Section

1 General

1.1 Introduction

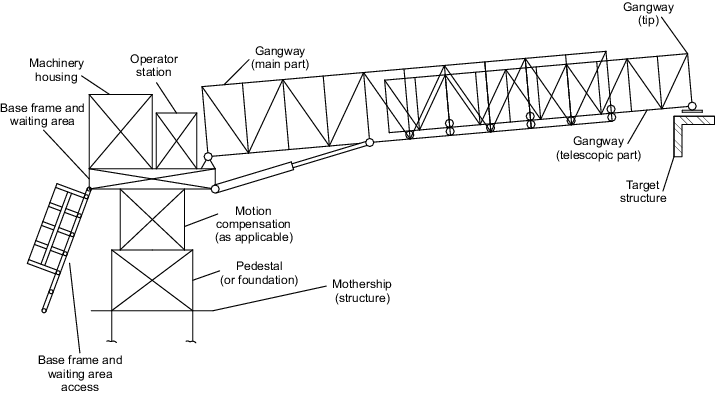

1.1.3 A typical arrangement of an OPTS is shown in Figure 1.1.1 Typical arrangement and

components of an OPTS and

the typical parts of an OPTS consist of:

- pedestal or foundation (not part of the mothership

structure);

- motion compensation system (optional);

- base frame;

- machinery housing (may not necessarily be mounted on the

base frame);

- Operator station (ideally placed close to the gangway);

- gangway, main part;

- gangway, telescopic part (usually installed but may also

be optional); and

- landing or connecting arrangement.

Other possible arrangements and layouts of an OPTS may not use all of the

shown parts and/or may use other components and arrangements.

Figure 1.1.1 Typical arrangement and

components of an OPTS

1.1.4 The operational and functional sequence of a typical motion compensated

OPTS as shown in Figure 1.1.1 Typical arrangement and

components of an OPTS may

be described as outlined in Table 1.1.1 Operational and functional

sequence of a typical motion compensated OPTS.

Table 1.1.1 Operational and functional

sequence of a typical motion compensated OPTS

| Operational step

|

Service condition

|

Persons on gangway

|

Functional/operational

description

|

| 1

|

Out-of-service

|

No

|

The OPTS is securely

stowed on deck of the mothership.

|

| 2

|

Out-of-service

|

No

|

The Operator prepares the

OPTS for service (e.g. release of stowage arrangements) and

takes position at the Operator station.

|

| 3

|

In-service

|

Possible

|

Personnel are boarding the

waiting area on the OPTS (directly or via the gangway).

|

| 4

|

In-service

|

No

|

The OPTS is powered

up.

|

| 5

|

In-service

|

No

|

The base frame and the

gangway are lifted up from their resting positions and the OPTS

is slewing to the off-board position.

|

| 6

|

In-service

|

No

|

The motion compensation

system (and the base frame) is taken to its neutral position

(usually in between maximum positions).

|

| 7

|

In-service

|

No

|

The motion compensation

system is activated.

|

| 8

|

In-service

|

No

|

The gangway will be luffed

up or down to adjust for a potential height difference between

the waiting area on the base frame and the target

structure.

|

| 9

|

In-service

|

No

|

The telescopic part of the

gangway will be extended towards the target structure on the

target unit.

|

| 10

|

In-service

|

No

|

The gangway

landing/connection arrangement:

- may land on;

- may be pushed against;

- may be structurally secured to;

the target structure to enable a safe

transfer of personnel.

|

| 11

|

In-service

|

No

|

The system may be switched

into a lower level of motion compensation where slewing and/or

telescoping and/or luffing are partly and passively compensating

mothership motions without external power supply.

|

| 12

|

In-service

|

Yes

|

The system is in active or

passive compensation mode and personnel may access the gangway

and transfer to the target unit, if allowed by the

Operator.

|

| 13

|

In-service

|

No

|

The system regains full

motion compensation and slewing and/or telescoping and/or

luffing are back to powered compensation.

|

| 14

|

In-service

|

No

|

The gangway

landing/connection arrangement is disconnected from target

structure by telescoping in.

|

| 15

|

In-service

|

No

|

The motion compensation

system (and the base frame) is taken to its neutral position

(see operational step 6).

|

| 16

|

In-service

|

No

|

The base frame and the

gangway are lowered to their resting positions.

|

| 17

|

In-service

|

Possible

|

The transferring personnel

is leaving the OPTS via the waiting area or via the

gangway.

|

| 18

|

Out-of-service

|

No

|

The OPTS is powered

down.

|

| 19

|

Out-of-service

|

No

|

The Operator secures the

OPTS on the mothership deck in its stowage position.

|

1.1.5 In certain circumstances the requirements of this Code may not

adequately cover the actual project, e.g. due to novel design or other reasons. In

such circumstances, the applicability of this Code may require further consideration

in which case it is recommended to contact LR at an early stage in order to discuss

and agree the specific technical requirements and the certification or

classification approach. In all circumstances, however, a specific risk assessment

as defined in Ch 1, 10 Risk assessment will be required.

1.1.6 In general, the lifting and supporting of persons with lifting

appliances in an offshore or open sea environment is regarded as an activity posing

higher risks for personnel compared to normal cargo handling operations. The

requirements in this document are intended to mitigate such elevated risks.

1.2 Scope

1.2.1 This Code covers the design, fabrication, survey and documentation

requirements for an OPTS. However, it should be noted that the requirements of Ch 1 General, Ch 4 Cranes and Submersible Lifting Appliances, Ch 8 Fittings, Loose Gear and Ropes, Ch 9 Machinery, Ch 10 Electrotechnical Systems, Ch 11 Materials and Fabrication, Ch 12 Testing, Marking and Surveys and Ch 13 Documentation of the Code for Lifting Appliances in a Marine Environment, July 2022 also apply (as applicable) except in such instances where

the specific requirements are otherwise defined in this Code.

1.2.2 OPTS for the purposes of these requirements cover the following systems:

- Systems installed on motherships providing safe passage

to fixed installations in open sea conditions by means of passive, active or

hybrid compensation systems (e.g. mothership to fixed wind energy offshore

structures). These three systems are defined in Ch 1, 2 Offshore Personnel Transfer System types.

- Systems installed on motherships providing safe passage

to other ships or offshore units or floating installations in open sea

conditions by means of passive, active or hybrid compensation systems (e.g.

mothership to ship transfer).

- Systems which are ‘bridging’ two floating structures in

open sea conditions (e.g. bridging of a ‘Flotel’ and an FPSO) usually by

means of passive compensation systems.

- Systems which fulfil a dual function of providing safe

transfer between installations and/or ships and/or offshore units in open

sea conditions and also providing cargo handling capabilities.

- Systems without a gangway but equipped with a personnel

containment such as a basket or other type of carrier which contains or

supports personnel for the purposes of transfer from the mothership to the

target unit (e.g. from mothership to fixed wind energy offshore structures).

- Systems not described in the above will be specially

considered on the basis of this Code and the Code for Lifting Appliances in a Marine Environment, July 2022. See

Ch 1, 1.1 Introduction.

1.2.3 The scope of this Code with respect to certification and classification

of the OPTS does not extend to:

- any aspects related to the operation of the OPTS;

- systems operating at an ambient air temperature below

-50°C;

- systems operating at an ambient air temperature above

+45°C;

- systems designed for minimum design temperatures below

-40°C (see

Ch 4, 2.25 Materials of the Code for Lifting Appliances in a Marine Environment, July 2022);

- gangway construction materials other than steel;

- systems with the gangway at an inclination of more than

20 degrees (with personnel on the gangway);

- ship to shore gangways and linkspans;

- structure of the mothership in way of the

pedestal/foundation;

- lifting, handling and erection of the OPTS or their

components;

- transport of an OPTS and/or its components;

- accidental collision loads, e.g. collision of the OPTS

with a structure or an object, etc.;

- explosion/blast loads;

- assembling or disassembling of the OPTS and/or its

components;

- scrapping or disabling of the OPTS and/or its

components;

- handling of loads (e.g. cargo) using the (optional)

dedicated crane functionality simultaneous with the transfer operation of

personnel;

- an OPTS being installed on naval vessels where the

mothership and/or target unit are moving during transfer; and

- any misuse.

1.2.4 Where an OPTS also serves as a conventional offshore crane in addition to

its personnel transfer functionality then the OPTS shall be designed in accordance

with the applicable requirements of the Code for Lifting Appliances in a Marine Environment, July 2022 in addition to the requirements given in this Code. In case

of any conflict the more onerous requirement shall prevail. It is recommended that

LR is contacted at an early stage in order to agree on a resolution of such issues.

1.2.5 In order for this Code to be applicable it is required that the ships

and/or floating units and/or offshore units are moored or a Dynamic Positioning

System or a Positional Mooring System is installed on the mothership supporting the

OPTS or which is served by the OPTS. The capability and performance of the position

keeping system and its reference systems are to be taken into account and are to

ensure safe operation of the OPTS in all environmental conditions for which the

personnel transfer system is designed. The requirement for the installation of

position keeping systems will be specially considered in case of small vessels or

other circumstances (e.g. low operational significant waves heights) where such

systems may be unreasonable or may not be applicable.

1.2.6 The OPTS is to be designed considering the individual characteristics of

the mothership. Such individual characteristics can be related to mothership

motions, mothership inclination, station keeping performance, etc. If the mothership

is unknown at the time of design, a design load envelope shall be defined which

includes design accelerations, inclinations and other loads and limiting parameters.

1.2.7 In case of a non-permanently installed OPTS, the design is to make

reference to a design envelope taking into account the maximum governing loads

required to be applied for the design of the OPTS. Any operational parameters and

safety requirements or any limitations as a result of the design of OPTS are to be

taken into consideration. It is to be ensured the aforementioned loads,

requirements, parameters and limitations of the actual OPTS are not exceeded when

installing and operating the OPTS on the actual temporary mothership.

1.3 Stakeholders

1.3.1 This Code is considered relevant to the following stakeholders:

- National and/or Coastal State Authorities.

- Owners and/or Operators of units and ships on which OPTS

are installed.

- Designers/manufacturers responsible for the design,

production and installation of OPTS.

- Lloyd’s Register plan appraisal Specialists.

- Lloyd’s Register site Surveyors.

1.4 Prerequisites

1.4.1 OPTS built in accordance with the requirements of this Code will be classed or

certified and will continue to be classed and certified as long as they are found,

upon examination at the prescribed surveys, to be maintained in accordance with the

requirements of the Code.

1.4.2 These requirements are framed on the understanding that:

- The OPTS and/or associated components and/or equipment

will at all times be properly operated and loaded in accordance with the

designer’s or manufacturer’s instructions and the loading conditions

approved by LR.

- Where the OPTS and/or associated components and/or

equipment is to be certified but not classed, the design criteria specified

conclude that Periodical Survey procedures, at least equivalent to LR’s,

will be adhered to by the Owner or the OPTS Operator.

- The OPTS and/or associated components and/or equipment

will at all times be properly operated by authorised personnel who are

sufficiently competent, trained and qualified.

- The OPTS and/or associated components and/or equipment

will be maintained by authorised personnel who are sufficiently competent,

trained and qualified.

- The OPTS installed on the mothership will not be

operated in environmental conditions more severe than those agreed for the

design basis and approval and shall not be subjected to marine operational

conditions that exceed the parameters used in design and established

according to this Code.

- Before performing a personnel transfer operation, the

Operator will ensure that the actual mothership (and target unit) motion

parameters at current sea state, the current wind speed, the actual

elevation gap between mothership and target unit and the required range of

the telescoping system and other relevant parameters, do not exceed the

limiting values as defined by the individual design and specified in the

instructions for use. Marine and offshore contractors and the Operator

responsible for personnel transfer operations will be informed of these

limitations and the necessary restrictions during the personnel transfer

operations will be put in place.

- The OPTS and/or associated components and/or equipment

and surroundings will be thoroughly inspected by the Operator prior to use

as required by the instructions for use.

- The manufacturer is to have a documented quality

assurance system in place (including a continuous improvement system) in

compliance with a recognised National or International Standard, e.g. ISO

9001 Quality management systems – Requirements. For further details

see

Ch 1, 11 Quality assurance system.

- Compliance with these requirements does not absolve the

designers and/or manufacturers of their contractual responsibilities to the

Owner/Operator for compliance with the specification and the overall design

and in-service performance of the OPTS and/or associated components and/or

equipment.

- It is the responsibility of the Operator or Owner to

ensure that the OPTS is safely operated in compliance with the instructions

for use issued by the designer/manufacturer.

1.5 Authority requirements

1.5.1 The responsible National Authority (i.e. Flag State) and/or Coastal State and/or

other regulatory authorities responsible for the offshore sector in which the OPTS

is intended to be operated may have additional requirements which need to be adhered

to as applicable in addition to these requirements.

1.5.2 In case of conflict with this Code, the requirements of the National

Authority and/or Coastal State and/or other regulatory authorities take

precedence.

1.6 Classification procedure

1.6.2 The classification of the OPTS covers the design, construction, examination, testing

and subsequent Periodical Surveys to the extent indicated within this Code and is

achieved by way of the engagement of LR Surveyors at the appropriate stages of

design, construction, installation, commissioning, and periodical examinations

during service. The following activities are undertaken by LR:

- Appraisal of plans covering structural, mechanical,

hydraulic, electrical and control engineering aspects of the OPTS.

- Verification that the material for structural components

and machinery items adopted for a classed OPTS complies with Ch 1, 12 Materials and fabrication of these requirements. The required documentation for the

materials used is to comply with Ch 1, 12 Materials and fabrication and Ch 1, 12.8 Documentation 12.8.2.

- Survey during fabrication of the critical and primary

structure and winches, hydraulic cylinders and other machinery, parts and

components at the place of manufacture, including verifying that materials

are in accordance with the approved plans and suitably qualified welders

using approved weld procedures are employed in the fabrication. Further

details are provided in Ch 1, 12 Materials and fabrication.

- Survey at the manufacturer to include the hydraulic,

electrical and control engineering systems.

- Verification of certificates for the appropriate forms

of wire ropes and chains which are to be manufactured at works approved by

LR.

- Survey of the gangway and remaining critical and primary

structure, winches, electrical, control and hydraulic systems during

installation and on-site assembly.

- Survey and testing of the motion compensation,

connection and disconnection systems and arrangements (as applicable).

- Survey during load and operational testing of the OPTS,

as specified in Ch 1, 13 Testing, marking and surveys.

- Periodical Surveys and tests, as specified in Ch 1, 13.9 Classification surveys.

1.6.4 The classification of an existing OPTS or an OPTS which is not permanently installed

on a specific unit or mothership will be specially considered.

1.7 Certification procedure

1.7.1 Where certification, which is distinct from classification, of the OPTS

is requested, the procedures to be adopted are the same as those for classification

outlined in Ch 1, 1.6 Classification procedure, with the

following exceptions:

- The required documentation for the materials used may

comply with Ch 1, 12.8 Documentation 12.8.3.

- A class notation will not be assigned to certified

OPTS.

- Periodical Surveys after commissioning of the OPTS need

not be carried out by LR. However, the Owner’s/Operator’s/designer’s

attention is drawn to Ch 1, 13.5 Periodical thorough examinations

with respect to the need for ongoing Surveys.

1.7.2 The certification of an existing OPTS will be carried out following the

procedure as given in Ch 1, 13.4 Initial Survey of existing installations.

The certification of an OPTS which is not permanently installed on a specific unit

or mothership will be specially considered.

1.8 Class notations

1.8.1 If the OPTS forms an essential feature of the mothership, the mandatory

class notation LA shall be applied.

1.8.2 The special feature class notation which may optionally be applied to

OPTS is defined as W2W.

1.9 Referenced Rules, Codes and Standards

1.9.1 The authority requirements and the requirements of Codes, Rules and Standards listed

in the following are to be applied in the following order of priority:

- The requirements of the National and/or Coastal State

Authorities and/or other regulatory authorities (responsible for the mothership

and/or the offshore area of operation respectively).

- The requirements of this Code for Offshore Personnel

Transfer Systems.

- The requirements of Lloyd’s Register’s Code for Lifting Appliances in a Marine Environment, July 2022.

- Other Lloyd’s Register Rules and Standards (as applicable);

and

- The list of ISO, EN and other standards (see

Ch 1, 1.9 Referenced Rules, Codes and Standards 1.9.5 and Ch 1, 1.9 Referenced Rules, Codes and Standards 1.9.6) provides a list of

preferred standards in case requirements are considered

necessary to be taken from such standards in the absence of

requirements in (a), (b), (c) or (d) above. However, the

application of such additional standards shall be agreed

between the Owner and/or Operator, designer/manufacturer of

the OPTS and LR as applicable and required for the

individual project on a case-by-case basis.

The order of standards may also depend on the requirements of the

National and/or Coastal State Authorities responsible for the ship

and/or the offshore area of operation respectively. The selection of

standards as defined in Ch 1, 1.9 Referenced Rules, Codes and Standards 1.9.1.(e) shall be agreed with

LR prior to commencing of the project.

1.9.2 The edition or version of the Rules, Codes or standards shall be the one being in

force on the contract date between the Owner/Operator and the yard building the

mothership. Where designs and/or projects are not related to a specific mothership,

the edition or version of the applicable Rules, Codes or Standards shall be the one

being in force on the contract date between the designer/manufacturer and LR for

certification of the OPTS.

1.9.3 If a recognised National or International Standard listed in the following has been

withdrawn it shall no longer be used unless it has been replaced by another valid

and recognised standard.

1.9.4 Lloyd’s Register Rules, Codes and Procedures;

- Code for Lifting Appliances in a Marine Environment, July 2022,

- Rules for the Manufacture, Testing and Certification of Materials, July 2022,

- Rules and Regulations for the Classification of Ships, July 2022,

- Rules and Regulations for the Classification of Offshore Units, July 2022,

- Rules for the Winterisation of Ships, July 2022,

- ShipRight Procedure Cyber Security for Ships and

Ships Systems,

- ShipRight Procedure Risk Based Certification

(RBC).

1.9.5 European standards:

- EN 614 Safety of machinery – Ergonomic design

principles,

- EN 842 Safety of machinery – Visual danger

signals – General requirements, design and testing,

- EN 1127-1 Explosive atmospheres – Explosion

prevention and protection – Part 1: Basic

concepts and methodology,

- EN 10204 Metallic products – Types of inspection

documents,

- EN 12077-2 Cranes safety – Requirements for health

and safety – Part 2: Limiting and indicating devices,

- EN 12385-1 Steel wire ropes – Safety – Part 1:

General requirements,

- EN 12385-2 Steel wire ropes – Safety – Part 2:

Definitions, designation and classification,

- EN 12385-3 Steel wire ropes – Safety – Part 3:

Information for use and maintenance,

- EN 12385-4 Steel wire ropes – Safety – Part 4:

Stranded ropes for general lifting applications,

- EN 12644-1 Cranes – Information for use and testing –

Part 1: Instructions,

- EN 12644-2 Cranes – Information for use and testing –

Part 2: Marking,

- EN 13001 Cranes – General design,

- EN 13135 Cranes – Safety – Design – Requirements for

equipment,

- EN 13411-3 Terminations for steel wire ropes – Safety

– Part 3: Ferrules and ferrule-securing,

- EN 13411-4 Terminations for steel wire ropes – Safety

– Part 4: Metal and resin socketing,

- EN 13411-6 Terminations for steel wire ropes – Safety

– Part 6: Asymmetric wedge socket,

- EN 13411-7 Terminations for steel wire ropes – Safety

– Part 7: Symmetric wedge socket,

- EN 13557 Cranes – Controls and control

stations,

- EN 13586 Cranes – Access,

- EN 13852-1 Cranes – General-purpose offshore

cranes,

- EN 14502-1 Cranes – Equipment for the lifting of

persons – Part 1: Suspended baskets,

- EN 14502-2 Cranes – Equipment for the lifting

of persons – Part 2: Elevating control

stations,

- EN 31010 Risk management – Risk assessment

techniques.

1.9.6 International Standards:

- ISO Guide 73 Risk management – Vocabulary,

- ISO 281 Rolling bearings – Dynamic load ratings and

rating life,

- ISO 898 Mechanical properties of fasteners made of

carbon steel and alloy steel,

- ISO 15138 Petroleum and natural gas

industries – Offshore production installations –

Heating, ventilation and air

conditioning,

- ISO 2232 Round Drawn Wire for General Purpose

Nonalloy Steel Wire Ropes – Specifications,

- ISO 2408 Steel wire ropes – Requirements,

- ISO 2923 Acoustics – Measurement of Noise on

Board Vessels,

- ISO 3108 Steel wire ropes – Test method

– Determination of measured breaking

force,

- ISO 3744 Acoustics – Determination of sound power

levels and sound energy levels of noise sources using sound pressure —

Engineering methods for an essentially free field over a reflecting

plane,

- ISO 4309 Cranes – Wire ropes – Care and maintenance,

inspection and discard,

- ISO 4413 Hydraulic fluid power – General rules and

safety requirements for systems and their components,

- ISO 4414 Pneumatic fluid power – General rules

and safety requirements for systems and their

components,

- ISO 4871 Acoustics – Declaration and verification of

noise emission values of machinery and equipment,

- ISO 5488 Ships and marine technology – Accommodation

ladders,

- ISO 5817 Welding – Fusion-welded joints in steel,

nickel, titanium and their alloys (beam welding excluded) – Quality

levels for imperfections,

- ISO 6336 Calculation of load capacity of spur and

helical gears,

- ISO 7010 Graphical symbols – Safety colours

and safety signs – Registered safety

signs,

- ISO 7061 Ships and marine technology – Aluminium

shore gangways for seagoing vessels,

- ISO 7731 Ergonomics – Danger signals for public and

work areas – Auditory danger signals,

- ISO 8566-1 Cranes – Cabins and control stations –

Part 1: General,

- ISO 9001 Quality management systems –

Requirements,

- ISO 9712 Non-destructive testing –

Qualification and certification of NDT

personnel,

- ISO 9927-1 Cranes – Inspections – Part 1:

General,

- ISO 10474 Steel and steel products – Inspection

documents,

- ISO 11201 Acoustics – Noise emitted by machinery and

equipment – Determination of emission sound pressure levels at a work

station and at other specified positions in an essentially free field

over a reflecting plane with negligible environmental

corrections,

- ISO 11688 Acoustics – Recommended practice for the

design of low-noise machinery and equipment,

- ISO 12100 Safety of machinery – General principles

for design – Risk assessment and risk reduction,

- ISO 12478-1 Cranes – Maintenance manual – Part 1:

General,

- ISO 12480-1 Cranes – Safe use – Part 1:

General,

- ISO 12482-1 Cranes – Condition monitoring – Part 1:

General,

- ISO 12944 Paints and varnishes – Corrosion protection

of steel structures by protective paint systems,

- ISO 13702 Petroleum and natural gas industries

– Control and mitigation of fires and

explosions on offshore production installations

– Requirements and guidelines,

- ISO 13849 Safety of machinery – Safety-related

parts of the control systems,

- ISO 13850 Safety of machinery – Emergency stop

function – Principles for design,

- ISO 14120 Safety of machinery – Guards –

General requirements for the design and

construction of fixed and movable guards,

- ISO 14122 Safety of machinery – Permanent

means of access to machinery,

- ISO 17894 Ships and marine technology – Computer

applications – General principles for the development and use of

programmable electronic systems in marine applications,

- ISO 19353 Safety of machinery – Fire prevention and

fire protection,

- ISO 20332 Cranes – Proof of competence of steel

structures,

- ISO 31000 Risk management – Guidelines,

- IEC 60079 Explosive atmospheres,

- IEC 60092-502 Electrical installations in ships

– Part 502: Tankers - Special

features,

- IEC 60529 Degrees of protection provided by

enclosures (IP Code),

- IEC 61000 Electromagnetic compatibility

(EMC),

- IEC 60204-32 Safety of machinery – Electrical

equipment of machines – Part 32: Requirements for hoisting

machines,

- IEC 60812 Analysis techniques for system reliability

– Procedure for failure mode and effects analysis (FMEA),

- IEC 61508 Functional safety of electrical/

electronic/ programmable electronic safety-related systems,

- IEC 61882 Hazard and Operability Studies (HAZOP

Studies) – Application Guide,

- IEC 61892-7 Mobile and fixed offshore units –

Electrical installations – Part 7:

Hazardous areas,

- IEC 62443 Security for industrial

automation and control systems,

- IEC 62745 Safety of machinery – Requirements

for cableless control systems of

machinery,

- ISO 80079-36 Explosive atmospheres – Part 36:

Non-electrical equipment for explosive atmospheres – Basic method and

requirements,

- ISO/IEC 27001 Information technology –

Security techniques – Information security

management systems – Requirements,

- ISO/IEC 90003 Software engineering – Guidelines for

the application of ISO 9001:2008 to computer software,

- IMO MSC.1/Circ. 1331 Guidelines for construction,

installation, maintenance and inspection/survey of means of embarkation

and disembarkation,

- IMO Code on Alerts and Indicators, 2009,

- IMO International Code for the Application of Fire

Test Procedures (2010 FTP Code),

- IMO Code for the Construction and Equipment of Mobile

Offshore Drilling Units (2009 MODU Code),

- IMO International Convention for the Safety of Life

at Sea (SOLAS), 1974,

- IMO SOLAS regulation II-1/3-9, Means of embarkation

on and disembarkation from ships,

- F.E.M. 1.001 Rules for the design of hoisting

appliances,

- EI Model Code of Safe Practice Part 15: Area

Classification for Installations Handling Flammable Fluids,

- ANSI/ISEA 121 American National Standard for Dropped

Object Prevention Solutions,

- API RP 505 Recommended Practice for Classification of

Locations for Electrical Installations at Petroleum Facilities

Classified as Class I, Zone 0, Zone 1, and Zone 2.

1.9.7 Recognised National or International Standards for the design of OPTS

and/or their components may be accepted as equivalent to the

requirements of this Code, provided LR is satisfied in each case

that the standard adequately takes into account all necessary

parameters (e.g. loads, environmental conditions, etc.) resulting

from the intended mode of operation. The relevant Standard is to be

specified in the submission and agreement shall be requested (in

accordance with Ch 1, 1.9 Referenced Rules, Codes and Standards 1.9.1.(e)) prior to the design

process commencing.

1.10 Terms and definitions

1.10.1 Active motion compensation means the compensation of the motions

of the mothership (and possibly also the target unit) to enable the safe transfer of

personnel by means of a combination of a power source, a control system and a

position/motion reference unit. See

Ch 1, 2.2 System types 2.2.1 for a detailed

description.

1.10.2 Base frame is defined as the structure providing rigid support of

the gangway and is usually located between the pedestal and/or the active motion

compensation system and the gangway.

1.10.3 Cargo basket or cargo trolley is a mobile or fixed containment for

goods, tools or similar items.

1.10.4 Components are all items which are essential for the operation of

the system. Those components (structural, machinery, electrical/control) usually

have well defined interfaces within the system boundaries of the OPTS (e.g.

hydraulic cylinders, winches).

1.10.5 Critical non-structural component is a component of the OPTS

where the failure of which may or will result in the loss of functionality or

complete loss of the OPTS, e.g. control system, control panel.

1.10.6 Critical structural component is a structural member of the OPTS

where the failure of which may or will result in the loss of the OPTS and/or one or

more of its components in the main load-path and/or cause harm to any personnel,

e.g. gangway chords and bracings, base frame, slewing ring, pedestal.

1.10.7 Dead load is the self-weight of any component of the OPTS which

is not included in the Live Load.

1.10.8 Design envelope is the range of operational parameters,

geometrical limitations, mothership motions, resulting loads, environmental

conditions, etc. to which the OPTS is required to be designed.

1.10.9 Effective gangway width is the maximum span within which loads may

be applied to the gangway flooring either by personnel or objects.

1.10.10 Emergency situation is defined as a hazardous situation needing

to be urgently ended or averted which can arise during normal operation of the OPTS

due to external influences, human interaction or as a consequence of a malfunction

or failure of any part of the OPTS. The emergency situations need to be considered

for exceptional design load cases.

1.10.11 Essential feature. A lifting appliance forms an essential feature

if the purpose of the mothership is impaired if the lifting appliance is not

functioning.

1.10.12 Failure load is the load when a structural member, component or

other part of the OPTS has just reached its load bearing capacity and any further

increase of the load will result in, e.g.:

- exceeding of yield strength; and/or

- exceeding of ultimate tensile strength; and/or

- exceeding of minimum breaking load; and/or

- immediate buckling; and/or

- mechanical components failing to fulfil their function.

1.10.13 Free floating mode is defined as the OPTS being in a state where the motions

of the mothership and/or target unit are not actively compensated. Reference is made

to Ch 1, 1.10 Terms and definitions 1.10.1.

1.10.14 Flooring is the supporting structure for persons using gangways,

walkways, waiting areas, or similar structures and arrangements.

1.10.15 Gangway is the structure which is intended to support and guide

the personnel on their way between the mothership supporting the OPTS and the target

unit.

1.10.16 Gangway tip is the end of the gangway structure (including any

telescopic part) which comes into contact with or is close to the target structure

during personnel transfer.

1.10.17 Guard is a physical barrier to provide protection from machines

and their components and parts which pose a potential hazard to personnel.

1.10.18 Guard-rail is a structure preventing persons falling from

gangways, walkways, waiting areas and similar arrangements.

1.10.19 Handrail is a part of a guard-rail which persons hold onto while

using gangways, walkways, waiting areas, and similar arrangements.

1.10.20 Hazard is a situation with the potential to cause harm to

personnel, the OPTS, target unit/structure and supporting mothership in terms of its

safety and integrity.

1.10.21 Live load is defined as the sum of the SWLC (as

defined in Ch 1, 1.10 Terms and definitions 1.10.45) and the static weight of any component of the appliance which is

directly connected to, and undergoes the same motion as, the Safe Working Load

during the lifting operation.

1.10.22 Loose gear is defined as hooks, hook blocks, shackles, blocks,

swivels, chains, rings and similar items not permanently attached to the OPTS or

items which can be removed and re-used elsewhere to serve a similar purpose under

the same Safe Working Load or working load limit.

1.10.24 Machinery components or systems are defined as mechanical

components which enable or aid the active or passive compensation function, or which

otherwise assist in moving of structural components of the OPTS (e.g. winches,

hydraulic cylinders, etc.).

1.10.25 Main load-path is, in general, defined as the route along the

critical structural components of the OPTS, e.g. from the pedestal or foundation via

an (optional) motion compensation system followed by the base structure, along the

gangway and up to the gangway tip.

1.10.26 Manufacturer's certificate validated by LR is defined as a

certificate issued by the manufacturer, validated by LR on the basis of inspection

and testing carried out by the manufacturer and which is in accordance with the

requirements of the Rules for the Manufacture, Testing and Certification of Materials, July 2022. In case of satisfactory

validation, the certificate will include the following statement:

‘We hereby certify that the material has been made by an approved

process and satisfactorily tested in accordance with the Rules of Clasifications

Register.’

1.10.27 Manufacturer's certificate is defined as a certificate issued by

the manufacturer based on the results of testing and inspection being satisfactorily

carried out in accordance with the requirements of the Rules for the Manufacture, Testing and Certification of Materials, July 2022, or the applicable National or International Standard.

The certificate is to be validated by the manufacturer's authorised representative,

independent of the manufacturing department. The certificate will contain a

declaration that the products are in compliance with the requirements of these Rules

or the applicable National or International Standard. This certificate is equivalent

to an inspection certificate EN 10204 Metallic products – Types of inspection

documents, 3.1 (or ISO 10474 Steel and steel products – Inspection

documents, 3.1) issued by the manufacturer of the materials.

1.10.28 Mothership is the vessel or (offshore) unit which carries the

OPTS.

1.10.29 Motion compensation is the ability of the OPTS to fully or partly

limit the translational and rotational motion effects of the moving mothership, i.e.

dynamic: roll, pitch, yaw, heave, sway and surge, and static: heel and trim.

1.10.30 Nominal gangway length is the average of the maximum and minimum

gangway length (e.g. considering telescopic extension).

1.10.31 Off-board lift is defined as a lifting operation which is not

limited to the mothership usually taking place over the side of the mothership.

1.10.32 Offshore crane is defined as a crane used in an offshore

environment which is handling cargo or personnel off-board the mothership usually by

means of a boom or jib in combination with a winch and an associated reeving

system.

1.10.33 Offshore Personnel Transfer System (OPTS) is defined as a system

which is installed on-board the mothership with the purpose to provide safe transfer

of personnel from the mothership to a fixed or floating target unit.

1.10.34 On-board (internal) lift is defined as a lifting operation which

is limited to the mothership the appliance is installed on.

1.10.35 Operator is the person operating the OPTS with the responsibility

for enabling the safe transfer of personnel between the mothership and the target

unit via the target structure.

1.10.36 Passive motion compensation is defined as a system which requires

no power source and no control system that enables motion compensation during the

transfer of personnel. See

Ch 1, 2.2 System types 2.2.1 for a detailed

description.

1.10.37 Personnel are the persons which are using the OPTS as a means to

safely move/transfer between the mothership and the target unit.

1.10.38 Personnel containment is a structure enabling the support of

persons in a limited and defined space by means of a basket or platform or similar

structure.

1.10.39 Platform is defined as the means for providing support for

personnel which are staying on such means for an extended period of time.

1.10.40 Primary structural component is a component which is not a

critical structural component but is directly supporting personnel, e.g. walkways,

flooring, handrails and their supports.

1.10.41 Residual motion (including acceleration and inclination) means

any motion that remains uncompensated by the motion compensation system.

1.10.42 Risk is the likelihood that a specified undesired event will

occur within a specified period of time, or under specified circumstances.

1.10.43 Risk acceptance criteria are the criteria to be applied to the

results of the risk assessment, to demonstrate that the OPTS and supporting

mothership are capable of providing an acceptable level of safety and integrity.

1.10.44 Risk assessment is the evaluation of the likelihood of specified

undesired consequences to the safety and integrity of the OPTS and supporting

mothership, together with the value judgements made concerning the significance of

the results.

1.10.49 Secondary structural component is a component which is not a

primary structural component, e.g. cable routings, etc.

1.10.50 Significant wave height (H1/3) is defined as

the average of the one third highest waves (measured from trough to crest) in a

short-term wave measurement record.

1.10.51 Supporting structure (pedestal or foundation) is defined as the

structure providing the base which is predominantly supporting the OPTS.

1.10.52 Suspended basket is a containment for personnel which is raised

and lowered by means of falls and a winch.

1.10.53 Target structure is the structure to which the OPTS supported by

the mothership will be aiming at, touching on or be connected to in order to enable

personnel to move safely between the mothership and the target unit.

1.10.54 Target unit is the floating or fixed installation to which or from

which personnel are being transferred by means of the OPTS installed on the

mothership.

1.10.55 Uniformly Distributed Load – Personnel (UDLP).

The uniformly distributed load, UDLP, is related to the transfer

of personnel and is specifically defined as the distributed load per area which

comprises of the weight of the maximum possible number of personnel simultaneously

and safely using the OPTS including applicable equipment.

1.10.56 Walkway is the means of providing support for personnel moving

from one location to another on the OPTS.

1.11 Abbreviations

1.11.1 ASD

Allowable Stress Design

1.11.2 CLAME

Lloyd’s Register’s Code for Lifting Appliances in a Marine Environment

1.11.3 COPTS

Lloyd’s Register’s Code for Offshore Personnel Transfer Systems

1.11.4 DP

Dynamic Positioning

1.11.5 EMC

Electro Magnetic Compatibility

1.11.6 EN

European Norm (Standard)

1.11.7 FAT

Factory Acceptance Test

1.11.8 FMEA

Failure Mode and Effects Analysis

1.11.9 FMECA

Failure Mode, Effects and Criticality Analysis

1.11.10 HAZID

Hazard Identification

1.11.11 HAZOP

Hazard and Operability Study

1.11.12 HPU

Hydraulic Power Unit

1.11.13 IACS

International Association of Classification Societies

1.11.14 ILO

International Labour Organisation

1.11.15 IMO

International Maritime Organization

1.11.16 ISO

International Organisation for Standardisation

1.11.17 ITP

Inspection and Test Plan

1.11.18 LRFD

Load and Resistance Factor Design

1.11.19 MCS

Motion Compensation System

1.11.20 MDT

Minimum Design Temperature

1.11.21 NDE

Non-Destructive Examination

1.11.22 NDT

Non-Destructive Testing

1.11.23 OPTS

Offshore Personnel Transfer System

1.11.24 PWHT

Post Weld Heat Treatment

1.11.25 QM

Quality Management

1.11.26 RBC

Risk Based Certification

1.11.27 RMS

Root Mean Square

1.11.28 SAT

Site Acceptance Text

1.11.30 SOLAS

International Convention on the Safety of Life at Sea

1.11.31 SWH

Significant wave height

1.11.32 SWL

Safe Working Load

1.11.33 UDL

Uniformly Distributed Load

1.11.34 WPS

Welding Procedure Specification

1.11.35 WPQ

Welder Performance Qualification

1.12 Information to be submitted

1.12.1 The plans and information listed in this sub-Section are required to be submitted by

the manufacturer (or designer) to LR enabling the classification or certification of

an OPTS.

1.12.2 General arrangement plan of the OPTS, including details of the integration with and

location (as applicable) on the mothership including all interfaces.

1.12.3 General arrangement plan showing details of escape and access routes and

arrangements.

1.12.4 Detailed specification of the OPTS and design basis of the OPTS including:

- general system description;

- system type of the OPTS (see

Ch 1, 2.2 System types);

- access type of the OPTS (see

Ch 1, 2.3 Access types) including number of persons

simultaneously allowed on the gangway;

- details of the operating cycle and modes (stowage,

pre-service, in-service, post-service and stowage) and associated loads and

location of personnel and Operator;

- description and/or illustration of flow of transferring

personnel using the OPTS;

- Safe Working Loads or Uniformly Distributed Loads

applicable to the OPTS (see

Ch 1, 3.3 Safe Working Load and Ch 1, 3.4 Uniformly Distributed Load);

- configurations and geometrical limitations of the

OPTS;

- maximum movements, angles, speeds and accelerations of

the OPTS (and associated significant wave heights as applicable);

- details of the connection and disconnection system;

- station keeping performance (e.g. system capability

plot) of the Dynamic Positioning (DP) System or other station keeping

systems and arrangements (all as applicable);

- details of the stowage arrangement;

- operational profile, load spectra and design lifetime of

the OPTS;

- access arrangements;

- details of any special operational (e.g. cargo trolley

or basket) or non-operational (e.g. alternative stowage position) modes not

listed in (d);

- detailed description of the motion compensation method,

concept and system; and

- minimum and maximum design and operating

temperatures.

1.12.6 Instructions for use including, but not limited to:

- detailed description and conditions of normal operation

personnel transfer and required condition of the OPTS to enable safe

operation;

- detailed conditions and limitations of operation, use,

access, environment (e.g. significant wave heights, wind, etc.),

configuration, geometry, mothership characteristics, etc. and related safety

measures;

- description and requirements for the state and design of

the target structure;

- detailed installation procedure (including any tests,

inspections, verifications, etc.) of the OPTS on-board;

- details of the Operators required:

- education and qualification

- training

- duties before, during and after operation;

- details of hazards to personnel within the operational

area of the OPTS and on the OPTS;

- details of noise reduction measures;

- description and associated safety measures concerning

limited or degraded operational modes;

- detailed description and conditions of pre- and

post-operation measures (taking into service and taking out of

service);

- maintenance requirements (including any testing

requirements) in case no dedicated maintenance manual exists;

- communication requirements between:

- Operator and personnel to be transferred

- Operator and mothership

- Operator and target unit;

- safe access; and

- emergency, safety, evacuation and contingency

procedures.

1.12.7 Maintenance manual and system addressing regular and irregular maintenance.

1.12.8 Emergency situations manual, if not part of the instructions for use, containing

details of the handling of such situations, including:

- general emergency operational procedures and contingency

plans;

- early warning escalation in order to enable safe

completion or abortion of a transfer cycle (see

Ch 1, 9.4 Active systems (ST-A or ST-H) 9.4.7);

- emergency stop;

- emergency disconnection;

- failure or damage of actuating system (e.g. hydraulic

oil leakage, electrical cable damage);

- fire within the OPTS and its components and

systems;

- Operator unable to continue his duties (e.g. passing

out);

- mothership or target unit positioning system failure

(e.g. DP failure);

- motion compensation system (or part of the system)

degrading or degraded;

- overloading of the system (e.g. excessive number of

personnel and/or equipment present on the gangway or in the personnel or

cargo basket); and

- other emergency situations.

1.12.9 Calculations (or equivalent) clearly indicating the basis of design,

operating criteria, dynamic loads, SWLs, UDLs, mothership accelerations and

inclinations, wind loads, weights and centres of gravity of the OPTS parts, and

relevant National or International Standards applied (see

Ch 1, 3 Loads and factors and Ch 1, 4 Load cases and load combinations).

1.12.10 Scantlings, weld details, NDE and assembly plans of all critical and

primary structural items comprising the OPTS, including the gangway/containment,

base frame (supporting the gangway/containment), slewing ring, pedestals and stowage

arrangements (all as applicable). Pedestals or foundation that are welded to the

hull structure of the mothership are a classification item where the mothership is

classed with LR. Classification item, in this context, means that the pedestals or

foundation are subjected to the classification procedures regardless of whether the

OPTS is subject to certification or classification, see

Figure 1.1.2 Classification items and

applicability of LR’s requirements for OPTS pedestals and

foundations.

Figure 1.1.2 Classification items and

applicability of LR’s requirements for OPTS pedestals and

foundations

1.12.11 Specification of the materials applied in the main structural components including

the pedestals/foundation.

1.12.13 Details of sheaves, axles, pivot pins, wheels, slewing ring, slewing ring bolts, and

other or similar items.

1.12.14 Details of blocks, chains, shackles, hooks and other loose gear items, indicating

material, Safe Working Load (SWL), proof loads (PL) and the standard to which they

have been manufactured.

1.12.15 The size, construction, finish and certified breaking loads of steel wire ropes and

fibre ropes.

1.12.17 Plans and calculations of machinery items, such as winch gearing, shafts, clutches,

brakes, coupling bolts, welded drums, winch frame and similar items and their

materials and stresses. In case the items are type approved by LR, the type approval

certificates and supporting information are to be submitted for consideration in

order to verify whether the actual OPTS design is compatible with the item and the

related type approval.

1.12.18 Description of operation with explanatory diagrams of the motion compensation system

including details of operating medium, i.e. pneumatic, hydraulic or electric

schematics, including power packs and standby sources of power.

1.12.19 Inspection and Test Plan (ITP), including:

- inspection/survey plan;

- Factory Acceptance Test (FAT), including operational

tests;

- pre-commissioning and commissioning procedures;

- on-board testing (or Site Acceptance Test (SAT));

and

- on-board overload and functional testing.

1.12.20 Plans of the circuit diagram of the electrical system, showing load currents and

ratings of all electrical equipment, types and sizes of cables, rating type and make

of all protecting devices.

1.12.21 Arrangement plan and circuit diagram of switchboard.

1.12.22 General arrangement of control stations (e.g. panels, consoles, cabins) and their

locations and details of controls and displays.

1.12.23 Schematic diagrams of control circuits and panels, interlocks and alarm systems.

1.12.24 Details of the control, alarm and safety concept including:

- The overall system operational concept including a

description of the intended operation of the control, alarm and safety

systems. The description shall include a demonstration that the design

provides an effective means of operation and control for all operating

conditions.

- Details of alarms and warnings including intended

Operator response and the message to be presented.

- Line diagrams of control circuits.

- Details of safety functions and devices (including

securing and latching arrangements) and of any overrides, including

consequences of use.

- List of monitored points.

- List of control points.

- Limit switches.

- Monitoring systems.

- Interface connections.

- Automatic safety systems and load limiting systems (if

any) including certification details.

- Test schedules (for both works testing and trials) which

should include methods of testing and test facilities provided.

- Where the design includes programmable electronic

systems, the documentation listed in Pt 6, Ch 1, 1.2 Documentation required for design review 1.2.6 of the Rules and Regulations for the Classification of Ships, July 2022.

See

Ch 1, 3.7 Mechanical, electrical and control aspects of the

Code for Lifting Appliances in a Marine Environment, July 2022.

1.12.25 In addition, the following information is required for reference purposes:

calculations of short-circuit currents and main bus-bars, sub-switchboard bus-bars

and the secondary side of transformers.

1.12.26 The following information concerning the corrosion protection system shall be

submitted, as a minimum:

- evidence that any primers used will have no deleterious

effect on subsequent welding or on subsequent coatings;

- details of the painting specification with regard to:

- the generic type of the coating and confirmation

of its suitability for the intended environment;

- the methods to be used to prepare the surface

before the coating is applied and the standard to be achieved.

Reference should be made to established International or National

Standards;

- the method of application of the coating;

and

- the number of coats to be applied and the total

dry film thickness;

- details of the areas to be coated;

- details of other means of corrosion protection (e.g.

suitable material selection, galvanisation, cathodic protection), see

Ch 1, 12.6 Fabrication 12.6.10; and

- Inspection and Testing Plan (ITP).

1.12.27 Information about the type of consideration and the possible review or

appraisal status codes of the submitted documents are provided in Table 1.1.2 Type of consideration and

review/appraisal status.

Table 1.1.2 Type of consideration and

review/appraisal status

| Document to be submitted

|

Reference

|

Type of

consideration and possible review/appraisal

status

|

| Basic and general information

|

| General

arrangement plans

|

See

Ch 1, 1.12 Information to be submitted 1.12.2 and Ch 1, 1.12 Information to be submitted 1.12.3

|

Noted

|

| Specification and design basis of the OPTS

|

See

Ch 1, 1.12 Information to be submitted 1.12.4

|

Noted

|

| Risk

assessment and safety concept

|

See

Ch 1, 1.12 Information to be submitted 1.12.5

|

Noted

|

| Instructions for use

|

See

Ch 1, 1.12 Information to be submitted 1.12.6

|

Noted

|

| Maintenance manual and system

|

See

Ch 1, 1.12 Information to be submitted 1.12.7

|

Noted

|

| Emergency

situations manual

|

See

Ch 1, 1.12 Information to be submitted 1.12.8

|

Noted

|

| Calculations

|

See

Ch 1, 1.12 Information to be submitted 1.12.9

|

Noted

|

| Structural components related

information

|

| Scantlings

of all main structural items

|

See

Ch 1, 1.12 Information to be submitted 1.12.10

|

Approved

|

| Specification of the materials

|

See

Ch 1, 1.12 Information to be submitted 1.12.11

|

Approved

|

| Scantling

plans and details of hydraulic cylinders

|

See

Ch 1, 1.12 Information to be submitted 1.12.12

|

Approved

|

| Sheaves,

axles, pivot pins, wheels, slewing ring, slewing ring bolts,

etc.

|

See

Ch 1, 1.12 Information to be submitted 1.12.13

|

Approved

|

| Items of

loose gear

|

See

Ch 1, 1.12 Information to be submitted 1.12.14

|

Approved

|

| Steel wire

ropes and fibre ropes

|

See

Ch 1, 1.12 Information to be submitted 1.12.15

|

Approved

|

| Indication

of critical, primary or secondary structure

|

See

Ch 1, 1.12 Information to be submitted 1.12.16

|

Approved

|

| Machinery related information

|

| Machinery

items

|

See

Ch 1, 1.12 Information to be submitted 1.12.17

|

Approved

|

| Description of operation

|

See

Ch 1, 1.12 Information to be submitted 1.12.18

|

Noted

|

| Survey related

information

|

| Inspection

and Test Plan (ITP)

|

See

Ch 1, 1.12 Information to be submitted 1.12.19

|

Agreed

(Notes 1 and 2)

|

| Electrotechnical systems related

information

|

| Plans of

the circuit diagram of the electrical system (incl.

switchboard)

|

See

Ch 1, 1.12 Information to be submitted 1.12.20 and Ch 1, 1.12 Information to be submitted 1.12.21

|

Approved

|

| General

arrangement of control stations

|

See

Ch 1, 1.12 Information to be submitted 1.12.22

|

Noted

|

| Schematic

diagrams of control circuits and panels, interlocks and alarm

systems

|

See

Ch 1, 1.12 Information to be submitted 1.12.23

|

Approved

|

| Control,

alarm and safety concept

|

See

Ch 1, 1.12 Information to be submitted 1.12.24

|

Approved

|

| Calculations of short-circuit currents and main bus-bars,

sub-switchboard bus-bars and the secondary side of

transformers

|

See

Ch 1, 1.12 Information to be submitted 1.12.25

|

Noted

|

| Miscellaneous information

|

| Corrosion

protection system

|

See

Ch 1, 1.12 Information to be submitted 1.12.26

|

Agreed

(Note 3)

|

|

Note 1: To be agreed between the designer/manufacturer and the

attending LR Surveyor.

Note 2: The test procedure and test loads are to be submitted

to the responsible LR plan appraisal office for

approval.

Note 3: To be agreed between the designer/manufacturer and the

LR Surveyor.

|

|