11.1.1 Drain plugs

are not normally a classification matter, but if they are fitted Surveyors

should be guided by the following.

11.1.2 Drain plugs

are acceptable in double bottoms or other tanks, but should not be

fitted in open spaces such as bilges or wells.

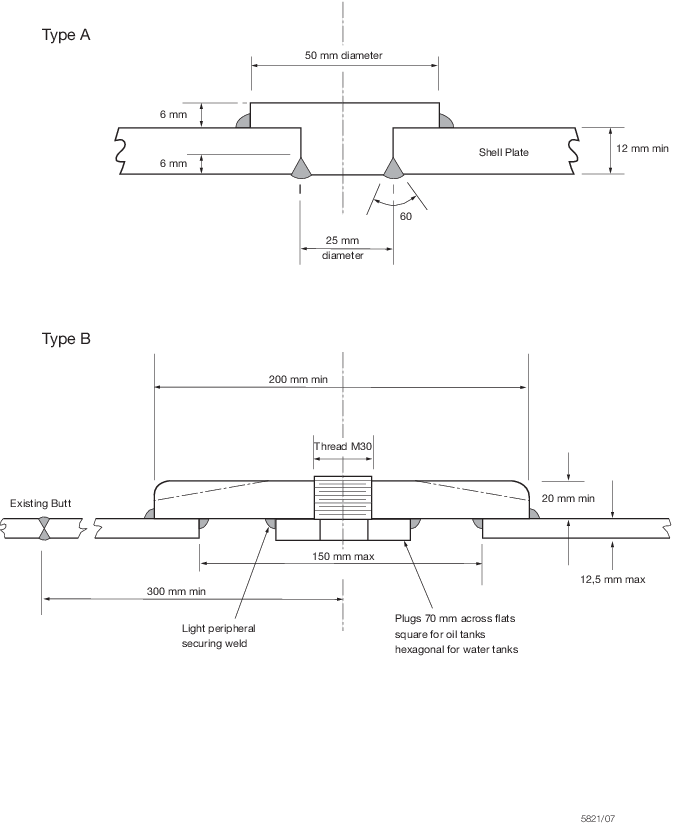

11.1.4 Where the

shell plating is less than 12,5 mm, then an adequate pad or doubling

is to be fitted in way of plugs, so that the maximum number of threads

is obtained with screwed plugs, Type B, see

Figure 7.11.1 Typical drain plug arrangements.

11.1.5 Where the

plugs stand proud of the shell plating, then some form of tapered

chafing or protection ring should be fitted externally. Where the

underside of the pad is recessed to ensure the plug head is flush

with the shell, the minimum thickness of the pad is not to be less

than the shell thickness.

11.1.6 All welds

in way of drain plugs are to be inspected visually and checked with

a suitable NDE method.

11.1.7 For identification

purposes, plugs with square heads are often fitted to oil tanks and

hexagonal heads for water tanks.

11.1.8 Drain plugs

should be kept clear of docking blocks, welded seams or butts, flat

of keel, suction strums or any other arrangements inside tanks.

11.1.9 Tank numbers,

etc. may be welded adjacent to each plug for identification purposes.

11.1.10 Where pads

are to be fitted on higher tensile steel, then the pads should be

of the same grade of steel.

Figure 7.11.1 Typical drain plug arrangements