Section

2 Fracture control

2.1 Grades of steel

2.1.1 The

resistance to fracture is controlled, in part, by the notch toughness

of the steel used in the structure. Steels with different levels of

notch toughness are specified in the Rules for the Manufacture, Testing and Certification of Materials, July 2022. The grade of steel to be used is, in general, related to

the thickness of the material and the stress pattern associated with

its location.

2.1.2 In order

to distinguish between the material grade requirements for different

hull members at varying locations along the ship, material classes

are assigned as shown in Table 2.2.1 Material classes and

grades.

For each class, depending on thickness, the material grade requirements

are not to be lower than those given in Table 2.2.2 Steel grades.

2.1.3 Where

tee or cruciform connections employ full penetration welds, and the

plate material is subject to significant strains in a direction perpendicular

to the rolled surfaces, it is recommended that consideration be given

to the use of special plate material with specified through thickness

properties, as detailed in Ch 3, 8 Plates with specified through thickness properties of

the Rules for Materials.

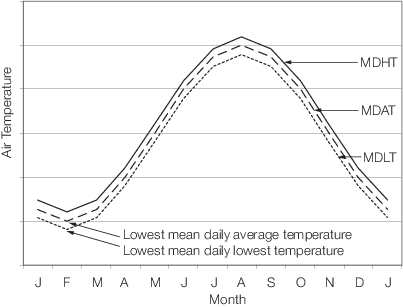

2.1.4 Design

for normal worldwide service assumes the navigation to areas of minus

10°C, where the design air temperature is to be taken as the lowest

mean daily average air temperature in the area of operation:

where

|

Mean |

= |

statistical

mean over a minimum of 20 years |

|

Average |

= |

average

during one day and one night |

|

Lowest |

= |

lowest during

the year |

|

MDHT |

= |

Mean Daily

High Temperature |

|

MDAT |

= |

Mean Daily

Average Temperature |

|

MDLT |

= |

Mean Daily

Low Temperature |

Figure 2.2.1 Design air temperature shows the

definition graphically.

The material grade of exposed structure of ships intended to operate in

external air temperatures below minus 10°C is to be in accordance with Pt 3, Ch 2, 2.3 Structures exposed to low temperatures.

Figure 2.2.1 Design air temperature

2.2 Refrigerated spaces

2.2.2 Unless

a temperature gradient calculation is carried out to assess the design

temperature in the items defined in Pt 3, Ch 2, 2.2 Refrigerated spaces 2.2.1, the temperature to which the steel deck may be subjected

is to be assessed as shown in Table 2.2.4 Assessment of deck

temperature.

Table 2.2.1 Material classes and

grades

| Structural member category

|

Material class/Minimum grade

|

| SECONDARY

|

| A1.

|

Longitudinal bulkhead strakes, other

than belonging to the Primary category

|

|

| A2.

|

Deck plating exposed to

weather, other than that belonging to the Primary or Special

category

|

Class I within 0,4L amidships

|

| A3.

|

Side plating

|

Grade A/AH outside 0,4L amidships

|

| PRIMARY

|

| B1.

|

Bottom plating,

including keel plate

|

|

| B2.

|

Strength deck plating,

excluding that belonging to the Special category

|

|

| B3.

|

Continuous longitudinal

plating of strength members above strength deck, excluding hatch

coamings

|

Class II within 0,4L amidships

|

| B4.

|

Uppermost strake in

longitudinal bulkhead

|

Grade A/AH outside 0,4L amidships

|

| B5.

|

Vertical strake (hatch

side girder) and uppermost sloped strake in top wing tank

|

|

| SPECIAL

|

| C1.

|

Sheerstrake

(or rounded gunwale) and stringer plate at strength deck, see Note 1

|

Class III within 0,4L amidships

|

| C2.

|

Deck strake at

longitudinal bulkhead excluding deck plating in way of inner skin bulkhead

of double hull ships, see Note 1

|

Class II outside 0,4L amidships

|

| Class I outside 0,6L amidships

|

| C3.

|

Strength deck plating at outboard

corners of cargo hatch openings (and plating intersections of the

longitudinal underdeck girders and the cross-deck strips) in container

carriers and other ships with similar hatch opening configurations

|

Class III within 0,4L amidships

|

|

|

|

Class II outside 0,4L amidships

|

|

|

|

Class I outside 0,6L amidships

|

|

|

|

Minimum Class III within cargo region

|

| C4.

|

Strength deck plating at corners of

cargo hatch openings in bulk carriers (see

Pt 3, Ch 2, 1.1 General 1.1.3), ore carriers, combination carriers and

other ships with similar hatch opening configurations

|

Class III within 0,6L amidships

|

| C5.

|

Trunk deck

and inner deck plating at corners of openings for liquid and gas domes in

membrane type liquefied gas carriers

|

Class II within rest of cargo region

|

| C6.

|

Bilge strake in ships with double

bottom over the full breadth and length less than 150 m

|

Class II within 0,6L amidships

|

|

|

|

Class I outside 0,6L amidships

|

| C7.

|

Bilge strake in other ships ,

see Note 1

|

Class III within 0,4L amidships

|

|

|

|

Class II outside 0,4L amidships

|

|

|

|

Class I outside 0,6L amidships

|

| C8

|

Longitudinal hatch coamings of length

greater than 0,15L including coaming top plate and flange

|

Class III within 0,4L

amidships

|

|

|

|

Class II outside 0,4L amidships

|

| C9.

|

End

brackets and deck house transition of longitudinal cargo hatch

coamings

|

Class I outside 0,6L amidships Not to be less than Grade

D/DH

|

| ADDITIONAL MINIMUM REQUIREMENTS FOR SINGLE STRENGTH

DECK SHIPS OF LENGTH GREATER THAN 150 m

|

| D1.

|

Longitudinal plating of strength deck where contributing to the

longitudinal strength

|

Grade B/AH within 0,4L amidships

|

| D2.

|

Continuous

longitudinal plating of strength members above strength deck

|

|

| D3

|

Continuous

longitudinal trunk deck plating of membrane type liquefied gas

carriers

|

Class II within 0,4L amidships

|

| D4

|

Single side

strakes for ships without inner continuous longitudinal bulkhead(s) between

bottom and strength deck

|

Grade B/AH within cargo region

|

| ADDITIONAL MINIMUM REQUIREMENTS FOR SHIPS OF LENGTH

GREATER THAN 250 m

|

| E1.

|

Sheerstrake

(or rounded gunwale) and stringer plate at strength deck, see Note 2

|

Grade E/EH within 0,4L amidships

|

| E2.

|

Bilge

strake, see Note 2

|

Grade D/DH within 0,4L amidships

|

| ADDITIONAL MINIMUM REQUIREMENTS FOR SINGLE SKIN BULK

CARRIERS SUBJECTED TO SOLAS REGULATION XII/6.4

|

| F1.

|

Lower

bracket of ordinary side frame, see Notes 6 and 7

|

Grade D/DH

|

| F2.

|

Side shell

strakes included totally or partially between the two points located to

0,125l above and below the intersection of side shell and bilge hopper

sloping plate or inner bottom plate, see Note 7

|

Grade D/DH

|

Note

1. Single strakes required to be of Class

III and within 0,4L amidships are to have breadths not less

than 800 + 5L mm, but need not be greater than 1800 mm, unless

limited by the geometry of the ship’s design.

Note

2. Single strakes required to be of Grade

D/DH or Grade E/EH and within 0,4L amidships are to have

breadths not less than 800 + 5L mm, but need not be greater

than 1800 mm, unless limited by the geometry of the ship’s design.

Note

3. For strength members not mentioned,

Grade A/AH may be generally used.

Note

4. Steel grade is to correspond to the

as-fitted thickness.

Note

5. Plating materials for sternframes

supporting the rudder and propeller boss, rudders, rudder horns and

shaft brackets are, in general, not to be of lower grades than

corresponding to Class II. For rudder and rudder body plates subjected

to stress concentrations (e.g. in way of lower support of semi-spade

rudders or at upper part of spade rudders) Class III is to be

applied.

Note

6. The term ‘lower bracket’ means webs of

lower brackets and webs of the lower part of side frames up to the

point of 0,125l above the intersection of side shell and bilge hopper

sloping plate or inner bottom plate.

Note

7. The span of the side frame, l, is

defined as the distance between the supporting structures.

Note

8. Corner inserts in way of complex

openings such as for lifts and side doors which may impinge on the

deck plating or stringer plate are to be of Grade D/DH for t ≤

20 mm and Grade E/EH for t > 20 mm.

Note

9. The material class used for

reinforcement and the quality of material (i.e. whether mild or higher

tensile steel) used for welded attachments, such as waterway bars and

bilge keels, is to be similar to that of the hull envelope plating in

way. Where attachments are made to rounded gunwale plates, special

consideration will be given to the required grade of steel, taking

account of the intended structural arrangements and attachment

details.

Note

10. The material class for deck plating,

sheer strake and upper strake of longitudinal bulkhead within 0,4L

amidships is also to be applied at structural breaks of the

superstructure, irrespective of position.

Note

11. Engine seat top plates outside

0,6L amidships may be Grade A/AH. Steel grade requirement

for top plates within 0,6L amidships will be specially

considered.

|

Table 2.2.2 Steel grades

| Thickness, t, in mm

|

Material class

|

|

|

I

|

II

|

III

|

|

|

Mild steel

|

H.T. steel

|

Mild

steel

|

H.T.

steel

|

Mild

steel

|

H.T.

steel

|

|

t ≤ 15

|

A

|

AH

|

A

|

AH

|

A

|

AH

|

| 15 < t ≤ 20

|

A

|

AH

|

A

|

AH

|

B

|

AH

|

| 20 < t ≤

25

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

| 25 < t ≤

30

|

A

|

AH

|

D

|

DH

|

D

|

DH

|

| 30 < t ≤

35

|

B

|

AH

|

D

|

DH

|

E

|

EH

|

| 35 < t ≤

40

|

B

|

AH

|

D

|

DH

|

E

|

EH

|

| t >

40

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

|

Note

See Notes under

Table 2.2.1 Material classes and

grades

|

Table 2.2.3 Grades of steel for refrigerated

spaces with a minimum design temperatures below 0°C

Minimum

design

temperature, in °C

|

Thickness, in mm

|

Grades of

steel

|

| <0 to –10

|

|

t ≤ 12,5

|

B/AH

|

|

|

12,5

|

t ≤ 25,5

|

D/DH

|

|

|

|

t > 25,5

|

E/EH

|

| <–10 to –25

|

|

t ≤ 12,5

|

D/DH

|

|

|

|

t > 12,5

|

E/EH

|

| <– 25

to –40

|

|

t ≤

12,5

|

E/EH

|

|

|

|

t

> 12,5

|

FH/LT–FH,

|

Table 2.2.4 Assessment of deck

temperature

| Arrangement

|

Deck

temperature

|

| (1) Deck not

covered with insulation in the refrigerated space

|

Temperature of the refrigerated

space

|

| (2) Deck

covered with insulation in the refrigerated space and not insulated on the

other side

|

Temperature of the space on the

uninsulated side

|

| (3) Deck

covered with insulation on both sides

|

|

| (a)

Temperature difference not greater than 11°C

|

Mean of the temperatures of the

spaces above and below the deck

|

| (b)

Temperature difference greater than 11°C but not greater than 33°C

|

Mean of the temperatures of the

spaces above and below the deck less 3°C

|

| (c)

Temperature difference greater than 33°C

|

Deck temperature will be

specially assessed

|

Note Where one of the internal spaces concerned is not

refrigerated, the temperature of the space is to be taken as 5°C.

|

2.3 Structures exposed to low temperatures

2.3.3 For ships where the optional Winterisation H notation is applied, see

Rules for the Winterisation of Ships, July 2022, note that the external design air

temperature defined in the Winterisation Rules is taken as 13°C lower than the

design air temperature, i.e. if the design air temperature is −11°C, then the

external design air temperature for the application of the Winterisation Rules is

−24°C.

2.4 Carriage of cold cargoes

2.4.1 For ships other than liquefied gas carriers, which are intended to be

loaded with liquid cargo having a temperature below −10°C, e.g. loading from cold

onshore storage tanks during winter conditions, the grade of steel for the cargo

tank boundary plating is to comply with the requirements of Table 2.2.6 Materials for Class I for low air temperatures where the design air temperature is to be taken as

the design minimum cargo temperature in °C. The design minimum cargo temperature is

to be specified in the Loading Manual, see

Pt 3, Ch 4, 8.2 Loading Manual 8.2.4.

Table 2.2.5 Material classes and grades for structures exposed to low air temperatures

| Structural member category

|

Material class

|

| Within 0,4 L

amidships

|

Outside 0,4

L amidships

|

| SECONDARY

|

I

|

I

|

- Deck plating exposed to weather, in

general

- Side plating above CWL, see Note

5

- Transverse bulkheads above CWL,

see Notes 5 and 6

|

|

|

| PRIMARY

|

II

|

I

|

- Strength deck plating

- Continuous longitudinal members above

strength deck, excluding longitudinal hatch coamings

- Longitudinal bulkhead above CWL,

see Notes 5 and 6

- Top wing tank bulkhead above CWL,

see Notes 5 and 6

|

|

|

| SPECIAL

|

III

|

II

|

- Sheerstrake at strength deck, see

Note 1

- Stringer plate in strength deck,

see Note 1

- Deck strake at longitudinal bulkhead,

see Note 2

- Continuous longitudinal hatch coamings,

see Note 3

|

|

|

|

Note 1. Not to be less than Grade E/EH within 0,4L amidships in

ships with length exceeding 250 m.

Note 2. In ships with breadth exceeding 70 m at least three deck

strakes are to be Class III.

Note 3. Not to be less than Grade D/DH.

Note 4. Within 0,4L amidships, single strakes which are required to

be of Class III or of Grade E/EH or FH are to have breadths not

less than 800 + 5L, but need not be taken greater than 1800

mm.

Note 5. The Cold Waterline (CWL) is to be taken as 0,3 m below the

minimum design Ballast Waterline (BWL).

Note 6. Applicable to plating attached to hull envelope plating

exposed to cold air. At least one strake is to be considered in

the same way as exposed plating and the strake width is to be at

least 600 mm. If thermal stress calculations are performed, then

the extent of plate requiring consideration is to be adjusted

accordingly.

|

Table 2.2.6 Materials for Class I for low air temperatures

| Thickness, mm

|

Design air temperature

|

| −11°C to −15°C

|

−16°C to −25°C

|

−26°C to −35°C

|

−36°C to −45°C

|

−46°C to −55°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤

10

|

A

|

AH

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

| 10 <

t ≤ 15

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

| 15 <

t ≤ 20

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 20 <

t ≤ 25

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 25 <

t ≤ 30

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 30 <

t ≤ 35

|

D

|

DH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 35 <

t ≤ 45

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 45 <

t ≤ 50

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

|

Note MS and HT are defined as Mild Steel and High Tensile Steel

respectively.

|

Table 2.2.7 Materials for Class II for low air temperatures

| Thickness, mm

|

Design air temperature

|

| −11°C to −15°C

|

−16°C to −25°C

|

−26°C to −35°C

|

−36°C to −45°C

|

−46°C to −55°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤ 10

|

A

|

AH

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

| 10 < t ≤ 20

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 20 < t ≤ 30

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 30 < t ≤ 40

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

| 40 < t ≤ 45

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 45 < t ≤ 50

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| Note. MS and

HT are defined as Mild Steel and High Tensile Steel

respectively.

|

Table 2.2.8 Materials for Class III for low air temperatures

| Thickness, mm

|

Design air

temperature

|

| −11°C to −15°C

|

−16°C to −25°C

|

−26°C to −35°C

|

−36°C to −45°C

|

−46°C to −55°C

|

| MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

MS

|

HT

|

| t ≤

10

|

B

|

AH

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

| 10 <

t ≤ 20

|

D

|

DH

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

| 20 <

t ≤ 25

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

E

|

FH

|

n/a

|

FH

|

| 25 <

t ≤ 30

|

D

|

DH

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

| 30 <

t ≤ 35

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 35 <

t ≤ 40

|

E

|

EH

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

| 40 <

t ≤ 50

|

E

|

EH

|

n/a

|

FH

|

n/a

|

FH

|

n/a

|

n/a

|

n/a

|

n/a

|

|

Note MS and HT are defined as Mild Steel and High Tensile Steel

respectively.

|

|