Section

4 Structure design and construction requirements

4.1 Pod structure

4.1.1 Podded

unit struts and pod bodies may be of cast, forged or fabricated construction

or a combination of these construction methods.

4.1.2 Means

are to be provided to enable the propeller shaft, bearings and seal

arrangements to be examined in accordance with LR's requirements and

the manufacturer's recommendations.

4.1.3 When

high tensile steel fasteners are used as part of the structural arrangement

and there is a risk that these fasteners may come into contact with

sea-water, carbon-manganese and low alloy steels with a specified

tensile strength of greater than 950 N/mm2 are not to be

used due to the risk of hydrogen embrittlement.

4.1.4 For

steerable pod units, an integral slewing ring is to be arranged at

the upper extremity of the strut to provide support for the slewing

bearing.

4.1.5 The

strut is to have a smooth transition from the upper mounting to the

lower hydrodynamic sections.

4.1.6 For

fabricated structures, vertical and horizontal plate diaphragms are

to be arranged within the strut and, where necessary, secondary stiffening

members are to be arranged.

4.1.7 Pod

unit structure scantling requirements are shown in Table 4.4.1 Podded propulsion unit -

fabricated structure requirements. Where the scantling

requirements in Table 4.4.1 Podded propulsion unit -

fabricated structure requirements cannot

be satisfied, direct calculations carried out in accordance with Vol 2, Pt 4, Ch 4, 4.3 Direct calculations may be considered.

Table 4.4.1 Podded propulsion unit -

fabricated structure requirements

| Location

|

Requirement

|

Notes

|

| Strut external shell plating

|

Thickness, in mm, is to be not less

than:

t = 0,0063s

f (h

7

k)0,5

|

The minimum thickness of plating diaphragms and

primary webs within the strut is to be not less than the Rule requirement

for the strut external plating. For internal diaphragms, panel stiffening is

to be provided where the ratio of spacing to plate thickness

(s/t) exceeds 100. Where there are no secondary members,

s is to be replaced by S.

|

| Strut primary framing

|

The section modulus in cm3 is to be

not less than:

z = 7,75h

7

le

2

S

k

|

This does not apply to full breadth plate

diaphragms.

|

| Strut secondary stiffening

|

The section in cm3 is to be not less

than:

z = 0,0056h

7

le

2

s

k

|

This does not apply to full breadth plate

diaphragms.

|

| Cylindrical pod body external shell

plating

|

Thickness, in mm, is to be not less

than:

t = 3,0Rg (h

7

k)0,5

|

|

| Symbols

|

|

f

|

= |

panel aspect ratio correction factor = [1,1 –

s/(2500S)] |

|

h7

|

= |

(T + C

w + 0.014V

2) |

|

le

|

= |

effective span of the member under consideration, in

metres |

|

s

|

= |

the frame spacing of secondary members, in mm |

|

R

g

|

= |

mean radius of pod body tube, in metres |

|

S

|

= |

the spacing of primary members, in metres |

|

4.1.8 The

connection between the strut and the pod body should generally be

effected through large radiused fillets in cast pod units or curved

plates in fabricated pod units.

4.1.9 The

structural response under the most onerous combination of loads is

not to exceed the normal operational requirements of the propulsion

or steering system components.

4.1.10 For

cast pod structures, the elongation of the material on a gauge length

of 5.65  is to be not less than 12 per cent where S

o is the actual cross sectional area of the test piece. is to be not less than 12 per cent where S

o is the actual cross sectional area of the test piece.

4.1.11 In

castings, sudden changes of section or possible constriction to the

flow of metal during casting are to be avoided. All fillets are to

have adequate radii which should, in general, be not less than 75

mm.

4.2 Hull support structure

4.2.1 For

supporting the main slewing bearing outer faces, a system of primary

structural members is to be provided in order to transfer the maximum

design loads and moments from the podded propulsion unit into the

ship’s hull without undue deflection. Due account is also to

be taken of the loads induced by the maximum ship’s motions

in the vertical direction resulting from combined heave and pitch

motion of the ship. Account is also to be taken of any manoeuvring

conditions that are likely to give rise to high mean or vibratory

loadings induced by the podded propulsion unit. See

Vol 2, Pt 4, Ch 4, 2.2 Documentation required for design review 2.2.1.(d).

4.2.2 The

hull support structure in way of the slewing bearing should be sufficiently

stiff that the bearing manufacturer’s limits on seating flatness

are not exceeded due to hull flexure as a consequence of the loads

defined under Vol 2, Pt 4, Ch 4, 4.2 Hull support structure 4.2.1.

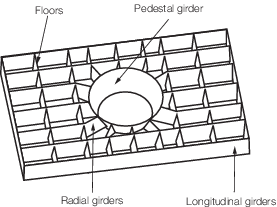

4.2.3 Generally,

the system of primary members is to comprise a pedestal girder directly

supporting the slewing ring and bearing. The pedestal girder is to

be integrated with the ship’s structure by means of radial girders

and transverses aligned at their outer ends with the ship’s

bottom girders and transverses, see

Figure 4.4.1 Hull support structure. Proposals to use alternative

arrangements that provide an equivalent degree of strength and rigidity

may be submitted for appraisal.

4.2.5 The

shell envelope plating and tank top plating in way of the aperture

for the podded drive (i.e. over the extent of the radial girders shown

in Figure 4.4.1 Hull support structure) is to be increased

by 50 per cent over the Rule minimum thickness to provide additional

local stiffness and robustness. However, the thickness of this plating

is not to be less than the actual fitted thickness of the surrounding

shell or tank top plating.

Figure 4.4.1 Hull support structure

4.2.6 The

scantlings of the primary support structure in way of the podded drive

are to be based upon the limiting design stress criteria specified

in Table 4.4.2 Direct calculation maximum

permissible stresses for steel fabricated structures, see

also

Vol 2, Pt 4, Ch 4, 4.3 Direct calculations 4.3.5. Primary

member scantlings are, however, not to be less than those required

by Vol 1, Pt 6, Ch 3, 7 Single bottom structures and Vol 1, Pt 6, Ch 3, 8 Double bottom structures.

Table 4.4.2 Direct calculation maximum

permissible stresses for steel fabricated structures

| Permissible stress values

|

| Location

|

Podded drive structure

|

Podded drive/hull

interface

|

| X-Y shear stress

|

0,26σo

|

0,35σo

|

| Direct stress due to bending

|

0,33σo

|

0,63σo

|

| Von Mises stress

|

0,40σo

|

0,75σo

|

| Localised Von Mises peak stresses

|

σo

|

σo

|

| Symbols

|

|

σo

|

= |

minimum yield strength of the material |

|

Note

1. The values stated above are intended

to give an indication of the levels of stress in the pod and ship

structure for the maximum loads which could be experienced during

normal service.

Note

2. If design is based on extreme or

statistically low probability loads, then proposals to use alternative

acceptance stress criteria may be considered.

|

4.2.7 The

pedestal girder is to have a thickness not less than the required

shell envelope minimum Rule thickness in way. Where abutting plates

are of dissimilar thickness, then the taper requirements of Vol 1, Pt 6, Ch 4 Hull Girder Strength are to be complied with.

4.2.8 In general,

full penetration welds are to be applied at the pedestal girder boundaries

and in way of the end connections between the radial girders and the

pedestal girder. Elsewhere, for primary members, double continuous

fillet welding is to be applied using a minimum weld factor of 0,34.

4.3 Direct calculations

4.3.1 Finite

element or other direct calculation techniques may be employed in

the verification of the structural design. The mesh density used is

to be sufficient accurately to demonstrate the response characteristics

of the structure and to provide adequate stress and deflection information.

A refined mesh density is to be applied to geometry transition areas

and those locations where high localised stress or stress gradients

are anticipated.

4.3.2 Model

boundary constraints are generally to be applied in way of the slewing

ring/ship attachment only.

4.3.3 The

loads applied to the mathematical model, see

Vol 2, Pt 4, Ch 4, 2.4 Global loads 2.4.1, are to include the self weight,

dynamic acceleration due to ship motion, hydrodynamic loads, hydrostatic

pressure, propeller forces and shaft bearing support forces. In situations

where a pod can operate in the flodded conditions or where flooding

of a pod adds significant mass to the pod, details are to be included.

4.3.6 For

cast structures, the localised von Mises stress should not exceed

0,6 times the nominal 0,2 per cent proof or yield stress of the material

for the most onerous design condition.

|