Section

7 Towing arrangements

7.1 Definition

7.1.1 Towing

can be defined as either receiving motive assistance from, or rendering

it to, another vessel.

7.2 Application

7.2.1 The

towing arrangements specified in this section are applicable to NS1,

NS2 and NS3 category ships carrying the corresponding optional towing

arrangement notation.

7.2.2 The

strength of strong points, fittings and machinery are to be proof

tested unless type approved.

7.2.3 In general,

ships complying with the requirements of this section will be eligible

to be classed with the notation TA1,

TA2 or TA3.

7.2.7 These

three levels of towing arrangements in 7.2.4 to 7.2.6 recognise towing

a ship of similar displacement at 6 knots in defined environmental

conditions (see

Table 5.7.3 Environmental conditions) and are appropriate for the weather conditions found

in the equivalent service areas, i.e. TA1 corresponds

to the weather conditions found with service area notation SA1.

7.2.10 Towing

operations are to be in accordance with the towing, mooring and arrangements

plan or equivalent information which is required to be placed on board. See

Vol 1, Pt 3, Ch 5, 7.4 Information required.

Table 5.7.1 Equipment - Minimum length and

breaking strength of towlines

| Equipment number

|

Equipment Letter

|

Towline

|

| Exceeding

|

Not Exceeding

|

Minimum length, in

metres

|

Minimum breaking

strength, in kN

|

| 50

|

70

|

A

|

180

|

98

|

| 70

|

90

|

B

|

180

|

98

|

| 90

|

110

|

C

|

180

|

98

|

| 110

|

130

|

D

|

180

|

98

|

| 130

|

150

|

E

|

180

|

98

|

| 150

|

175

|

F

|

180

|

98

|

| 175

|

205

|

G

|

180

|

112

|

| 205

|

240

|

H

|

180

|

129

|

| 240

|

280

|

I

|

180

|

150

|

| 280

|

320

|

J

|

180

|

174

|

| 320

|

360

|

K

|

180

|

207

|

| 360

|

400

|

L

|

180

|

224

|

| 400

|

450

|

M

|

180

|

250

|

| 450

|

500

|

N

|

180

|

277

|

| 500

|

550

|

O

|

190

|

306

|

| 550

|

600

|

P

|

190

|

338

|

| 600

|

660

|

Q

|

190

|

370

|

| 660

|

720

|

R

|

190

|

406

|

| 720

|

780

|

S

|

190

|

441

|

| 780

|

840

|

T

|

190

|

479

|

| 840

|

910

|

U

|

190

|

518

|

| 910

|

980

|

V

|

190

|

559

|

| 980

|

1060

|

W

|

200

|

603

|

| 1060

|

1140

|

X

|

200

|

647

|

| 1140

|

1220

|

Y

|

200

|

691

|

| 1220

|

1300

|

Z

|

200

|

738

|

| 1300

|

1390

|

A

|

200

|

786

|

| 1390

|

1480

|

B

|

200

|

836

|

| 1480

|

1570

|

C

|

220

|

888

|

| 1570

|

1670

|

D

|

220

|

941

|

| 1670

|

1790

|

E

|

220

|

1024

|

| 1790

|

1930

|

F

|

220

|

1109

|

| 1930

|

2080

|

G

|

220

|

1168

|

| 2080

|

2230

|

H

|

240

|

1259

|

| 2230

|

2380

|

I

|

240

|

1356

|

| 2380

|

2530

|

J

|

240

|

1453

|

| 2530

|

2700

|

K

|

260

|

1471

|

| 2700

|

2870

|

L

|

260

|

1471

|

| 2870

|

3040

|

M

|

260

|

1471

|

| 3040

|

3210

|

N

|

280

|

1471

|

| 3210

|

3400

|

O

|

280

|

1471

|

| 3400

|

3600

|

P

|

280

|

1471

|

| 3600

|

3800

|

Q

|

300

|

1471

|

| 3800

|

4000

|

R

|

300

|

1471

|

| 4000

|

4200

|

S

|

300

|

1471

|

| 4200

|

4400

|

T

|

300

|

1471

|

| 4400

|

4600

|

U

|

300

|

1471

|

| 4600

|

4800

|

V

|

300

|

1471

|

| 4800

|

5000

|

W

|

300

|

1471

|

| 5000

|

5200

|

X

|

300

|

1471

|

| 5200

|

5500

|

Y

|

300

|

1471

|

| 5500

|

5800

|

Z

|

300

|

1471

|

| 5800

|

6100

|

A*

|

300

|

1471

|

Table 5.7.2 Design weather factors

| Applicable notation

|

Wind speed coefficient, C

mw

|

Weather factor, K

|

| TA1

|

0,0150

|

8

|

| TA2

|

0,0129

|

7,2

|

| TA3

|

0,0108

|

6,3

|

Table 5.7.3 Environmental conditions

| Beaufort Scale

|

Equivalent Mean Wind Speed

(knots)

|

Wind Speed Coefficient, C

mw

|

Weather Factor, K

|

| 14

|

116

|

0,0025

|

3

|

| 5

|

1721

|

0,0046

|

3,8

|

| 6

|

2227

|

0,0067

|

4,7

|

| 7

|

2833

|

0,0086

|

5,5

|

| 8

|

3440

|

0,0108

|

6,3

|

| 9

|

4147

|

0,0129

|

7,2

|

| 10+

|

48+

|

0,0150

|

8

|

7.3 Materials

7.3.1 Towing

hawsers and towing pennants can be of steel wire rope, natural fibre

or synthetic fibre. The diameter, construction and specification of

steel wire or fibre towlines are to comply with Ch 10 Equipment for Mooring and Anchoring of the Rules for Materials. Where synthetic fibre ropes

are used the size and construction will be specially considered.

7.3.3 The

design loads applied to deck fittings by this Section relate to conventional

fibre ropes (i.e. polypropylene, polyester and nylon). Consideration

should be given to the elongation properties of the actual line used.

7.3.4 Wire

ropes used in association with winches (on which the rope is stored

on the winch drum) are to be of suitable construction.

7.4 Information required

7.4.1 Plans

are to be of sufficient detail for plan approval purposes. Plans covering

the following items are to be submitted for approval:

7.4.2 The

towing arrangement plan is to be submitted for information. It is

to include the following in respect of each shipboard fitting:

- Location on the ship.

- Fitting type.

- Safe working load (SWL).

- Manner of applying towing line load, including limiting fleet

angles.

The towing arrangement plan is to be provided on board the ship

for the guidance of the Master.

7.5 Towing arrangements

7.5.1 A towing

arrangement is to be provided at both the fore and aft end of the

ship.

7.5.2 The

fixed towing equipment is to comprise a securing arrangement which

is a strong point and may be in the form of a stopper bollard, bracket,

deck clench or towing slip. A fairlead, rollers or other appropriate

towline guides as necessary are to be included in the arrangement.

7.5.3 Loose

towing equipment is to comprise a towing hawser and a towing pennant.

The towing pennant may comprise a length of chafing chain. In the

absence of a length of chafing chain suitable arrangements (e.g. a

low friction sheath) are to be provided.

7.5.4 Fairleads

and guides are to be designed so as to prevent excessive bending stress

in the towing hawser, towing pennant or chafing chain, whichever is

applicable. The bending ratio of the guides bearing surface to the

diameter of the applicable towline element is not to be less than

7 to 1. For fibre rope towing hawsers and towing pennants the bending

ratio is to comply with the rope manufacturer's specification.

7.5.5 The

fairlead or guide is to have an opening large enough to allow the

passage of the largest element of the loose towing equipment.

7.5.6 The

fairlead or guide is to be fitted as close to the deck as practicable

and in a position so that the tow will be approximately parallel to

the deck when under tension between the strong point and the guide.

7.5.7 The

selection of shipboard fittings is to be made by the shipyard in accordance

with an acceptable National or International standard. If the shipboard

fitting is not selected from an acceptable National or International

standard then the design load used to assess its strength and its

attachment to the ship is to be in accordance with the design load

given in Vol 1, Pt 3, Ch 5, 7.6 Strength requirements for towing arrangements 7.6.3. The design

is to be submitted for approval. Any weld, bolt or equivalent device

connecting the shipboard fitting to the supporting structure is part

of the shipboard fitting and is subject to the National or International

standard applicable to that shipboard fitting.

7.5.8 Deck

fittings and strong points are to be located on longitudinals, beams

and/or girders, which are part of the deck construction so as to facilitate

efficient distribution of the towing load. Other equivalent arrangements

will be considered, providing the strength is confirmed as adequate

for the intended use.

7.5.9 To avoid

chafing, the arrangement is to be designed so that no element of the

loose towing equipment, when under tension, is to contact with the

ships hull at any point other than those specified as a securing

arrangement, fairlead or guide. The final point of contact of the

towline with the ship is to be positioned as close as practicable

to the centre line so as to reduce the adverse effect on manoeuvrability.

7.5.10 The

chafing arrangement is to extend a minimum of 3 m outboard of the

fairlead or guide when in the deployed position and 2 m inboard.

7.5.11 The

loose towing equipment is to be located as near as practicable to

the strong point and is to be designed to be capable of being rigged

and deployed in the absence of power. It is recommended that extra

loose gear meeting the requirements of this Section be carried on

board to provide for redundancy.

7.5.13 Irrespective

of strength requirements, no fibre rope is to be less than 20 mm in

diameter.

7.6 Strength requirements for towing arrangements

7.6.1 The minimum Breaking Load (hereinafter referred to as BL) of the

towing hawser carried on board the ship is assessed in tonnes, and is not to be less

than that calculated below:

|

BL

|

= |

(0,03Δ2/3 + (C

mw

A

t

)) K

|

where

|

Δ |

= |

displacement, in tonnes, of the ship at its design draught

waterline |

|

C

mw

|

= |

wind speed coefficient, which is to be taken from Table 5.7.2 Design weather factors for the relevant notation

|

|

K

|

= |

weather

factor, which is to be taken from Table 5.7.2 Design weather factors for the relevant notation

|

|

A

t

|

= |

transverse projected area, in m2, of the hull and

of all superstructures, houses, masts, etc. above the design draught

|

7.6.2 The

strength of other loose towing equipment e.g. links, shackles rings

and chafing chain is to be determined on the basis of a design load

equal to 1,25 times the BL of the towing hawser.

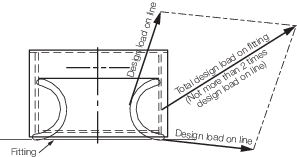

7.6.3 The

strength of shipboard fittings and their supporting structure is to

be determined on the basis of a design load equal to 1,25 times the BL of the towing hawser. The design load is to be applied through

the towline according to the arrangement shown on the towing arrangement

plan. The point of action of the force on the fitting is to be taken

as the point of attachment of the mooring line or towline or at a

change in its direction. The total design load applied to a fitting

need not be more than twice the design load, see

Figure 5.7.1 Design load applied to fittings.

7.6.4 The

stress in all loose and fixed towing equipment constructed of steel,

and its supporting structure, is not to exceed the specified minimum

yield stress of the material in bending and 60 per cent of the specified

minimum yield stress of the material in shear. Special consideration

will be given if the vessel and/or towing equipment is not constructed

of steel.

7.6.5 The

reinforced members (carling) beneath shipboard fittings are to be

effectively arranged for any variation of direction (horizontally

and vertically) of the towing forces (which is to be not less than

the design load) acting through the arrangement of connection to the

shipboard fittings. Other arrangements will be specially considered

provided that the strength is confirmed as adequate for the service.

7.6.6 For

the assessment of fairleads and their supporting structure, due consideration

is to be given to lateral loads. The strength of the fairlead is to

be sufficient for all angles of towing load up to 90° horizontally

from the ship's centreline and 30° vertically from the horizontal

plane.

7.6.7 For

the assessment of a strong point and its supporting structure, the

applied load is to be in the direction that the towing pennant or

towing hawser will take up during normal deployment. It is also to

be applied at the maximum height possible above the deck for that

specific type of strong point.

7.6.8 The

structural arrangements of strong points, bollards and fairleads are

to be such that continuity will be ensured. Abrupt changes in section;

sharp corners and other points of stress concentration are to be avoided.

7.6.9 Strong

points are to be fitted in way of a transverse or longitudinal deck

girder or beam to facilitate efficient distribution of the towing

load.

7.6.10 The

SWL of each towing arrangement component is to be no greater than

80 per cent of the design load applied.

Figure 5.7.1 Design load applied to fittings

|