Section

11 Furnaces subject to external pressure

11.1 Maximum thickness

11.1.1 Furnaces,

plain or corrugated, are not to exceed 22,5 mm in thickness.

11.2 Corrugated furnaces

11.2.1 The

minimum thickness, t, of corrugated furnaces is to be

determined by the following formula:

where p and c are defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

t

|

= |

thickness

of the furnace plate measured at the bottom of the corrugations, in

mm |

|

C

|

= |

1060

for Fox, Morison and Deighton corrugations |

| = |

1130 for Suspension Bulb corrugations |

|

D

o

|

= |

external diameter of the furnace measured at the bottom of the

corrugations, in mm. |

11.3 Plain furnaces, flue sections and combustion chamber bottoms

11.3.1 The

minimum thickness, t, between points of substantial support,

of plain furnaces or furnaces strengthened by stiffening rings, of

flue sections and of the cylindrical bottoms of combustion chambers

is to be determined by the following formulae, the greater of the

two thicknesses obtained being taken:

where t, c and p are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

C

|

= |

or 0,85 whichever is the greater or 0,85 whichever is the greater

|

|

D

o

|

= |

external diameter of the furnace, flue or combustion chamber,

in mm |

|

L

|

= |

length

of section between the centres of points of substantial support, in

mm |

x and σ are as defined in Vol 2, Pt 8, Ch 1, 11.7 Dished and flanged ends for unsupported vertical boiler furnaces 11.7.1.

11.3.2 Where

stiffeners are used for strengthening plain cylindrical furnaces,

or combustion chambers, the second moment of area, I,

of the stiffener is to be determined by the following formula:

where p is as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

D

o

|

= |

external diameter of the furnace flue or combustion chamber,

in mm |

|

L

|

= |

length

of section between the centres of points of substantial support, in

mm |

For proportion of stiffening rings, see

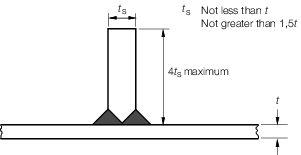

Figure 1.11.1 Furnace, flue and combustion chamber stiffeners.

Figure 1.11.1 Furnace, flue and combustion chamber stiffeners

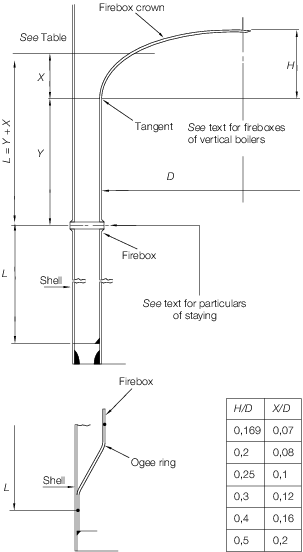

11.4 Plain furnaces of vertical boilers

11.4.1 The

thickness of plain furnaces not exceeding 2000 mm in external diameter

is to be determined by the formulae given in Vol 2, Pt 8, Ch 1, 11.3 Plain furnaces, flue sections and combustion chamber bottoms 11.3.1, the greater of the two

thicknesses being taken:

where

|

D

o

|

= |

external diameter of the furnace, in mm. Where the furnace is

tapered, the diameter to be taken for calculation purposes is to be

the mean of that at the top and that at the bottom where it meets

the substantial support from flange, ring or row of stays |

11.4.2 For

furnaces under 760 mm in external diameter, the thickness is to be

not less than 8 mm, and for furnaces 760 mm in external diameter and

over, the thickness is to be not less than 9,5 mm.

Figure 1.11.2 Effective length, L, for use in 11.4

11.4.3 A

circumferential row of stays connecting the furnace to the shell will

be considered to provide substantial support to the furnace, provided

that:

- The diameter of the stay is not less than 22,5 mm or twice the

thickness of the furnace, whichever is the greater.

- The pitch of the stays at the furnace does not exceed 14 times

the thickness of the furnace.

11.5 Hemispherical furnaces

11.5.1 The

minimum thickness, t, of unsupported hemispherical furnaces

subject to pressure on the convex surface is to be determined by the

following formula:

|

t

|

= |

+ c + c

|

where t, c and p are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

x and

σ are as defined in Vol 2, Pt 8, Ch 1, 11.7 Dished and flanged ends for unsupported vertical boiler furnaces 11.7.1

|

C

|

= |

or 0,85, whichever is the greater or 0,85, whichever is the greater

|

|

R

o

|

= |

outer radius of curvature of the furnace, in mm. |

11.5.2 In no case is the maximum thickness to exceed 22,5 mm, or the ratio  to exceed 100. to exceed 100.

11.6 Dished and flanged ends for supported vertical boiler furnaces

11.6.1 The

minimum thickness, t, of dished and flanged ends for

vertical boiler furnaces that are subject to pressure on the convex

side and are supported by central uptakes, is to be determined by

the following formula:

where t, c, p, Ro and σ are as

defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

11.7 Dished and flanged ends for unsupported vertical boiler furnaces

11.7.1 The

minimum thickness, t, of dished and flanged ends for

vertical boiler furnaces that are subject to pressure on the convex

side and are without support from stays of any kind, is to be determined

by the following formula, but is in no case to be less than the thickness

of the firebox:

where t, c and p are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

x

|

= |

specified

minimum lower yield stress or 0,2 per cent proof stress in N/mm2 at

a temperature 90°C above the saturated steam temperature corresponding

to the design pressure for carbon and carbon manganese steel with

a specified minimum tensile strength of 400 N/mm2

|

|

C

|

= |

or 0,85 whichever is the greater or 0,85 whichever is the greater

|

|

R

o

|

= |

outside radius of the crown plate, in mm |

| = |

|

|

σ |

= |

specified

minimum lower yield stress or 0,2 per cent proof stress in N/mm2 at

a temperature 90°C above the saturated steam temperature corresponding

to the design pressure for the steel actually used.

|

11.7.2 The

inside radius of curvature, R

i, of the end

plate is to be not greater than the external diameter of the cylinder

to which it is attached.

11.7.3 The

inside knuckle radius, r

i, see

Figure 1.4.2 Typical dished ends(a), of the arc joining

the cylindrical flange to the spherical surface of the end is to be

not less than four times the thickness of the end plate and in no

case less than 65 mm.

11.8 Ogee rings

11.8.1 The

minimum thickness, t, of the ogee ring which connects

the bottom of the furnace to the shell of a vertical boiler and sustains

the whole vertical load on the furnace is to be determined by the

following formula:

where t, c and p are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

D

i

|

= |

inside diameter of boiler shell, in mm |

|

D

o

|

= |

outside diameter of the lower part of the furnace where it joins

the ogee ring, in mm. |

11.8.2 Proposals

to use a flat plate annular ring which connects the bottom of the

furnace to the shell of a vertical boiler and sustains any unbalanced

vertical load on the furnace will be the subject of special consideration.

11.9 Uptakes of vertical boilers

11.9.1 The

minimum thickness, t, of internal uptakes of vertical

boilers is to be determined by the following formulae, the greater

of the two thicknesses obtained being taken:

where t and p are as defined

in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

D

o

|

= |

external diameter of uptake, in mm |

|

L

|

= |

length

of uptake between the centres of points of substantial support, in

mm. |

|