Section

1 General

1.1 Application

1.1.1 The requirements

for longitudinal and transverse global strength for both mono-hull

and multi-hull craft of composite construction, are contained within

this Chapter. Due consideration is taken of the dynamic effects, where

appropriate, in both the crest and trough wave landing conditions.

1.2 Symbols and definitions

1.2.1 Unless

specified otherwise the symbols used in this Chapter are defined as

follows:

|

a

i

|

= |

cross sectional area of the individual ply, i,

in m2

|

|

E

i

|

= |

E

ti, or E

ci of

the individual ply i, relative to its position above

or below the neutral axis, in N/mm2

|

|

E

ci

|

= |

compressive modulus of individual ply, i, in N/mm2

|

|

E

ti

|

= |

tensile modulus of individual ply, i, in N/mm2

|

i

i

|

= |

inertia of

the of individual ply, i, about the neutral axis, in

mm4

|

Σ(E

i

i)H

i)H

|

= |

total

(E

)H (stiffness) for the hull midship section,

in Nm4/mm2 )H (stiffness) for the hull midship section,

in Nm4/mm2

|

|

σci

|

= |

compressive

stress within an individual element, i, in N/mm2

|

|

σti

|

= |

tensile

stress within an individual element, i, in N/mm2

|

|

τH

|

= |

shear

stress at any position along the length of the craft, in N/mm2

|

|

x

i

|

= |

the distance to the centre of area of the individual ply, i,

from the outer surface of the keel plate laminate, in metres

|

|

y

i

|

= |

vertical distance from the hull transverse neutral axis to the

centre of the individual ply, in metres |

|

y

NA

|

= |

the distance of the neutral axis, from the outer surface of

the keel plate laminate, in metres |

L

R and B are

as defined in Pt 3, Ch 1, 6.2 Principal particulars.

1.2.2 The strength

deck is to be taken as follows:

-

Where there is a

complete upper deck the strength deck is the upper deck.

-

Where the upper deck

is stepped, as in the case of raised quarterdeck craft, the strength

deck is stepped as shown in Figure 6.1.1 Strength deck.

Figure 6.1.1 Strength deck

1.3 General

1.3.1 The additional

pressures arising from the influence of the global loading are considered

in the determination of the longitudinal strength requirements for

local and secondary stiffening and bottom shell laminate.

1.3.2 All continuous

longitudinal structural material is to be included in the calculation

of the stiffness, (E

)H, of the hull midship section, and the lever, y

i, is to be measured vertically from the neutral

axis to the centre of the individual ply, i. The inertia

of an individual horizontal ply, i, about its own axes

is to be ignored. )H, of the hull midship section, and the lever, y

i, is to be measured vertically from the neutral

axis to the centre of the individual ply, i. The inertia

of an individual horizontal ply, i, about its own axes

is to be ignored.

1.3.3 Structural

members which contribute to the overall hull girder strength are to

be carefully aligned so as to avoid discontinuities resulting in abrupt

variations of stresses and are to be kept clear of any form of openings

which may affect their structural performance.

1.3.4 In general,

superstructures or deckhouses will not be accepted as contributing

to the global longitudinal or transverse strength of the craft. However,

where it is proposed to include substantial, continuous stiffening

members, special consideration will be given to their inclusion on

submission of the designer's/builder's calculations. Such calculations

are to make due allowance for superstructure efficiency. See

also

Pt 7, Ch 6, 2.5 Superstructures global strength.

1.3.5 Where continuous

deck longitudinals or deck girders are arranged above the strength

deck, special consideration may be given to the inclusion of their

sectional area in the calculation of the hull stiffness (E

)H. The lever is to be taken to a position corresponding

to the depth of the longitudinal member above the moulded deckline

at side amidships. Each such case will be individually considered. )H. The lever is to be taken to a position corresponding

to the depth of the longitudinal member above the moulded deckline

at side amidships. Each such case will be individually considered.

1.3.6 Adequate

transition brackets are to be fitted at the ends of effective continuous

longitudinal strength members in the deck and bottom structures.

1.3.7 Scantlings

of all continuous longitudinal members of the hull girder based on

the minimum section stiffness requirements given in Pt 8, Ch 6, 2.2 Bending strength are to be maintained within 0,4L

R amidships. However, in special cases, based on consideration

of type of ship, hull form and loading conditions, the scantlings

may be gradually reduced towards the ends of the 0,4L

R part,

bearing in mind the desire not to inhibit the vessel's loading and

operational flexibility. L

R is as defined

in Pt 8, Ch 6, 1.2 Symbols and definitions 1.2.1.

1.4 Openings

1.4.1 Deck openings

having a length in the fore and aft directions exceeding 0,1B m

or a breadth exceeding 0,05B m, are always to be deducted

from the sectional areas used in the section stiffness calculation. B is as defined in Pt 8, Ch 6, 1.2 Symbols and definitions 1.2.1.

1.4.2 Deck openings

smaller than stated in Pt 8, Ch 6, 1.4 Openings 1.4.1 including

manholes, need not be deducted provided they are isolated and the

sum of their breadths or shadow area breadths (see

Pt 8, Ch 6, 1.4 Openings 1.4.3), in one transverse section does

not exceed 0,06 (B

1 - Σ b

1).

where

|

B

1

|

= |

breadth of craft at section considered |

|

Σ b1

|

= |

sum

of breadths of deductible openings. |

Where a large number of deck openings are proposed in any transverse

space, special consideration will be required.

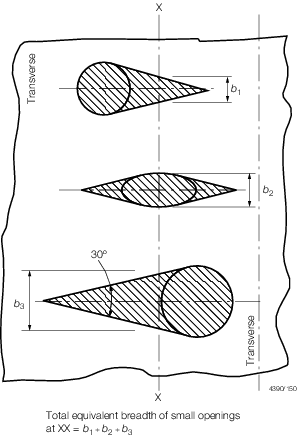

1.4.3 Where calculating

deduction-free openings, the openings are assumed to have longitudinal

extensions as shown by the shaded areas in Figure 6.1.2 Isolated openings. The shadow area is obtained by drawing two tangent

lines to an opening angle of 30o. The sections to be considered

are to be perpendicular to the centreline of the ship and are to result

in the maximum deduction in each transverse space.

1.4.4 Isolated

openings in longitudinals or longitudinal girders need not be deducted

if their depth does not exceed 25 per cent of the web depth or 75

mm whichever is the lesser.

1.4.5 Openings

are considered isolated if they are spaced not less than 1 m apart.

1.4.6 A reduction

for drainage holes and scallops in beams and girders, etc. is not

necessary so long as the original section stiffness at deck or keel

is reduced by no more than three per cent.

1.5 Direct calculation procedure

1.5.1 In direct

calculation procedures capable of deriving the wave induced loads

on the ship, and hence the required modulus, account is to be taken

of the ship's actual form and weight distribution.

1.5.2 Clasifications

Register's (hereinafter referred to as 'LR') direct calculation method

involves derivation of response to regular waves by strip theory,

short-term response to irregular waves using the sea spectrum concept,

and long-term response predictions using statistical distributions

of sea states. Other direct calculation methods submitted for approval

are normally to contain these three elements and produce similar and

consistent results when compared with LR's methods.

Figure 6.1.2 Isolated openings

1.6 Approved calculation systems

1.6.1 Where the

assumptions, method and procedures of a longitudinal strength calculation

system have received general approval from LR, calculations using

the system for a particular ship may be submitted.

1.7 Information required

1.7.1 In order

that an assessment of the longitudinal strength requirements can be

made, the following information is to be submitted, in LR's standard

format where appropriate:

-

General arrangement

and capacity plan or list, showing details of the volume and position

of centre of gravity of all tanks and compartments.

-

Details of the calculated

lightweight and its distribution.

-

Details of the weights, fore and aft extents, and centres of gravity

of all deadweight items for each of the main loading conditions. It is recommended

that this information be submitted in the form of a preliminary Loading

Manual.

-

Still water bending moments and shear forces for each of the main loading

conditions. It is recommended that in the preliminary Loading Manual, a suitable

margin be applied to the still water bending moments and shear forces to allow for

changes between the preliminary and final loading manuals. The responsibility for

the correctness of the submitted still water bending moments and shear forces

rests with the designer.

1.8 Loading guidance information

1.8.1 Sufficient

information is to be supplied to the Master of every craft to enable

him to arrange loading in such a way as to avoid the creation of unacceptable

stresses in the craft's structure.

|