Section

2 Towing

2.1 Application

2.1.1 The strength of shipboard fittings used for normal towing operations at bow, sides

and stern and their supporting hull structures are to comply with the requirements

specified in this sub-Section.

2.2 Arrangements

2.2.1 Shipboard fittings for towing are to be located on stiffeners and/or girders which

are part of the deck construction so as to facilitate efficient distribution of the

towing load. Other arrangements are acceptable, provided that the strength is

confirmed adequate for the intended service.

2.3 Design load

2.3.1 The design load applied to shipboard fittings and supporting hull structure is not to

be less than 1,25 times the intended maximum towing load (e.g. static bollard pull)

as indicated on the towing arrangements plan.

2.3.2 When a safe towing load (TOW) greater than that determined according to

Pt 3, Ch 10, 2.8 Safe towing load (TOW) 2.8.1 is

requested, then the design load is to be increased in accordance with the

appropriate TOW/design load relationship given in this Section.

2.3.3 The side projected area is to be considered for selection of towing lines and the

loads applied to shipboard fittings and supporting hull structure.

2.3.4 The increase of the minimum breaking strength for synthetic ropes need not to be

considered for the loads applied to shipboard fittings and supporting hull

structure.

2.3.5 The design load is to be applied to fittings in all directions that could

occur by considering the arrangement shown on the towing and mooring arrangements

plan. Where the towing line takes a turn at a fitting, the total design load applied

to the fitting is equal to the resultant of the design loads acting on the line,

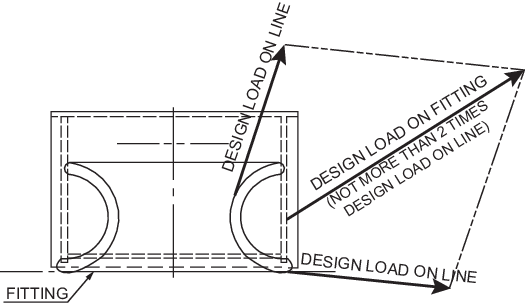

see

Figure 10.2.1 Design load applied to

fittings.

However, in no case does the design load applied to the fitting need to be greater

than twice the design load on the line.

Figure 10.2.1 Design load applied to

fittings

2.4 Strength of fittings

2.4.1 Shipboard fittings are to be selected from an acceptable National or International

Standard and to be based on the intended maximum towing load (e.g. static bollard

pull) as indicated on the towing arrangements plan.

2.4.2 Towing bitts (double bollards) are to be chosen for the towing line attached with an

eye splice if the industry standard distinguishes between different methods to

attach the line, i.e. figure-of-eight or eye splice attachment.

2.4.3 When the shipboard fitting is not selected from an accepted industry

standard, the strength of the fitting based on net scantlings and its attachment to

the ship is to be adequate for the loads specified in Pt 3, Ch 10, 2.3 Design load 2.3.1 based on the

acceptance criteria given in Pt 3, Ch 10, 2.5 Strength of supporting hull structures 2.5.2 or Pt 3, Ch 10, 2.5 Strength of supporting hull structures 2.5.3 as appropriate. Towing bitts (double bollards) are required

to resist the loads caused by the towing line attached with an eye splice. For

strength assessment, beam theory or finite element analysis using net scantlings is

to be applied, as appropriate. Corrosion additions and wear down allowance is to be

added to the net scantlings as defined in Pt 3, Ch 10, 2.6 Corrosion addition and Pt 3, Ch 10, 2.7 Wear allowance.

2.5 Strength of supporting hull structures

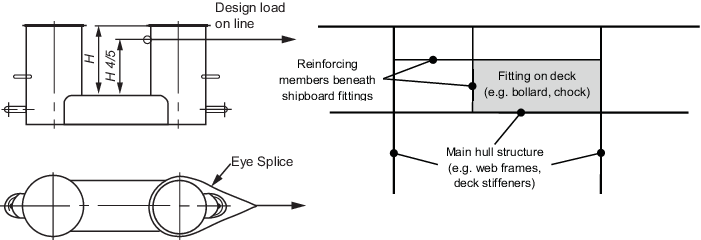

2.5.1 The net scantlings of the supporting hull structure for the fittings are

to be adequate for the loads specified by the Pt 3, Ch 10, 2.3 Design load 2.3.1

based on the acceptance criteria given in by Pt 3, Ch 10, 2.5 Strength of supporting hull structures 2.5.2 or Pt 3, Ch 10, 2.5 Strength of supporting hull structures 2.5.3 as appropriate. The reinforced members beneath

shipboard fittings are to be effectively arranged for any variation of direction

(horizontally and vertically) of the towing forces acting upon the shipboard

fittings, see

Figure 10.2.2 Supporting hull structure for a sample arrangement. Proper alignment of the

fitting and its supporting hull structure is to be ensured. The acting point of the

towing force on a shipboard fitting is to be taken at the attachment point of a

towing line or at a change in its direction. For bollards and bitts the attachment

point of the towing line is to be taken not less than 4/5 of the tube height above

the base as indicated in Figure 10.2.2 Supporting hull structure Corrosion additions and wear down allowance are to be added to

the net scantlings as defined in Pt 3, Ch 10, 2.6 Corrosion addition and

Pt 3, Ch 10, 2.7 Wear allowance.

2.5.3 For strength calculations by means of finite element analysis, the geometry is to be

idealised as realistically as possible. The ratio of element length to width is not

to exceed 3. Girders are to be modelled using shell or plane stress elements.

Symmetric girder flanges are generally to be modelled by beam or truss elements. At

least three elements are to be used across the depth of the girder. In way of small

openings in girder webs the web thickness is to be reduced to a mean thickness over

the web height. Large openings are to be modelled. Stiffeners are generally to be

modelled by using shell, plane stress, or beam elements. Stresses are to be read

from the centre of the individual element. For shell elements the stresses are to be

evaluated at the mid- plane of the element. The equivalent stress within the

supporting structure of fittings is not to exceed the specified minimum yield

strength of the material.

Figure 10.2.2 Supporting hull structure

Table 10.2.1 Allowable stress within the supporting structure of shipboard

fittings

|

|

Normal stress, in N/mm2

|

Shear stress, in N/mm2

|

| Allowable stress

|

|

|

| where

σo = specified minimum yield

strength of the material in N/mm2

Note Normal

stress is defined as the sum of bending and axial stresses. No

stress concentration factors are accounted for and as such may

need to be considered separately.

|

2.6 Corrosion addition

2.6.1 An allowance for corrosion is to be added to the net thickness derived as indicated

below:

- For the supporting hull structure, a corrosion addition of 2

mm is to be added to the net thickness derived.

- For pedestals and foundations on deck which are not part of

a fitting according to an accepted industry standard, 2,0 mm.

- For shipboard fittings not selected from an accepted

industry standard, 2,0 mm.

2.7 Wear allowance

2.7.1 In addition to the corrosion addition given in Pt 3, Ch 10, 2.6 Corrosion addition, the wear

allowance, tw, for shipboard fittings that are not selected from

an acceptable National or International standard, is not to be less than 1,0 mm,

added to surfaces which are intended to regularly contact the line.

2.8 Safe towing load (TOW)

2.8.1 The safe towing load (TOW) is the load limit for towing purposes. The TOW

used is not to exceed 80 per cent of the design load specified by Pt 3, Ch 10, 2.3 Design load 2.3.1.

2.8.2 The TOW, in tonnes, of each shipboard fitting is to be marked (by weld bead or

equivalent) on the deck fittings used for towing.

2.8.3 The above requirements on the TOW apply for the use with no more than one towline

line. If not otherwise chosen, for towing bitts (double bollards) the TOW is the

load limit for a towing line attached with an eye-splice.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|