Section

4 Bulkhead requirements

4.1 Number and disposition of bulkheads

4.1.1 All

ships are to have a collision bulkhead, an after peak bulkhead, generally

enclosing the sterntubes in a watertight compartment, and a watertight

bulkhead at each end of the machinery space. Additional watertight

bulkheads are to be fitted so that the total number of bulkheads is

at least in accordance with Table 3.4.1 Total number of bulkheads.

Table 3.4.1 Total number of bulkheads

| Length, L, in metres

|

Total number of bulkheads

|

|

|

Machinery amidships

|

Machinery aft, see Note

|

|

|

≤ 65

|

4

|

3

|

| > 65

|

≤ 85

|

4

|

4

|

| > 85

|

≤ 90

|

5

|

5

|

| > 90

|

≤ 105

|

5

|

5

|

| > 105

|

≤ 115

|

6

|

5

|

| > 115

|

≤ 125

|

6

|

6

|

| > 125

|

≤ 145

|

7

|

6

|

| > 145

|

≤ 165

|

8

|

7

|

| > 165

|

≤ 190

|

9

|

8

|

| > 190

|

|

To be considered individually

|

Note With after peak bulkhead forming after boundary of

machinery space.

|

4.1.2 The

bulkheads in the holds should be spaced at reasonably uniform intervals.

Where non-uniform spacing is unavoidable and the length of a hold

is unusually great, the transverse strength of the ship is to be maintained

by fitting web frames, increased framing, etc. and details are to

be submitted.

4.1.3 Proposals

to dispense with one or more of these bulkheads will be considered,

subject to suitable structural compensation, if they interfere with

the requirements of a special trade.

4.1.4 Where

applicable, the number and disposition of bulkheads are to be arranged

to suit the requirements for subdivision, floodability and damage

stability, and are to be in accordance with the requirements of the

National Authority in the country in which the ship is registered.

4.2 Collision bulkhead

4.2.1 A collision

bulkhead shall be fitted which shall be watertight up to the bulkhead

deck. This bulkhead shall be located at a distance from the forward

side of the stem, on the waterline on which L

L is

measured, of not less than 0,05L

L or 10 m,

whichever is the less, and, except as may be permitted by the Administration,

not more than 0,08L

L or 0,05L

L +

3 m, whichever is the greater.

4.2.2 Where

any part of the ship below the waterline extends forward of the forward

side of the stem, on the waterline on which L

L is

measured, e.g. a bulbous bow, the distances stipulated in Pt 3, Ch 3, 4.2 Collision bulkhead 4.2.1 are to be measured from a

point either:

-

at the mid-length

of such extension;

-

at a distance

0,015L

L forward of the forward side of the

stem, on the waterline on which L

L is measured;

or

-

at a distance

3 m forward of the forward side of the stem, on the waterline on which L

L is measured, whichever is the least.

4.2.3 No doors,

manholes, access openings, ventilation ducts or any other openings

shall be fitted in the collision bulkhead below the bulkhead deck.

4.3 After peak bulkhead

4.3.1 All ships are to have an after peak bulkhead generally enclosing the

sterntube and rudder trunk in a watertight compartment. In twin screw ships where the

bossing ends forward of the after peak bulkhead, the sterntubes are to be enclosed in

suitable watertight spaces inside or aft of the shaft tunnels. The sterntubes are to be

enclosed in watertight spaces of moderate volume. In passenger ships, the stern gland is

to be situated in a watertight shaft tunnel or other watertight space separate from the

sterntube compartment and of such volume that, if flooded by leakage through the stern

gland, the bulkhead deck will not be submerged.

4.4 Height of bulkheads

4.4.1 The

collision bulkhead is normally to extend to the uppermost continuous

deck or, in the case of ships with combined bridge and forecastle

or a long superstructure which includes a forecastle, to the superstructure

deck. However, if a ship is fitted with more than one complete superstructure

deck, the collision bulkhead may be terminated at the deck next above

the freeboard deck. Where the collision bulkhead extends above the

freeboard deck, the extension need only be to weathertight standards.

4.4.2 The

after peak bulkhead may terminate at the first deck above the load

waterline, provided that this deck is made watertight to the stern

or to a watertight transom floor. In passenger ships, the after peak

bulkhead is to extend watertight to the bulkhead deck. However, it

may be stepped below the bulkhead deck provided the degree of safety

of the ship as regards watertight subdivision is not thereby diminished.

4.4.3 The

remaining watertight bulkheads are to extend to the freeboard deck.

In passenger ships of restricted draught and all ships of unusual

design, the height of the bulkheads will be specially considered.

4.5 Watertight recesses, flats and loading ramps

4.5.1 Watertight

recesses in bulkheads are generally to be so framed and stiffened

as to provide strength and stiffness equivalent to the requirements

for watertight bulkheads.

4.5.2 In collision

bulkheads, any recesses or steps in the bulkhead are to fall within

the limits of bulkhead positions given in Pt 3, Ch 3, 4.2 Collision bulkhead 4.2.1. Where the bulkhead is extended

above the freeboard deck or bulkhead deck, the extension need only

be to weathertight standards. If a step occurs at that deck, the deck

need also only be to weathertight standards in way of the step, unless

the step forms the crown of a tank, see

Pt 4, Ch 1, 4 Deck structure.

4.5.3 Where

bow doors are fitted and a sloping loading ramp forms part of the

extension of the collision bulkhead above the bulkhead deck the ramp

shall be weathertight over its complete length. In cargo ships the

part of the ramp which is more than 2,3 m above the bulkhead deck

may extend forward of the limit specified in Pt 3, Ch 3, 4.2 Collision bulkhead 4.2.1 or Pt 3, Ch 3, 4.2 Collision bulkhead 4.2.2. Ramps not meeting the above

requirements shall be disregarded as an extension of the collision

bulkhead.

4.5.4 The

number of openings in the extension of the collision bulkhead above

the freeboard deck shall be restricted to the minimum compatible with

the design and normal operation of the ship. All such openings shall

be capable of being closed weathertight.

4.6 Longitudinal subdivision

4.6.1 When

timber load lines are to be assigned, double bottom tanks within the

midship half-length are to have adequate longitudinal subdivision.

4.7 Separation and protection of tanks

4.7.1 Where the cross contamination of liquids stored in adjacent tanks is

hazardous to machinery, these tanks are to be separated by cofferdams. Hazardous

pairings of liquid consumables include but are not limited to the following:

- Fuel oil and lubricating oil;

- Fuel oil and technical water (e.g. feedwater);

- Lubricating oil and technical water;

- Fuel oil and urea.

4.7.2 Tanks carrying liquids for the purposes of fire fighting (e.g. foam

concentrate) are to be separated by cofferdams from adjacent tanks containing liquid

fuels.

4.7.3 Tanks carrying fresh water for human consumption (potable water) are to

be separated by cofferdams from adjacent tanks containing liquid substances harmful

to human health. Fresh water for other purposes and water ballast are not considered

harmful.

4.7.4 Where a cofferdam as specified in Pt 3, Ch 3, 4.7 Separation and protection of tanks 4.7.1 is

impracticable, special consideration may be given, subject to the arrangements

complying with the following:

- The thickness of common boundary plates is increased by 1 mm;

- Common boundaries have full penetration welds.

4.7.5 Where a corner to corner situation occurs, tanks are not considered to be

adjacent.

4.7.6 Where fitted, cofferdams are to be suitably ventilated, provided with a

suitable drainage arrangement, see

Pt 5, Ch 13, 3.5 Tanks and cofferdams, and be of

sufficient size to allow proper inspection, maintenance and safe evacuation.

4.7.8 For vessels which do not comply with the accidental fuel oil outflow

performance standard given in MARPOL Annex 1, Regulation

12A-11, fuel oil tanks are to be bounded by

double bottom and double side tanks or void spaces such that the distance between

the fuel oil tank boundary and the shell plating is not less than that given in

Table 3.4.2 Fuel oil tank boundary

requirements and Figure 3.4.1 Fuel oil tank boundary

lines. For double hull oil tankers

where the requirements of Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.17 conflict with this requirement Pt 4, Ch 9, 1.2 Application and ship arrangement 1.2.17 is to take precedent. Alternatively

the accidental oil outflow performance standard specified in MARPOL Annex 1 Regulation 12A may be complied with.

Table 3.4.2 Fuel oil tank boundary

requirements

Fuel oil tank

capacity (C),

|

Minimum double

side

width (d

s)

|

Minimum double

bottom depth (d

b)

|

m3

|

metres

|

metres

|

|

C ≥ 5000

|

|

|

|

|

or

|

or

|

|

|

d

s = 2,0

|

d

b = 2,0

|

|

|

whichever is the

lesser,

but not less than 1,0

|

whichever is the

lesser,

but not less than 0,76

|

| 600 ≤ C < 5000

|

|

|

|

|

or

|

or

|

|

|

d

s = 1,0

|

d

b = 2,0

|

|

|

whichever is the

greater,

see Note

|

whichever is the

lesser,

but not less than 0,76

|

|

C < 600

|

d

s = 0

|

d

b = 0

|

| Symbols

|

|

C

|

= |

the ship’s total volume of fuel oil,

including that of small fuel oil tanks, in

m3, at 98 per cent tank filling |

|

db

|

= |

the distance, in metres, between the bottom

of the fuel oil tank and the moulded line of the bottom

shell plating. In the turn of bilge area and at

locations without a clearly defined turn of bilge, the

fuel oil tank boundary line shall run parallel to the

line of the midship flat bottom as shown in Figure 3.4.2 Definition of

db

|

|

Note

1. However, for individual

tanks with an fuel oil capacity of less than 500

m3, the minimum distance is 0,76 m.

Note

2. Fuel oil tanks with a

maximum individual capacity not greater than 30

m3 need not comply with the requirements of

this Table, provided the aggregate capacity of such excluded

tanks is not greater than 600 m3.

Note

3. Suction wells in fuel oil

tanks may protrude into the double bottom below the boundary

line defined by the distance d

b, provided that such wells are as small as

practicable and the distance between the well bottom and the

bottom shell plating is not less than 0,5d

b.

|

Figure 3.4.1 Fuel oil tank boundary

lines

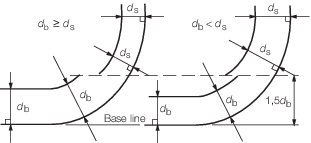

Figure 3.4.2 Definition of

db

4.7.9 No individual fuel oil tank is to have a capacity greater than 2,500

m3.

4.8 Watertight tunnels and passageways

4.8.1 Where

a machinery space is situated with a compartment or compartments between

it and the after peak bulkhead, the shafting is to be enclosed in

a watertight tunnel large enough to permit proper examination and

repair of shafting. A sliding watertight door, capable of being operated

locally from both sides, is to be provided at the forward end of the

tunnel. Consideration may, however, be given to the omission of the

watertight door, subject to satisfactory compliance with any relevant

statutory requirements. Where two or more shafts are fitted, the tunnels

shall be connected by an interconnecting passage. There shall be only

one door between the machinery space and the tunnel spaces where two

shafts are fitted and only two doors where there are more than two

shafts.

4.8.2 Pipe

tunnels are to have dimensions adequate for reasonable access.

4.8.3 Where

fore and aft underdeck passageways are arranged at the ship's side,

the after access thereto is to be by a watertight trunk led to the

upper deck. Alternative arrangements to prevent the engine room being

flooded, in the event of a collision or if the passageway doors are

left open, will be considered.

4.9 Means of escape

4.10 Oil tankers

4.10.1 For

subdivision requirements within the cargo tank region for oil tankers, see

Pt 4, Ch 9, 1 General.

|