Section

5 Pipe joints

5.1 General

5.1.1 Connections

in piping systems may be made by any of the methods described in this

Section, or by special types of approved joints which have been shown

to be suitable for the design conditions. Details of connection methods,

not described in this Section are to be submitted for consideration.

5.1.2 The

selection of pipe connections in piping systems is to recognise the

boundary fluids, pressure and temperature conditions, external or

cyclic loading and location.

5.1.3 Pipe

connections in accordance with national or other established standards

will be accepted where the standards are appropriate to the piping

system.

5.1.4 The

type and location of pipe connections are to recognise the need to

facilitate Periodic Survey of piping systems and associated items

of machinery and the need for cold ‘pull up’ if required.

5.1.5 Pipe

connections are not to be used to compensate for pipe misalignment.

5.1.6 Piping

with joints is to be adequately adjusted, aligned and supported. Supports

or hangers are not to be used to force alignment of piping at the

point of connection.

5.1.7 Pipes

passing through, or connected to, watertight decks are to be continuous

or provided with an approved bolted or welded connection to the deck

or bulkhead.

5.2 Flange connections

5.2.1 The dimensions and configuration of flanges and bolting are to be selected

in accordance with recognised standards. The dimensions and bolting arrangements of

nonstandard flanges will be the subject of special consideration.

5.2.2 Gaskets are to be suitable for the conveyed fluids under design pressure

and temperature conditions and their dimensions and configuration is to be in accordance

with recognised standards. Gasket materials used in oil piping systems are to be

impervious to oil and the thinnest possible as determined from manufacturer's

recommendations that the flange arrangement will allow, to ensure the minimum loss of

bolt stress due to gasket relaxation.

5.2.3 Flange connections having components sensitive to heat, including gaskets or isolation

kits, are not to be used in spaces where leakage or failure caused by fire could result

in fire spread, flooding or loss of a Mobility or Ship Type system.

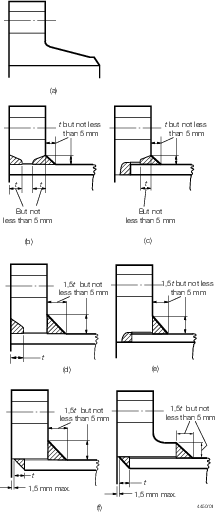

5.2.4 Acceptable flange pipe connections are indicated in Figure 1.5.1 Typical welded-on flanges. Limiting applications of different types of

flange connections are indicated in Table 1.5.1 Limiting design conditions for

flange types depending on the size, pressure and

temperature.

Figure 1.5.1 Typical welded-on flanges

Table 1.5.1 Limiting design conditions for

flange types

| Flangetype

|

Maximumpressure

|

Maximumtemperature

|

Maximumpipe o.d.

|

Maximumpipe bore

|

|

|

|

°C

|

mm

|

mm

|

| (a)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

No

restriction

|

No

restriction

|

No

restriction

|

| (b)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

No

restriction

|

168,3

foralloy steels*

|

No

restriction

|

| (c)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

No

restriction

|

168,3

foralloy steels*

|

75

|

| (d)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

425

|

No

restriction

|

No

restriction

|

| (e)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

425

|

No

restriction

|

75

|

| (f)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

425

|

No

restriction

|

No

restriction

|

| * No restriction for carbon steels

|

5.3 Screwed-on flanges

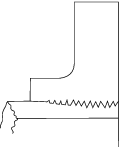

5.3.1 Where

flanges are secured by screwing, as indicated in Figure 1.5.2 Screwed on flange, the pipe and flange

are to be screwed with a vanishing thread and the diameter of the

screwed portion of the pipe over the thread is not to be appreciably

less than the outside diameter of the unscrewed pipe. After the flange

has been screwed hard home the pipe is to be expanded into the flange.

Figure 1.5.2 Screwed on flange

5.3.2 The

vanishing thread on a pipe is to be not less than three pitches in

length, and the diameter at the root of the thread is to increase

uniformly from the standard root diameter to the diameter at the top

of the thread. This may be produced by suitably grinding the dies,

and the flange should be tapered out to the same formation.

5.3.3 Such

screwed and expanded flanges may be used for steam for a maximum design

pressure of 30 bar and maximum design temperature of 370°C and

for feed for maximum design pressure of 50 bar.

5.4 Welded-on flanges, butt welded joints and fabricated branch pieces

5.4.1 The

types of welded-on flanges are to be suitable for the pressure, temperature

and service for which the pipes are intended.

5.4.3 Welded-on

flanges are not to be a tight fit on the pipes. The maximum clearance

between the bore of the flange and the outside diameter of the pipe

is to be 3 mm at any point, and the sum of the clearances diametrically

opposite is not to exceed 5 mm.

5.4.4 Where

butt welds are employed in the attachment of flange type (a), in pipe-to-pipe

joints or in the construction of branch pieces, the adjacent pieces

are to be matched at the bores. This may be effected by drifting,

roller expanding or machining, provided that the pipe wall is not

reduced below the designed thickness. If the parts to be joined differ

in wall thickness, the thicker wall is to be gradually tapered to

the thickness of the thinner at the butt joint. The welding necks

of valve chests are to be sufficiently long to ensure that the valves

are not distorted as the result of welding and subsequent heat treatment

of the joints.

5.4.5 Where

backing rings are used with flange type (a) they are to fit closely

to the bore of the pipe and should be removed after welding. The rings

are to be made of the same material as the pipes or of mild steel

having a sulphur content not greater than 0,05 per cent.

5.4.6 Branches

may be attached to pressure pipes by means of welding provided that

the pipe is reinforced at the branch by a compensating plate or collar

or other approved means, or alternatively that the thickness of pipe

and branch are increased to maintain the strength of the pipe. These

requirements also apply to fabricated branch pieces.

5.4.7 Welding

may be carried out by means of the shielded metal arc, inert gas metal

arc, oxy-acetylene or other approved process, but, in general, oxy-acetylene

welding is suitable only for flange type (a) and is not to be applied

to pipes exceeding 100 mm diameter or 9,5 mm thick. The welding is

to be carried out in accordance with the appropriate paragraphs of Vol 2, Pt 1, Ch 4 Requirements for Fusion Welding of Pressure Vessels and Piping.

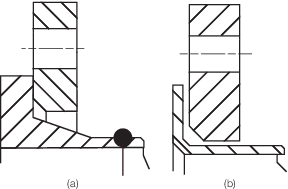

5.5 Loose flanges

5.5.1 Loose

flange designs as shown in Figure 1.5.3 Loose flange arrangements may

be used provided they are in accordance with a recognised National

or International Standard.

Figure 1.5.3 Loose flange arrangements

5.6 Socket weld joints

5.6.1 Socket

weld joints may be used in Class III systems with carbon steel pipes

of any outside diameter. Socket weld fittings are to be of forged

steel and the material is to be compatible with the associated piping.

In particular cases, socket weld joints may be permitted for piping

systems of Class I and II having outside diameter not exceeding 88,9

mm. Such joints are not to be used where fatigue, severe erosion or

crevice corrosion is expected to occur or where toxic or asphyxiating

media are conveyed, other than for carbon dioxide fire-extinguishing

distribution piping.

5.6.2 The

thickness of the socket weld fittings is to meet the requirements

of Vol 2, Pt 7, Ch 1, 6.1 Wrought steel pipes and bends 6.1.3, but is to be not

less than 1,25 times the nominal thickness of the pipe or tube. The

diametrical clearance between the outside diameter of the pipe and

the bore of the fitting is not to exceed 0,8 mm, and a gap of approximately

1,5 mm is to be provided between the end of the pipe and the bottom

of the socket.

5.6.3 The

leg lengths of the fillet weld connecting the pipe to the socket weld

fitting are to be such that the throat dimension of the weld is not

less than the nominal thickness of the pipe or tube.

5.7 Threaded sleeve joints

5.7.1 Threaded

sleeve joints, in accordance with national or other established standards,

may be used with carbon steel pipes within the limits given in Table 1.5.2 Limiting design conditions for

threaded sleeve joints. Such joints are not

to be used where fatigue, severe erosion or crevice corrosion is expected

to occur or where flammable or toxic media is conveyed.

Table 1.5.2 Limiting design conditions for

threaded sleeve joints

| Thread

type

|

Outside pipe diameter, in mm

|

| Class 1

|

Class II

|

Class III

|

| Tapered thread

|

<33,7

|

<60,3

|

<60,3

|

| Parallel thread

|

—

|

—

|

<60,3

|

5.8 Welded sleeve joints

5.8.1 Welded

sleeve joints may be used in Class III systems with carbon steel pipes

of any outside diameter. In particular cases, welded sleeve joints

may be permitted for piping systems of Class I and II having outside

diameter not exceeding 88,9 mm. Such joints are not to be used where

fatigue, severe erosion or crevice corrosion is expected to occur

or where toxic media are conveyed.

5.8.2 Welded

sleeve joints are not to be used in the following locations:

- Bilge pipes in way of deep tanks.

- Cargo oil piping outside of the cargo area for bow or stern loading/discharge.

- Air and sounding pipes passing through cargo tanks.

5.8.3 Welded

sleeve joints may be used in piping systems for the storage, distribution

and utilisation of fuel oil, lubricating or other flammable oil systems

in machinery spaces provided they are located in readily visible and

accessible positions. see also

Vol 2, Pt 7, Ch 3, 2.8 Temperature indication 2.8.2.

5.8.4 Welded

sleeve joints are not to be used at deck/bulkhead penetrations that

require continuous pipe lengths.

5.8.6 The

sleeve material is to be compatible with the associated piping and

the leg lengths of the fillet weld connecting the pipe to the sleeve

are to be such that the throat dimension of the weld is not less than

the nominal thickness of the pipe or tube.

5.8.7 The

minimum length of the sleeve is to conform to the following formula:

5.9 Screwed fittings

5.9.1 Screwed

fittings, including compression fittings, of an approved type may

be used in piping systems for pipes not exceeding 51 mm outside diameter.

Where the fittings are not in accordance with an acceptable standard

then LR may require the fittings to be subjected to special tests

to demonstrate their suitability for the intended service and working

conditions.

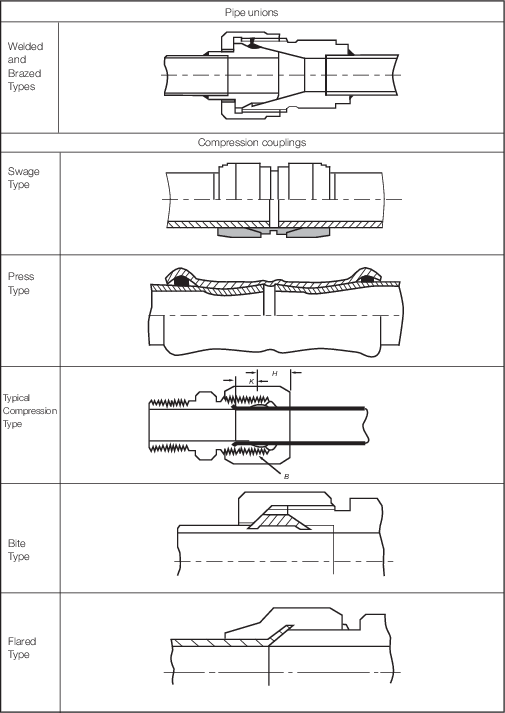

5.10 Other mechanical couplings

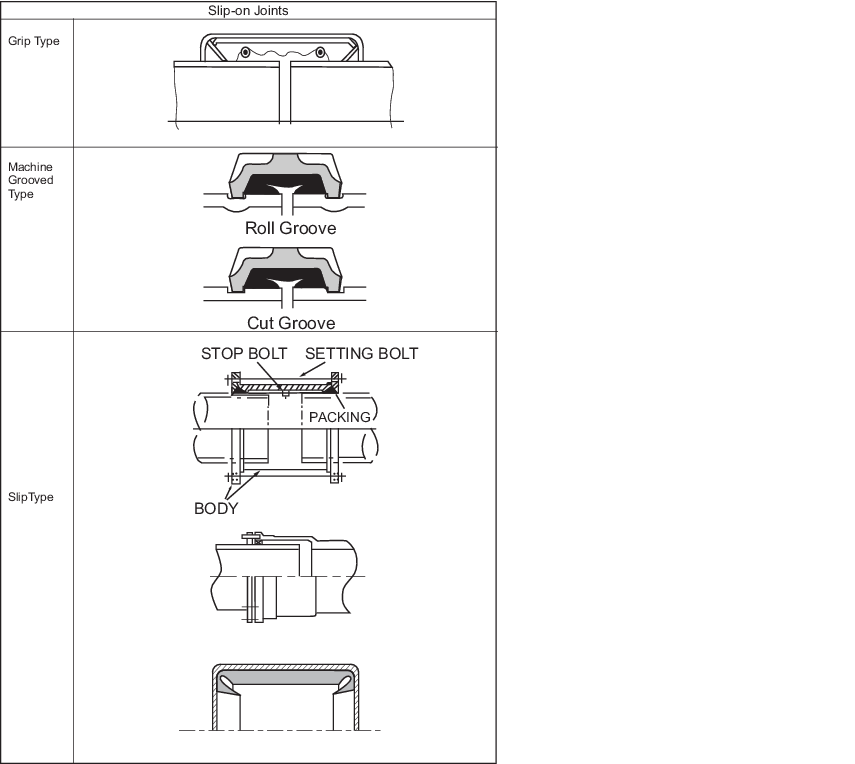

5.10.1 Pipe unions, compression couplings, or slip-on joints, as shown in Figure 1.5.4 Examples of mechanical joints

(Part 1) and Figure 1.5.5 Examples of mechanical joints

(Part 2), may be used if

type approved for the service conditions, the pipe material and the intended

application. The type approval is to be based on the results of testing of the actual

joints. The acceptable use for each service is indicated in Table 1.5.3 Application of mechanical

joints and dependence

upon the class of piping, with limiting pipe dimensions, working pressure and

temperature is indicated in Table 1.5.4 Application of mechanical joints

depending on class of piping.

Figure 1.5.4 Examples of mechanical joints

(Part 1)

Figure 1.5.5 Examples of mechanical joints

(Part 2)

Table 1.5.3 Application of mechanical

joints

| Systems

|

Type of connections

|

| Pipe unions

|

Compression coupling

|

Slip-on joints

|

| Flammable

fluids (Flash point <60° C)

|

| Aircraft and vehicle fuel oil lines

see Notes 2 & 4

|

+

|

+

|

+

|

| Vent lines see Note 2 &

3

|

+

|

+

|

+

|

| Flammable

fluids (Flash point > 60° C)

|

| Aircraft and vehicle fuel oil lines

see Note 2 & 4

|

+

|

+

|

+

|

| Ship’s machinery fuel oil lines

see Notes 2 & 3

|

+

|

+

|

+

|

| Lubricating oil lines see

Notes 2 & 3

|

+

|

+

|

+

|

| Hydraulic oil see Notes 2

& 3

|

+

|

+

|

+

|

| Thermal oil see Notes 2 &

3

|

+

|

+

|

+

|

| Sea

water

|

| Bilge lines see Note 1

|

+

|

+

|

+

|

| HP sea-water and water spray (not

permanently filled) see Note 3

|

+

|

+

|

+

|

| Water filled fire-extinguishing

systems, e.g. sprinkler systems see Note 3

|

+

|

+

|

+

|

| Non-water filled fire-extinguishing

systems, e.g. foam, drencher systems see Note 3

|

+

|

+

|

+

|

| Ballast system see Note

1

|

+

|

+

|

+

|

| Cooling water system see Note

1

|

+

|

+

|

+

|

| Tank cleaning services

|

+

|

+

|

+

|

| Non-essential systems

|

+

|

+

|

+

|

| Fresh

water

|

| Cooling water system see Note

1

|

+

|

+

|

+

|

| Chilled water systems see Note

1

|

+

|

+

|

+

|

| Condensate return see Note

1

|

+

|

+

|

+

|

| Made water and demineralised water

system

|

+

|

+

|

+

|

| Ancillary system

|

+

|

+

|

+

|

| Sanitary/Drains/Scuppers

|

| Deck drains (internal) see

Note 6

|

+

|

+

|

+

|

| Sanitary drains

|

+

|

+

|

+

|

| Scuppers and discharge (overboard)

|

+

|

+

|

-

|

| Sounding

/Vent

|

| Water tanks/Dry spaces

|

+

|

+

|

+

|

| Oil tanks (f.p.>60° C) see

Notes 2 & 3

|

+

|

+

|

+

|

| Intakes and uptakes see Note

7

|

|

|

|

| HVAC trunking see Note 7

|

|

|

|

| Miscellaneous

|

| High pressure (HP) air systems

see Note 1

|

+

|

+

|

|

| Medium pressure (MP) air systems

(Starting air) see Note 1

|

+

|

+

|

|

| Low pressure (LP) air systems (incl.

Control air) see Note 1

|

+

|

+

|

|

| Service air (non-essential)

|

+

|

+

|

+

|

| Brine

|

+

|

+

|

+

|

| CO2 system see Note

1

|

+

|

+

|

|

| Nitrogen system

|

+

|

+

|

|

| Steam

|

+

|

+

|

see Note 5

|

| KEY

|

| +

|

Application is allowed

|

|

|

|

Application is not allowed

|

|

|

Note

1. Mechanical joints that include any

components which readily deteriorate in case of fire, are to be of an

approved fire-resistant type when fitted in machinery spaces of

category A. Mechanical couplings fitted on the ‘bilge main’ in

machinery spaces of category A are to be of steel, CuNi or equivalent

material.

|

Note

2. Slip-on joints are not accepted

inside machinery spaces of category A, munition stores, or

accommodation spaces. Slip-on joints are accepted in other machinery

and service spaces provided that the joints are located in easily

visible and accessible positions.

|

Note

3. Mechanical joints are to be of an

approved fire-resistant type, except when they are fitted on open

decks having little or no fire risk as defined in SOLAS Chapter II-2,

Regulation 9.2.3.3.2.2(10).

|

Note

4. Mechanical joints are to be of an

approved fire-resistant type

|

|

|

Note

6. Mechanical joints are only permitted

above the limit of watertight integrity.

|

Note

7. Requirements for HVAC trunking or gas

turbine updates and intakes are addressed in the relevant Sections of

the Rules.

|

Table 1.5.4 Application of mechanical joints

depending on class of piping

| Types of

joints

|

Classes of piping systems

|

| Class I

|

Class II

|

Class III

|

| Pipe unions

|

|

|

|

| Welded and brazed type

|

+ (OD ≤ 60,3 mm)

|

+ (OD ≤ 60,3 mm)

|

+

|

| Compression couplings

|

|

|

|

| Swage type

|

-

|

-

|

+

|

| Bite type

|

+ (OD ≤ 60,3 mm)

|

+ (OD ≤ 60,3 mm)

|

+

|

| Typical compression type

|

+ (OD ≤ 60,3 mm)

|

+ (OD ≤ 60,3 mm)

|

+

|

| Flared type

|

+ (OD ≤ 60,3 mm)

|

+ (OD ≤ 60,3 mm)

|

+

|

| Press type

|

-

|

-

|

+

|

|

Slip-on joints

|

|

|

|

| Machine grooved type

|

+

|

+

|

+

|

| Grip type

|

-

|

+

|

+

|

| Slip type

|

-

|

+

|

+

|

| KEY

+

Application is allowed

- Application is not allowed

|

5.10.2 Where the application of mechanical joints results in a reduction in pipe

wall thickness due to the use of bite type rings or other structural elements, this is

to be taken into account in determining the minimum wall thickness of the pipe to

withstand the design pressure.

5.10.3 Materials of mechanical joints are to be compatible with the piping

material and internal and external media.

5.10.4 Mechanical joints for pressure pipes are to be tested to a burst pressure of

4 times the design pressure. For design pressures above 200 bar the required burst

pressure will be specially considered.

5.10.5 Mechanical joints, which in the event of damage could cause fire or

flooding, are not to be used in piping sections directly connected to the ship’s side

below the limit of watertight integrity or tanks containing flammable fluids.

5.10.6 The mechanical joints are to be designed to withstand internal and external

pressure as applicable and where used in suction lines are to be capable of operating

under vacuum.

5.10.7 The number of mechanical joints in flammable fluid systems is to be kept to

a minimum. In general, flanged joints are to conform to a recognised standard.

5.10.8 Generally, slip-on joints are not to be used in pipelines in cargo holds,

tanks, and other spaces which are not easily accessible. Application of these joints

inside tanks may only be accepted where the medium conveyed is the same as that in the

tanks.

5.10.9 Usage of slip type slip-on joints as the main means of pipe connection is

not permitted except for cases where compensation of axial pipe deformation is

necessary.

5.10.10 Restrained slip-on joints are permitted in steam pipes with a design

pressure of 10 bar or less on the weather decks of oil and chemical tankers to

accommodate axial pipe movement, see

Vol 2, Pt 7, Ch 2, 2.7 Provision for expansion.

5.10.11 Mechanical joints are to be tested in accordance with the test requirements

in LR’s Type Approval Test Specification Number 2, as relevant to the service conditions

and the intended application. The programme of testing is to be agreed with LR.

5.10.12 The type or location of pipe joints may be limited by the shock policy requirements

defined by the Naval Administration. The use of mechanical joints is to be considered

against the shock requirements.

5.11 Additional requirements for mechanical couplings

5.11.1 Mechanical pipe connections having sealing components sensitive to heat

are not to be used in spaces where leakage or failure caused by fire could result in

fire spread, flooding or loss of a Mobility or Ship Type system.

5.12 Piping for gaseous fire-extinguishing

systems

5.12.2 The

piping for carbon dioxide fire-extinguishing systems is to comply

with the requirements of Chapter 5 - Fixed Gas Fire-Extinguishing Systems of the

FSS Code, as applicable. For purposes of classification, any use of

the word ‘Administration’ in the FSS Code is to be taken

to mean LR.

5.12.3 Where a low-pressure CO2 system is fitted, the piping system is to be

designed in such a way that the CO2 pressure at the nozzles is not less than

1 N/mm2.

5.12.4 Materials for the distribution manifolds between the carbon dioxide storage

bottles and the discharge valves to each section and associated pipes, valves and

fittings of high pressure systems are to be manufactured and tested in accordance with

the requirements for Class I piping systems. Pipes are to meet the minimum wall

thickness requirements of Table 1.5.5 Minimum thickness for steel pipes for CO2 fire-extinguishing

and the manifold system is to be hydraulically tested to a pressure of 190 bar. A high

pressure system is defined as a system where the carbon dioxide is stored at ambient

temperature. Materials for the distribution manifolds between the carbon dioxide storage

vessel(s) and the discharge valves to each section and associated pipes, valves and

fittings of low pressure systems are to be manufactured and tested in accordance with

the requirements for Class II piping systems and the manifold system is to be

hydraulically tested to a pressure of 33 bar. A low pressure system is defined as a

system where the carbon dioxide is stored at a working pressure in the range of 18 bar

to 22 bar.

5.12.5 Piping downstream of the distribution valve(s) for high pressure systems is

to be manufactured and tested in accordance with the requirements for Class II piping

and is to meet the minimum wall thickness requirements of Table 1.5.5 Minimum thickness for steel pipes for CO2 fire-extinguishing.

After installation the distribution system is to be leak tested at a pressure of 6 bar.

Piping downstream of the distribution valve(s) for low pressure systems is to be

manufactured and tested in accordance with the requirements for Class III piping. After

installation the distribution system is to be leak tested at a pressure of 6 bar. Class

III piping may be used for open-ended distribution piping downstream of the distribution

valve(s) of high pressure systems where agreed by LR and where meeting the minimum wall

thickness requirements of Table 1.5.5 Minimum thickness for steel pipes for CO2 fire-extinguishing

and where a minimum of ten per cent of the piping is hydraulically tested at a pressure

of 125 bar. This testing is to be carried out before installation.

5.12.6 Any

part of the carbon dioxide fire-extinguishing system piping is to

be of galvanised steel or of corrosion-resistant steel. Where full

penetration butt welding is used, the pipe is to be protected against

corrosion in the area of the weld seam after welding. The process

for protecting the pipe internally against corrosion is to be of an

approved type. All pipes are to be arranged to be self-draining. Where

pipes are to be led into refrigerated spaces, this is subject to special

consideration. The ends of distribution pipes downstream of the distribution

valve(s) are to extend at least 50 mm beyond the last nozzle and are

to be fitted with a dirt trap consisting of an open-ended tee with

a capped nipple.

Table 1.5.5 Minimum thickness for steel pipes for CO2 fire-extinguishing

| External diameter D, in mm

|

Minimum thickness, in mm

|

| From bottles to

distribution station

|

From distribution

station to nozzles

|

| 21,3 - 26,9

|

3,2

|

2,6

|

| 30 - 48,3

|

4

|

3,2

|

| 51 - 60,3

|

4,5

|

3,6

|

| 63,5 - 76,1

|

5

|

3,6

|

|

|

|

|

| 82,5 - 88,9

|

5,6

|

4

|

| 101,6

|

6,3

|

4

|

| 108 - 114,3

|

7,1

|

4,5

|

| 127

|

8

|

4,5

|

|

|

|

|

| 133 - 139,7

|

8

|

5

|

| 152,4 -

168,3

|

8,8

|

5,6

|

|

Note 1. Pipes are to be galvanized at least inside, except those fitted in

the engine room where galvanizing may not be required at the discretion

of LR. Effects of galvanising shall be taken into account in the relevant

calculations e.g. volume flow.

|

|

Note 2. For threaded pipes, where allowed, the minimum wall thickness is to

be measured at the bottom of the thread.

|

|

Note 3. The external diameters and thicknesses have been selected from ISO

Recommendations R336 for smooth welded and seamless steel pipes. Diameter

and thickness according to other national or international standards may

be accepted.

|

|

Note 4. For larger diameters the minimum wall thickness will be subject to

special consideration by LR.

|

|

Note 5. In general the minimum thickness is the nominal wall thickness and

no allowance need be made for negative tolerance or reduction in

thickness due to bending.

|

5.12.7 If

it is necessary for carbon dioxide pipes to pass through accommodation

spaces, the pipe is to be seamless and is to meet the requirements

for Class II pipes. Joints are to be made only by welding and the

pipes are to be hydraulically tested after installation at a pressure

of 50 bar.

5.12.8 The

following means are permitted for making joints on carbon dioxide

fire-extinguishing system piping;

-

Full penetration

butt welding, where the pipe is galvanised, see

Vol 2, Pt 7, Ch 1, 5.12 Piping for gaseous fire-extinguishing systems 5.12.6.

-

Couplings as permitted by Table 1.5.3 Application of mechanical

joints.

-

Cone connections.

-

Tapered screw

joints, where allowed by Vol 2, Pt 7, Ch 1, 5.12 Piping for gaseous fire-extinguishing systems 5.12.11 and

where meeting the requirements of Vol 2, Pt 7, Ch 1, 5.12 Piping for gaseous fire-extinguishing systems 5.12.11.

-

Flanged joints.

-

Socket weld joints

to acceptable National Standards and where allowed by Vol 2, Pt 7, Ch 1, 5.12 Piping for gaseous fire-extinguishing systems 5.12.9 and where meeting the requirements

of Vol 2, Pt 7, Ch 1, 5.12 Piping for gaseous fire-extinguishing systems 5.12.10.

5.12.9 Socket

weld joints of an approved type may be used downstream of the distribution

valve(s), provided that the requirements for materials and limitations

on outside diameter applicable for Class II piping are applied.

5.12.10 Where

socket weld joints are utilised, the pipes in the way of the weld

joints are to be adequately supported and the joints are to be located

where they are visible. Where welding is to be carried out in situ,

the piping is to be kept clear of adjacent structures to allow sufficient

access for preheating and welding, which is to be carried out in accordance

with approved procedures.

5.12.11 Threaded

joints are only allowed inside protected spaces and in carbon dioxide

bottles storage rooms. They should have no exposed screw threads and

any thread sealing medium should be selected as to ensure no protrusions

or debris might be produced into the pipe.

|