Section

3 Buckling

3.1 General

3.1.1 This

Section contains the requirements for buckling control of plate panels

subject to in-plane compressive and/or shear stresses and buckling

control of primary and secondary stiffening members subject to axial

compressive and shear stresses.

3.1.2 The

requirement for buckling control of plate panels is contained in Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements. The requirements for secondary

stiffening members are contained in Vol 1, Pt 6, Ch 2, 3.7 Secondary stiffening in direction of compression. The requirements for primary members are contained

in Vol 1, Pt 6, Ch 2, 3.9 Buckling of primary members and Vol 1, Pt 6, Ch 2, 3.10 Shear buckling of girder webs

3.1.3 In general

all areas of the structure are to meet the buckling strength requirements

for the design stresses. The design stresses are to be taken as the

global hull girder bending and shear stresses derived in accordance

with Vol 1, Pt 6, Ch 4 Hull Girder Strength. In addition, where

the structural member is subject to local compressive loads, then

the design stresses are to be based on these loads.

3.1.4 The buckling requirements are to be met using the net scantlings, hence any

additional thickness for corrosion margin or enhanced scantlings is not included in the

scantlings used to assess the buckling performance. For corrosion margins, see

Vol 1, Pt 6, Ch 6, 3.8 Corrosion margin.

3.2 Symbols

3.2.1 The

symbols used in this Section are defined below and in the appropriate

sub-Section:

|

|

= |

|

|

a

|

= |

panel

length, i.e. parallel to direction of compressive stress being considered,

in mm |

|

b

|

= |

panel

breadth, i.e. perpendicular to direction of compressive stress being

considered, in mm |

|

S

p

|

= |

span of primary members, in metres |

|

σ

e

|

= |

elastic compressive buckling stress, in N/mm2

|

|

σ

c

|

= |

critical compressive buckling stress, including the effects

of plasticity where appropriate, in N/mm2

|

|

τ

e

|

= |

elastic shear buckling stress, in N/mm2

|

|

τ

c

|

= |

critical shear buckling stress, in N/mm2

|

|

b

eb

|

= |

lesser of 1,9t

p

or 0,8b mm or 0,8b mm

|

|

A

te

|

= |

cross-sectional area of secondary stiffener, in cm2,

including an effective breadth of attached plating, b

eb

|

|

s

|

= |

length

of shorter edge of plate panel, in mm (typically the spacing of secondary

stiffeners) |

|

= |

length of longer edge

of plate panel, in metres. |

|

S

|

= |

spacing

of primary member, in metres (measured in direction of compression) |

3.3 Plate panel buckling requirements

3.3.1 The

section gives methods for evaluating the buckling strength of plate

panels subjected to the following load fields:

-

uni-axial compressive

loads;

-

shear loads;

-

bi-axial compressive

loads;

-

uni-axial compressive

loads and shear loads;

-

bi-axial compressive

loads and shear loads.

3.3.7 However,

where some members of the structure have been designed such that elastic

buckling of the plate panel between the stiffeners is allowable, then

the requirements of Vol 1, Pt 6, Ch 2, 3.5 Additional requirements for plate panels which buckle elastically must

be applied to the buckling analysis of the stiffeners supporting the

plating. In addition, panels which do not satisfy the panel buckling

requirements must be indicated on the appropriate drawing and the

effect of these panels not being effective in transmitting compressive

loads taken into account for the hull girder strength calculation, see

Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus 1.4.9 and Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus 1.4.10

3.3.8 In general

the plate panel buckling requirements for more complex load fields, see

Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements 3.3.1.(c), Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements 3.3.1.(d) and Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements 3.3.1.(e), are to be complied with.

Where this is not possible, due to elastic buckling of the panel,

then the critical buckling stress, σc, may be based

on the ultimate collapse strength of the plating, σu from Vol 1, Pt 6, Ch 2, 3.5 Additional requirements for plate panels which buckle elastically 3.5.4, instead of the elastic buckling

stress, σe, derived in Vol 1, Pt 6, Ch 2, 3.3 Plate panel buckling requirements 3.3.5. In addition, the requirements of Vol 1, Pt 6, Ch 2, 3.5 Additional requirements for plate panels which buckle elastically are to be met for the supporting secondary stiffeners and

primary members.

3.4 Derivation of the buckling stress for plate panels

3.4.1 The critical compressive buckling stress, σc, for a plate

panel subjected to uni-axial in-plane compressive loads is to be derived in accordance

with Table 2.3.2 Buckling stress of plate

panels

Table 2.3.2 Buckling stress of plate

panels

| Mode

|

Elastic buckling stress, N/mm2

see Note

|

|

| (a)

Uni-axial compression:

|

|

|

|

|

(i) Long narrow panels, loaded on the

narrow edge

|

|

|

|

|

AR < 1

|

|

|

(ii)

Short broad panels, loaded on the broad edge

|

|

|

|

|

|

| (b) Pure shear:

|

|

|

| NOTE u is to be the minimum dimension

|

NOTE

The critical buckling stresses, in N/mm2,

are to be derived from the elastic buckling stresses as follows:

|

σc= σe when σe <

|

τc = τe when τe <

|

=

σo

when σe ≥ when σe ≥

|

=

τo

when τe ≥ when τe ≥

|

|

|

|

| Symbols and definitions

|

|

σe

|

= |

elastic compressive buckling stress, in

N/mm2

|

|

τe

|

= |

elastic shear buckling stress, in N/mm2

|

a and b are the panel dimensions in mm, see figures

above

|

tp

|

= |

thickness of plating, in mm |

|

Φ |

= |

stress distribution factor for linearly varying

compressive stress across plate width |

|

|

= |

0,47μ2 – 1,4μ + 1,93 for μ ≥ 0 |

|

μ |

= |

where σd1 and σd2 are the

smaller and larger average compressive stresses respectively where σd1 and σd2 are the

smaller and larger average compressive stresses respectively |

|

|

E

|

= |

Young’s Modulus of elasticity of material, in

N/mm2

|

|

C

|

= |

stiffener influence factor for panels with stiffeners

perpendicular to compressive stress |

|

|

= |

1,3 when plating stiffened by floors or deep

girders |

|

|

= |

1,21 when stiffeners are built up profiles or rolled

angles |

|

|

= |

1,10 when stiffeners are bulb flats |

|

|

= |

1,05 when stiffeners are flat bars |

|

|

= |

σd and τd are the design

compressive and design shear stresses in the direction

illustrated in the figures. With linearly varying stress across

the plate panel, σd is to be taken as σd2.

|

|

3.4.3 For

welded plate panels with plating thicknesses below 8 mm, the critical

compressive buckling stress is to be reduced to account for the presence

of residual welding stresses. The critical buckling stress for plating

is to be taken as the minimum of:

or

where

|

σr

|

= |

reduction

in compressive buckling stress due to residual welding stresses |

| = |

|

|

βRS

|

= |

residual

stress coefficient dependent on type of weld (average value of βRS to be taken as 3)

|

tp and σ

o are defined in Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1

σc is derived in Vol 1, Pt 6, Ch 2, 3.4 Derivation of the buckling stress for plate panels 3.4.1

b is defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

3.4.4 In general

the effect of lateral loading on plate panels (for example hydrostatic

pressure on bottom shell plating) may be neglected and the critical

buckling stresses calculated considering the in-plane stresses only.

3.4.5 Unless

indicated otherwise, the effect of initial deflection on the buckling

strength of plate panels may be ignored.

3.5 Additional requirements for plate panels which buckle elastically

3.5.1 Elastic

buckling of plate panels between stiffeners occurs when both the following

conditions are satisfied:

-

The design compressive

stress, σd, is greater than the elastic buckling stress

of the plating, σ

e

-

The elastic buckling

stress is less than half the yield stress

3.5.3 The

effective breadth of attached plating for stiffeners, girder or beams

that is to be used for the determination of the critical buckling

stress of the stiffeners attached to plating which buckles elastically

is to be taken as follows:

|

b

eu

|

= |

|

where

|

b

eu

|

= |

effective panel breadth perpendicular to direction of compressive

stress being considered |

b is given in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

3.5.4 The

ultimate buckling strength of plating, σ

u,

which buckles elastically, may be determined as follows:

-

shortest edge

loaded, i.e. A

R ≥ 1:

-

longest edge loaded

i.e. A

R < 1:

where

A

R and s are

defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

tp, E and σ

ow are defined

in Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1.

3.6 Shear buckling of stiffened panels

3.7 Secondary stiffening in direction of compression

3.7.1 The

buckling performance of stiffeners will be considered satisfactory

if the following conditions are satisfied:

where

σc

(a),

σc

(t), σc

(w) and

σc

(f) are the critical buckling stress of

the stiffener for each mode of failure, see

Vol 1, Pt 6, Ch 2, 3.7 Secondary stiffening in direction of compression 3.7.2

σ

d is the design compressive stress, see also

Vol 1, Pt 6, Ch 2, 3.1 General 3.1.3 and Vol 1, Pt 6, Ch 2, 3.5 Additional requirements for plate panels which buckle elastically

λσ is

the buckling factor of safety given in Table 5.3.2 Allowable stress factors f

1 in Vol 1, Pt 6, Ch 5 Structural Design Factors The

value of λ

σ to be chosen depends

on the buckling assessment of the attached plating, see Note

3, Table 5.3.2 Allowable stress factors f

1

3.7.2 The

critical buckling stresses for the overall, torsional, web and flange

buckling modes of longitudinals and secondary stiffening members under

axial compressive loads are to be determined in accordance with Table 2.3.3 Buckling stress of secondary

stiffeners

Table 2.3.3 Buckling stress of secondary

stiffeners

| Mode

|

Elastic buckling stress, N/mm2

|

Critical

buckling stress, N/mm2

see Note

|

| (a)

|

Overall

buckling (perpendicular to plane of plating without rotation of

cross-section)

|

|

σc(a)

|

| (b)

|

Torsional

buckling

|

|

σc(t)

|

| (c)

|

Web

buckling (excluding flat bar stiffeners)

|

|

σc(w)

|

| (d)

|

Flange

buckling

|

|

σc(f)

|

NOTE

The critical buckling stresses are to be derived from

the elastic buckling stresses as follows:

|

|

σc

|

= |

σe when σe <

|

|

|

= |

when σe ≥ when σe ≥

|

|

| Symbols

|

|

tw

|

= |

web thickness, in mm |

|

bf

|

= |

flange width, in mm (including web thickness) |

e

e

|

= |

effective span length of stiffener, in metres |

|

Cf

|

= |

end constraint factor |

|

|

= |

1 where both ends are pinned |

|

|

= |

2 where one end is pinned and the other end

fixed |

|

|

= |

4 where both ends are fixed |

|

E

|

= |

Young's Modulus of elasticity of the material, in

N/mm2

|

a

a

|

= |

moment of inertia, in cm4, of

longitudinal, including attached plating of effective width

b

eb. For stiffeners attached to plating which buckles

elastically, see 4.5, the effective width of plating is to

be taken as b

eu. |

t

p and σo are given in Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1

A

te and b

eb are given in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

|

|

|

|

It

|

= |

St.Venant's of inertia, in cm4, of

longitudinal (without attached plating) |

| = |

for flat bars for flat bars |

| = |

for built up profiles, rolled angles and bulb

plates for built up profiles, rolled angles and bulb

plates |

|

Ip

|

= |

polar moment of inertia, in cm4, of profile

about connection of stiffener to plating |

| = |

for flat bars for flat bars |

| = |

for built up profiles, rolled angles and bulb

plates for built up profiles, rolled angles and bulb

plates |

|

Iw

|

= |

sectional moment of inertia, in cm6, of

profile and connection of stiffener to plating |

| = |

for flat bars for flat bars |

| = |

for 'Tee' profiles for 'Tee' profiles |

| = |

for 'L' profiles, rolled angles and bulb

plates for 'L' profiles, rolled angles and bulb

plates |

|

C

|

= |

spring stiffness exerted by supporting plate

panel |

| = |

|

|

kp

|

= |

1 – ηp, and is not to be taken as less than

zero. For built up profiles, rolled angles and bulb plates,

k

p need not be taken less than 0,1 |

|

ηp

|

= |

|

m is determined as follows: e.g.m = 2 for K = 25

|

|

|

|

K range

|

0 ≤

k < 4

|

4 ≤

k < 36

|

36 ≤ k < 144

|

144 ≤ k < 400

|

400 ≤ k < 900

|

900 ≤ k < 1764

|

(m — 1)2

m

2 ≤ k < m

2 (m + 1)2

|

|

|

|

m

|

1

|

2

|

3

|

4

|

5

|

6

|

m

|

|

|

|

|

K

|

= |

|

σd is the design stress, in N/mm2

all other symbols as defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1 or Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1.

|

|

3.7.4 The

critical buckling stresses of the stiffener web, σc(w),

and flange, σc(f), are to be greater than the critical

torsional buckling stress, hence:

σc(w) > σc(t)

σc(f) > σc(t)

3.7.5 To ensure

that overall buckling of the stiffened panel cannot occur before local

buckling of the secondary stiffener, the critical overall buckling

stress σc(a), is to be greater than the critical torsional

buckling stress, hence:

σc(a) > σc(t)

3.8 Secondary stiffening perpendicular to direction of compression

3.8.1 Where

a stiffened panel of plating is subjected to a compressive load perpendicular

to the direction of the stiffeners, see

Figure 2.3.2 Secondary stiffening perpendicular to direction of compression e.g. a transversely

stiffened panel subject to longitudinal compressive load, the requirements

of this section are to be applied.

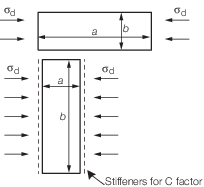

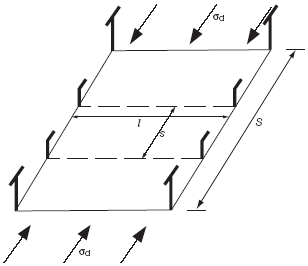

Figure 2.3.2 Secondary stiffening perpendicular to direction of compression

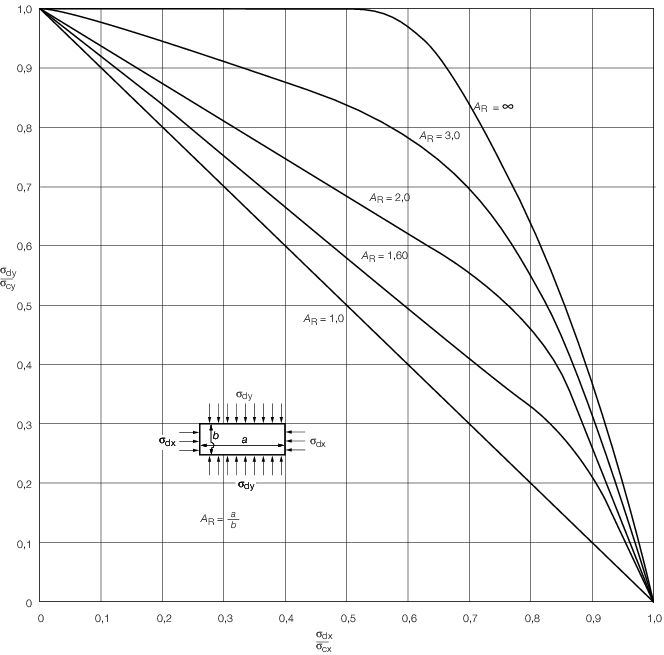

Figure 2.3.3 Interaction limiting stress curves

of G for plate panels subject to bi-axial compression

3.8.2 The

minimum moment of inertia of each stiffener including attached effective

plating of width, b

eb, to ensure that overall

panel buckling does not precede plate buckling is to be taken as:

where

|

D

|

= |

|

|

κ |

= |

A

R

2 Π2

|

|

A

R

|

= |

plate panel aspect ratio |

|

|

= |

|

|

Π |

= |

|

|

N

L

|

= |

number of plate panels |

|

N

L–1

|

= |

number of stiffeners |

|

υ

|

= |

0,3 |

s, l and S are defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1 and shown in Figure 2.3.2 Secondary stiffening perpendicular to direction of compression

t

p and E are defined in Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1.

3.9 Buckling of primary members

3.9.2 To prevent

global buckling from occurring before local panel buckling, transverse

primary girders supporting axially loaded longitudinal stiffeners

are to have a sectional moment of inertia, including attached plating,

of not less than the following:

S

p and s are

as defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

|

lg

|

= |

is the sectional

moment of inertia including attached plating |

where

|

σep

|

= |

|

| = |

|

σ

d is design stress, in N/mm2

σ

o and A

te are

as defined in Vol 1, Pt 6, Ch 2, 3.2 Symbols 3.2.1

σ

e(a) is the elastic column buckling

stress, see

Vol 1, Pt 6, Ch 2, 3.7 Secondary stiffening in direction of compression 3.7.2

E is defined in Vol 1, Pt 6, Ch 2, 1.3 Symbols and definitions 1.3.1

e is defined in Table 2.3.3 Buckling stress of secondary

stiffeners

e is defined in Table 2.3.3 Buckling stress of secondary

stiffeners

3.10 Shear buckling of girder webs

3.11 Pillars and pillar bulkheads

|