Section

4 Bow doors

4.1 Application

4.1.1 The requirements

of this Section are applicable to the arrangement, strength and securing

of bow doors, both the visor and the side opening type doors, and

inner doors leading to a complete or long forward enclosed superstructure.

4.1.2 Other types

of bow door will be specially considered.

4.2 General

4.2.1 The attention

of Owners and Builders is drawn to the additional statutory regulations

for bow doors that may be imposed by the National Authority.

4.2.2 Bow doors

are to be situated above the freeboard deck. A watertight recess in

the freeboard deck located forward of the collision bulkhead and above

the deepest waterline fitted for arrangement of ramps or other related

mechanical devices may be regarded as a part of the freeboard deck.

4.2.3 An inner

door is to be fitted. The inner door is to be part of the collision

bulkhead. The inner door need not be fitted directly above the bulkhead

below, provided it is located within the limits specified for the

position of the collision bulkhead, see

Pt 3, Ch 2, 4 Bulkhead arrangements. A vehicle ramp may be arranged

for this purpose, provided its position complies with Pt 3, Ch 2, 4 Bulkhead arrangements and the ramp is weathertight

over its complete length. In this case the upper part of the ramp

higher than 2,3 m above the freeboard deck may extend forward of the

limit specified in Pt 3, Ch 2, 4 Bulkhead arrangements.

If this is not possible a separate inner weathertight door is to be

installed, as far as practicable within the limits specified for the

position of the collision bulkhead.

4.2.4 Bow doors

are to be fitted as to ensure tightness consistent with operational

conditions and to give effective protection to inner doors. Inner

doors forming part of the collision bulkhead are to be weathertight

over the full height of the cargo space and arranged with fixed sealing

supports on the aft side of the doors.

4.2.5 Bow doors

and inner doors are to be arranged so as to preclude the possibility

of the bow door causing structural damage to the inner door or to

the collision bulkhead in the case of damage to or detachment of the

bow door. If this is not possible, a separate inner weathertight door

is to be installed, as indicated in Pt 7, Ch 5, 4.2 General 4.2.3.

4.2.6 The requirements

for inner doors are based on the assumption that vehicles are effectively

lashed and secured against movement in the stowed position.

4.3 Symbols and definitions

4.3.1 The symbols

used in this Section are defined as follows:

|

A

s

|

= |

area stiffener web in cm2

|

|

A

x

|

= |

area, in m2, of the transverse vertical projection

of the door between the levels of the bottom of the door and the upper

deck or between the bottom of the door and the top of the door, whichever

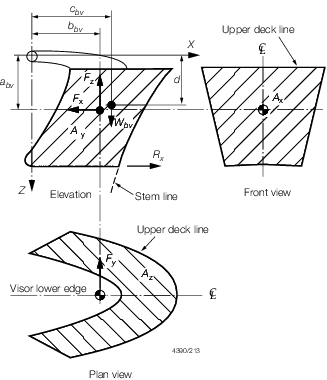

is the lesser, as shown in Figure 5.4.2 Bow visor (upward hinging)

|

|

A

y

|

= |

area, in m2, of the longitudinal vertical projection

of the door between the levels of the bottom of the door and the upper

deck or between the bottom of the door and the top of the door, whichever

is the lesser

|

|

A

z

|

= |

area of the horizontal projection of the door between the levels

of the bottom of the door and the upper deck or between the bottom

of the door and the top of the door, in m2, whichever is

the lesser, as shown in Figure 5.4.2 Bow visor (upward hinging)

|

|

h

|

= |

height

of the door between the levels of the bottom of the door and the upper

deck or between the bottom of the door and the top of the door, in

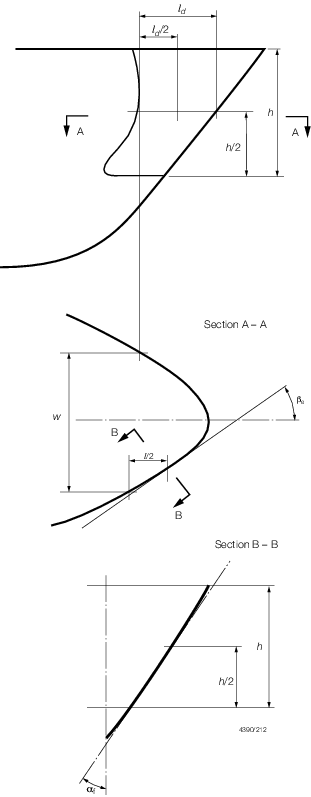

metres, whichever is the lesser, as shown in Figure 5.4.1 Measurement of αf and βe

|

|

W

bv

|

= |

mass of the visor door, in tonnes |

|

τ |

= |

shear stress,

in N/mm2

|

|

σ |

= |

bending

stress, in N/mm2

|

|

σa

|

= |

material

yield stress, in N/mm2

|

|

σeq

|

= |

equivalent

stress, in N/mm2

|

|

|

= |

. .

|

Figure 5.4.1 Measurement of αf and βe

4.3.2

Locking

device. A device that locks a securing device in the closed

position.

4.3.3

Securing

device. A device used to keep the door closed by preventing

it from rotating about its hinges.

Figure 5.4.2 Bow visor (upward hinging)

4.3.4

Side-opening

doors. Side-opening doors are opened either by rotating outwards

about a vertical axis through two or more hinges located near the

outboard edges or by horizontal translation by means of linking arms

arranged with pivoted attachments to the door and the craft. It is

anticipated that side-opening doors are arranged in pairs.

4.3.5

Supporting

device. A device used to transmit external or internal loads

from the door to a securing device and from the securing device to

the craft's structure, or a device other than a securing device, such

as a hinge, stopper or other fixed device, that transmits loads from

the door to the craft's structure.

4.3.6

Visor

doors. Visor doors are opened by rotating upwards and outwards

about a horizontal axis through two or more hinges located near the

top of the door and connected to the primary structure of the door

by longitudinally arranged lifting arms.

4.4 Strength criteria

4.4.1 Scantlings

of the primary members, securing and supporting devices of bow doors

and inner doors are to be able to withstand the design loads defined

in Pt 7, Ch 5, 4.5 Design loads. The shear, bending and

equivalent stresses are not to exceed 43/k

a N/mm2, 64/k

a N/mm2 and 80/k

a N/mm2 respectively.

4.4.3 For metal

to metal bearings in securing and supporting devices, the nominal

bearing pressure calculated by dividing the design force by the projected

bearing area is not to exceed 80 per cent of the yield stress of the

bearing material. For other bearing materials, the permissible bearing

pressure is to be determined according to the manufacturer's specification.

4.4.4 The arrangement

of securing and supporting devices is to be such that threaded bolts

do not carry support forces. The maximum tension in way of threads

of steel bolts not carrying support forces is not to exceed 125/k

s N/mm2.

4.5 Design loads

4.5.1 The design

external pressure, P

e, for the determination

of scantlings for primary members, securing and supporting devices

of bow doors is taken to be not less than the following:

where

|

V

max

|

= |

maximum speed in knots as defined in Pt 1, Ch 2, 2.2 Definitions 2.2.11.

|

|

L

R

|

= |

Rule length of craft, in m as defined in Pt 3, Ch 1, 6 Definitions

|

|

λ

G

|

= |

Service group factor for mono-hull craft, see

Pt 1, Ch 2 Classification Regulations

|

|

|

= |

0,5 for Group 1

and 2 |

|

|

= |

0,6 for Group 3 |

|

|

= |

0,8 for Group 4 |

|

|

= |

1,0 for Groups

5 and 6 |

|

|

= |

For multi-hull craft, λG will be specially considered and may be reduced where the

freeboard is significant

|

|

C

H

|

= |

0,0125L

R for L

R <

80 m

|

|

|

= |

1,0 for L

R ≥ 80 m

|

|

α

f

|

= |

flare angle at the point to be considered, defined as the angle

between a vertical line and the tangent to the side shell plating,

measured in a vertical plane normal to the horizontal tangent to the

shell plating, see

Figure 5.4.1 Measurement of αf and βe

|

|

β

e

|

= |

entry angle at the point to be considered, defined as the angle

between a longitudinal line parallel to the centreline and the tangent

to the shell plating in a horizontal plane, see

Figure 5.4.1 Measurement of αf and βe

|

4.5.2 The design

external forces, F

x, F

y and F

z, in kN, for the determination of scantlings of

securing and supporting devices of bow doors are taken to be not less

than P

e

A

x, P

e

A

y and P

e

A

z respectively. Where P

e is the external

pressure, defined in Pt 7, Ch 5, 4.5 Design loads 4.5.1, with

the flare angle, αf, and the entry angle, βe,

measured at the point on the bow door,  d/2 aft of the stem line on the plane h/2

above the bottom of the door, as shown in Figure 5.4.1 Measurement of αf and βe

. A

x, A

y, A

z and h as defined in Pt 7, Ch 5, 4.3 Symbols and definitions 4.3.1.

d/2 aft of the stem line on the plane h/2

above the bottom of the door, as shown in Figure 5.4.1 Measurement of αf and βe

. A

x, A

y, A

z and h as defined in Pt 7, Ch 5, 4.3 Symbols and definitions 4.3.1.

4.5.3 For bow

doors, including bulwark, of unusual form or proportions, the areas

used for the determination of the design values of external forces

will be specially considered.

4.5.5 The lifting

arms of a visor and its supports are to be dimensioned for the static

and dynamic forces applied during the lifting and lowering operations,

and a minimum wind pressure of 1,5kN/m2 is to be taken.

4.5.6 The design

external pressure, in kN/m2, for the determination of scantlings

for primary members, securing and supporting devices and surrounding

structure of inner doors is to be taken as the greater of 0,45L

R and 10h

2, where h

2 is

the distance, in m, from the load point to the top of the cargo space

and L

R as defined in Pt 3, Ch 1, 6.2 Principal particulars 6.2.1.

4.5.7 The design

internal pressure for the determination of scantlings for securing

devices of inner doors is not to be taken less than 25 kN/m2.

4.6 Scantlings of bow doors

4.6.1 The strength

of bow doors is to be commensurate with that of the surrounding structure.

4.6.2 Bow doors

are to be adequately stiffened and means are to be provided to prevent

lateral or vertical movement of the doors when closed. For visor doors

adequate strength for the opening and closing operations is to be

provided in the connections of the lifting arms to the door structure

and to the craft structure.

4.6.3 The thickness

of the bow plating is not to be less than that required for the side

shell plating, using bow door stiffener spacing, but in no case less

than the minimum required thickness of fore end shell plating.

4.6.4 The section

modulus of horizontal or vertical stiffeners is not to be less than

that required for end framing. Consideration is to be given, where

necessary, to differences in fixity between craft's frames and bow

doors stiffeners.

4.6.6 The bow

door secondary stiffeners are to be supported by primary members constituting

the main stiffening of the door.

4.6.7 The primary

members of the bow door and the hull structure in way are to have

sufficient stiffness to ensure integrity of the boundary support of

the door.

4.7 Scantlings of inner doors

4.7.1 Scantlings

of the primary members are generally to be supported by direct calculations

in association with the external pressure given in and permissible

stresses given in Pt 7, Ch 5, 4.4 Strength criteria 4.4.1. In general,

formulae for simple beam theory may be applied.

4.7.2 Where inner

doors also serve as a vehicle ramps, the scantlings are not to be

less than those required for vehicle decks.

4.7.3 The distribution

of the forces acting on the securing and supporting devices is, in

general, to be supported by direct calculations taking into account

the flexibility of the structure and actual position and stiffness

of the supports.

4.8 Securing and supporting of bow doors

4.8.1 Bow doors

are to be fitted with adequate means of securing and supporting so

as to be commensurate with the strength and stiffness of the surrounding

structure. The hull supporting structure in way of the bow doors is

to be suitable for the same design loads and design stresses as the

securing and supporting devices. Where packing is required, the packing

material is to be of a comparatively soft type, and the supporting

forces are to be carried by the steel structure only. Other types

of packing may be considered. Maximum design clearance between securing

and supporting devices is, in general, not to exceed 3 mm. A means

is to be provided for mechanically fixing the door in the open position.

4.8.2 Only the

active supporting and securing devices having an effective stiffness

in the relevant direction are to be included and considered to calculate

the reaction forces acting on the devices. Small and/or flexible devices

such as cleats intended to provide load compression of the packing

material are, in general, not to be included in the calculations called

for in Pt 7, Ch 5, 4.8 Securing and supporting of bow doors 4.8.8. The number of securing

and supporting devices are, in general, to be the minimum practical

whilst taking into account the requirements for redundant provision

given in Pt 7, Ch 5, 4.8 Securing and supporting of bow doors 4.8.9 and Pt 7, Ch 5, 4.8 Securing and supporting of bow doors 4.8.10 and the available space for

adequate support in the hull structure.

4.8.3 For opening

outwards visor doors, the pivot arrangement is generally to be such

that the visor is self closing under external loads, that is M

y > 0. Moreover, the closing moment, M

y,

as given in Pt 7, Ch 5, 4.5 Design loads 4.5.4 is to be not

less than:

where

W

bv, a

bv, b

bv and c

bv are

as defined in Pt 7, Ch 5, 4.3 Symbols and definitions 4.3.1

F

x and F

z as defined in Pt 7, Ch 5, 4.5 Design loads 4.5.2.

4.8.4 Securing

and supporting devices are to be adequately designed so that they

can withstand the reaction forces within the permissible stresses

given in Pt 7, Ch 5, 4.4 Strength criteria 4.4.1.

4.8.5 For visor

doors the reaction forces applied on the effective securing

and supporting devices assuming the door as a rigid body are determined

for the following combination of external loads acting simultaneously

together with the self weight of the door.

| Case 1

|

F

x and F

z.

|

| Case 2

|

0,7F

y acting on each side separately together with 0,7F

x and 0,7F

z.

|

where F

x, F

y and F

z are to be determined

as indicated in Pt 7, Ch 5, 4.5 Design loads 4.5.2 and applied

at the centroid of projected areas.

4.8.6 For side-opening

doors the reaction forces applied on the effective securing

and supporting devices assuming the door as a rigid body are determined

for the following combination of external loads acting simultaneously

together with the self weight of the door:

| Case 1

|

F

x, F

y and F

z acting on both doors.

|

| Case 2

|

0,7 F

x and 0,7F

z acting on both doors and 0,7F

y acting on each door separately.

|

where

F

x, F

y and F

z are to be determined

as indicated in Pt 7, Ch 5, 4.5 Design loads 4.5.2 and applied

at the centroid of projected areas.

4.8.8 The distribution

of the reaction forces acting on the securing and supporting devices

may require to be supported by direct calculations taking into account

the flexibility of the hull structure and the actual position and

stiffness of the supports.

4.8.9 The arrangement

of securing and supporting devices in way of these securing devices

is to be designed with redundancy so that in the event of failure

of any single securing or supporting device the remaining devices

are capable of withstanding the reaction forces without exceeding

by more than 20 per cent the permissible stresses as given in Pt 7, Ch 5, 4.4 Strength criteria 4.4.1.

4.8.10 For visor

doors, two securing devices are to be provided at the lower

part of the door, each capable of providing the full reaction force

required to prevent opening of the door within the permissible stresses

given in Pt 7, Ch 5, 4.4 Strength criteria 4.4.1. The opening moment, M

o, to be balanced by this reaction force, is not

to be taken less than:

where

W

bv, A

x, d

bv and a

bv are

as defined in Pt 7, Ch 5, 4.3 Symbols and definitions 4.3.1.

4.8.11 For visor

doors, the securing and supporting devices excluding the hinges

should be capable of resisting the vertical design force (F

z - 10W

bv), in kN, within the permissible

stresses given in Pt 7, Ch 5, 4.4 Strength criteria 4.4.1.

4.8.12 All load

transmitting elements in the design load path, from door through securing

and supporting devices into the craft structure, including welded

connections, are to be the same strength.

4.8.13 For side-opening

doors, thrust bearing has to be provided in way of girder ends

at the closing of the two leaves to prevent one leaf to shift towards

the other one under effect of unsymmetrical pressure, see

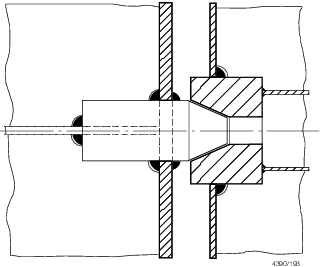

Figure 5.4.3 Typical thrust bearing. Each part of the thrust

bearing has to be kept secured on the other part by means of securing

devices. Any other arrangements serving the same purpose are to be

submitted for appraisal.

Figure 5.4.3 Typical thrust bearing

4.9 Securing and locking arrangement

4.9.1 Securing

devices are to be simple to operate and easily accessible. Securing

devices are to be equipped with mechanical locking arrangement (self

locking or separate arrangement), or be of the gravity type. The opening

and closing systems as well as securing and locking devices are to

be interlocked in such a way that they can only operate in the proper

sequence.

4.9.2 Bow doors

and inner doors giving access to vehicle decks are to be provided

with an arrangement for remote control, from a position above the

freeboard deck, of:

-

the closing and opening

of the doors, and

-

associated securing

and locking devices for every door.

Indication of the open/closed position of every door and every

securing and locking device is to be provided at the remote control

stations. The operating panels for operation of doors are to be inaccessible

to unauthorised persons. A notice plate, giving instructions to the

effect that all securing devices are to be closed and locked before

leaving harbour, is to be placed at each operating panel and is to

be supplemented by warning indicator lights.

4.9.3 Where hydraulic

securing devices are applied, the system is to be mechanically lockable

in the closed position so that in the event of loss of the hydraulic

fluid, the securing devices remain locked. The hydraulic system for

securing and locking devices is to be isolated from other hydraulic

circuits when in the closed position.

4.9.4 Separate

indicator lights and audible alarms are to be provided on the navigation

bridge and on the operating panel to show that the bow door and inner

door are closed and that their securing and locking devices are properly

positioned. The indication panel is to be provided with a lamp test

function. The indicator lights are to be provided with a permanent

power supply, further, arrangements are to be such that it is not

possible to turn off these lights in service.

4.9.5 The indicator

system is to be designed on the fail-safe principle and is to show

by visual alarms if the door is not fully closed and not fully locked

and by audible alarms if securing devices become open or locking devices

become unsecured. The power supply for the indicator system is to

be independent of the power supply for operating and closing the doors.

The sensors of the indicator system are to be protected from water,

ice formation and mechanical damages.

4.9.6 The indication

panel on the navigation bridge is to be equipped with a mode selection

function `harbour/sea voyage', so arranged that audible alarm is given

if the craft leaves harbour with the bow door or inner door not closed

and with any of the securing devices not in the correct position.

4.9.7 A water

leakage detection system with audible alarm and television surveillance

are to be arranged to provide an indication to the navigation bridge

and to the engine control room of leakage through the inner door.

4.9.8 Between

the bow door and the inner door a television surveillance system is

to be fitted with a monitor on the navigation bridge and in the engine

control room. The system is to be able to monitor the position of

doors and a sufficient number of their securing devices. Special consideration

is to be given for lighting and contrasting colour of objects under

surveillance.

4.9.9 A drainage

system is to be arranged in the area between bow door and ramp, as

well as in the area between the ramp and inner door where fitted.

The system is to be equipped with an audible alarm function to the

navigation bridge for water level in these areas exceeding 0,5 m above

the car deck level.

4.10 Operating and Maintenance Manual

4.10.1 An Operating

and Maintenance Manual for the bow door and inner door is to be provided

on board and contain necessary information on:

-

main particulars

and design drawings,

-

service conditions,

e.g. service area restrictions, acceptable clearances for supports,

-

maintenance and

function testing,

-

register of inspections

and repairs.

This manual is to be submitted for approval.

4.10.2 Documented

operating procedures for closing and securing the bow door and inner

door are to be kept on board and posted at an appropriate place.

|