Section

2 Hull girder strength

2.1 General

2.1.1 Longitudinal

strength calculations are to be submitted for all ships with a Rule

length, L

R, exceeding 50 m and are to cover

the range of operating conditions proposed in order to determine the

required hull girder strength. The still water, wave and dynamic bending

moments and shear forces are to be calculated in accordance with the

requirements of Vol 1, Pt 5, Ch 4 Global Design Loads

2.1.2 For

ships of ordinary hull form with a Rule length, L

R,

less than 50 m, the minimum hull girder strength requirements are

generally satisfied by scantlings obtained from local strength requirements.

However, longitudinal strength calculations may be required by LR,

dependent upon the form, constructional arrangement and proposed loading.

2.2 Bending strength

2.2.1 The

effective geometric properties of all critical transverse sections

along the length of the ship are to be calculated directly from the

dimensions of the section using only effective material elements which

contribute to the global longitudinal strength irrespective of the

grades of steel incorporated in the construction, see

Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus

2.2.2 Where

higher tensile is fitted to satisfy global strength requirements,

the extent of higher tensile steel is to be as specified in Vol 1, Pt 6, Ch 2, 1.6 Higher tensile steel 1.6.3 Where a mix of steel

grades is used for plating and associated stiffeners, then the lower

of the steel grades is to be used for the derivation of the permissible

stresses, see 2.2.3.

2.2.3 The

longitudinal strength of the ship is to satisfy the following criteria

for the hogging and sagging conditions:

where

|

σp

|

= |

maximum

permissible hull vertical bending stress, in N/mm2

|

|

f

σhg

|

= |

limiting hull bending stress coefficient, derived as follows: |

| = |

(i) from 0,3L

R to 0,7L

R

f

σhg = 0,75

(ii)

for continuous longitudinal structural members aft of 0,3L

R and forward of 0,7L

R

f

σhg = 0,319 + 2,311 x/L

R –

2,974 (x/L

R)2

|

where

|

x |

= |

the distance,

in metres, from the F.P. for locations within the forward end of L

R and from the A.P. for locations within the aft end of L

R

|

|

f

σws

|

= |

1,2, limiting working stress coefficient |

| = |

NOTE, the σws criterion may be relaxed if it

can be demonstrated that either:

(i) a continuous fatigue

control monitoring system is to be adopted for the in-service life

of the ship

(ii) a fatigue design assessment procedure

is applied which demonstrates that a higher limiting working stress

coefficient, f

σws, may be applied

|

σ

o

(MS) = specified

yield stress, in N/mm2, for mild steel

σB, σD and σ

ws are

given in Table 4.2.1 Longitudinal component

stresses

f

hts and σ

o are defined

in Vol 1, Pt 6, Ch 4, 1.3 Symbols and definitions 1.3.1

Table 4.2.1 Longitudinal component

stresses

| Component stress type

|

Nominal stress

(N/mm2)

|

| Hull girder bending stress at strength deck, see Note 1

|

|

| Hull girder bending stress at keel, see Note 1

|

|

| Hull girder bending stress range, see Note 2

|

|

| Symbols

|

|

M

R = Rule bending moment, in kNm, given in Vol 1, Pt 5, Ch 4, 3.10 Hull girder design loads

|

|

M

WHog = hogging value of M

W, in kNm, given in Vol 1, Pt 5, Ch 4, 3.3 Vertical wave bending moments

|

|

M

WSag = sagging value of M

W, in kNm, given in Vol 1, Pt 5, Ch 4, 3.3 Vertical wave bending moments

|

|

Z

D = actual section modulus at deck, in m3

|

|

Z

B = actual section modulus at keel, in m3

|

Note

1. The hogging and sagging bending

moments are to be considered.

Note

2. The stress range at the keel or other

longitudinally effective material should be used if it is greater than

the stress range at the strength deck.

|

2.2.4 Special

consideration will be given to increasing the permissible stress outside

0,3L

R to 0,7L

R provided

that sufficient buckling checks are carried out.

2.2.5 The

requirements for ships of special or unusual design and for special

operations will be individually considered.

2.2.6 Where

different grades of steel are used then it should be ensured that

the design stress in each structural member is less than the permissible

hull vertical bending stress, i.e.

where

2.2.7 The

design stress due to hull girder bending, σhg, for

each structural member is given by

where

|

Z

i

|

= |

actual section modulus at structural element being considered,

in m3

|

M

R is given in Table 4.2.1 Longitudinal component

stresses.

2.3 Shear strength

2.3.1 The shear strength of all ships is to satisfy the requirements given in

this Section.

2.3.3 For ships with large openings in the side shell and/or a complex

arrangement of longitudinal bulkheads and decks is proposed, shear flow calculations or

direct calculation may be required.

2.3.4 Where shear flow calculation procedures other than those available within

ShipRight are employed, the requirements of Vol 1, Pt 6, Ch 3, 1.4 Equivalents are to be complied with.

2.3.5 The assessment of still water shear stresses is to take into consideration

the effectiveness of the following:

- continuous superstructures;

- the sizes and arrangements of window and door openings;

- access openings or cut-outs in side shell, longitudinal bulkheads,

etc.

2.3.6 The shear strength of the ship at any position along the length is to

satisfy the following criterion:

where

δο is to be taken as the minimum value of δi, and

|

τp

|

= |

maximum permissible shear stress, in N/mm2

|

| = |

f

τ

h

g

τ

ο

|

|

f

τ hg

|

= |

0,75f

hts, limiting hull shear stress coefficient |

|

= |

the inertia of the hull about the transverse neutral axis at the

section concerned, in m4

|

|

A

z

|

= |

the first moment of area of the longitudinal members about the

neutral axis, in m3

Only longitudinally effective members that lie between the

vertical level being considered and the vertical extremity are to be included |

|

δi

|

= |

|

|

t

i

|

= |

the plate thickness of the structural member at the vertical level

and section under consideration, in mm |

f

hts and τo are defined in Vol 1, Pt 6, Ch 4, 1.3 Symbols and definitions 1.3.1.

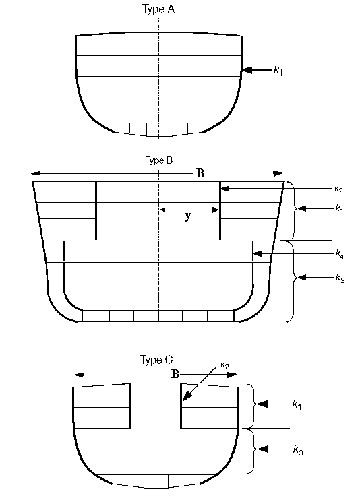

Table 4.2.2

k

i factors

| Hull

configuration

|

k

i factors

|

|

Member

1

k1 =

0,5

|

|

Member 1

Member 2

Member 3

Member 4

|

Member 1

Member 2

Member 3

|

| Symbols

|

Note i = structural index for different hull configurations

Note = 1 or 3, the side shell at the section under

consideration

Note = 2 or 4, the longitudinal bulkheads at the section of

consideration

Note

A

T = half the total effective shear area at the section

under consideration, in cm2, A

T= A

i

Note

A

i = the area of structural member i at the section under

consideration, in cm2

Note

y

is the distance of structural member 2 from the centreline

|

Note

1. For hull configurations not included

above, k

i factors are to be specially considered.

Note

2. Where it is necessary to increase the

thickness of the side shell or longitudinal bulkhead(s) to meet these

requirements, the original thicknesses are to be used in the

calculation of the cross-sectional areas A

i.

|

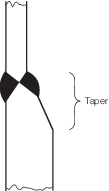

2.3.8 Where a plate is tapered, the permissible combined shear stress is not to

be exceeded at any point in way of the taper, see

Figure 4.2.1 Tapered plates

2.4 Torsional strength

2.4.1 Torsional

stresses are typically small for mono-hulls of ordinary form and can

generally be ignored.

2.4.2 The

calculation of torsional stresses and/or deflections may be required

when considering ships with large deck openings, unusual form or proportions,

or special operating modes which induce significant torsional stresses.

Calculations may in general be required to be carried out using direct

calculation procedures. Such calculations are to be submitted in accordance

with Vol 1, Pt 6, Ch 4, 1.5 General

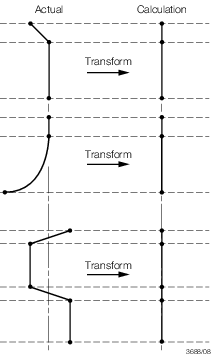

Figure 4.2.1 Tapered plates

Figure 4.2.2 Calculation of A

i for non vertical

parts of structural members (referenced from Table 4.2.2)

2.5 Superstructures global strength

2.5.1 The

effectiveness of the superstructure in absorbing hull girder bending

loads is to be established where the first tier of the superstructure

extends within 0,4L

R amidships and where:

1 > b

1 + 3h

1

1 > b

1 + 3h

1

where

1

1

|

= |

length of

first tier, in metres |

|

b

1

|

= |

breadth of first tier, in metres |

|

h

1

|

= |

‘tween deck height of first tier, in metres |

2.5.2 For

superstructures with one or two tiers extending outboard to the ship’s

side shell, the effectiveness in absorbing hull girder bending loads

in the uppermost effective tier may be assessed by the following factor:

|

ηs

|

= |

7

((ε – 5) γ4 + 94 (5 – ε) γ3 + 2800 (ε – 5,8) γ2 + 27660 (9

– ε) γ) f(λ, N) x 10–7

|

-

where

f (1, N = 1) = 1

f (λ, N = 2) = 0,90λ3 – 2,17λ2 + 1,73λ + 0,50

and

|

N |

= |

1 if  2 < 0,7

2 < 0,7 1

1

|

| = |

2 if  2 ≥ 0,7

2 ≥ 0,7 1

1

|

|

λ |

= |

or 1, whichever is less or 1, whichever is less

|

|

ε |

= |

or 5, whichever is less or 5, whichever is less

|

|

γ |

= |

or 25, whichever is less or 25, whichever is less

|

w

w

|

= |

1 for N = 1

1 for N = 1

|

| = |

(2 1 +

1 +  2)/3 for N = 2

2)/3 for N = 2

|

L

R is defined in Vol 1, Pt 6, Ch 4, 1.2 Hull girder strength notations 1.2.1, in metres

1, b

1, h

1 are defined in Vol 1, Pt 6, Ch 4, 2.5 Superstructures global strength 2.5.1,

in metres.

1, b

1, h

1 are defined in Vol 1, Pt 6, Ch 4, 2.5 Superstructures global strength 2.5.1,

in metres.

2

2

|

= |

length of

second tier, in metres. |

2.5.3 The

design stress due to hull girder bending, σhg, in the

uppermost effective tier at side may be derived according to the following

formula:

where

|

Zs

|

= |

section modulus at the structural element being considered,

in m3. The section modulus is to include the superstructure

tiers, assuming the tiers to be ηs effective.

|

2.5.5 The

uppermost effective tier may need to fulfil the requirements for strength

deck when the following applies:

where

ηs is defined in Vol 1, Pt 6, Ch 4, 2.5 Superstructures global strength 2.5.2

|

Z0

|

= |

section modulus of hull only at hull upper deck, in m3

|

100

100

|

= |

moment of

inertia of hull and effective tiers, assuming tiers to be 100 per

cent effective, in m4

|

|

h

|

= |

height

from hull upper deck to uppermost effective tier, in metres. |

2.6 Buckling strength

2.6.1 The

buckling requirements in Vol 1, Pt 6, Ch 2, 3 Buckling are

to be applied to plate panels and longitudinals subject to hull girder

compression and shear stresses. The design stresses are to be based

on the design values of still water and wave bending moments and shear

forces and are given in Vol 1, Pt 6, Ch 4, 2.2 Bending strength 2.2.4 and Vol 1, Pt 6, Ch 4, 2.3 Shear strength 2.3.7 The design factors of safety

are given in Vol 1, Pt 6, Ch 5 Structural Design Factors

2.6.2 When

a Level 2 extreme strength assessment is applied, the Owner may specify

in the tailoring document that the buckling assessment of plate panels

subject to compressive stresses is not required. In this case the

buckling requirements of Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements may

be relaxed. The requirements of Vol 1, Pt 6, Ch 2, 3.6 Shear buckling of stiffened panels for shear buckling and the remainder of Vol 1, Pt 6, Ch 2, 3 Buckling must always be complied with.

|