12.1.1 When links

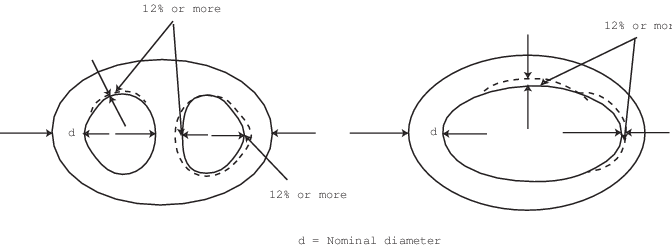

within any length of chain cable are worn by 12% or greater (see

Vol 1, Pt 1, Ch 3, 5.3 Examination and testing – General 5.3.6 of the Rules

for Naval Ships) the length is to be renewed. For ships not built

in accordance with LR Rules where the fitted thickness is not available

in the ship’s documentation, plan approval advice should be

sought. The worn size of each condemned length is to be reported.

Chain cable worn to the renewal size should be removed from the chain

locker only if replacement cable is readily available, but if worn

cable is to be retained pending replacement, the worn lengths should

be fitted at the locker end of the cable.

12.1.2 Chain cable

worn so far below renewal size, that it is considered by the Surveyor

to be hazardous for it to be retained, should be removed whether or

not replacement cable is available. As a general guide, cable reduced

by greater than 15 per cent or more from its nominal diameter should

be removed.

12.1.3 When deciding

whether a worn length of cable should be removed, the general condition

of the links is of importance. If there are slack studs, deformed

links or links worn into a notch, it is expected that the cable would

break at a load far below the nominal breaking strength for the measured

diameter, whereas considerable wear which is not accompanied by the

above defects may be less significant, see

Figure 7.12.1 Anchor chain.

12.1.4 The practice

of ‘walking the cable’ by disconnecting the anchor length

and refitting it at the locker end should be encouraged in order to

promote uniform weardown of the cable, and this may be conveniently

effected when the cables are ranged for survey.

12.1.5 Particularly

close attention should be paid to the condition of the chain locker

at every opportunity, and a complete survey carried out at Special

Survey.

12.1.6 When inspecting

anchors and cables, the Surveyor should look for any signs of defective

links or shackles, attention being given to the fit of the shackle

pins. The Surveyor should prohibit the excessive use of oxy/acetylene

torches when opening up shackles of special quality steel. Excessive

heat produced by the torch has a detrimental effect on the properties

of the steel which can cause loss of strength and/or severe cracking.

Lugless shackles in particular are to be closely examined for any

evidence of cracking. The attention of those responsible for the subsequent

shackling up of the cable should be drawn to the importance of fitting

suitable locking pins to the shackle pins.

12.1.7 Crown pin

retaining bolts should be given special attention whenever anchors

and cables are ranged. On certain types of stockless anchors when

the fit of the crown pin becomes too slack in the head, allowing excessive

lateral movement, it is acceptable to fit sleeves in each end of the

head as a temporary repair measure for a short period of time to allow

a new crown pin to be prepared. Adequate clearance should, however,

be allowed to ensure normal free tripping of the anchor head.

12.1.8 In the case

of repair of anchors, the necessity for retesting would depend on

the nature of the repair.

Figure 7.12.1 Anchor chain