Section

4 Construction Monitoring

4.1 Construction Monitoring notation – CM

4.1.1 The

Construction Monitoring (CM) notation may be assigned

if extended controls on structural alignment, fit-up and workmanship

standards are applied to critical areas, as identified during the

design of the ship. Construction Monitoring is applied primarily to

verify the quality of workmanship required to improve the fatigue

resistance of critical details, though other construction quality

requirements can be specified in the CM plan.

4.1.2 The

fatigue life of structural details can be adversely affected by a

variety of factors, including workmanship defects. Criteria for workmanship

defects can be considered in the CM plan. The most common factors

that impact on fatigue are:

-

Misalignment of

structural members; i.e. poor fit-up;

-

Welding defects;

-

Materials defects;

-

Stress concentrations

resulting from incorrect geometry of structure, inadequate plate edge

finish or generally poor manufacturing;

-

Erroneous cut-outs

due to inappropriate routing of systems;

-

Discontinuity

of structural members.

4.2 Identification of critical areas

4.2.1 A critical

area is generally a structurally significant item or structural joint

that has been subjected to an enhanced calculation or assessment.

As a consequence, the performance of the item or joint will be influenced

by the workmanship and fit-up in the building yard. In some areas,

where there are high cyclic stresses, an enhanced workmanship and

alignment standard is required in order to achieve the specified design

hull fatigue life.

4.2.3 Critical

areas may also be identified by LR from one of the following optional

assessments. In general, these will be associated with reinforcement

and alignment of specific critical joints; they will not be associated

with general deformation criteria:

-

Extreme Strength

Assessment (ESA), specified in Vol 1, Pt 6, Ch 4, 3 Extreme Strength Assessment, ESA;

-

Residual Strength

Assessment (RSA), specified in Vol 1, Pt 6, Ch 4, 4 Residual Strength Assessment, RSA;

-

Whipping Assessment

(WH), specified in Vol 1, Pt 4, Ch 2, 6 Whipping.

4.2.4 In addition,

critical areas may be identified by the designer, Naval Administration

or Owner from one of the following:

-

Known areas of

high stress identified by structural engineers;

-

Areas that have

experienced failure on similar ships in service;

-

Structures with

specific alignment requirements; e.g. masts, shaft brackets.

4.2.5 The

critical areas, locations and assessment criteria are to be detailed

in the Construction Monitoring plan. The plan should also contain

templates to be used to record specific alignment requirements. The

CM plan may be supported by a high-stress key plan identifying critical

regions on the ship.

4.2.6 Development

of the CM plan is the responsibility of the designer; LR will identify

the critical locations to be subjected to monitoring, following appraisal

of the assessments identified in Vol 1, Pt 3, Ch 6, 4.2 Identification of critical areas 4.2.2 and Vol 1, Pt 3, Ch 6, 4.2 Identification of critical areas 4.2.3 above. In general, areas with

stress ranges greater than σws, see

Vol 1, Pt 6, Ch 4, 2.2 Bending strength 2.2.3, and areas where

general or detailed fatigue analysis has been undertaken will be listed

in the appraisal documentation. LR may develop the CM plan on behalf

of the designer, if so requested.

4.2.7 It is

recommended that the areas for Construction Monitoring be identified

and the criteria developed in a workshop with the Owner, Naval Administration,

Builder and LR.

4.3 Construction monitoring criteria

4.3.2

Normal

alignment is assigned to structure which requires an enhanced

level of survey above the normal survey requirement but does not require

enhanced levels of alignment above the agreed production standard,

such as the Naval Survey Guidance for Steel Ships:

-

Structure will

be inspected by the Builder, before welding, for compliance with the

general shipbuilding tolerances laid down in the agreed production

standard.

-

A representative

sample of alignment measurements will be undertaken by LR during the

survey to confirm compliance with the agreed production standard.

-

Where there are

non-compliances, the relevant shipyard department will be requested

by LR to undertake full measurements and to produce a report for review

by LR which details the non-compliances.

4.3.3

Enhanced

alignment is assigned where critical areas have enhanced alignment

requirements to maintain structural performance:

-

The relevant shipyard

department will be required to provide a report, based on templates

in the CM plan, detailing the achieved alignment at each location.

-

LR will review

the alignment report and request check measurements as necessary to

confirm the results.

-

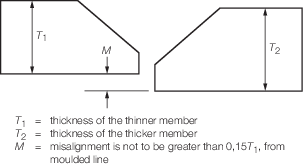

The maximum allowable

misalignment between the interconnection of structural members is

to be 15 per cent of the thinner of the members being connected. This

alignment criterion is to be applied where longitudinally effective

structure is butted; e.g. plating at ring butts, longitudinal butts, see

Figure 6.4.1 Alignment criterion.

-

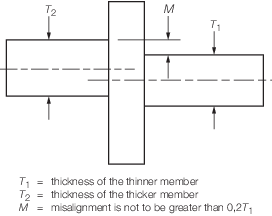

For all cruciform

joints, the maximum allowable misalignment between the interconnection

of structural members is to be 20 per cent of the thinner of the members

being connected. This alignment criterion is to be applied where there

is alignment through a thickness; e.g. intercostal longitudinal bulkheads

through a transverse bulkhead, bilge keel plate alignment with internal

structure through shell plating, see

Figure 6.4.2 Cruciform joints.

Figure 6.4.1 Alignment criterion

Figure 6.4.2 Cruciform joints

4.3.4

Specific

alignment is assigned where there are specific alignment criteria

identified by the designer which need to be verified by LR:

-

the relevant shipyard

department will be required to provide a report detailing the achieved

alignment at each location;

-

LR will review

the alignment report and request check measurements as necessary to

confirm the results;

-

the alignment

criteria and templates, where appropriate, are to be defined by the

designer for each critical area defined.

4.3.5

Close-up

inspection is assigned to structure which has no specific alignment

requirement but requires an increased level of inspection; for example,

to verify correct plate thickness or maximum permitted plate deformation.

Close-up inspection may be required to verify a particular or unusual

structural feature:

-

Structure will

be subject to an enhanced close-up visual inspection by LR Surveyor(s).

-

Dry surveys should

identify where units or compartments contain construction monitoring

points. These are to be identified by the Builder as a specific witness

point.

4.3.6 Non-destructive

examination, in addition to the general levels of NDE required in Vol 1, Pt 6, Ch 6 Material and Welding Requirements, may be specified by the designer

for critical areas, which LR will verify:

-

The relevant shipyard

department will be required to undertake the additional NDE required

at each location and record the results.

-

LR will review

and audit the NDE measurements as necessary to confirm the results.

4.4 Construction Monitoring survey

4.4.1 Construction

Monitoring is a process for monitoring workmanship standards and alignment

in critical areas. It is the Builder’s responsibility to carry

out the necessary checks and document the results for relevant critical

locations, irrespective of the Surveyor(s) attendance at hold points.

Shipyard personnel are responsible for the inspection and recording

of all CM requirements, in accordance with the approved CM plan.

4.4.2 LR will

provide third party inspection to confirm that the critical areas

to be covered by CM conform to the required/agreed standards based

on check inspections and audit activities. Where LR undertakes a CM

inspection to verify the implementation of the CM plan, it will cover:

-

weld specification

in terms of type, size and finish/treatment, including:

-

fit-up and alignment

before commencement of welding;

-

alignment

after application of first root run;

-

back gouging;

-

final welding

and alignment;

-

stress relief

grinding of weld profile (where required for enhanced fatigue performance);

-

the continuity

of structural members, where required;

-

plate edge radius

and roughness;

-

joints for radius

and tapering;

-

openings and penetrations

for radius corners.

4.4.3 LR will

review all of the specific CM records, as defined in Vol 1, Pt 3, Ch 6, 4.3 Construction monitoring criteria, and in a few cases request that

measurements be presented. It is not intended that the attending Surveyor(s)

witness each stage of the fabrication process for every critical area,

except during the early stages of construction whilst the process

is being established.

4.4.4 CM activities

will generally be undertaken in conjunction with routine dry surveys

required for all construction units. A few specific CM items require

measurement by the shipyard; these are described as Enhanced or Specific

Alignment.

4.4.5 Non-compliances

will not be permitted in the critical areas identified within the

CM plan. Where defects are identified within defined critical sections,

LR is to agree the remedial action to be taken with the Shipbuilder

before rectification is commenced.

4.4.6 On satisfactory

completion of all surveys and measurements, LR Surveyor(s) will recommend

the assignment of the CM notation.

|