Section

1 General

1.1 Application

1.1.1 All cargo ships, regardless of tonnage, except those engaged solely in the

carriage of either liquid or solid bulk cargoes, are to be provided with a Cargo

Securing Manual approved by the Flag Administration, as required by SOLAS 1974 (as

amended). Pt 3, Ch 14, 2 Fixed cargo securing fittings, materials and testing, Pt 3, Ch 14, 4 Ship structure, Pt 3, Ch 14, 7 Container securing arrangements for stowage using cell guides (if applicable) and Pt 3, Ch 14, 10 Surveys apply to all ships for which a Cargo Securing Manual is required.

It is recommended that the container securing arrangements in the Cargo Securing Manual

be designed in accordance with Pt 3, Ch 14, 3 Loose container securing fittings, materials and testing , Pt 3, Ch 14, 5 Container securing arrangements for stowage on exposed decks without cell guides, Pt 3, Ch 14, 6 Container securing arrangements for underdeck stowage without cell guides, Pt 3, Ch 14, 8 Determination of forces for container securing arrangements and Pt 3, Ch 14, 9 Strength of container securing arrangements. Furthermore, it is recommended that the container securing

arrangements be submitted to Lloyd’s Register (hereinafter referred to as LR), for

formal approval. In cases where LR is authorised to carry out the approval of the Cargo

Securing Manual on behalf of a National Administration and the container securing

arrangements have not been designed on the basis of the LR Rules nor received formal LR

approval, the Cargo Securing Manual will be annotated accordingly, highlighting this

fact. In general, Cargo Securing Manuals can be approved by LR if authorised by the

National Authority.

1.1.2 Fixed

fittings which are part of the container lashing equipment or which

may affect the strength of the ship’s hull are subject to approval

on the basis of the requirements of this Chapter. Details of the connection

and the supporting ship structure require approval to satisfy the

design loads determined in accordance with Pt 3, Ch 14, 8 Determination of forces for container securing arrangements or the safe working load of the fixed fitting, as

applicable. Drawings are to be submitted showing details of the fittings,

the attachment, the local foundations and information about the intended

materials and welding.

1.1.3 The

requirements for container securing arrangements have been framed

in relation to ISO Standard Series 1 ISO 1496-1:1990, including Amendment

Nos. 1, 2 and 3, Freight Containers. For previous ISO 1496-1:1984

containers, reference should be made to the July 2008 LR Rules. Proposals

to consider higher allowable forces in accordance with ISO 1496-1,

including Amendment No. 4, 2006, will be specially considered. Proposals

for the securing of other types of containers will be specially considered.

1.1.4 Containers

are to be loaded so as not to exceed the weights and distribution

within the stack according to the Cargo Securing Manual (CSM). The

permissible loading patterns are to be clearly indicated on the Container

Securing Arrangement Plan carried on board the ship.

1.1.5 Containers

may be approved and certified using LR’s Container Certification

Scheme.

1.1.6 Where

it is intended and specified that loose or fixed parts of the container

securing system are used for lifting appliance purposes, e.g. pedestal

sockets and fittings used for lifting of hatch covers, or twistlocks

used for vertical tandem lifting, the requirements of LR’s Code for Lifting Appliances in a Marine Environment, July 2022 are

applicable. If no approval from lifting aspects is sought, the devices

will be considered as part of a container securing arrangement only.

1.1.7 For ships having the class notation Container Ship, an effective

breakwater is to be fitted to protect the containers against green sea impact loads. For

other ships which are equipped for the carriage of containers on deck, protection of the

cargo is recommended by the provision of a breakwater. See also

Pt 3, Ch 14, 8.2 Ship motion, wind and green sea forces acting on containers.

1.1.8 Forward

of 0,75L, it is recommended that all door ends face aft

in order to improve the performance of the container walls to withstand

green sea loads.

1.1.9 Improper

ship handling related to course and speed or threshold phenomena like

parametric rolling can create adverse forces acting on the ship and

the cargo which are in excess of the forces determined on the basis

of Section Pt 3, Ch 14, 8 Determination of forces for container securing arrangements. It is the responsibility

of the Master to apply good seamanship in order to mitigate excessive

ship motions to reduce forces acting on the cargo stowage arrangements.

1.2 Classification notations and descriptive notes

1.2.1 Ships

with container securing arrangements which are designed and constructed

in accordance with this Chapter will be eligible to be assigned the

special features notation CCSA (certified container securing

arrangements). In addition to the fixed fittings, the Initial and

Periodical Survey requirements of Section Pt 3, Ch 14, 10 Surveys for all loose fittings are applicable. Where loose container

securing fittings are supplied for part container stowage only, the

special features notation will be suitably modified.

1.2.2 Ships

with container securing arrangements which are designed and constructed

in accordance with this Chapter, but where the Initial and Periodical

Survey requirements for loose fittings in Section Pt 3, Ch 14, 10 Surveys are not requested, will be eligible

to be assigned the descriptive note CSA (container securing

arrangement) and for an entry to be made in column 6 of the Register

Book.

1.2.3 On container ships an approved onboard lashing program to calculate forces

acting on the container stowage arrangement is to be provided, complying with this

chapter. This may be an extension to the loading instrument covered under Pt 3, Ch 4, 8.3 Loading instrument.

The ship will be eligible to be assigned the special features notation BoxMax,

with one or more of the supplementary letters V and W. The notation

BoxMax(V,W) may be supplemented with the letter L if the conditions for

this notation are satisfied. BoxMax may be supplemented with the letter M

if the conditions for this notation are satisfied..

1.2.4 Special consideration may be given to waiving the requirement for an onboard

lashing program as required by Pt 3, Ch 4, 8.4 Onboard lashing program 8.4.1 and e.g. For smaller

container ships where the container securing arrangements are relatively

straightforward.

1.2.5 It

is a prerequisite for assignment of the special features notation BoxMax that the container securing arrangements in the Cargo Securing

Manual are designed in accordance with this Chapter and submitted

to Lloyd’s Register for formal approval.

1.2.6 The container securing arrangements of a container ship may take into

account specific voyage routes and seasons, provided the ship has been assigned the

special features notation BoxMax with one of the following supplementary letter

sequences: V or V,W or V,W,L or M. The features offered by

these supplementary letter sequences are defined in Table 14.1.1 BoxMax notation features .

1.2.7 The onboard lashing program is to be capable of performing calculations

specific to defined sea areas and seasons, and the weather dependent factors for these

areas and seasons have been supplied by LR.

- If the weather dependent factors have been supplied by LR for specific

sea areas, the ship will be eligible to be assigned the special features notation

BoxMax(V).

- If the factors have been supplied by LR for specific sea areas in combination with

seasons, the ship will be eligible to be assigned the special features notation

BoxMax(V,W).

- If the factors have been supplied by LR for limited voyages, the

ship will be eligible to be assigned the special features notation

BoxMax(V,W,L).

- If the factors have been supplied by LR for ship motions and

environmental conditions, the ship will be eligible to be assigned the special

features notation BoxMax(M).

See also

Pt 3, Ch 4, 8.4 Onboard lashing program.

1.2.9 A ship designed to carry containers that is provided with safe access and

securing arrangements in accordance with the Rules for Ergonomic Container Lashing, July 2022 will

be eligible to be assigned the special features notation ECL (Ergonomic Container

Lashing), with supplementary descriptor.

Table 14.1.1 BoxMax notation features

| Notation

|

Additional feature description

|

| BoxMax(V)

|

V: Voyage dependencies

The assessment of the loads

acting on the containers and the container securing arrangements may take

account of the areas on the trading route of the ship. The North Atlantic

represents one of the most severe weather areas in the world. For other

areas the weather conditions may be less severe, and hence the assignment

of the BoxMax(V) notation allows weather dependent factors to be

applied to the environmental (dynamic) loads acting on the container

stacks in-hold or on-deck.

For the V feature,

the weather dependent factors are determined on the basis of the annual

environmental wave data, see Note 1.

The

weather dependent factors applicable to annual environmental wave data

for the requested sea areas will be supplied by LR, see Note

2.

|

| BoxMax(V,W)

|

W: Weather dependency (Season dependency)

The

BoxMax(V,W) notation allows the change in weather conditions

for various seasons to be taken into account for the assessment of the

environmental loads acting on container stacks in-hold or on-deck. For

example, this allows enhanced flexibility for the carriage of containers

in the summer season, when the weather conditions are usually less severe

than in the winter months.

For the W feature,

the weather dependent factors are determined on the basis of the seasonal

environmental wave data.

The weather dependent factors applicable to

seasonal environmental wave data for the requested sea areas will be

supplied by LR, see Note 2.

|

| BoxMax(V,W,L)

|

L:

Limited duration voyages

The BoxMax(V,W,L) notation

potentially allows increased flexibility for the carriage of containers

on board the ship for limited duration voyages. When applying the

L feature, limited duration voyage factors are applicable for

voyages of less than 48 hours. They are suitable for short coastal

voyages, for example between ports such as Hamburg and Rotterdam or

between Hong Kong and Xiamen (China). Typically it will allow enhanced

flexibility for the carriage of containers and may allow reduced lashing

requirements between local ports.

The process of

application of the BoxMax(V,W,L) limited duration voyage feature

is given in Pt 3, Ch 14, 1.3 Application of the BoxMax(V,W,L) notation.

The weather dependent factors applicable to limited

duration voyages based on wave heights predicted by weather forecasts

will be supplied by LR.

|

| BoxMax(M)

|

M:

Ship motion monitoring

The BoxMax(M) notation allows maximum

flexibility in the way containers are carried for any voyage. The degree

of lashing can be fully appropriate to operation, see Note

3.

The Master will be required to manage the motion of the ship

during the voyage by good seamanship and by weather routing, and not

exceed the declared ship motions.

The maximum motion of the ship

during the voyage is to be recorded and compared to the declared ship

motion.

The process of application of the BoxMax(M) ship

motion monitoring feature is given in Pt 3, Ch 14, 1.4 Application of the BoxMax(M) notation.

|

|

Note 2: LR will supply

weather dependent factors applicable to the list of sea areas requested

by the owner. The requested sea areas must cover the whole of the voyage

route to be used. If the vessel sails outside of the requested sea areas

then all the weather dependent factors should be set to 1,0.

Note 3: LR will supply weather dependent factors in the form of a look up

table specific to the ship; the voyage factors shall be selected based on

the maximum ship motion being declared.

|

1.3 Application of the BoxMax(V,W,L) notation

1.3.1 The BoxMax(V,W,L) notation requires the following process to be applied by the

Ship’s Master.

1.3.2 For the limited duration voyage feature to be applicable the following process must

be in place:

- The ship must subscribe to an ocean weather forecast service provided by a

recognised and reputable met ocean weather forecasting organisation. The

forecast is to include wind speed and wave heights for a minimum period of 5

days and preferably 10 days. The responsibility for selection of the weather

forecasting organisation lies with the Master.

- The limited voyage feature shall not hazard safe navigation and

adverse weather conditions should be avoided as far as possible.

1.3.3 The limited duration voyage feature can only be applied in the following

scenarios:

- The maximum length of a limited duration voyage is 48 hours in Open Water. A

limited duration voyage may be slightly extended at the Master’s discretion

provided the forecast is favourable. Voyages longer than this will need to

be considered using the BoxMax(V,W) approaches.

- There should be no warnings for major storms with maximum sustained winds of

more than 119 km per hour for an area within 500 miles from the long-range

weather forecast.

where:

| Open Water

|

May be taken as starting at the outer harbour limits or harbour

breakwater, as applicable. The concept of Open Water here is used to

define the point at which the ship will leave the confines of the

port and any estuaries or inshore navigation confines.

|

| Tdepart

|

Is to be taken as the estimated time in hours after the initial

forecast that the ship enters Open Water after leaving the port of

departure.

|

| Tarrive

|

Is to be taken as the estimated time in hours after the initial

forecast that the ship leaves Open Water prior to entering the port

of arrival.

|

1.3.4 The supplied weather dependent factors applicable to limited duration voyages are

based on the significant wave height.

1.3.5 The Master needs to select the appropriate significant wave height for the limited

duration voyage, HSL. The significant wave height for the limited

duration voyage is to be rounded up to the next integer and is to be selected as follows:

|

HSL |

= |

Hforecast if the

Tarrive is less than 72 hours after the time of

the initial forecast. |

| = |

Hforecast + 1 m if the

Tarrive is more than 72 hours after the time of

the initial forecast. |

| = |

Hforecast + 2 m if the

Tarrive is more than 96 hours after the time of

the initial forecast.

where

Hforecast is the maximum significant wave

height predicted for the limited duration voyage. It is to be

extracted from the forecast at the time of planning the cargo

stowage up to the time when the vessel leaves Open Water prior to

entering the port of arrival. The forecast period is not to be less

than 5 days.

|

The time of the initial forecast is to be taken as the most recent forecast prior to

commencement of cargo planning operations.

1.3.6 When the ship departs, if the latest forecast is more severe than the

earlier forecasts, then is to be taken as the maximum significant wave height from

the latest forecast for the period up to the time the ship leaves Open Water prior

to entering the port of arrival +24 hours for the planned voyage, if this exceeds

from Pt 3, Ch 14, 1.3 Application of the BoxMax(V,W,L) notation 1.3.5.

1.3.7 The significant wave height used for the limited duration voyage should be recorded

in the cargo plan information and the onboard lashing computer for the voyage. The

ship specific weather dependent coefficients for a range of significant wave heights

will be provided by Clasifications Register as part of the BoxMax(V,W,L)

notation.

1.3.8 Example of application of BoxMax(V,W,L):

Scenario 1

|

|

|

|

|

|

Date

|

14 July

|

15 July

|

16 July

|

17 July

|

18 July

|

19 July

|

|

|

|

Voyage schedule

|

Planning commences at 14:00

|

|

|

Stowage and lashing

Leaves quayside At

13:00

Enters Open Water at 16:00

|

Voyage 18 hours

Leaves Open Water at 10:00

Arrive at quayside

|

|

|

|

|

Forecast day 14 July @ 12:00

– initial forecast

|

|

|

|

Forecast time

|

12:00

|

|

|

|

|

|

|

|

|

Time from initial forecast

|

|

|

|

T

depart = 76 hrs

|

T

arrive = 94 hrs

|

|

|

|

|

Forecast wave height

|

3,3 m

|

3,3 m

|

3,7 m

|

3,7 m

|

3,5 m

|

3,5 m

|

|

|

|

Hforecast

|

3,7 m

|

|

|

|

ΔHforecast

(Tarrive>72h)

(Tarrive<96h)

|

1,0 m

|

|

|

|

Limited duration HSL

|

3,7 m + 1,0 m = 4,7 m

rounded up to the next integer = 5 m

|

|

|

|

Action

|

Plan lashing requirement with

HSL = 5 m

|

|

|

|

Forecast day 15 July @ 12:00

|

|

|

|

Forecast time

|

-

|

12:00

|

|

|

|

|

|

|

|

Forecast wave height

|

-

|

3,5 m

|

3,7 m

|

3,5 m

|

3,3 m

|

3,2 m

|

|

|

|

Action

|

-

|

Monitor weather forecast –

no change in wave height expected

|

|

|

|

Forecast day 16 July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

12:00

|

|

|

|

|

|

|

Forecast wave height

|

-

|

-

|

3,7 m

|

3,7 m

|

3,5 m

|

3,3 m

|

|

|

|

Action

|

-

|

-

|

Monitor weather forecast –

no change in wave height expected

|

|

|

|

Forecast day 17 July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

-

|

12:00

|

|

|

|

|

|

Forecast wave height

|

-

|

-

|

-

|

3,8 m

|

4,1 m

|

4,0 m

|

|

|

|

Action

|

-

|

-

|

-

|

Max forecast wave height

increased to 4,1 m.

4,1 m is less than planning wave

height of 5,0 m

Voyage can be

undertaken.

Monitor latest forecast and

actual sea state

|

|

|

|

Forecast day 18 July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

-

|

-

|

12:00

|

|

|

|

|

Forecast wave height

|

-

|

-

|

-

|

-

|

4,2 m

|

4,0 m

|

|

|

|

Action

|

-

|

-

|

-

|

Monitor latest forecast and

actual sea state

|

|

|

|

|

|

Scenario 2

|

|

|

|

|

|

Date

|

14 July

|

15 July

|

16 July

|

17 July

|

18 July

|

19 July

|

|

|

|

Voyage schedule

|

Planning commences at 14:00

|

|

|

Stowage and lashing

Leaves quayside At

13:00

Enters Open Water at 16:00

|

Voyage 18 hours

Leaves Open Water at 10:00

Arrive at quayside

|

|

|

|

|

Forecast day 14

July @ 12:00 – initial forecast

|

|

|

|

Forecast time

|

12:00

|

|

|

|

|

|

|

|

|

Time from initial forecast

|

|

|

|

T

depart = 76 hrs

|

T

arrive = 94 hrs

|

|

|

|

|

Forecast wave height

|

3,3 m

|

3,3 m

|

3,7 m

|

3,7 m

|

3,5 m

|

3,3 m

|

|

|

|

Hforecast

|

3,7 m

|

|

|

|

ΔHforecast

(Tarrive>72h)

(Tarrive<96h)

|

1,0 m

|

|

|

|

Limited duration HSL

|

3,7 m + 1,0 m = 4,7 m rounded up to the

next integer = 5 m

|

|

|

|

Action

|

Plan lashing requirement with

HSL = 5 m

|

|

|

|

Forecast day 15

July @ 12:00

|

|

|

|

Forecast time

|

-

|

12:00

|

|

|

|

|

|

|

|

Forecast wave height

|

-

|

3,5 m

|

3,7 m

|

3,7 m

|

3,5 m

|

3,8 m

|

|

|

|

Action

|

-

|

Monitor weather

forecast

|

|

|

|

Forecast day 16

July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

12:00

|

|

|

|

|

|

|

Forecast wave height

|

-

|

-

|

3,7 m

|

3,7 m

|

4,4 m

|

4,5 m

|

|

|

|

Action

|

-

|

-

|

Forecast indicates increasing waveheight

(Maximum wave height still below HSL of 5 m)

Consider reassessing lashing requirement with increased waveheight.

Monitor weather forecast

|

|

|

|

Forecast day 17

July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

-

|

12:00

|

|

|

|

|

|

Forecast wave height

|

-

|

-

|

-

|

4,8 m

|

5,5 m

|

5,4 m

|

|

|

|

Action

|

-

|

-

|

-

|

Final forecast from

Tdepart to Tarrive + 24

hours is higher than HSL, hence cargo plan needs

to be reassessed. Master needs to select an appropriate

HSL value, e.g. 6 m. Might result in delay to

planned departure.

|

|

|

|

Forecast day 18

July @ 12:00

|

|

|

|

Forecast time

|

-

|

-

|

-

|

-

|

12:00

|

|

|

|

|

Forecast wave height

|

-

|

-

|

-

|

-

|

5,5 m

|

5,4 m

|

|

|

|

Action

|

-

|

-

|

-

|

-

|

Monitor latest forecast and

actual sea state

|

|

|

|

|

|

1.4 Application of the BoxMax(M) notation

1.4.1 The BoxMax(M) notation requires the following process to be applied by the

Ship’s Master.

1.4.2 For the ship motion monitoring notation to be applicable the following process must

be in place:

- At the start of a voyage, the Master shall declare the

maximum expected ship motions and environmental conditions and assign weather

dependent factors accordingly. The responsibility for selection of appropriate

ship motions and environmental conditions lies with the Master.

- The ship motion monitoring feature shall not hazard safe

navigation and adverse weather conditions should be avoided as far as

possible.

1.4.3 The supplied weather dependent factors applicable to ship motion notation are based

on the declared ship motion and environmental conditions.

1.4.4 The maximum ship motion, environmental conditions and weather dependent factors

planned for the voyage should be recorded in the cargo plan information and the

onboard lashing computer for the voyage. The ship specific weather dependent

coefficients for a range of ship motion and environmental conditions will be

provided by LR as part of the BoxMax(M) notation.

1.4.5 LR can provide ship specific guidance with regard to voyage ship motion predictions

and environmental loading.

1.5 Plans and information required

1.5.1 For

all fixed cargo securing arrangements, except container securing arrangements,

the following information and plans are to be submitted:

-

Details of certification

including safe working load (SWL) of fixed cargo securing fittings.

-

Plans of structure

in way of fixed cargo securing fittings.

-

Direction of

loads imposed on the ship’s fixed cargo securing fittings.

-

A general arrangement

of fixed cargo securing fittings.

1.5.2 For

container securing arrangements, the following plans and information

are to be submitted:

- General arrangement plan showing the disposition and design weights of

the containers.

- Rule length.

- Details of materials, stiffness and scantling of lashing bridges

including heights from base line, heights of bottom of bridge, heights of each tier.

- Details of green water protection including longitudinal,

transverse and vertical extents.

- Details of materials, design, scantlings of cell guides

structure, pedestals, and other container securing arrangements, where fitted.

- Details of certification, including safe working load

(SWL), of fixed and loose container securing fittings.

- Details of twistlock height and separation clearances.

- Details of stacking cones and their arrangements in holds.

- Details of lashing rod diameters and dimensions in x, y and z

directions.

- Plans of structure in way of fixed container securing

fittings and arrangements.

- Design values of the following ship parameters for the

container load departure and arrival conditions:

- Moulded draught (T

c)

- Transverse metacentric height

(GM).

- Cargo Securing Manual, see

Pt 3, Ch 14, 1.5 Plans and information required 1.5.3.

1.5.3 The Cargo Securing Manual is to include the following information:

- For vessels with an approved onboard lashing program,

representative lashing calculations based on one design GM value within the

following range:

- A lower design GM value of 2,5 per cent of the

breadth B.

- An upper design GM value of 7,5 per cent of

B for ships with a breadth less than 52 m and 10 per cent of

B for ships where B ≥ 52 m.

- For vessels without an approved onboard lashing program,

representative lashing calculations based on design GM values as follows:

- A lower design GM value of 2,5 per cent of the

breadth B.

- An upper design GM value of 7,5 per cent of

B for ships with a breadth less than 52 m and 10 per cent of

B for ships where B >= 52 m.

- Actual GM values of the ship in the container loaded

condition from the approved Trim and Stability Booklet or Loading Manual

when the actual design GM values are outside the range specified in i) and

ii).

- For vessels with notation BoxMax(V), BoxMax(V,W),

BoxMax(V,W,L) or BoxMax(M) representative calculations based on

applicable weather reduction factors are to be included in the Cargo Securing

Manual.

1.5.4 Where

containers of types other than ISO containers are to be incorporated

in the stowage arrangement, the Cargo Securing Manual is to indicate

clearly the locations where these containers are stowed. The manual

is also to indicate the container weights and required securing arrangements

for stacks composed entirely of ISO Standard containers.

1.6 Securing systems

1.6.1 Containers

are to be secured by one, or a combination, of the following systems:

- Corner locking devices.

- Rod, wire or chain lashings.

- Buttresses, shores or equivalent structural restraint.

- Cell guides.

Alternative systems will be considered on the basis of their

suitability for the intended purpose.

1.6.2 Dunnage

is not to be used in association with approved container securing

systems except where forming part of an approved line load stowage,

see Pt 3, Ch 14, 5.5 Line Load stowage.

1.7 Symbols and definitions

1.7.1 The following definitions are applicable to this Chapter, except where

otherwise stated:

|

a

|

= |

breadth of the container, in metres (for longitudinally stowed

containers) |

|

b

|

= |

length of the container, in metres (for longitudinally stowed

containers) |

|

ci

|

= |

height of container i, in metres |

|

di

|

= |

flange thickness of container securing device (e.g. twistlock) below

container i, in metres |

|

a0

|

= |

acceleration parameter |

|

|

= |

|

|

asurge

|

= |

longitudinal acceleration due to surge, in m/s2

|

|

asway

|

= |

transverse acceleration due to sway, in m/s2

|

|

aheave

|

= |

vertical acceleration due to heave, in m/s2

|

|

aroll

|

= |

roll acceleration at the centre of motion of the vessel, in

rad/s2

|

|

|

= |

0,69

|

|

apitch

|

= |

acceleration due to pitch, in rad/s2

|

|

Tp

|

= |

period of pitch of the ship, in seconds |

| = |

|

where

|

C1 |

= |

0,95 for Motion Case 1 |

| = |

0,52 for all other Motion Cases |

|

Tr

|

= |

period of roll of the ship, in seconds |

| = |

|

|

φ |

= |

design roll angle for container securing arrangements, in

degrees |

| = |

fHsRφf but not less than 12 degrees |

where

|

φf |

= |

55fBKe

(– 0,025B) but need not be taken greater than 30 degrees |

If φf is less than φm:

|

φf |

= |

55fgmfVfBKe(-0,025B)

but is not to be taken greater than φm |

where

φm the minimum unrestricted roll angle, in degrees, is to be taken as:

For ships with a breadth greater than 58 m:

|

|

= |

22 degrees for GM values below 7,5 per cent of the breadth,

B |

| = |

18 degrees for GM values above 10 per cent of the breadth,

B

for GM values between 7,5 and 10 per cent of the breadth,

B, the minimum unrestricted roll angle is to be determined by

linear interpolation.

|

For ships with a breadth less than 54 m

For ships with breadth, B, between 54 m and 58 m, the minimum unrestricted roll

angle is to be determined by linear interpolation.

|

fv |

= |

is to be taken as 1,0 |

|

fgm |

= |

but is not to be taken less than 1,0 but is not to be taken less than 1,0 |

Note The calculations assume that the

Master takes action to avoid synchronous rolling and parametric rolling. LR can provide

ship specific guidance with regard to synchronous rolling and parametric rolling.

|

Ψ |

= |

design pitch angle, in degrees, |

| = |

|

but need not exceed 8°

|

e

|

= |

base of natural logarithms |

| = |

2,7183 |

|

fap

|

= |

hull form coefficient |

| = |

for Motion Case MC1: |

| = |

1,2R

A

0,3 for R

A > 1,0 |

| = |

1,2 for R

A ≤ 1,0 |

| = |

for all other Motion Cases: |

| = |

1,0 |

|

fBK

|

= |

bilge keel coefficient |

|

|

= |

1,2 for ships without bilge keels |

|

|

= |

1,0 for ships with bilge keels |

|

fHs

|

= |

weather-dependent factor for acceleration |

|

|

= |

1,0 for unrestricted worldwide service |

|

fHsP

|

= |

weather-dependent factor for pitch |

|

|

= |

1,0 for unrestricted worldwide service |

|

fHsR

|

= |

weather-dependent factor for roll |

|

|

= |

1,0 for unrestricted worldwide service |

|

fHsVw |

= |

weather-dependent factor for wind |

| = |

1,0 for unrestricted worldwide service |

|

Cp1

|

= |

hull whipping factor |

|

fMC

|

= |

Motion Case coefficient |

|

fwh

|

= |

whipping coefficient |

|

|

= |

0,45 for x

c/L ≥ 0,75

intermediate values are to be

obtained by linear interpolation |

|

fwl

|

= |

length-dependent factor for whipping |

|

|

= |

1,0 for L ≥ 350 m

intermediate values are to

be obtained by linear interpolation |

|

g

|

= |

acceleration due to gravity and is to be taken as 9,81

m/s2

|

|

xc

|

= |

longitudinal centre of gravity of a container forward of the aft end

of L, in metres |

|

zc

|

= |

vertical centre of gravity of a container above the keel, in

metres |

|

cvcg |

= |

vertical location of the centre of gravity of the container measured positive

upward from the bottom of the corner castings. To be taken at 33 percent of the

height of the container. Other values of cvcg will be

specially considered.

|

|

xom

|

= |

longitudinal centre of motion forward of the aft end of L. To

be taken at the LCF of the ship |

|

z

om

|

= |

vertical centre of motion above the keel. To be taken as the greater

of 2T

c /3 + KG/3, T

c or D/2 |

|

A

|

= |

side area of the container, in m2

|

|

GM

|

= |

transverse metacentric height of the ship, in metres |

|

KG

|

= |

vertical distance of the centre of gravity of the ship above the

keel, in metres |

|

LCF |

= |

longitudinal centre of flotation. To be taken at 0,48L from

the aft end of L

|

|

R

|

= |

the rating, or maximum operating gross weight for which the container

is certified, and is equal to the tare weight plus payload of the container, in

tonnes |

|

T

c

|

= |

moulded draught in the container load condition, in metres |

|

V

w

|

= |

wind speed, in m/s. |

| = |

40 fHsVw |

|

W

|

= |

weight of the container and contents, in tonnes. The following

minimum weights W are to be used: |

|

|

= |

2,5 tonnes for 20 ft containers |

|

|

= |

3,5 tonnes for 40 ft containers |

|

|

= |

4,0 tonnes for 45 ft containers |

|

|

= |

4,5 tonnes for 48 ft and 53 ft containers. |

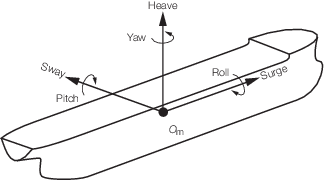

Figure 14.1.1 Diagrammatic representation of

symbols

Figure 14.1.2 Ship coordinate system and sign

convention of motions

1.7.2 The

sign convention for ship motions and accelerations is shown in Figure 14.1.2 Ship coordinate system and sign

convention of motions. This is based on a

right-handed coordinate system. The roll, pitch and yaw motions are

defined positive clockwise as shown. For instance, positive sway is

defined as the translation toward port and positive pitch as the rotation

of the bow down and stern up.

|