3.3.1 The provision of padeyes is to be such that a uniform lift is achieved with no

off-centre loading of the lifting appliance occurring.

3.3.2 The design of padeyes is to be in accordance with a recognised National or

International Standard.

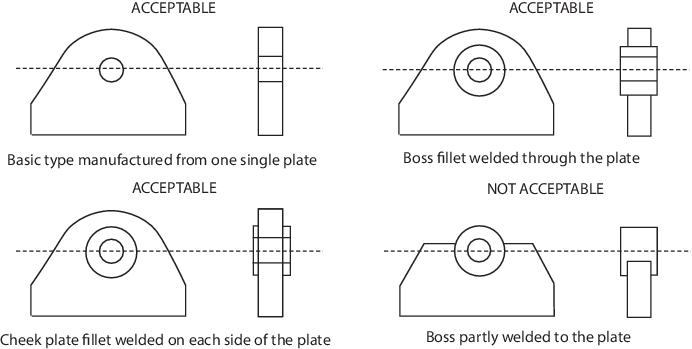

3.3.3 The padeye can be manufactured from one single plate, have a cheek plate

fillet welded on each side of the plate or have a boss which is fillet welded

through the plate, see

Figure 10.3.1 Acceptable padeye design. Padeyes

where the boss is only partly welded to the plate are not permitted.

Figure 10.3.1 Acceptable padeye design

3.3.4 All padeyes and lifting lugs are to be marked with their specific SWL. The locations

and SWL of the padeyes and lifting lugs are to be recorded on the towing and lifting

arrangement plan.

3.3.5 All padeyes and lifting lugs are to be tested to 1,5 times the SWL, as a vertical

load only.