3.2.2 If no FEA is available, a simplified approach may be used. This can be based on the

empirically determined stress concentration factors (SCFs) from the ‘Stress

concentration factors’ sub-section of the applicable Rules, if within its validity

range, and a relative stress gradient inversely proportional to the fillet

radius.

3.2.3 Bending and torsional stresses must be addressed separately. The combination of these

is addressed by the acceptability criterion.

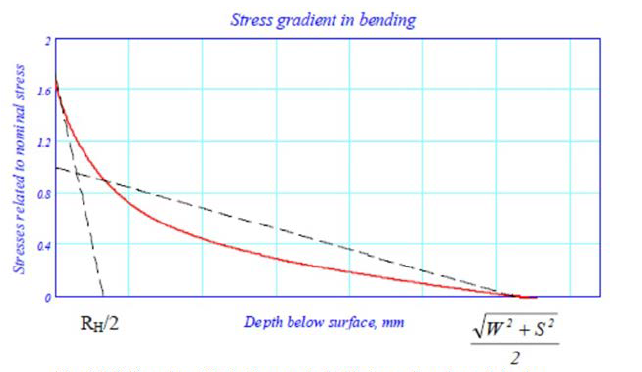

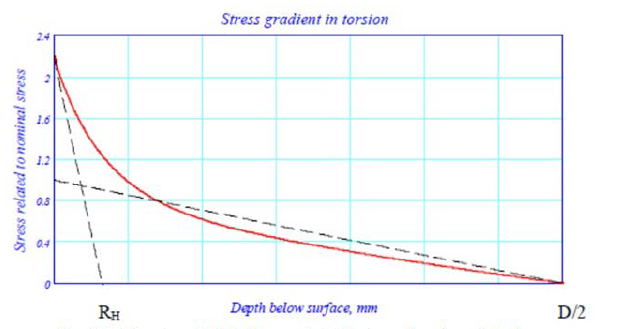

3.2.4 The subsurface transition-zone stresses, with the minimum hardening

depth, can be determined by means of local stress concentration factors along an

axis perpendicular to the fillet surface. These functions, αB-local and

αT-local, have different shapes due to the different stress

gradients.

3.2.5 The SCFs αB and αT are valid at the surface. The

local αB-local and αT-local drop with increasing depth. The

relative stress gradients at the surface depend on the kind of stress raiser, but

for crankpin fillets they can be simplified to 2/RH in bending and

1/RH in torsion. The journal fillets are handled analogously by using

RG and DG. The nominal stresses are assumed

to be linear from the surface to a midpoint in the web between the crankpin fillet

and the journal fillet for bending, and to the crankpin or journal centre for

torsion.

3.2.7 The corresponding SCF for the journal fillet can be found by replacing

RH with RG for bending and by replacing

RH with RG and D with

DG for torsion.

Figure 3.3.2 Bending SCF in the crankpin fillet as a function of depth

Figure 3.3.3 Torsional SCF in the crankpin fillet as a function of depth

3.2.8 If the pin is hardened only and the end of the hardened zone is closer to the fillet

than three times the maximum hardness depth, FEA should be used to determine the

actual stresses in the transition zone.