5.1.1 The structure

and the attachment of the bilge keels to the shell plating is to be

thoroughly examined for possible fractures or evidence of damage.

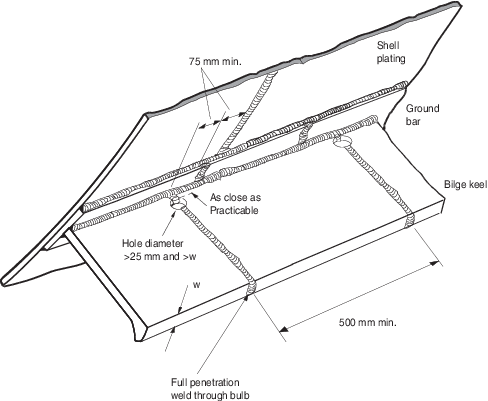

5.1.2 The diagram

shows a typical bilge keel which may be found in use today on existing

ships. In carrying out inspection of all welded connections, emphasis

should be placed on locations where fractures may initiate typically

in the connection to the steel or ground bar at the bilge keel ends, see

Figure 7.5.1 Double plate bilge keel construction.

5.1.5 Butt welds

of perpendicular flat bar bilge keels should have a hole drilled through

the connection. This hole should have a minimum diameter of 25 mm

and extend beyond the fore and aft edges of the butt weld, see

Figure 7.5.4 Repair of perpendicular bilge keels. Where all butt welds have been

subjected to non-destructive examination and found satisfactory, the

holes may be omitted. In this case, for the information of Surveyors

at future surveys, a recommendation should be made for the insertion

of a note in the memoranda, viz. “continuous flat bar (if fitted)

and bilge keel butt welds ND examination (date) - stop holes not drilled.”

5.1.6 In assisting

with the assessment of the butt welding of perpendicular flat bars

and bilge keels, an examination can be made of the material in way

of these holes to verify the absence of defects, from which fractures

may initiate, such as lack of weld penetration.

5.1.7 Bilge keels

are not generally required for classification purposes and there may

be no objection to removal of a damaged length without replacement,

provided the watertight and structural integrity of the hull is unimpaired

and measures are taken to control the scarring of hull plating.

5.1.8 When it is

decided to dispense with a section of bilge keel after damage, the

new ends should be finished in a taper similar to existing ends, see

Figure 7.5.3 Bilge keel termination.

5.1.9 If the ground

bar is to be retained, then the connecting welds of the damaged/removed

section should be ground smooth.

5.1.11 Butts in

bilge keel should be kept clear of butts in ground bars. Butts in

ground bars are to be kept clear of butts in shell.

5.1.12 Repairs to

bilge keels are to be carried out in accordance with Figure 7.5.2 Repair of double plate bilge keel or Figure 7.5.4 Repair of perpendicular bilge keels as appropriate. In double plate bilge keels care is to

be taken so that only the outer bilge keel plate is attached to the

shell plating, ground bars, lugs and internal diaphragms are not to

be attached to the shell. Repair materials are to be of the same grade

and thickness as the original material.

Figure 7.5.4 Repair of perpendicular bilge keels