2.1.1 The following

checks should be made on an annual basis concurrent with the Annual

Survey, to verify that:

-

all oily water separating

equipment, oil filtering equipment, process units, oil content meters

and oil/water interface detectors are of an approved type;

-

the piping arrangements

and associated pumps used to transfer oil/oily water are such that

no oil can be inadvertently pumped overboard;

-

all bilge and ballast

systems which are used to transfer oily water/ballast water have no

modifications made to the piping systems since they were approved

and installed;

-

all oil filters are

clean and in good order and that the alarms are working efficiently;

-

the oily water separator

operates satisfactorily and that any water which, when discharged

overboard, does not contain any undue oily residue (maximum of 15

ppm);

-

oil monitoring equipment

is in good working order and that the automatic and manual operation

of the means to stop the discharge of effluent is satisfactory;

-

indicators and recording

devices in the monitor are operable and to verify that a sufficient

supply of consumables for the recorders are on board;

-

to test, where fitted,

the automatic stopping device required for non-discharge in Internationally

recognized environmentally sensitive areas;

-

upon satisfactory completion

of the above, the IOPP Certificate or equivalent should be suitably

endorsed; and

-

the Oil Record Book

should be examined and confirmed effective.

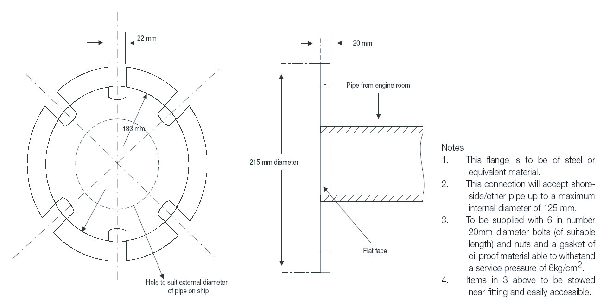

2.1.2 The Surveyor

is to check that a standard discharge connection is fitted (see

Figure 17.2.1 Standard discharge connection) and that the discharge arrangements

are satisfactory.

Figure 17.2.1 Standard discharge connection