Section

4 Dished ends subject to internal pressure

4.1 Minimum thickness

4.1.1 The thickness, t, of semi-ellipsoidal and hemispherical unstayed ends, and

the knuckle section of torispherical ends, dished from plate, having

pressure on the concave side and satisfying the conditions listed

below, is to be determined by the following formula:

4.1.2 For semi-ellipsoidal

ends:

the external height, H ≥ 0,18 D

o

where

|

D

o

|

= |

the external diameter of the parallel portion of the end, in

mm. |

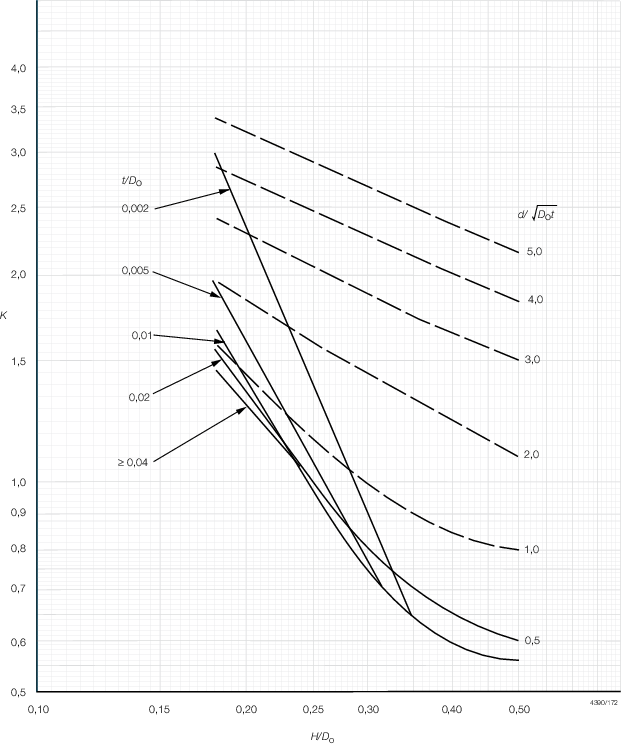

Figure 4.4.1 Shape Factor

4.1.3 For torispherical

ends:

- the internal radius, R

i ≤ D

o

- the internal knuckle radius, r

i ≥ 0,1D

o

- the internal knuckle radius, r

i ≥ 3t

- the external height, H ≥ 0,18 D

o and

is determined as follows:

4.1.4 In addition

to the formula in Pt 15, Ch 4, 4.1 Minimum thickness 4.1.1 the

thickness, t, of a torispherical head, made from more

than one plate, in the crown section is to be not less than that determined

by the following formula:

where t, p, R

i, σ and J are as defined in Pt 15, Ch 4, 1.7 Definition of symbols.

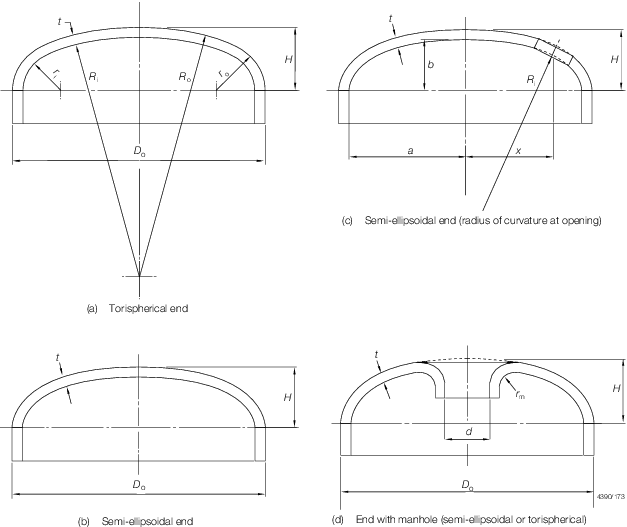

Figure 4.4.2 Typical dished ends

4.1.8 For ends

which are butt welded to the shell the thickness of the edge of the

flange for connection to the shell is to be not less than the thickness

of an unpierced seamless or welded shell, whichever is applicable,

of the same diameter and material and determined by Pt 15, Ch 4, 2.1 Minimum thickness.

4.2 Shape factors for dished ends

4.3 Dished ends with unreinforced openings

4.3.1 Openings

in dished ends may be circular, obround or approximately elliptical.

4.3.2 The upper

curves in Figure 4.4.1 Shape Factor provide

values of K, to be used in Pt 15, Ch 4, 4.1 Minimum thickness 4.1.1, for ends with unreinforced openings. The selection of the

correct curve depends on the value of  and a trial calculation is necessary to select the correct

curve, and a trial calculation is necessary to select the correct

curve,

where

|

d

|

= |

the

diameter of the largest opening in the end plate, in mm (in the case

of an elliptical opening, the larger axis of the ellipse) |

|

t

|

= |

minimum

thickness, after dishing, in mm |

|

D

o

|

= |

outside diameter of dished end, in mm |

4.3.3 The following

requirements must in any case be satisfied:

4.4 Flanged openings in dished ends

4.4.2 Where

openings are flanged, the radius, r

m of the

flanging is to be not less than 25 mm, see

Figure 4.4.2 Typical dished ends. The thickness of the

flanged portion may be less than the calculated thickness.

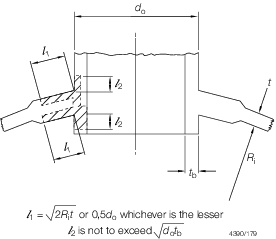

4.5 Location of unreinforced and flanged openings in dished ends

4.5.1 Unreinforced

and flanged openings in dished ends are to be so arranged that the

distance from the edge of the hole to the outside edge of the plate

and the distance between openings are not less than those shown in Figure 4.4.3 Limits for reinforcement.

Figure 4.4.3 Limits for reinforcement

4.6 Dished ends with reinforced openings

4.6.1 Where

it is desired to use a large opening in a dished end of less thickness

than would be required by Pt 15, Ch 4, 4.3 Dished ends with unreinforced openings,

the end is to be reinforced. This reinforcement may consist of a ring

or standpipe welded into the hole, or of reinforcing plates welded

to the outside and/or inside of the end in the vicinity of the hole,

or a combination of both methods, see

Figure 4.4.4 Opening in dished ends. Forged reinforcements

may be used.

4.6.5 If the

material of the ring or the reinforcing plates has an allowable stress

value lower than that of the end plate, then the effective cross-sectional

area, A, is to be multiplied by the ratio:

4.7 Torispherical dished ends with reinforced openings

4.7.1 If an

opening and its reinforcement are positioned entirely within the crown

section, the compensation requirements are to be as for a spherical

shell, using the crown radius as the spherical shell radius. Otherwise,

the requirements of Pt 15, Ch 4, 4.6 Dished ends with reinforced openings are to

be applied.

|