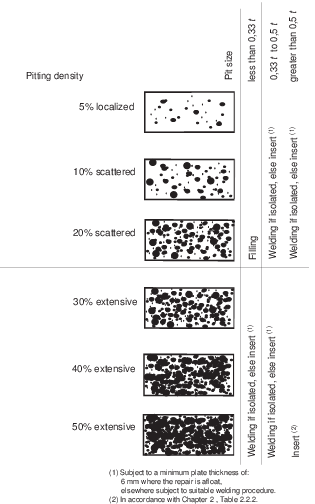

1.1.1 Pitting results

from very localized corrosion and usually affects horizontal surfaces.

It can be found to be shallow or deep and with an intensity of localized,

scattered or extensive. See

Figure 12.1.2 Pitting intensity

1.1.2 Localized

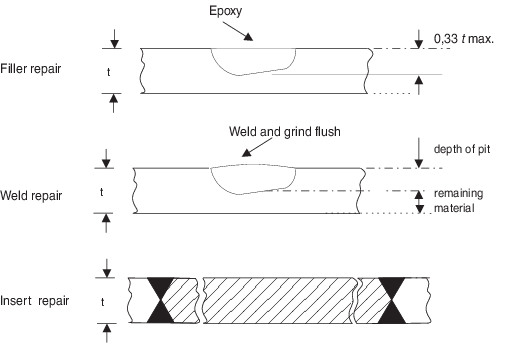

shallow pitting less than 0,33t may be repaired by filling

with a suitable epoxy compound which should be applied in accordance

with the manufacturer’s instructions. See

Figure 12.1.1 Repair of pitting

1.1.3 Isolated deep

pits greater than 0,33t may be repaired by welding, provided

the thickness of material left at the bottom of the pit exceeds 6

mm. Where the repair is not carried out afloat, lesser thickness may

be welded where it can be demonstrated that the welder will not burn

through the plating. All welding or pitting is to be carried out in

accordance with established welding procedures. See

Figure 12.1.1 Repair of pitting

1.1.4 The pitting

must be suitably cleaned and prepared to permit a repair by welding.

The electrodes used are to be of an approved type from LR’s

list of approved welding consumables for use in ship construction,

suitable for the grade of steel to be welded. A minimum of four weld

beads are to be deposited in any pit. Care is to be taken to ensure

that stop and start positions are outside the pit and that the welding

direction is alternated for successive layers. Inspection of the welds

during and after repair should be supplemented by NDE methods for

the discovery of any surface cracks.

1.1.5 Where the

pitting intensity is found to be extensive (above 25 per cent of the

surface area) in association with deep pits (over 50 per cent of the

original fitted thickness), or where the thickness of material left

at the bottom of the pit is less than 6 mm, the affected plating should

be cropped and renewed. See

Figure 12.1.1 Repair of pitting

1.1.6 There have

been a number of instances where internal corrosion has occurred in

the bottom shell plating of oil tanks, especially in way of suction

strums, which has been undetected during previous surveys. Some of

this corrosion is being caused by bacterial attack (commonly known

as SRB - sulphate reducing bacteria) and may be localized or widespread.

This corrosion is also appearing within tanks where the bottom plating

forms part of a tank top.

1.1.7 SRB is often

very rapid localized pitting/erosion and hence early recognition/detection

may be critical in preventing a hole from forming.

Figure 12.1.1 Repair of pitting

Figure 12.1.2 Pitting intensity