Section

4 Shell envelope framing

4.1 General

4.1.1 Except

as otherwise specified within this Section, the scantlings and arrangements

for shell envelope framing are to be determined in accordance with

the procedures described in, or as required by Pt 8, Ch 3, 4 Shell envelope framing for mono-hull craft, using the pressures from Pt 5 Design and Load Criteria appropriate to multi-hull craft.

4.1.2 The requirements

in this Section apply to longitudinally and transversely framed shell

envelopes.

4.2 Bottom outboard longitudinal stiffeners

4.2.1 The bottom

outboard longitudinal stiffeners are to be supported by bottom transverse

web frames, floors, bulkheads, or other primary structure, generally

spaced not more than 2 m apart.

4.2.2 Bottom

outboard longitudinal stiffeners are to be continuous through the

supporting structures.

4.2.3 Where it

is impracticable to comply with the requirements of Pt 8, Ch 4, 4.2 Bottom outboard longitudinal stiffeners 4.2.2, or where it is desired to terminate

the bottom outboard longitudinal stiffeners in way of the transom,

bulkheads or integral tank boundaries, they are to be bracketed in

way of their end connections to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets.

4.2.4 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.3 Bottom outboard longitudinal primary stiffeners

4.3.1 The bottom

outboard longitudinal primary stiffeners are to be supported by bottom

transverse web frames, floors, bulkheads, or other primary structure,

generally spaced not more than 6 m apart.

4.3.2 Bottom

outboard longitudinal primary stiffeners are to be continuous through

the supporting structures.

4.3.3 Where it

is impracticable to comply with the requirements of Pt 8, Ch 4, 4.3 Bottom outboard longitudinal primary stiffeners 4.3.2, or where it is desired to terminate

the bottom outboard longitudinal primary stiffeners in way of the

transom, bulkheads or integral tank boundaries, they are to be bracketed

in way of their end connections to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets.

4.3.4 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.4 Bottom outboard transverse stiffeners

4.4.1 Bottom

outboard transverse stiffeners are defined as local stiffening members

which support the bottom shell, and which may be continuous or intercostal.

4.4.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for high speed or displacement

type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.5 Bottom outboard transverse frames

4.5.1 Bottom

outboard transverse frames are defined as stiffening members which

support the bottom shell. They are to be effectively continuous and

be bracketed at their end connections to side frames and bottom floors

as appropriate.

4.5.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.6 Bottom outboard transverse web frames

4.6.1 Bottom

outboard transverse web frames are defined as primary stiffening members

which support bottom shell longitudinals. They are to be continuous

and be substantially bracketed at their end connections to side web

frames and bottom floors.

4.6.2 Where it

is impracticable to comply with the requirements of Pt 8, Ch 4, 4.6 Bottom outboard transverse web frames 4.6.1, or where it is desired to terminate

the bottom inboard transverse web frames in way of bulkheads or integral

tank boundaries, etc. all web frames are to be bracketed in way of

their end connections, to maintain the continuity of structural strength.

Particular care is to be taken to ensure accurate alignment of the

brackets. All brackets are to be `soft toed' (see

Figure 3.4.1 `Soft-toe' in Chapter 3) and are to

terminate on suitable supporting structure capable of carrying the

transmitted bending moment.

4.6.3 The Rule

requirements for the bending moment, shear force, shear stress and

deflection are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.7 Bottom inboard longitudinal stiffeners

4.8 Bottom inboard longitudinal primary stiffeners

4.9 Bottom inboard transverse stiffeners

4.10 Bottom inboard transverse frames

4.11 Bottom inboard transverse web frames

4.12 Side outboard longitudinal stiffeners

4.12.1 The side

outboard longitudinal stiffeners are to be supported by side transverse

web frames, bulkheads, or other primary structure, generally spaced

not more than 2 m apart.

4.12.2 Side

outboard longitudinal stiffeners are to be continuous through the

supporting structures.

4.12.3 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.12 Side outboard longitudinal stiffeners 4.12.2, or where it is desired to

terminate the side outboard longitudinal stiffeners in way of the

transom, bulkheads or integral tank boundaries, they are to be bracketed

in way of their end connections to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets.

4.12.4 The Rule

requirements for the bending moment, shear force, shear stress and

deflection are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.13 Side outboard longitudinal primary stiffeners

4.13.1 The side

outboard longitudinal primary stiffeners are to be supported by side

transverse web frames, bulkheads, or other primary structure, generally

spaced not more than 6 m apart.

4.13.2 Side

outboard longitudinal primary stiffeners are to be continuous through

the supporting structures.

4.13.3 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.13 Side outboard longitudinal primary stiffeners 4.13.2, or where it is desired to

terminate the side outboard longitudinal primary stiffeners in way

of the transom, bulkheads or integral tank boundaries, they are to

be bracketed in way of their end connections to maintain the continuity

of structural strength. Particular care is to be taken to ensure accurate

alignment of the brackets.

4.13.4 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.14 Side outboard transverse stiffeners

4.14.1 Side

outboard transverse stiffeners are defined as local stiffening members

which support the side shell, and which may be continuous or intercostal.

4.14.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.15 Side outboard transverse frames

4.15.1 Side

outboard transverse frames are defined as stiffening members supporting

the side shell and spanning continuously between bottom floors/frames

and decks. They are to be effectively constrained against rotation

at their end connections.

4.15.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.16 Side outboard transverse web frames

4.16.1 Side

outboard transverse web frames are defined as primary stiffening members

which support side shell longitudinals, they are to be continuous

and be substantially bracketed at their end connections to side web

frames and side floors.

4.16.2 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.16 Side outboard transverse web frames 4.16.1, or where it is desired to

terminate the side outboard transverse web frames in way of bulkheads

or integral tank boundaries, etc. all web frames are to be bracketed

in way of their end connections, to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets. All brackets are to be `soft toed' see

Figure 3.4.1 `Soft-toe' in Chapter 3, and are to

terminate on suitable supporting structure capable of carrying the

transmitted bending moment.

4.16.3 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.17 Side inboard longitudinal stiffeners

4.18 Side inboard longitudinal primary stiffeners

4.19 Side inboard transverse stiffeners

4.20 Side inboard transverse frames

4.21 Side inboard transverse web frames

4.22 Wet-deck longitudinal stiffeners

4.22.1 The wet-deck

longitudinal stiffeners are to be supported by transverse web frames,

bulkheads, or other primary structure, generally spaced not more than

2 m apart.

4.22.2 Wet-deck

longitudinal stiffeners are to be continuous through the supporting

structures.

4.22.3 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.22 Wet-deck longitudinal stiffeners 4.22.2, or where it is desired to

terminate the wet-deck longitudinal stiffeners in way of the transom,

bulkheads or integral tank boundaries, they are to be bracketed in

way of their end connections to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets.

4.22.4 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.23 Wet-deck longitudinal primary stiffeners

4.23.1 The wet-deck

longitudinal primary stiffeners are to be supported by transverse

web frames, bulkheads, or other primary structure, generally spaced

not more than 6 m apart.

4.23.2 Wet-deck

longitudinal primary stiffeners are to be continuous through the supporting

structures.

4.23.3 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.23 Wet-deck longitudinal primary stiffeners 4.23.2, or where it is desired to

terminate the wet-deck longitudinal primary stiffeners in way of the

transom, bulkheads or integral tank boundaries, they are to be bracketed

in way of their end connections to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets.

4.23.4 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.24 Wet-deck transverse stiffeners

4.24.1 Wet-deck

transverse stiffeners are defined as local stiffening members which

support the wet-deck shell, and which may be continuous or intercostal.

4.24.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (b).

4.25 Wet-deck transverse frames

4.25.1 Wet-deck

transverse frames are defined as stiffening members which support

the wet-deck shell, they are to be effectively continuous and be bracketed

at their end connections to side frames and side floors as appropriate.

4.25.2 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

4.26 Wet-deck transverse web frames

4.26.1 Wet-deck

transverse web frames are defined as primary stiffening members which

support wet-deck longitudinals. They are to be continuous and be substantially

bracketed at their end connections to side web frames and side floors.

4.26.2 Where

it is impracticable to comply with the requirements of Pt 8, Ch 4, 4.26 Wet-deck transverse web frames 4.26.1, or where it is desired to

terminate the wet-deck transverse web frames in way of bulkheads or

integral tank boundaries, etc. all web frames are to be bracketed

in way of their end connections, to maintain the continuity of structural

strength. Particular care is to be taken to ensure accurate alignment

of the brackets. All brackets are to be 'soft toed', see

Figure 3.4.1 `Soft-toe' in Chapter 3, and are to

terminate on suitable supporting structure capable of carrying the

transmitted bending moment.

4.26.3 The Rule

requirements for bending moment, shear force, shear stress and deflection

are to be determined from the general equations given in Pt 8, Ch 3, 1.15 Stiffeners general, using the design pressure

from Pt 5, Ch 3, 3.1 Hull structures or Pt 5, Ch 4, 3.1 Hull structures for non-displacement or

displacement type craft as appropriate, and the coefficients ΦM, ΦS and Φδ as indicated in Table 3.1.10 Shear force, bending moment and

deflection coefficients in Chapter 3 for the

load model (a).

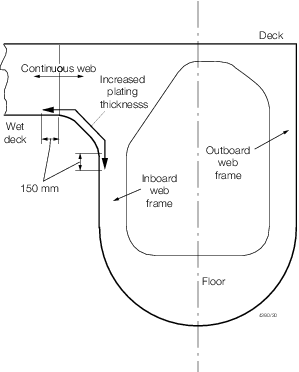

4.26.6 Primary

transverse web frame members which link the strength deck to the wet-deck

structure and which carry the transverse global loading, are additionally

to comply with Pt 8, Ch 6, 3.4 Torsional strength.

4.26.7 Particular

care is to be taken to ensure that the continuity of transverse structural

strength is maintained. All primary transverse members are to be continuous

through the side inboard structure and be integrated into transverse

bulkheads or other primary structure within each hull, see

Figure 4.4.1 End connection detail, wet-deck structure. In the case of trimaran

type craft the primary transverse members are to be continuous through

the centre hull. Additionally the side inboard shell laminate in way

of the intersection is to be locally increased in thickness by not

less than 50 per cent. Copies of direct calculations are to be submitted

for consideration.

Figure 4.4.1 End connection detail, wet-deck structure

4.27 Novel features

4.27.1 Where

the Rules do not specifically define the requirements for novel features

then the scantlings and arrangements are to be determined by direct

calculations. Such calculations are to be carried out on the basis

of the Rules, recognised standards and good practice, and are to be

submitted for consideration.

|