Section

2 Hull girder strength for mono-hull craft

2.1 General

2.1.1 Longitudinal

strength calculations are to be submitted for all craft with a Rule

length, L

R, exceeding 45 m covering the range

of load and ballast conditions proposed, in order to determine the

required hull girder strength. Still water, static wave and dynamic

bending moments and shear forces are to be calculated for both departure

and arrival conditions.

2.1.2 For craft

of ordinary hull form with a Rule length, L

R,

less than 45 m, the minimum hull girder strength requirements are

generally satisfied by scantlings obtained from local strength requirements.

However longitudinal strength calculations may be required at LR's

discretion, dependent upon the form, constructional arrangement and

proposed loading.

2.1.3 Where the

Rule length, L

R, of the craft exceeds 75 m,

or for new designs of large, structurally complicated craft, the design

loads and scantling determination formulae in this Chapter are to

be supplemented by direct calculation and structural analysis by 3-D

finite element methods. These supplementary calculations are to include

the results of model tests and full scale measurement where available

or required by LR. Full details of such methods and all assumptions

and calculations, which are to be based on generally accepted theories,

are to be submitted for appraisal.

2.2 Bending strength

2.2.1 The effective

geometric properties of the midship section are to be calculated directly

from the dimensions of the section using only the effective material

elements which contribute to the global longitudinal strength. For

the purposes of this analysis an element may be of deck plating, longitudinal

girder, inner bottom, etc. or other continuous member.

2.2.2 The longitudinal

strength of craft  is to satisfy both the following criteria: is to satisfy both the following criteria:

L

WL is as defined in Pt 3, Ch 1, 6.2 Principal particulars 6.2.5

σk,  , σt and σd are given

in Table 6.2.1 Longitudinal component

stresses , σt and σd are given

in Table 6.2.1 Longitudinal component

stresses

σa is as defined in Pt 7, Ch 6, 1.2 Symbols and definitions 1.2.1.

Table 6.2.1 Longitudinal component

stresses

| Component stress

type

|

Nominal stress

(N/mm2)

|

| Hull girder bending stress at strength

deck amidships

|

|

| Hull girder bending stress at keel

amidships

|

|

| Actual stress in bottom longitudinals

amidships due to design pressure load

|

|

| Actual stress in bottom plating

amidships due to design pressure load

|

|

| Symbols and definitions

|

|

|

|

|

|

|

|

Z

d

|

= |

actual section modulus at deck, in m3

|

|

|

Z

k

|

= |

actual section modulus at keel, in m3

|

|

|

= |

maximum section modulus of bottom longitudinal

stiffener, associated with plating, amidships, in cm3

|

|

s,  , β and t

p are as defined in Pt 7, Ch 6, 1.2 Symbols and definitions. , β and t

p are as defined in Pt 7, Ch 6, 1.2 Symbols and definitions.

|

2.3 Shear strength

2.3.1 The shear

strength of the craft at any position along its length is to satisfy

the following criterion:

where

|

Q

R

|

= |

design hull shear force at any section along the hull length, L

R, in kN determined from Pt 5, Ch 5, 5 Design criteria and load combinations

|

|

A

τ

|

= |

shear area of transverse section, in m2, is to be

taken as the effective net sectional area of the shell plating and

longitudinal bulkheads after deductions for openings. For longitudinal

strength members which are inclined to the vertical, the area of the

member to be included in the calculation is to be based on the area

projected onto the vertical plane, see

Figure 6.2.1 Effective shear area

|

|

τp

|

= |

maximum

permissible mean shear stress, in N/mm2

|

|

|

= |

f

σgτa

|

|

f

σg

|

= |

limiting hull shear stress coefficient taken from Table 7.3.2 Limiting stress coefficients for

global loading

|

τa is as defined in Pt 7, Ch 6, 1.2 Symbols and definitions 1.2.1.

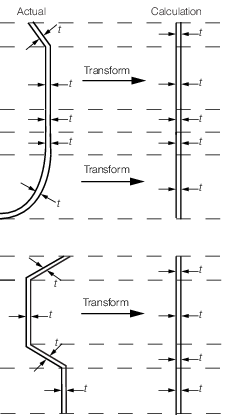

Figure 6.2.1 Effective shear area

2.4 Torsional strength

2.4.1 Torsional

stresses are typically small for mono-hulls of ordinary form of Rule

length, L

R, less than 75 m and can generally

be ignored.

2.4.2 The calculation

of torsional stresses and/or deflections may be required when considering

craft with large deck openings, unusual form or proportions. Calculations

may in general be required to be carried out using a direct calculation

procedure. Such calculations are to be submitted in accordance with Pt 7, Ch 6, 1.5 Direct calculation procedure.

2.5 Superstructures global strength

2.5.1 Where the side walls of superstructures are aligned with the side shell, and

these side walls are fully plated with scantlings as for side shell, the effect of the

superstructure in global strength can be estimated from Pt 7, Ch 6, 2.5 Superstructures global strength 2.5.2 to Pt 7, Ch 6, 2.5 Superstructures global strength 2.5.6. In case there are openings in the side walls that would

affect the connection of the superstructure deck with the hull, or when the side walls

are not in-line with the side shell, the effectiveness of the superstructure in global

strength is to be determined by direct calculation.

The effectiveness of the superstructure in absorbing hull girder bending

loads is to be established where the first tier of the superstructure extends within

0,4L amidship and where:

where

d

d

|

= |

length of first tier, in metres |

|

b

d

|

= |

breadth of first tier, in metres |

|

h

d

|

= |

'tween deck height of first tier, in metres |

2.5.2 For superstructures with one or two tiers extending outboard to the craft's

side shell, the effectiveness in absorbing hull girder bending loads in the uppermost

effective tier may be assessed by the following factor:

where

|

f(λ, N=1) |

= |

1 |

|

f(λ, N=2) |

= |

0,90λ3 – 2,17λ2 + 1,73λ + 0,50 |

and

|

N

|

= |

1 if  2 < 0,7

2 < 0,7 1

1

|

|

|

= |

2 if  2 ≥ 0,7

2 ≥ 0,7 1

1

|

|

λ |

= |

or 1, whichever is less or 1, whichever is less |

|

ε |

= |

or 5, whichever is less or 5, whichever is less |

|

γ |

= |

or 25, whichever is less or 25, whichever is less |

w

w

|

= |

1 for N = 1

1 for N = 1 |

|

|

= |

for N = 2 for N = 2 |

|

L

R

|

= |

is as defined in Pt 7, Ch 6, 1.2 Symbols and definitions 1.2.1, in metres |

1, b

1, h

1

1, b

1, h

1

|

= |

is as defined in Pt 7, Ch 6, 2.5 Superstructures global strength 2.5.1, in metres |

2

2

|

= |

length of second tier, in metres. |

2.5.3 The hull girder compressive bending stress σL, in the uppermost

effective tier at side may be derived according to the following formula:

2.5.4 The compressive stress, σL, in the uppermost effective tier at

side is to be checked against buckling in accordance with Pt 7, Ch 7, 4 Buckling control.

2.5.5 The uppermost effective tier may need to fulfil the requirements for

strength deck when the following applies:

where

|

ηs

|

= |

as defined in Pt 7, Ch 6, 2.5 Superstructures global strength 2.5.2

|

|

Z

0

|

= |

section modulus of hull only at hull upper deck, in m3

|

100

100

|

= |

moment of inertia of hull and effective tiers, assuming tiers to be

100 per cent effective, in m4

|

|

h

|

= |

height from hull upper deck to uppermost effective tier, in

metres. |

2.5.6 The deformation of large openings in side walls of superstructures is to be

investigated. They shall not exceed the deformation limit of the closing appliances.

|