8.5.1 Rubbing

strakes or barwhales are to be fitted to the bottom shell. In longitudinally

framed ships they are to be placed directly below longitudinals. Typical

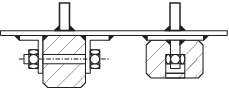

arrangements of rubbing strakes are shown in Figure 2.8.2 Rubbing strakes. Usually they consist

of a steel frame welded to the hull supports with a bolted connection

to softer material but rubbing strips can be constructed of solid

steel sections. They are to be free of projections or other discontinuities

which could lead to damage of the shell plating.

Figure 2.8.2 Rubbing strakes

8.5.2 It is

recommended that rubbing strakes are not to be spread more than 1,5m

apart. For rubbing strakes spaced greater than 1,5m the bottom structure

is to be specially considered.

8.5.3 The

rubbing strake housing both internally and externally is to be efficiently

coated to prevent corrosion. Where different materials are used the

materials are to be selected or insulated to ensure that there is

no galvanic corrosion.

8.5.4 Rubbing

strakes are to be continuously welded to the hull. Butts between sections

of rubbing strake are to be butt welded together before being welded

to the hull. Where this is not possible, ceramic rather than copper

backing strips are to be used.

8.5.5 Rubbing

strakes are to be of the same grade of steel as the shell plate to

which they are attached.

8.5.6 The

ends of rubbing strakes are to be tapered at an angle of not less

than 1 in 3 with no discontinuities in the welding in this region.

Where not supported by internal longitudinals, the ends of strakes

are to be arranged to pass 30 to 50 mm over the end of transverse

frames or floors.

8.5.7 Due

consideration is to be given to the depth of the rubbing strakes with

regard to the nature of the beach. In no case are they to be less

than 100 mm projection.