Section

8 Sternframes and appendages

8.1 General

8.1.1 Sternframes,

propeller bosses and shaft brackets may be constructed of forged or

cast steel, or may be fabricated from plate.

8.1.4 Sternframes,

shaft brackets, etc. are to be effectively integrated into the ship’s

structure and their design is to be such as to facilitate this.

8.2 Sternframes

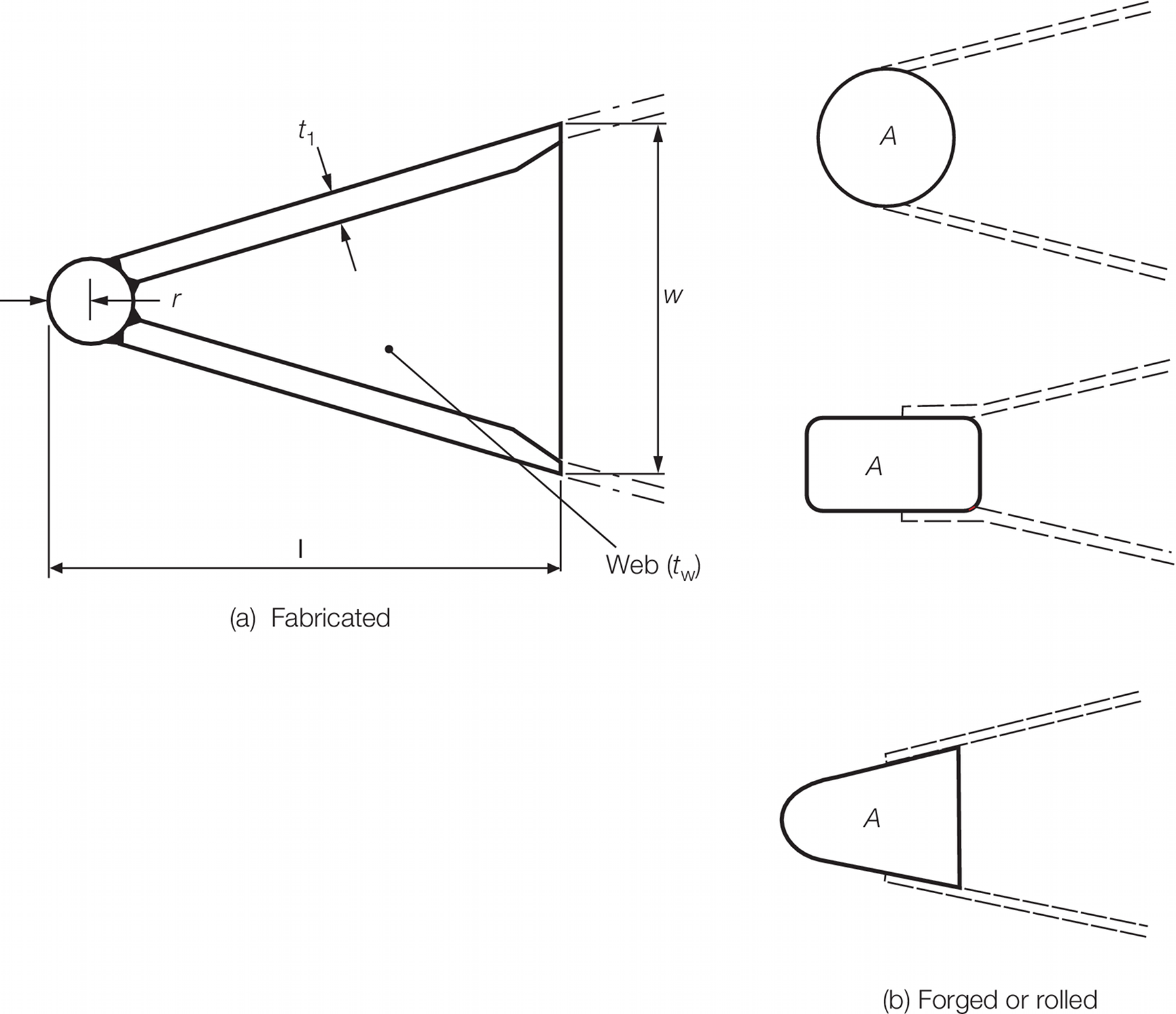

8.2.1 The scantlings

of sternframes are to be determined from Table 5.8.1 Sternframes. The scantlings for sternframe configurations other than

described in this Section, and for cast steel sternframes, will be

specially considered, but the strength is to be at least equivalent

to a fabricated sternframe.

Table 5.8.1 Sternframes

| Item

|

Parameter

|

Requirement

|

|

|

|

Forged or roll

steel

|

Fabricated

steel

|

|

(1) Propeller posts

|

A

|

for L ≤ 60 m :  0,8T cm2 0,8T cm2

|

-

|

|

|

A

|

for L > 60 m : 32T

cm2

|

-

|

|

|

t

1

|

-

|

12 + 0,11L mm

|

|

|

r

|

-

|

18 + 0,17L mm

|

|

|

l

|

-

|

150  mm mm

|

|

|

W

|

-

|

100  mm mm

|

|

|

t

W

|

-

|

5 + 0,05L mm

|

|

(2) Sternpost in twin screw ships and non-propelled ships

|

A

|

for L ≤ 60 m :  0,7T cm2 0,7T cm2

|

-

|

|

|

A

|

for L > 60 m : 28T

cm2

|

-

|

|

|

t

1

|

-

|

8 + 0,07L mm

|

|

|

r

|

-

|

12 + 0,11L mm

|

|

|

l

|

-

|

150  mm mm

|

|

|

W

|

-

|

100  mm mm

|

|

|

t

W

|

-

|

5 + 0,05L mm

|

|

(3) Propeller shaft boss

|

tb

|

|

|

(4) Solepieces (open type sternframe) supporting the lower

rudder pintle

|

Z

T

|

c.f.Ar(V + 5,6)2 × (a/b –

0,15) × 0,95 a/b cm3

see Note 4

|

|

Z

V

|

0,5Z

T cm3

|

|

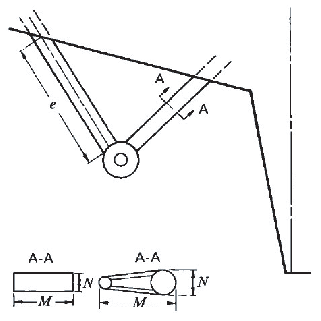

(5) Double arm shaft brackets

|

Z

T

|

(16 ×

10–6 × D

ts

3) + 8 cm3

|

|

N

|

≥ 0,05e mm

|

|

M:N

|

between 2,5 and 5

|

| Symbols

|

L, T are as defined in Pt 3, Ch 5, 1.4 Symbols and definitions 1.4.1

|

e

|

= |

length of the longest shaft bracket strut, in mm |

|

f

|

= |

coefficient dependent on type of rudder profile and

rudder angle, see

Table 12.2.5 Rudder coefficient f

in Chapter 12 for rudder

angles in excess of 45° no higher factors than those for rudder

angles of 45° need to be applied. |

|

k

o

|

= |

material factor, = (235/σo)

(24/σo) |

|

t

2

|

= |

10 mm for a propeller shaft boss integrated in the

sternframe or supported by a single arm bracket and t

2 = 0 for a propeller shaft boss supported by double arm

shaft brackets. |

|

t

b

|

= |

finished thickness of boss, in mm |

|

A

|

= |

cross-sectional area of forged or rolled steel stern

post, in cm2

|

|

A

r

|

= |

total rudder area, in m2

|

|

D

ts

|

= |

Required mild steel diameter of tail shaft in way of

the boss, in mm |

|

N

|

= |

the thickness of the shaft bracket strut, in mm |

|

V

|

= |

maximum service speed with the ship in loaded

condition, in km/h |

|

Z

T

|

= |

section modulus against transverse bending, in

cm3

|

|

Z

V

|

= |

section modulus against vertical bending, in

cm3

|

|

Note

1. In fabricated sternframes the

connection of the propeller post to the boss is to be by full

penetration welding.

Note

2. Solepieces supporting movable nozzles

will be specially considered.

Note

3. The support of a solepiece by a fixed

nozzle arrangement will be specially considered.

Note

4. The length 'a' of the solepiece

should be taken as not less than 0,4b in the formula for

Z

T.

|

Figure 5.8.1 Propeller posts

Figure 5.8.2 Open sternframe

Figure 5.8.3 Shaft brackets

8.2.3 Fabricated

sternframes are to be strengthened by transverse webs, spaced not

more than 700 mm apart.

8.2.4 Solepieces

are to be carried well forward and efficiently scarfed into the keel.

Special care is to be taken to avoid any stress-raising details at

the point where the solepiece enters the shell plating.

8.2.5 Stern posts

and rudder stock lower bearings are to be connected to floors of which

the thickness is to be increased by 2 mm, above the thickness required

by Pt 3, Ch 5, 7.2 Bottom structure.

8.3 Propeller shaft bossing

8.3.1 The finished

thickness of the propeller boss in single and twin screw ships is

to comply with Table 5.8.1 Sternframes. The

length of the boss is to be adequate to accommodate the aftermost

shaft bearing, and to allow for a proper connection to the propeller

post or shaft brackets.

8.4 Shaft brackets

8.4.1 Where the

propeller shafting is exposed for some distance clear of the hull,

it is to be supported adjacent to the propeller by independent brackets

having two arms. The use of single arm brackets will receive special

consideration.

8.4.2 Shaft brackets

are to be designed to ensure a satisfactory connection to the internal

hull structure; hard spots are to be avoided. Bracket arms are generally

to be carried through the shell plating, which is to be locally increased

in thickness, see

Pt 3, Ch 5, 2.4 Shell plating 2.4.5.

The connection of the arms to the bearing boss and shell plating is

to be by full penetration welding.

8.4.3 The scantlings

of double arm shaft brackets are to comply with the requirements of Table 5.8.1 Sternframes. The scantlings of single

arm brackets will be specially considered.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|