2.3.1 Measurements

are to be made to the surface of the parent plate and not to a weld,

fitting or other raised part.

2.3.2 In assessing

the out-of-roundness of pressure vessels, the difference between the

maximum and minimum internal diameters measured at one cross-section

is not to exceed the amount given in Table 4.2.1 Tolerances for cylindrical

shells.

Table 4.2.1 Tolerances for cylindrical

shells

| Nominal internal diameter of

vessel, in mm

|

Difference between maximum and

minimum diameters

|

Maximum departure from designed

form

|

- ≤ 300

- > 300 ≤ 460

- > 460 ≤ 600

- > 600 ≤ 900

- > 900 ≤ 1220

- > 1220 ≤ 1520

- > 1520 ≤ 1900

|

1,0 per cent of

internal diameter

|

- 1,2 mm

- 1,6 mm

- 2,4 mm

- 3,2 mm

- 4,0 mm

- 4,8 mm

- 5,6 mm

|

- > 1900 ≤ 2300

- > 2300 ≤ 2670

- > 2670 ≤ 3950

|

19 mm

|

|

|

|

19 mm

0,4 per cent of internal diameter

|

0,2 per cent of

internal diameter

|

2.3.4 Shell

sections are to be measured for out-of-roundness, either when laid

flat on their sides or when set up on end. When the shell sections

are checked while lying on their sides, each measurement for diameter

is to be repeated after turning the shell through 90° about its

longitudinal axis. The two measurements for each diameter are to be

averaged, and the amount of out-of-roundness calculated from the average

values so determined.

2.3.6 The

external circumference of the completed shell is not to depart from

the calculated circumference (based upon nominal inside diameter and

the actual plate thickness) by more than the amounts given in Table 4.2.2 Circumferential tolerances.

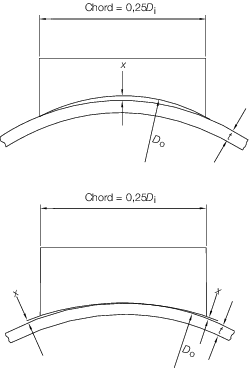

Figure 4.2.1 Tolerances for cylindrical shells

Table 4.2.2 Circumferential tolerances

Outside diameter

(nominal inside diameter plus twice actual plate thickness), in mm

|

Circumferential

tolerance

|

| 300 to 600 inclusive

|

±5 mm

|

| Greater than 600

|

±0,25 per cent

|