloyd’s Register upon request.

2.2.7 Design requirements for towline guiding fittings

The Rules mandate that the towline guiding fittings, such as fairleads,

staples, gob-eyes, towing pins, stern rollers and equivalent components which guide

the towline, are able to sustain the force exerted by the towline loaded under a

tension equal to the DL, in the most unfavourable anticipated position of the

towline without exceeding the following stress level criteria:

- Normal stress σ ≤ 0,75σref;

- Shear stress σ ≤ 0.47σref;

- Equivalent stress σe ≤ 0,85σref,

where

- σref: Reference stress of the material, in

N/mm2, normally to be taken as

, but may be taken as σy for

fittings not made of welded construction; , but may be taken as σy for

fittings not made of welded construction;

- k: Material factor, defined as function of the minimum

guaranteed yield stress σy, see

Table 2.2.2 Material factor k.

Table 2.2.2 Material factor k

| σy

(N/mm2)

|

k

|

| 235

|

1

|

| 315

|

0,78

|

| 355

|

0,72

|

| 390

|

0,68

|

In addition, towline guiding fittings used for guiding the towline when towing on a

towing winch must be able to sustain the force exerted by the towline loaded under a

tension equal to the BHL of the associated winch in the most unfavourable

anticipated position of the towline without exceeding the above-mentioned stress

level criteria.

Finally, where a towline guiding fitting (e.g. fairlead or guide pin) has been

designed for a specific Safe Working Load (SWL), defined as the maximum static

working load, the fitting should be able to sustain a force equal to 2 times the SWL

without exceeding the above-mentioned stress level criteria.

2.2.8 Additional design guidance for towline guiding fittings

In addition to the Rule requirements outlined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.7, the following

design guidelines should be followed.

When considering the above design checks for the strength of towline guiding

fittings, at the discretion Lloyd’s Register, where the yielding check of the

towline guiding fittings is carried out by means of a three-dimensional finite

element model, an increase of the permissible stress levels given above by 10 per

cent (compared to a beam model) will be specially considered.

Sizing and radiusing of towline guiding fittings should be appropriate to prevent

fretting or abrasion of any towlines.

All towline guiding fittings should be regularly checked and maintained to ensure

their condition does not affect smooth carriage of the towline.

The placement of towline guiding fittings should be such that they do not cause undue

friction or bending beyond the specified limits of the towline manufacture.

Adequate towline guiding fittings should be supplied and arranged to effectively lead

and restrain the towline within the designed limits of its sweep.

Towing guiding fittings should generally be arranged in such a position (noting the

position of towing equipment and towline path) as to minimise heeling moment due to

the towline force.

2.2.9 Design requirements for towing hooks

The classification Rules require that towing hooks and their load carrying

attachments (connecting the towing hook to the hull structure) must be able to

sustain the DL without exceeding an equivalent stress level (based on von Mises

criterion) of 0.80σy.

The supporting calculations to demonstrate this are to be provided to Lloyds Register

and must consider the DL being applied in the most unfavourable anticipated position

for the structure.

2.2.10 Additional design guidance for towing hooks

In addition to the mandatory Rule requirements the following additional guidance

should be complied with.

Towing hooks should be provided with an emergency quick-release device operable from

a position on the bridge with full view and control of the towing operation, as well

as at a location near the hook where the device can be safely operated. Identical

means of control for the emergency quick-release devices should be provided at each

control station and are to be protected against unintentional use.

The force necessary to open the hook under load should not be greater than 150 N.

The applicable procedures for the emergency quick-release device should be

communicated to the crew and vital information should be displayed next to the

control desk or another appropriate location.

Towing hooks should generally be arranged in such a position (noting the position of

towline guiding fittings and towline path) as to minimise heeling moment due to the

towline force.

2.2.11 Guidelines on testing of towing hooks

The following guidelines outline the appropriate testing regimes for towing hooks

installed on board tugs.

Towing hooks, including the associated emergency quick-release devices,

should be load tested to the DL, as defined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.3, at a specialised facility equipped to generate the required line

tension (e.g. maker’s premises) and witnessed by Lloyd’s Register.

In case a towing hook is of conventional, proven design, for which load testing has

been previously performed in a manner deemed acceptable by Lloyd’s Register,

(evidence and results of load testing should be supplied), it may be sufficient to

perform on board function testing in accordance with the guidelines specified

below.

The proper functioning of the towing equipment should be verified by on

board testing witnessed by Lloyd’s Register. Function testing should be performed

both for normal operating conditions in accordance with the towing arrangement plan

(see

Ch 2, 2.2 Towing arrangements for Tugs 2.2.2) and for emergency conditions (emergency quick-release, failure of

main power supply). The safe operation of the towing hook from all control stations

should be demonstrated.

Towing hooks should be function tested on board. The correct functioning

of the hook and the associated supporting structure should be demonstrated at a

towline force equal to the bollard pull, as defined in Ch 1, 1.3 Definitions 1.3.1. The emergency quick-release

should be function tested under normal power supply conditions with a towline force

corresponding to the minimum thrust (engine(s) clutched in and running at idle

speed), as well as in a dead-ship condition (without strain in the towline).

Operational tests should be performed by the crew in order to ensure the satisfactory

operation of the towing equipment, in particular the emergency quick-release

systems, as requested by the operating manual.

Records of operational tests are should be kept on board and made available to

Lloyd’s Register upon request.

2.2.12 Design requirements for towing equipment supporting structures

The Classification Rules require that the supporting structures of

towing equipment should be able to sustain the load exerted on the supporting

structure under the action of the towline loaded under a tension equal to the DL in

the most unfavourable anticipated position of the towline, without exceeding the

stress level criteria:

- Normal stress σ ≤ 0,75σref;

- Shear stress σ ≤ 0.47σref;

- Equivalent stress σe ≤

0,85σref,

where

- σref: Reference stress of the material, in N/mm2,

normally to be taken as

, but may be taken as σy for

fittings not made of welded construction; , but may be taken as σy for

fittings not made of welded construction;

- k: Material factor, defined as function of the minimum

guaranteed yield stress σy, see

Table 2.2.2 Material factor k.

In addition, the supporting structures of towing equipment engaged for

escort operations or when towing on a towing winch must be able to sustain the load

exerted on the supporting structure under the action of the towline loaded under a

tension equal to the BHL of the associated winch, as specified in Ch 1, 1.3 Definitions 1.3.5, in the most unfavourable

anticipated position of the towline without exceeding the stress level criteria

specified above.

Also, where a towline guiding fitting has been designed for a specific SWL, defined

as the maximum static working load, the associated supporting structure should be

able to sustain a force equal to 2 times the SWL without exceeding the stress level

criteria specified above.

2.2.13 Additional design guidelines for towing equipment supporting structure

In case the yielding check of the towing equipment supporting structures is carried

out by means of a threedimensional finite element model, increase of the permissible

stress levels given above by 10 per cent (compared to a beam model) will be

specially considered by Lloyd’s Register.

Care should be taken that if towing equipment supporting structure is also exposed to

other loads (e.g. weather deck loadings ) in combination with the with loads from

towing, then these additional loads should be superimposed into the strength

assessment in order to produce the most conservative case for analysis.

2.2.14 Additional design guidelines for winch emergency release systems

The emergency release system should be operable under all normal and reasonably

foreseeable abnormal conditions (these may include, but are not limited to, the

following: vessel electrical failure, extreme list/trim angles, load applied at the

limits of operating load, fleet angle, variable load (for example due to heavy

weather), etc.).

Emergency release systems should allow the winch drum to rotate and allow the towline

to pay out in a controlled manner.

An alternative source of energy should also be provided such that normal operation of

the emergency release system can be sustained under dead-ship conditions for at

least three complete emergency release system operations of the most demanding winch

connected to it.

Where the winch design is such that the brake is applied by spring tension and

released using hydraulic or pneumatic power, sufficient power should be provided to

operate the emergency release system, in a dead-ship situation, for a minimum of

five minutes. This may be reduced to the time required for the full length of the

towline to feed off the winch drum at the minimum load as specified below if this is

less than five minutes, noting that after the emergency release system has been

activated it is considered good practice for the brake to first completely open and

then automatically tighten slightly to ensure a controlled release of the

towline.

The emergency release system should function as quickly as reasonably practicable and

within a maximum of three seconds after activation.

Arrangements should ensure that when emergency release system is activated, there is

sufficient resistance to rotation to avoid uncontrolled unwinding of the towline

from the drum.

The towline load required to rotate the winch drum should be no greater than:

- the lesser of five tonnes or five per cent of the maximum BHL of the

associated winch when two layers of towline are on the drum,

or

- 15 per cent of the BHL of the associated winch where it is demonstrated that

the resistance to rotation does not exceed 25 per cent of the force that

will result in listing sufficiently to immerse of the lowest unprotected

opening.

The emergency release system should be capable of operating at 100 per cent of the

BHL of the associated winch.

Emergency release operation should be possible from the bridge and from the winch

control station on deck. The winch control station on deck should also be in a safe

location.

The emergency release control should be located in close proximity to the emergency

stop button for winch operations and both should be clearly identifiable, clearly

visible, and easily accessible and positioned to allow safe operability.

The emergency release function should take priority over any emergency stop function.

Activation of the winch emergency stop from any location should also not inhibit

operation of the emergency release system from any location.

Emergency release system control buttons are should be of the 'lock-in' type or

require positive action to cancel.

Controls for emergency use should be protected against accidental use.

The following emergency release system alarms and indications should be provided on

the bridge:

- Low fluid pressure in the control system

- Low accumulator/air pressure

- Low battery voltage (separate alarm and indication not required where

electrical power is supplied from the tug's emergency batteries).

Wherever practicable, control of the emergency release system should be provided by a

hard-wired system, fully independent of programmable electronic systems.

Programmable electronic systems that operate or may affect the control of emergency

release systems should generally be considered as safety critical/ essential

systems.

The emergency release system reset function should be always available from the

bridge regardless of the activation location and without manual intervention on the

working deck.

2.2.15 Guidelines on testing of winch emergency release systems

For each emergency release system or type thereof, should be verified either at the

manufacturer's works or as part of the commissioning of the towing winch when it is

installed on board. Where verification solely through testing is impractical (e.g.

due to health and safety), testing may be combined with inspection, analysis or

demonstration will be considered by Lloyd’s Register on a case-by-case basis.

The performance capabilities of the emergency release system should be documented and

made available on board the ship on which the winch has been installed.

The full functionality of the emergency release system should be tested as part of

the shipboard commissioning trials to the satisfaction of the Surveyor. Testing may

be conducted either during a Bollard Pull test or by applying the towline load

against a strong point on the deck of the tug that is certified to the appropriate

load.

For novel designs the emergency release systems should also be load tested with the

towline at an upward angle of 45 degrees with the horizontal plane at a towline

force of not less than 50 per cent of the design bollard pull.

2.2.17 Additional design guidelines for towlines

In addition to the Classification Rule requirements the following design guidelines

should be followed.

The breaking strength of towlines should be in accordance with appropriate industry

standards for marine operations, but not less than the appropriate DL.

In addition, the breaking strength of towlines used on a towing winch should not be

less than the BHL of the associated winch (see

Ch 1, 1.3 Definitions 1.3.5).

The towline should be protected from being damaged by chafing and abrasion. To this

end cargo rails, bulwarks, and other elements, supporting the towline should be

sufficiently rounded with consideration to the bend radius limit of the towline in

order to ensure that that the towline breaking strength is maintained.

The total length of the towline applied on a towing winch is to be such that under

normal operation at least half a layer remains on the drum. In no case should less

than three turns remain on the drum during normal operation.

2.3 Towing arrangements for Escort Tugs

2.3.2 Materials used in towing equipment should comply with the applicable class

requirements for materials. Class certificates are generally required for the

materials used for winch drums, drum shafts, winch brake components, winch

supporting frames, towing hooks and towline guiding fittings installed upon classed

vessels.

2.3.4 Documents to be submitted

In order for the plan appraisal of the towing equipment and the associated

foundations to be undertaken, the following documents should be submitted for

appraisal (Assuming no Type Approval is in place):

- Drawings of towing winches, including winch drums, main shaft, load carrying

non-rotating structures (support frame), winch brakes. Gear and clutch

information is also to be submitted for information;

- Hydraulic, electrical and control system diagrams of the towing winch, as

applicable (note that this may be used for information as required);

- Drawings of the towline guiding fittings used for escorting;

- Drawings of foundations and under deck supporting structures (clearly

showing reinforcements) of towing equipment including scantlings and

attachment methods as appropriate.

In addition to the above and to further facilitate the plan appraisal the follow may

be supplied to Lloyd’s Register for information:

- Escort towing arrangement plan, showing the location and general layout of

the towing equipment used for escorting, the range of anticipated lines of

action of the towlines with the associated maximum steady towline forces

(also known as the quasi-static towline force) and the corresponding points

of application of the towline forces on the towing equipment;

- Summary tables of maximum steering force Fs, in kN, and

maximum braking force Fb, in kN, for the intended range of

speeds VY, in kn, (In case the final values are not yet

available, estimated values may be submitted as preliminary information for

the purposes of an initial design review. Where a discrepancy between the

final values and the preliminary values exists, the drawings may need to be

re-reviewed against the final values);

- Arrangement drawings of the escort winch and towline guiding fittings used

for escorting (fairlead, staple etc);

- Design information of escort winch, including maximum rated line pull, winch

brake holding force, rendering and recovering loads and specification of

emergency quick-release arrangement

- Design calculations of escort winch, including winch drums, main shaft, load

carrying non-rotating structures (support frame) and braking capacity;

- Design load of towline guiding fittings used for escorting;

- Design calculations of the towline guiding fittings and the supporting

structures of towing equipment used for escorting, including detailed

analysis reports in case three-dimensional finite element models have been

used.

Additionally, where deemed necessary by Lloyd’s Register, buckling and/or fatigue

analysis, performed in accordance with a standard or code of practice recognised by

Lloyd’s Register, may be required to be submitted for information.

In case the final values are not yet available, estimated values may be submitted as

preliminary information for the purposes of an initial design review. In case the

discrepancy between the final values and the preliminary values, the drawings may

need to be re-reviewed against the final values.

2.3.5 Consideration of the design load

One of the critical factors in the design appraisal of the towing

equipment used for escort and its foundations is the design load (DL) that should be

considered for the strength assessment. This is outlined in the Rules and also given

in Table 2.2.3 Design loads: escort

tug of this guidance for easy reference

Table 2.2.3 Design loads: escort

tug

| Maximum steady towline force

Ft,MAX [kN]

|

Design ,load, DL [kN]

|

| General

|

Protected waters

|

| T ≤ 500

|

[3]T

|

[2,4]T

|

| 500 < T < 1000

|

[(2000 − T)/500]T

|

[(2000 − T)/625]T

|

| T ≥ 1000

|

[2]T

|

[1,6]T

|

The DL (in the Rules and in the table) take into consideration the

assumed dynamic effects through the application of the dynamic amplification factor

(DAF) which is clearly designated in square brackets in Table 2.2.3 Design loads: escort

tug (see also

Ch 1, 1.3 Definitions 1.3.4).

2.3.6 Design requirements for escort winches

The Rules require that the scantlings for escort winches (including winch drums, drum

shafts, brakes, support frames and connections to the hull structure) are to be

determined by direct calculations using the Design Loads (outlined in Table 2.2.3 Design loads: escort

tug)

The calculations should demonstrate that the escort winches (in particular the

components which are exposed to the tension in the towline, such as the winch drums,

drum shafts, brakes, support frame and connection to the hull structure) are able

to:

- sustain the DL, without permanent deformation, and;

- sustain the BHL, (as defined in Ch 1, 1.3 Definitions 1.3.5), without exceeding an

equivalent stress level (based on von Mises criterion) of

0,80σy;

- sustain the loads for the RP condition, as foreseen by the designer, without

exceeding an equivalent stress level (based on the von Mises criterion) of

0,40σy.

where

- σy : Minimum specified yield stress of material, in

N/mm2;

- RP: Is the Rated Pull i.e. the winch maximum hauling in load at the first

inner layer.

In each calculation case the most unfavourable anticipated position of the

towline should be considered.

2.3.7 Additional design guidance for escort winches

In addition to the Rule requirements outlined in Ch 2, 2.3 Towing arrangements for Escort Tugs 2.3.6, the following design guidelines should be followed.

Winches should be provided with an emergency quick-release device operable from a

position on the bridge with full view and control of the towing operation. Means of

control for the emergency quick-release device should be protected against

unintentional use.

Escort winches should generally be arranged in such a position (noting the position

of towline guiding fittings and towline path) as to minimise heeling moment due to

the towline force.

The winch brake should normally act directly on the drum and should be operable

(either manually or otherwise) in case of failure of the primary power supply

system.

The dimensioning of the winch drum should take into account the rope bending

specifications provided by the towline manufacturer.

Due consideration should be given to preventing the towline slipping over the flanges

of the drum.

Escort winches intended to be used in conditions where dynamic oscillations of the

towline are likely to occur, such as in open sea areas or other areas exposed to

waves, should be equipped with an active pay-out and haul-in system. This system

should automatically and reliably pay-out the towline in a controlled manner when

the towline force exceeds a 23 pre-set (adjustable) level equal to 110 per cent of

the rated towline force Ft,R ,and as the towline force is reduced,

actively haul-in the towline to prevent slack-line events thereby maintaining a

pre-set or adjustable towline force consistent with the rated towline force.

Pay-out and haul-in speeds and pull capability should be chosen taking into account

the anticipated escort services and the dynamic characteristics of the escort

tug.

Escort operations in conditions where dynamic oscillations of the towline are likely

to occur should not be based on the use of the brakes of the winch drum.

Escort operations performed by escort tugs with the service restriction notation

protected waters and any escort operation in calm water conditions, such as in ports

and sheltered waters, may be based on the use of the brakes of the winch drum. As a

minimum, the winch brake holding load (BHL) should be equal to or greater than two

times the maximum steady towline force Ft,MAX.

Escort winches should be fitted with equipment to continuously measure the tension in

the towline. The measured data should be displayed in the wheelhouse next to the

control desk or another appropriate location.

The escort towing system should be designed so as to enable the proper spooling of

the towline when hauling in. Generally this can be achieved by a suitable design of

the fairlead or staple guiding the towline between the escort winch and the assisted

ship.

Where a spooling device is fitted, it should be designed for the same

design load and stress criteria as the towline guiding fittings, see

Ch 2, 2.2 Towing arrangements for Tugs 2.2.7.

2.3.8 Guidelines on testing of escort winches

The following guidelines outline the appropriate testing regimes for escort winches

installed on board escort tugs.

Escort winches, including the associated emergency quick-release device

should generally be load tested to the DL, as defined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.5, or the BHL, as defined in Ch 1, 1.3 Definitions 1.3.5, whichever is the

greatest. Generally, load testing should be conducted at a specialised facility

equipped to generate the required line tension (e.g. maker’s premises) and witnessed

by Lloyd’s Register.

In case an escort winch is of conventional, proven design, for which load testing has

been previously performed in a manner deemed acceptable by Lloyd’s Register

(evidence and results of load testing should be supplied), it may be sufficient to

perform on board function testing in accordance with the requirements specified

below.

The proper functioning of the towing equipment used for escort services

should be verified by on board testing witnessed by Lloyd’s Register. Function

testing should be performed both for normal operating conditions in accordance with

the escort towing arrangement plan, seeCh 2, 2.3 Towing arrangements for Escort Tugs 2.3.4, and

for in emergency conditions (emergency quick-release, failure of main power supply).

The safe operation of the escort winch from all control stations should be

demonstrated.

Escort winches should be function tested on board. The correct

functioning of the winch brake, the load carrying winch components and the

associated supporting structure should be demonstrated at a towline force equal to

the bollard pull, as defined in Ch 1, 1.3 Definitions 1.3.1. The emergency quick-release

should be function tested under normal power supply conditions with a towline force

corresponding to the minimum thrust (engine(s) clutched in and running at idle

speed), as well as in a dead-ship condition (without strain in the towline).

Winch operating modes which should be function tested include hauling in and paying

out of the towline, braking and the active pay-out and haul-in system when

fitted.

Hydraulic and electrical systems should be function tested on board in accordance

with Lloyd’s Register’s requirements for machinery and electrical systems.

Operational tests should be performed by the crew in order to ensure the satisfactory

operation of the towing equipment used for escort services, in particular the

emergency quick-release systems, as requested by the operating manual.

Records of operational tests should be kept on board and made available to Lloyd’s

Register upon request.

2.3.9 Design requirements for towline guiding fittings

The Rules mandate that the towline guiding fittings used for escort services, such as

fairleads, staples, and equivalent components which guide the towline, are able to

sustain the force exerted by the towline loaded under a tension equal to the DL, in

the most unfavourable anticipated position of the towline without exceeding the

following stress level criteria:

- Normal stress σ ≤ 0,75σref;

- Shear stress σ ≤ 0.47σref;

- Equivalent stress σe ≤ 0,85σref,

where

- σref : Reference stress of the material, in

N/mm2, normally to be taken as

, but may be taken as σy for

fittings not made of welded construction; , but may be taken as σy for

fittings not made of welded construction;

- k: Material factor, defined as function of the minimum

guaranteed yield stress σy,

Table 2.2.4 Material factor k

| σy (N/mm2)

|

k

|

| 235

|

1

|

| 315

|

0,78

|

| 355

|

0,72

|

| 390

|

0,68

|

In addition, towline guiding fittings should be able to sustain the force exerted by

the towline loaded under a tension equal to the BHL of the associated winch in the

most unfavourable anticipated position of the towline without exceeding the

above-mentioned stress level criteria

Finally, where a towline guiding fitting has been designed for a specific Safe

Working Load (SWL), defined as the maximum static working load, the fitting should

be able to sustain a force equal to 2 times the SWL without exceeding the

above-mentioned stress level criteria.

2.3.10 Additional design guidance for towline guiding fittings

In addition to the Rule requirements out lined in Ch 2, 2.2 Towing arrangements for Tugs 2.2.7, the following design guidelines should be followed.

When considering the aforementioned design checks for the strength of towline guiding

fittings, at the discretion Lloyd’s Register, where the yielding check of the

towline guiding fittings is carried out by means of a three-dimensional finite

element model, an increase of the permissible stress levels given above by 10 per

cent (compared to a beam model) will be specially considered.

Sizing and radiusing of towline guiding fittings should be appropriate to prevent

fretting or abrasion of any towlines.

All towline guiding fittings should be regularly checked and maintained to ensure

their condition does not affect smooth carriage of the towline.

The placement of towline guiding fittings should be such that they do not cause undue

friction or bending beyond the specified limits of the towline manufacture.

Adequate towline guiding fittings should be supplied and arranged to effectively lead

and restrain the towline within the designed limits of its sweep.

2.3.11 Design requirements for towing equipment supporting structures

The Classification Rules require that the supporting structures of towing

equipment should be able to sustain the load exerted on the supporting structure

under the action of the towline loaded under a tension equal to the DL in the most

unfavourable anticipated position of the towline, without exceeding the stress level

criteria:

- Normal stress σ ≤ 0,75σref;

- Shear stress σ ≤ 0.47σref;

- Equivalent stress σe ≤ 0,85σref,

where

- σref : Reference stress of the material, in N/mm2,

normally to be taken as

, but may be taken as σy for

fittings not made of welded construction; , but may be taken as σy for

fittings not made of welded construction;

- k : Material factor, defined as function of the minimum guaranteed yield

stress σy, see

Table 2.2.4 Material factor k.

In addition, the supporting structures of towing equipment engaged for

escort operations must be able to sustain the load exerted on the supporting

structure under the action of the towline loaded under a tension equal to the BHL of

the associated winch, as specified in Ch 1, 1.3 Definitions 1.3.5, in the most unfavourable

anticipated position of the towline without exceeding the stress level criteria

specified above.

Also, where a towline guiding fitting has been designed for a specific SWL, defined

as the maximum static working load, the associated supporting structure should be

able to sustain a force equal to 2 times the SWL without exceeding the stress level

criteria specified above.

2.3.12 Additional design guidelines for towing equipment supporting structure

In case the yielding check of the towing equipment supporting structures is carried

out by means of a threedimensional finite element model, increase of the permissible

stress levels given above by 10 per cent (compared to a beam model) will be

specially considered by Lloyd’s Register.

Care should be taken that if towing equipment supporting structure is also exposed to

other loads (e.g. weather deck loadings ) in combination with the with loads from

towing, then these additional loads should be superimposed into the strength

assessment in order to produce the most conservative case for analysis.

2.3.13 Additional design guidelines for winch emergency quick-release systems

The emergency quick-release device should be capable of releasing the towline under

the maximum anticipated load regardless of the angle of the towline and the tug’s

trim and heel. This device should be operable from a position on the bridge with

full view and control of the towing operation.

The emergency quick- release system should be operable under all normal and

reasonably foreseeable abnormal conditions (these may include, but are not limited

to, the following: vessel electrical failure, extreme list/trim angles, load applied

at the limits of operating load, high fleet angle, variable load (for example due to

heavy weather), etc.).

Means of control for the emergency quick-release device should be protected against

unintentional use.

The time delay between the initiation and actual start of the emergency quick-release

(pay-out of the towline) should be as short as reasonably practicable.

The speed of paying out should be such that the tension in the towline is reduced as

fast as reasonably possible, taking into consideration that paying out should be in

a controlled manner. To that end effective means to prevent spinning (free,

uncontrolled rotation) of the winch drum should to be provided as spinning of the

winch drum could cause the towline to get stuck and disable the release function of

the winch.

After a quick-release event the winch brakes should be able to operate normally

(automatically), while the winch motor should be engaged manually (not

automatically).

The applicable procedures for the emergency quick-release device, including time

delays and release speed, should be communicated to the crew and such vital

information should be displayed next to the control desk or another appropriate

location.

2.3.14 Guidelines on testing of winch emergency release systems

For each emergency release system or type thereof, should be verified either at the

manufacturer's works or as part of the commissioning of the escort winch when it is

installed on board. Where verification solely through testing is impractical (e.g.

due to health and safety), testing may be combined with inspection, analysis or

demonstration will be considered by Lloyd’s Register on a case-by-case basis.

The performance capabilities of the emergency release system should be documented and

made available on board the ship on which the winch has been installed.

The full functionality of the emergency release system should be tested as part of

the shipboard commissioning trials to the satisfaction of the Surveyor. Testing may

be conducted either during a Bollard Pull test or by applying the towline load

against a strong point on the deck of the tug that is certified to the appropriate

load.

For novel designs the emergency release systems should also be load tested with the

towline at an upward angle of 45 degrees with the horizontal plane at a towline

force of not less than 50 per cent of the design bollard pull.

2.3.16 Additional design guidelines for towlines

In addition to the Classification Rule requirements the following design guidelines

should be followed.

The breaking strength of towlines should be in accordance with appropriate industry

standards for marine operations, but not less than the appropriate DL.

In addition, the breaking strength for towlines used for escort services

on an escort winch should not be less than the BHL of the associated winch

(see

Ch 1, 1.3 Definitions 1.3.5)

The towline should be protected from being damaged by chafing and abrasion. To this

end cargo rails, bulwarks, and other elements, supporting the towline should be

sufficiently rounded with consideration to the bend radius limit of the towline in

order to ensure that that the towline breaking strength is maintained.

It is recommended that the total length of the towline applied on a towing winch is

to be such that under normal operation at least half a layer remains on the drum. In

no case should less than three turns remain on the drum during normal operation.

2.3.17 Additional recommended equipment for Escort tugs

Escort tugs should be equipped with a calibrated heeling angle measurement system

(inclinometer).

The measured heeling angle should be displayed in the wheelhouse next to the control

desk or another appropriate location where the readout is prominent.

2.4 Fendering

2.4.2 Design requirements for Fenders

The Rules stipulate that ‘An efficient fender is to be fitted to the ship's side at

deck level extending all fore and aft’.

2.4.3 Additional design guidelines for Fenders

The following additional guidance should be applied with respect to the fendering

arrangements for tugs.

A robust and efficient fendering system should be fitted in all areas intended for

pushing. The purpose of the fendering system is to distribute the pushing force and

limit its dynamic component on the hull structure of both the tug and the assisted

ship.

The design of the fendering system, in particular the contact area and stiffness

distribution, should result in an acceptable pressure distribution on the supporting

structure of the tug (and the assisted ship) under the maximum anticipated loads

during pushing operations.

The design load (DL) to be considered for the strength assessment of the fender

supporting structure may be taken as follows:

The DL takes into consideration anticipated dynamic effects through the application

of the DAF (designated in square brackets in the formula) in but not bouncing

effects.

The fender supporting structure should be able to sustain the DL, as specified above,

without exceeding the following stress level criteria.

- Normal stress σ ≤ 0,75σref;

- Shear stress σ ≤ 0.47σref;

- Equivalent stress σe ≤ 0,85σref,

where

- σref : Reference stress of the material, in N/mm2,

normally to be taken as

, but may be taken as σy for

fittings not made of welded construction; , but may be taken as σy for

fittings not made of welded construction;

- k : Material factor, defined as function of the minimum guaranteed

yield stress σy, see

Table 2.2.4 Material factor k.

Note, within the context of this guidance note, it is considered that during pushing

operations the contact between the tug and assisted ship is maintained and that no

bouncing (e.g. under wave action) is taking place as it is understood that pushing

operations are normally halted when bouncing starts to occur due to operational

difficulties in keeping position within the pushing area of the assisted ship as

well as controlling the associated impact type loads.

Therefore forces resulting from bouncing loads are not considered, if this assumption

is not valid for the design and the operational profile of the vessel then these

dynamic forces are should be included in any fendering calculations. Calculations of

the additional forces and their application to the design should be forwarded to

Lloyd’s Register at the earliest possible convenience for timely consideration.

2.5 Escort operation performance numeral and trials

2.5.1 For Escort tugs, Lloyd’s Register offers the specific notations EPN (F,B,V,C)

and CFD EPN (F,B,V) to denote the escort performance numeral of the vessel.

In the case of EPN the escort performance numeral is obtained by full scale

testing and for CFD EPN it is obtained through CFD.

The EPN is made up of a series of values, i.e. (F,B,V,C). These are defined as:

- F: Maximum steering force, in tonnes.

- B: Maximum braking force, in tonnes.

- V: Speed, in knots, at which F and B are determined.

- C: Time, in seconds, required for the escort tug in manoeuvring from

maintained oblique position of the tug giving it a maximum steering force on

one side of the assisted vessel to a mirror position on the other

side.

Where escort performance numerals are predicted using computational fluid dynamics,

the escort performance numeral ‘C’ is omitted

2.6 Anchoring equipment

2.6.2 Additional design guidelines for anchors

The design of all anchor heads should be such so as to minimise stress

concentrations, and in particular, the radii on all parts of cast anchor heads

should be as large as possible, especially where there is considerable change of

section.

Anchors which must be specially laid the right way up, or which require the fluke

angle or profile to be adjusted for varying types of sea bed, will not generally be

considered for normal ship use.

The number of anchors and chain cables which should be carried should

generally be in line with the aforementioned Table 13.7.1 Equipment requirements of the Rules and Regulations for the Classification of Ships, July 2022. However for vessels with the type

notation tug which are limited to operations within protected waters or

extended protected waters Lloyd’s Register will specially consider a reducing the

required number of required anchors and chain cables to 1.

Lloyds Register may further specially consider a reduction of the number of anchors

and chain cables as depicted in Table 2.2.5 Reduced number of anchors and chain cables based on redundancy

principles. Basis of this consideration will

be the service and operational restrictions of the vessel and the levels of

redundancy on board, for example:

- The tug is equipped with at least twin propulsion, of which each main engine

can maintain sufficient propulsion power to safely return to berth. For this

purpose, the main engines should be able to run self-supporting, i.e.

independent of generator sets intended for auxiliary power, unless these are

able to run parallel and, in case of black-out, have automatic starting and

connecting to switchboard within 45 seconds;

- A single failure, except fire, should not cause total propulsion failure;

- A fixed fire-fighting installation is provided.

Table 2.2.5 Reduced number of anchors and chain cables based on redundancy

principles

| Type notation

|

Service restriction notation

|

Nr

|

| Tug

|

Protected waters/Extended protected

waters

|

0

|

| Tug

|

Specified coastal service, or Specified

operating or service areas

|

1

|

| Tug

|

(unrestricted)

|

2

|

| Escort tug

|

Any

|

1

|

| Escort tug

|

(unrestricted)

|

2

|

Lloyd’s register will specially consider the case where a spare anchor is supplied as

an alternative to a second bower anchor. In such cases special provisions, such as a

crane and suitable storage space for the spare anchor, should be present on

board.

For tugs with a service restriction notation denoting that they are restricted to

operations within protected waters or extended protected waters, effectively

operating in a fixed and limited area, Lloyd’s Register will specially consider the

case that the spare anchor is stored ashore.

2.7 Machinery and Electrotechnical systems

2.7.1 All mechanical and Electrotechnical systems are to be in compliance with the relevant

requirements within the Rules.

Which Rules are applicable to the vessel is dependent on the mechanical and

electrical outfit of the vessel.

2.8 Fire protection, detection and extinction

2.8.2 Both the Class Rules and statute stipulate that tugs of 500 gross tons

or more, on international voyages, where provision is made within International

Conventions, are to be provided with the fire safety measures required by the

International Convention for the Safety of Life at Sea, 1974, as amended.

In addition, the Class Rules stipulate that tugs of 500 gross tons or more employed

on national voyages are to comply with the fire safety measures prescribed and

approved by the Government of the Flag State.

2.8.3 For tugs of less than 500 gross tons The Rules and Regulations for the Classification of Ships, July 2022 also contain relevant requirements in

Pt 6, Ch 4, 2 Fire detection, protection and extinction. The

content of this section is within the spirit of the International Convention and

Protocol requirements for ships of Convention size. However it is to be noted that

the content of this section are “intended to apply to new and, as far as reasonable

and practicable, or as found necessary by the relevant Administration, to existing

cargo ships of less than 500 GT.”. As such, consideration will be given to the

acceptance of fire safety measures prescribed and approved by the Government of the

Flag State instead.

Ch 3, 3.1 Fire safety for tugs of less than 500 GT

of this document includes Lloyd’s Register supported fire protection, detection and

extinction minimum standard guidance.

|